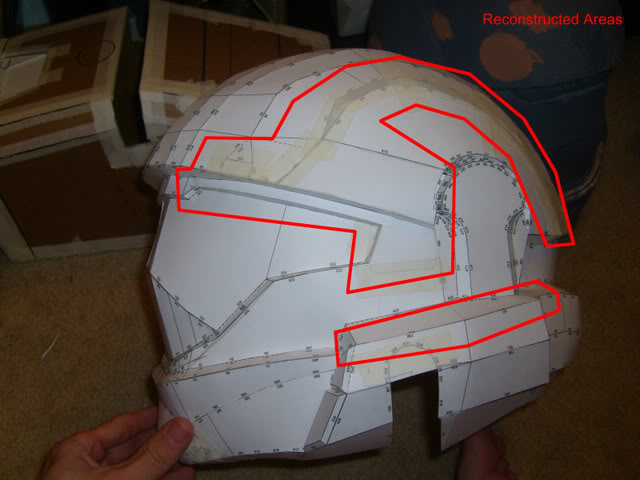

I've been holding off on posting photos of this project for a while because I wanted to get to (more or less) a final stage on it before making a thread. This helmet started off as the lower-resolution ODST pep file (the one with the reduced detailing). During the pepakura stage, I made several modifications to the base model to change it to the Legacy Effects version. The game version and the LE versions have several differences, and the LE version is quite different from the Weta version as well, so special attention had to be given toward the LE detailing. After scrutinizing screen captures from both the "We Are ODST" commercial and the making-of videos, I got to this point with the pepakura model and at that point hit it with fiberglass. Note that the entire jaw portion was redesigned, as well as the temple areas above the visor and the ear portions:

And then sculpting began as usual. Here it is together with my Recon helmet for size comparison:

Since this is for a group costume for Dragon Con, I made a two-part mold for this so castings could be made. Starting with a clay retaining wall to shape the mold seam, I then coated each side in five layers of rubber. On the final layer I patted in some cotton cloth (so that it would be embedded into the rubber), and then fiberglassed directly onto that cotton cloth (so that the rubber and fiberglass were one connected piece for simplicity).

Over the past couple days I've been making castings for our group. The first two castings were made out of just fiberglass resin with micro bulb filler in them to make a gel coat. That worked pretty well. Then I tried a casting out of Smooth-On Smooth Cast Onyx, and I ended up not liking it too much because it set up too quickly in this heat (and I didn't have any curing inhibitor on hand). So for the later castings I'll just be using the fiberglass resin.

I'm currently sculpting the visor buck for vacuum forming, so I'm really close to finishing these helmets. We are contemplating selling castings of these after our four helmets are made, but we're going to focus on our costumes before everything else first.

And then sculpting began as usual. Here it is together with my Recon helmet for size comparison:

Since this is for a group costume for Dragon Con, I made a two-part mold for this so castings could be made. Starting with a clay retaining wall to shape the mold seam, I then coated each side in five layers of rubber. On the final layer I patted in some cotton cloth (so that it would be embedded into the rubber), and then fiberglassed directly onto that cotton cloth (so that the rubber and fiberglass were one connected piece for simplicity).

Over the past couple days I've been making castings for our group. The first two castings were made out of just fiberglass resin with micro bulb filler in them to make a gel coat. That worked pretty well. Then I tried a casting out of Smooth-On Smooth Cast Onyx, and I ended up not liking it too much because it set up too quickly in this heat (and I didn't have any curing inhibitor on hand). So for the later castings I'll just be using the fiberglass resin.

I'm currently sculpting the visor buck for vacuum forming, so I'm really close to finishing these helmets. We are contemplating selling castings of these after our four helmets are made, but we're going to focus on our costumes before everything else first.