I've been contemplating this build ever since I finished making my vacformed stormtrooper armor in 2002. After discussing it at great length many times, doodling out countless sketches of the pieces and parts, and untold hours of studying the miniatures and source artwork, my friend Matt and I finally started on it yesterday morning.

The beginning was modest enough. We began with a piece of 2" insulation foam:

Then we cut out the outline of the shoulder plate and checked to see how it looked:

The plan is to make a full-scale suit of armor. This means that a normal-sized person will be looking out through the throat of the armored Marine.

Satisfied with the scale and shape of the first slice, we made a series of smaller slices:

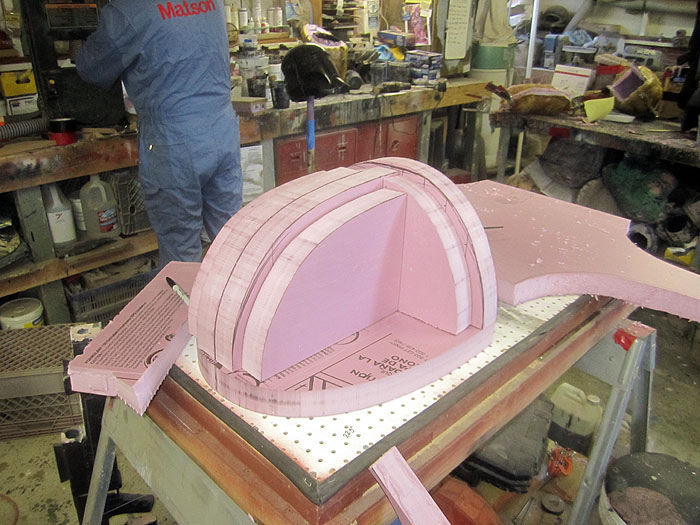

Then we laid them all up and glued them together with Gorilla Glue:

After gluing them, we bound them together with a customized strapping system referred to among professionals as "duct tape:"

While waiting for the glue to set up, I did another test fit:

Once the glue was set, the next step was to smooth out the edges with a combination saw, a body rasp, and a flapwheel grinder. Still, there were recesses that needed filling. To fill the grooves I used a little bit of urethane expanding foam:

With a bit more sanding and grinding, the general shape was pretty well established:

In the next day or two I'll be posting pictures of the last little bits of smoothing out the shoulder plate as well as the first couple of pulls on the vacforming table.

Stay tuned...

The beginning was modest enough. We began with a piece of 2" insulation foam:

Then we cut out the outline of the shoulder plate and checked to see how it looked:

The plan is to make a full-scale suit of armor. This means that a normal-sized person will be looking out through the throat of the armored Marine.

Satisfied with the scale and shape of the first slice, we made a series of smaller slices:

Then we laid them all up and glued them together with Gorilla Glue:

After gluing them, we bound them together with a customized strapping system referred to among professionals as "duct tape:"

While waiting for the glue to set up, I did another test fit:

Once the glue was set, the next step was to smooth out the edges with a combination saw, a body rasp, and a flapwheel grinder. Still, there were recesses that needed filling. To fill the grooves I used a little bit of urethane expanding foam:

With a bit more sanding and grinding, the general shape was pretty well established:

In the next day or two I'll be posting pictures of the last little bits of smoothing out the shoulder plate as well as the first couple of pulls on the vacforming table.

Stay tuned...