Hey everyone, Gabe (lostviking) had asked me to post up pictures of the process for molding the beautiful Reach shotgun he had made for me. I began by doing the layouts on 1/8th hardboard. I use tape to layout the borders around the parts and so I know how to cut the rim board.

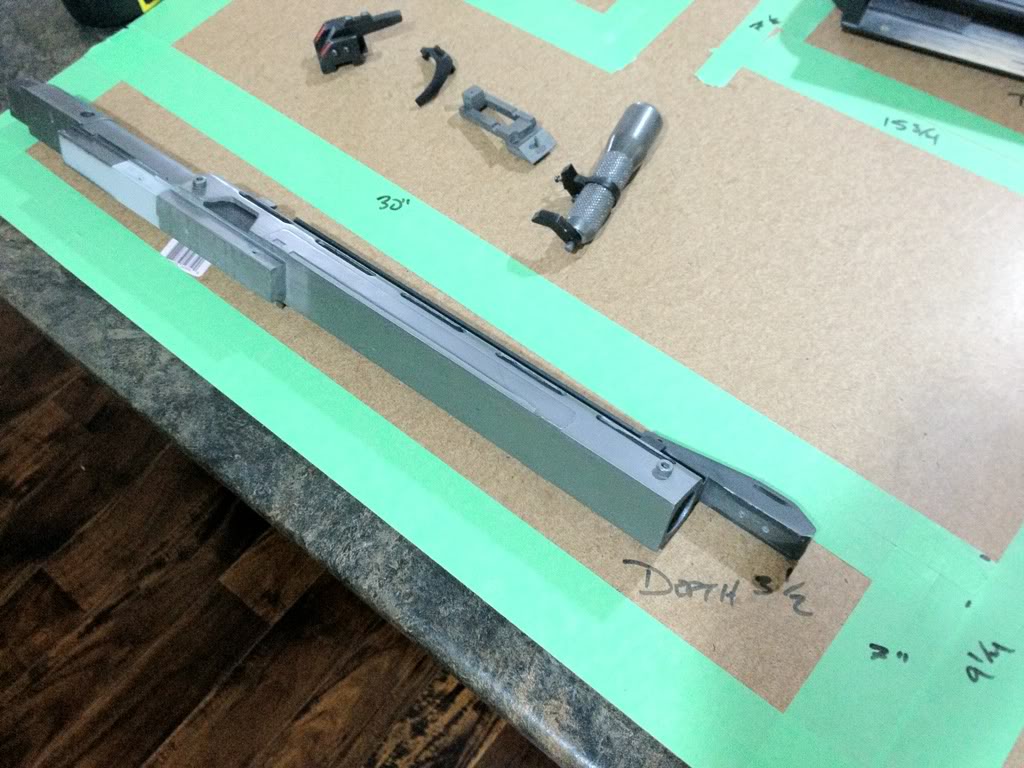

The parts on the hard board, you can see the barrel shroud has two stripes of tape around it denoting where the registration keys will go.

Once the parts are all laid out I measure the length, width and depth of the parts. I make all of the measurements I write them all down so as to figure out the best way to cut them from the sheet of mdf.

And the final layout:

Some of the parts will be traced on the hardboard to facilitate when I clay up the parts. You will see what I mean shortly.

The parts on the hard board, you can see the barrel shroud has two stripes of tape around it denoting where the registration keys will go.

Once the parts are all laid out I measure the length, width and depth of the parts. I make all of the measurements I write them all down so as to figure out the best way to cut them from the sheet of mdf.

And the final layout:

Some of the parts will be traced on the hardboard to facilitate when I clay up the parts. You will see what I mean shortly.