- Member DIN

- S114

Hello All, I'll be posting my progress in here as I scratch-build my first styrofoam weapon, the Reach M6G. I don't expect my first go at this to be perfect, but I'm pretty confident I can do it.

Here are the supplies needed:

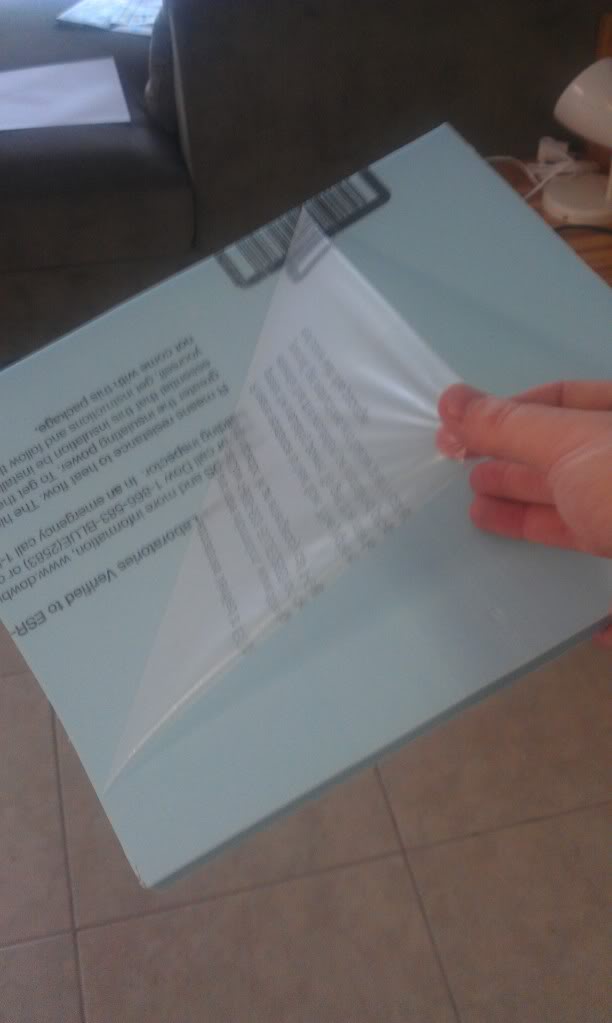

-Home Insulation foam- I got the 1/2" thickness because it has a nice smooth consistency throughout its core, unlike the white EPS foam which seems to be made of millions of little spheres pressed together, that just seemed like the spheres would fall apart during carving/sanding...but I could be wrong about that...

Its a powder blue color and comes in sheets 4' x 8' (so I have A LOT of it)

Also, this type of styrofoam has a thin laminated layer that you will need to peel off of BOTH sides...

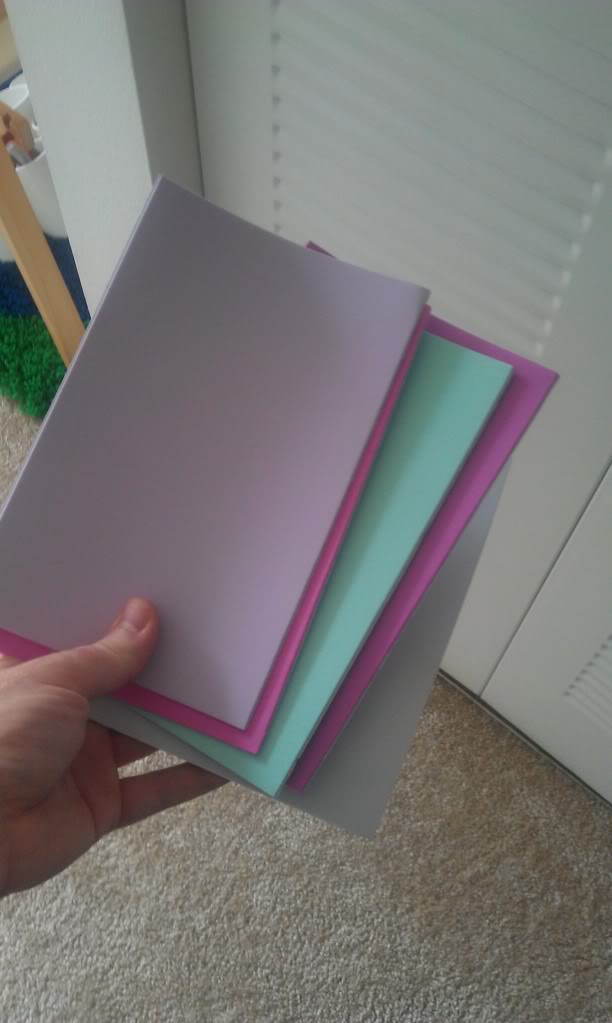

-Foamies- I love these things. Great for layering on smooth details.

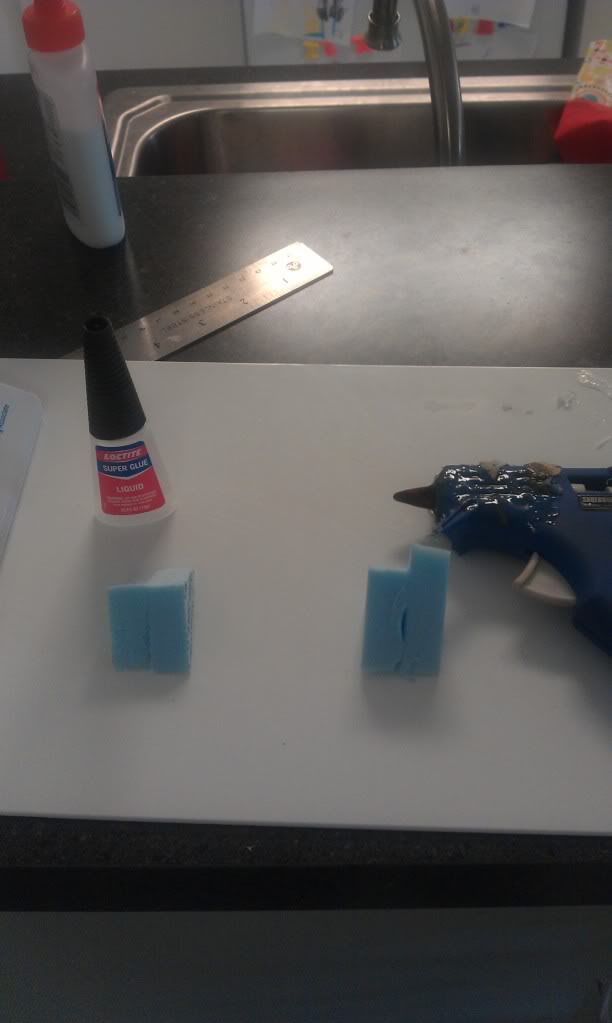

-Glue- I did a glue test to see what would be best, I'm a trial and error/figure it out for myself kind of guy. I tested super glue vs. hot glue, and found pros and cons with both.

The super glue slightly disintegrated the foam, but held strong. I don't see this as being an issue with gluing large sections from the interior, not too close to the edges.

The hot glue melted the foam quite a bit, but it seems like it will be fine as long I stay away from the seems/edges.

Also, the super glue was much easier to carve through once dry.

You can see what excess glue did to both samples in the picture above...the super glue did less damage so I will be using it as the primary adhesive.

-Blades- Most of the carving will be done with Exacto brand 'a' blades. I also needed something longer so i found this long thin box cutter at Harbor Freight, the knife and blades were super cheap, $1 for the knife, $1 for 10 blades.

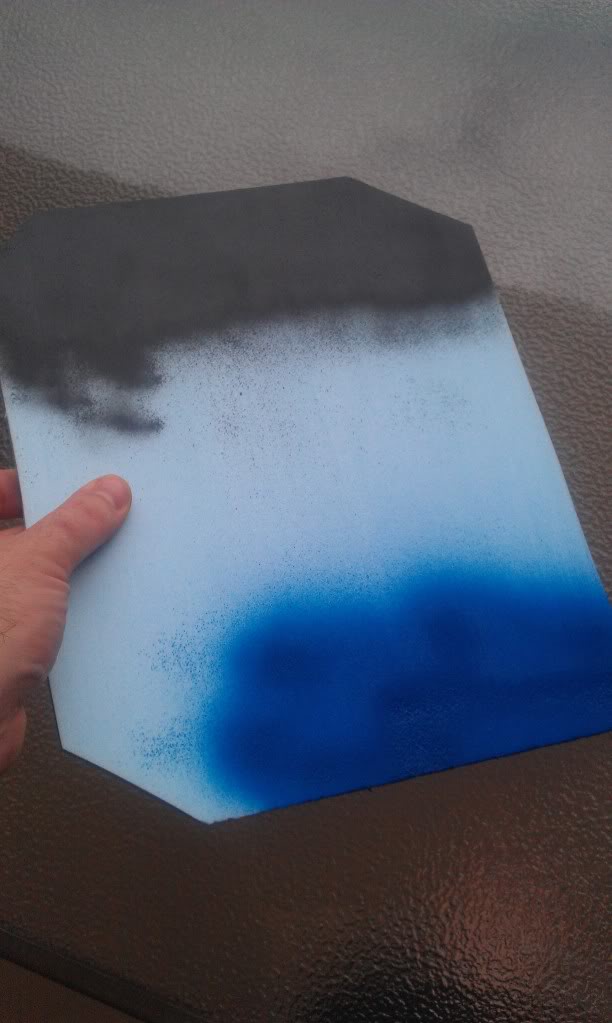

-Paint- I did a paint test to see what would happen...the black one is plasti-dip and the blue one is Rustoleum. The blue paint alone disintegrated the foam, the plasti-dip did not. So if you are going to try this building method, make sure you seal your project with plasti-dip (or maybe another sealer? plasti-dip is my preferred method) before painting.

-Blueprints- I'm going to go the same route that I went with my Cardboard MA37, using a 1:1 scale printout, cutting away layers and using them as stencils. It is also important to use reference pics from multiple angles rather than guess what it looks like from the front, back, top, bottom, etc.

Thats all for now, hopefully I'll have some progress to report later tonight, will probably have to do the bulk shape of it a few times before I get it right...

Here are the supplies needed:

-Home Insulation foam- I got the 1/2" thickness because it has a nice smooth consistency throughout its core, unlike the white EPS foam which seems to be made of millions of little spheres pressed together, that just seemed like the spheres would fall apart during carving/sanding...but I could be wrong about that...

Its a powder blue color and comes in sheets 4' x 8' (so I have A LOT of it)

Also, this type of styrofoam has a thin laminated layer that you will need to peel off of BOTH sides...

-Foamies- I love these things. Great for layering on smooth details.

-Glue- I did a glue test to see what would be best, I'm a trial and error/figure it out for myself kind of guy. I tested super glue vs. hot glue, and found pros and cons with both.

The super glue slightly disintegrated the foam, but held strong. I don't see this as being an issue with gluing large sections from the interior, not too close to the edges.

The hot glue melted the foam quite a bit, but it seems like it will be fine as long I stay away from the seems/edges.

Also, the super glue was much easier to carve through once dry.

You can see what excess glue did to both samples in the picture above...the super glue did less damage so I will be using it as the primary adhesive.

-Blades- Most of the carving will be done with Exacto brand 'a' blades. I also needed something longer so i found this long thin box cutter at Harbor Freight, the knife and blades were super cheap, $1 for the knife, $1 for 10 blades.

-Paint- I did a paint test to see what would happen...the black one is plasti-dip and the blue one is Rustoleum. The blue paint alone disintegrated the foam, the plasti-dip did not. So if you are going to try this building method, make sure you seal your project with plasti-dip (or maybe another sealer? plasti-dip is my preferred method) before painting.

-Blueprints- I'm going to go the same route that I went with my Cardboard MA37, using a 1:1 scale printout, cutting away layers and using them as stencils. It is also important to use reference pics from multiple angles rather than guess what it looks like from the front, back, top, bottom, etc.

Thats all for now, hopefully I'll have some progress to report later tonight, will probably have to do the bulk shape of it a few times before I get it right...