Well, I think that after lurking for about two years now, it is about time to make my first post. So here it is!

I have been making armour for two years (since I was 13). I've made two foam suits (with pepped helmets), and while they are the two coolest things I've ever created, I have never been completely happy with them. As you might be able to tell, I am a bit of a perfectionist.

So, my goal for this build is to make it to the best of my ability, and end up with something that I will be truly happy with (a pretty tall order for me).

Enough about me, more about my project, the MJOLNIR Mark VI from Halo 3:

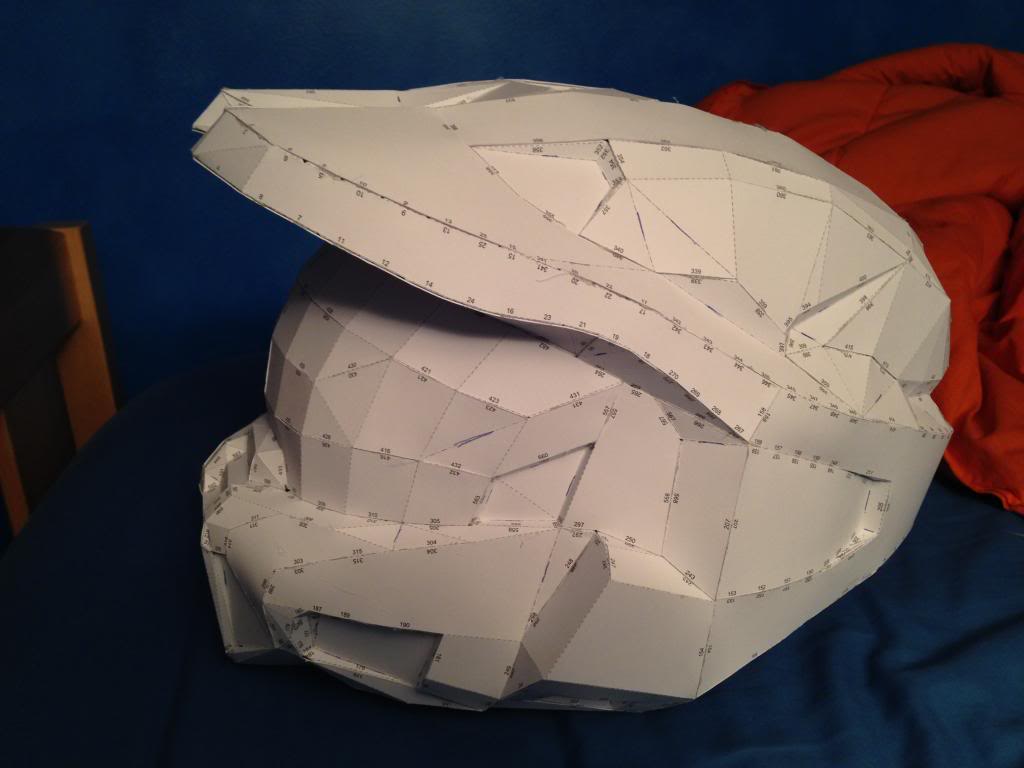

So here you can see that I pepped the helmet using a low-def model (I think it was by DANNIFOOD4LESS). I would have used a high-def model, but with the method I'm using it didn't really matter. Anyway, I prefer adding detail by hand, I think it is easier than trying to piece together really small bits of paper.

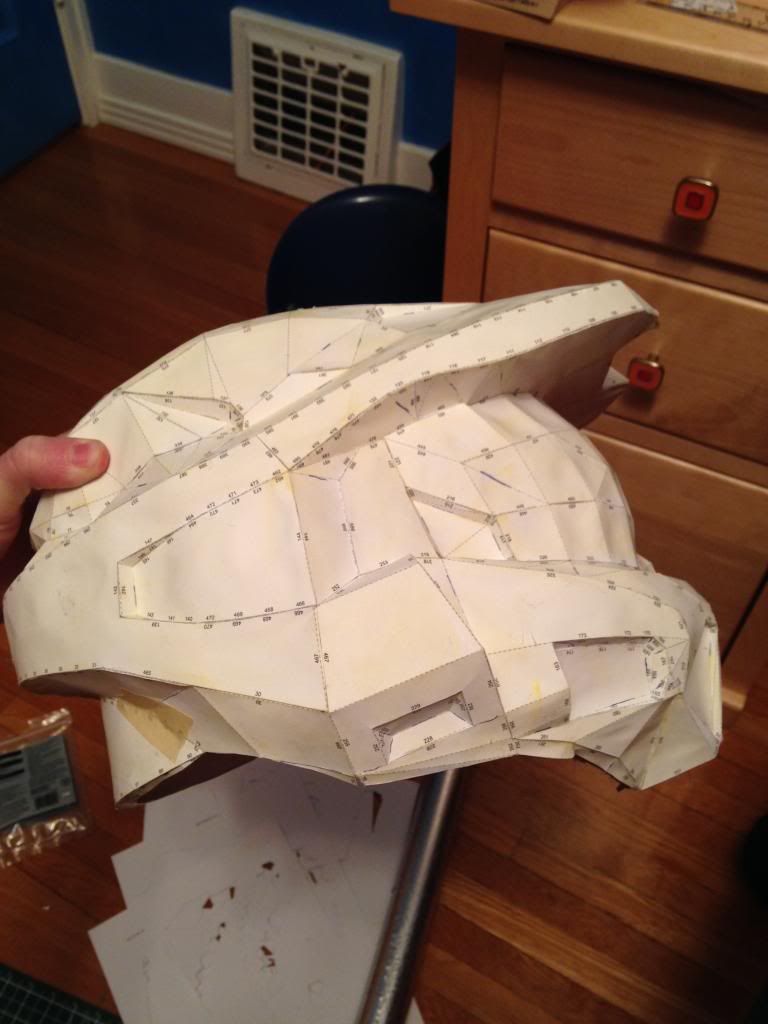

I resined the helmet with watered down wood glue, as per the "Wood Glue Method" that Justinian117 posted, except that I used LePage Carpenter's Glue. It seems to have worked pretty well.

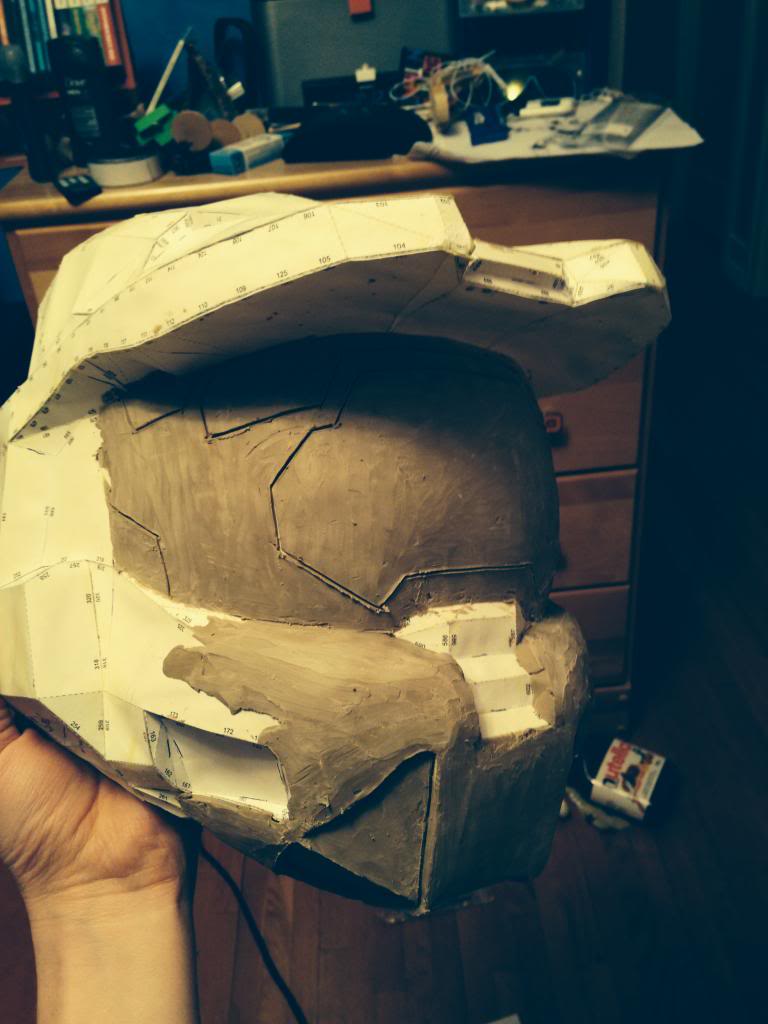

I glassed the helmet using fiberglass cloth and the watered down wood glue. I ran out of fiberglass near the end of glassing it, so I cut up an old rag and used that for the back of the helmet. This was NOT a good choice. It never hardened properly; I had to rip it out, buy more fiberglass cloth, and reglass that area (unfortunately I don't have pictures of that).

Pulling out the rag resulted in this though, and I had to tape it back together on the outside as well (although it really wasn't a big deal at all, it just really annoyed me at the time).

Once the fiberglass had cured, it was solid enough to start sculpting onto it (but definitely not strong enough to actually wear it). I started with the visor:

Then I went to bed. The next day I decided it would be a good idea to gather some reference pictures outside of my head (the plastic is to stop the clay from drying, I also sprayed it with water):

The jaw was next on the docket, and I also cut in some lines on the visor (just because I was impatient, they weren't the final lines or even symmetrical at all).

(sorry about the filter that's on most of the pictures - I took them with my iPhone and it seems to automatically add the "instant" filter...)

The next day I got rid of the imperfect visor lines and did the other side of the jaw (as well as the bottom of the jawline, but that has been getting smushed away as the helmet rests on it). I also filled in the nose and started working on that. All the bumps on the sculpt (or most of them, anyway) are from the water I sprayed on it to keep the clay from drying.

I'm going to have to continue in the next post, because it says that I can only have 15 pictures.

I have been making armour for two years (since I was 13). I've made two foam suits (with pepped helmets), and while they are the two coolest things I've ever created, I have never been completely happy with them. As you might be able to tell, I am a bit of a perfectionist.

So, my goal for this build is to make it to the best of my ability, and end up with something that I will be truly happy with (a pretty tall order for me).

Enough about me, more about my project, the MJOLNIR Mark VI from Halo 3:

So here you can see that I pepped the helmet using a low-def model (I think it was by DANNIFOOD4LESS). I would have used a high-def model, but with the method I'm using it didn't really matter. Anyway, I prefer adding detail by hand, I think it is easier than trying to piece together really small bits of paper.

I resined the helmet with watered down wood glue, as per the "Wood Glue Method" that Justinian117 posted, except that I used LePage Carpenter's Glue. It seems to have worked pretty well.

I glassed the helmet using fiberglass cloth and the watered down wood glue. I ran out of fiberglass near the end of glassing it, so I cut up an old rag and used that for the back of the helmet. This was NOT a good choice. It never hardened properly; I had to rip it out, buy more fiberglass cloth, and reglass that area (unfortunately I don't have pictures of that).

Pulling out the rag resulted in this though, and I had to tape it back together on the outside as well (although it really wasn't a big deal at all, it just really annoyed me at the time).

Once the fiberglass had cured, it was solid enough to start sculpting onto it (but definitely not strong enough to actually wear it). I started with the visor:

Then I went to bed. The next day I decided it would be a good idea to gather some reference pictures outside of my head (the plastic is to stop the clay from drying, I also sprayed it with water):

The jaw was next on the docket, and I also cut in some lines on the visor (just because I was impatient, they weren't the final lines or even symmetrical at all).

(sorry about the filter that's on most of the pictures - I took them with my iPhone and it seems to automatically add the "instant" filter...)

The next day I got rid of the imperfect visor lines and did the other side of the jaw (as well as the bottom of the jawline, but that has been getting smushed away as the helmet rests on it). I also filled in the nose and started working on that. All the bumps on the sculpt (or most of them, anyway) are from the water I sprayed on it to keep the clay from drying.

I'm going to have to continue in the next post, because it says that I can only have 15 pictures.

Attachments

-

IMG_2796_zps4985e403.jpg95.9 KB · Views: 343

IMG_2796_zps4985e403.jpg95.9 KB · Views: 343 -

IMG_2801_zps181e5c18.jpg49.3 KB · Views: 347

IMG_2801_zps181e5c18.jpg49.3 KB · Views: 347 -

IMG_2805_zpsc596c057.jpg69.3 KB · Views: 345

IMG_2805_zpsc596c057.jpg69.3 KB · Views: 345 -

IMG_2832_zps2b45b017.jpg61.2 KB · Views: 338

IMG_2832_zps2b45b017.jpg61.2 KB · Views: 338 -

IMG_2833_zps6fe7e60a.jpg60.2 KB · Views: 321

IMG_2833_zps6fe7e60a.jpg60.2 KB · Views: 321 -

IMG_2839_zpsc78070b0.jpg71.7 KB · Views: 341

IMG_2839_zpsc78070b0.jpg71.7 KB · Views: 341 -

IMG_2837_zps8d15b354.jpg35.5 KB · Views: 324

IMG_2837_zps8d15b354.jpg35.5 KB · Views: 324 -

IMG_2836_zps6e632d3c.jpg56.7 KB · Views: 322

IMG_2836_zps6e632d3c.jpg56.7 KB · Views: 322 -

IMG_2834_zpsdb02931f.jpg56.5 KB · Views: 319

IMG_2834_zpsdb02931f.jpg56.5 KB · Views: 319 -

IMG_2854_zpsff2dd273.jpg75.5 KB · Views: 312

IMG_2854_zpsff2dd273.jpg75.5 KB · Views: 312 -

IMG_2848_zps7e479996.jpg64.6 KB · Views: 348

IMG_2848_zps7e479996.jpg64.6 KB · Views: 348 -

IMG_2843_zpse1253118.jpg75.5 KB · Views: 319

IMG_2843_zpse1253118.jpg75.5 KB · Views: 319 -

IMG_2857_zps633d3362.jpg69 KB · Views: 339

IMG_2857_zps633d3362.jpg69 KB · Views: 339 -

IMG_2863_zpsad1b8b97.jpg65.8 KB · Views: 338

IMG_2863_zpsad1b8b97.jpg65.8 KB · Views: 338