Hello to all the 405th members!

After about 2 months, I completed the ODST costume I embarked on starting May 5th and finished a few hours before San Diego comic con. I wish I had had more time because I had a lot of sleepless nights, cancelled plans and I also didn't do as good of a job as I think I could have if I had allotted myself more time. I had lots of fun, frustration and satisfaction making this build and really the most I hope for out of this post is to help encourage people to go out and try to make a costume! With no formal training other than a job where I paint a lot, I was a complete newbie to absolutely every technique and procedure but I ended up with a half decent costume and a lot of hope for the future in improving it and even starting new ones.

I'b be more than happy to answer any questions about the procedure (although not claiming to be an expert, but sometimes an amateur mind is helpful to newcomers). I'll go over as much helpful stuff as I can without trying to bore anyone.

I'll start with the finished product and go through the steps of the build which took just over 2 months. My friend (Dutch) started his at the same time but didn't have time to make a helmet so here we are at Comic con

I'd also like to personally thank all the members of the 405th at comic con that we met up with. They were VERY kind, welcoming, helpful and enjoyable. They encouraged us newcomers to keep up with our work and were a blast to hang out with.

Here we go

The basics - I'm from San Francisco, with no modeling background whatsoever. I have a flair for artistry but no real training on anything that would help me with this project. I'm just over 5'10" and 175lb making me just about exactly average for this project. Also, I'd be horribly short for a Spartan.

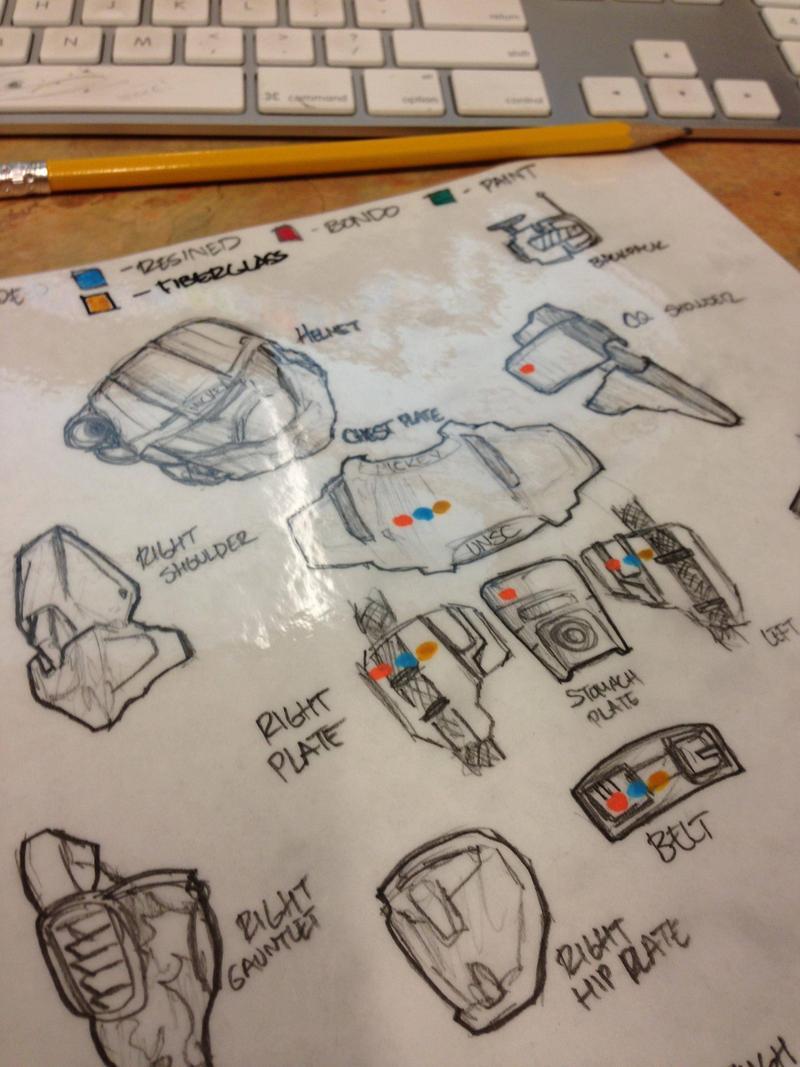

I chose to go with the fiberglass/resin/bondo method because of a few simple reasons. I felt it would last longer, be stronger and I liked the look of finished costumes vs foam. More or less, it was all personal preference that lead me to this but I would certainly like to try the foam approach on a future project as I would like to have one of both to compare them. Initial thoughts was the fiberglass was itchy, messy, took longer to form (especially when an area needed lots of bondo) but was very strong, solid and took/held paint very well.

I found essentially every pepakura file I ever needed on the 405th database. A very minimal amount of web searching was needed to find a few more obscure items that were 'Mickey' specific. After a lot of research on things like how to bondo, rondo, fiberglass, sanding tricks, mounting tricks and things of that nature, I dove in, making an expensive trip to Home Depot, Osh hardware, Tap Plastics and Auto Zone. At the end of this project, all said and done, I spent about $700. I had most of the necessary tools already such as my dremel, electric sander, drill and glue gun.

Pardon the large amount of pictures. I'll try to bold the areas where I offer my amateur advice and explanation of the process for any newcomers that may be reading!

Step 1 - Start somewhere

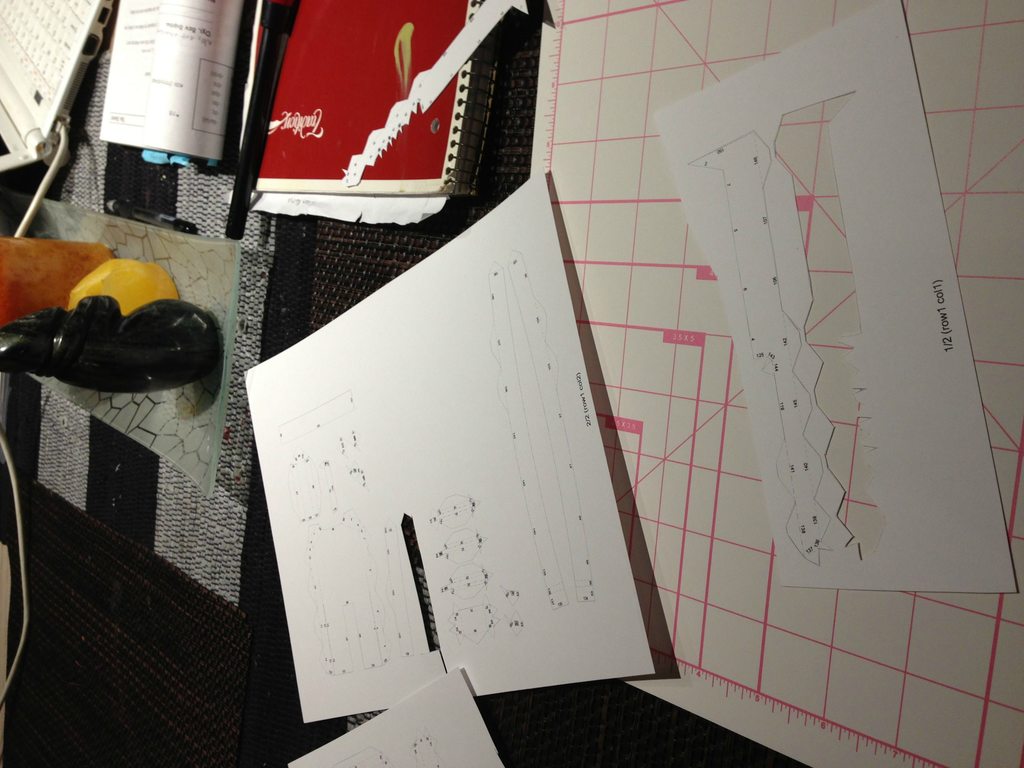

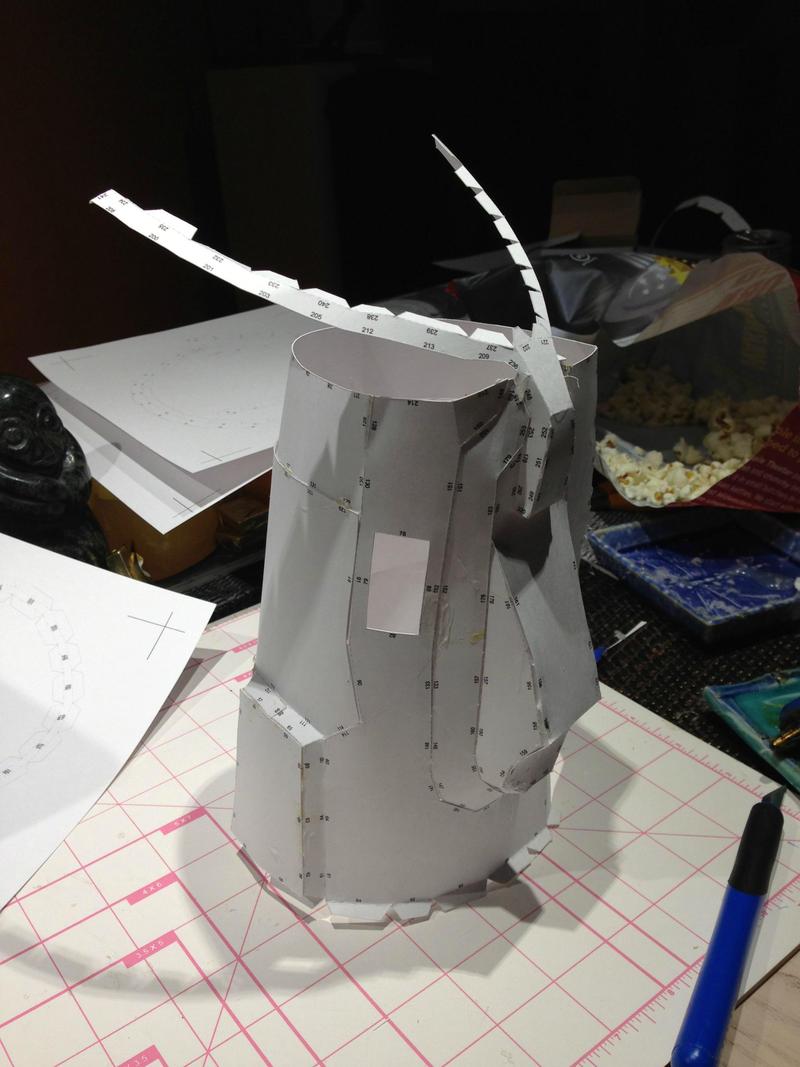

After downloading all the proper paper files and reading about how to scale them, I dove into cutting a few pieces and gluing them together. It took awhile to get an effective cutting, scoring and gluing method down.

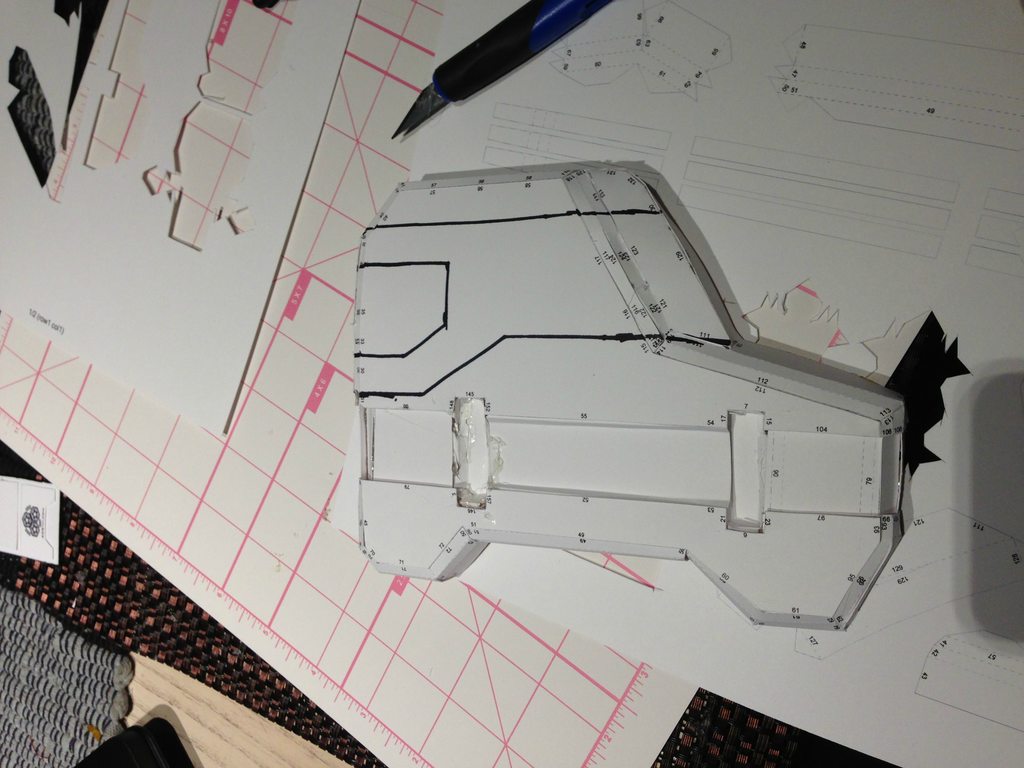

After many hours of cutting and gluing, the chest and belts were done and got resined.

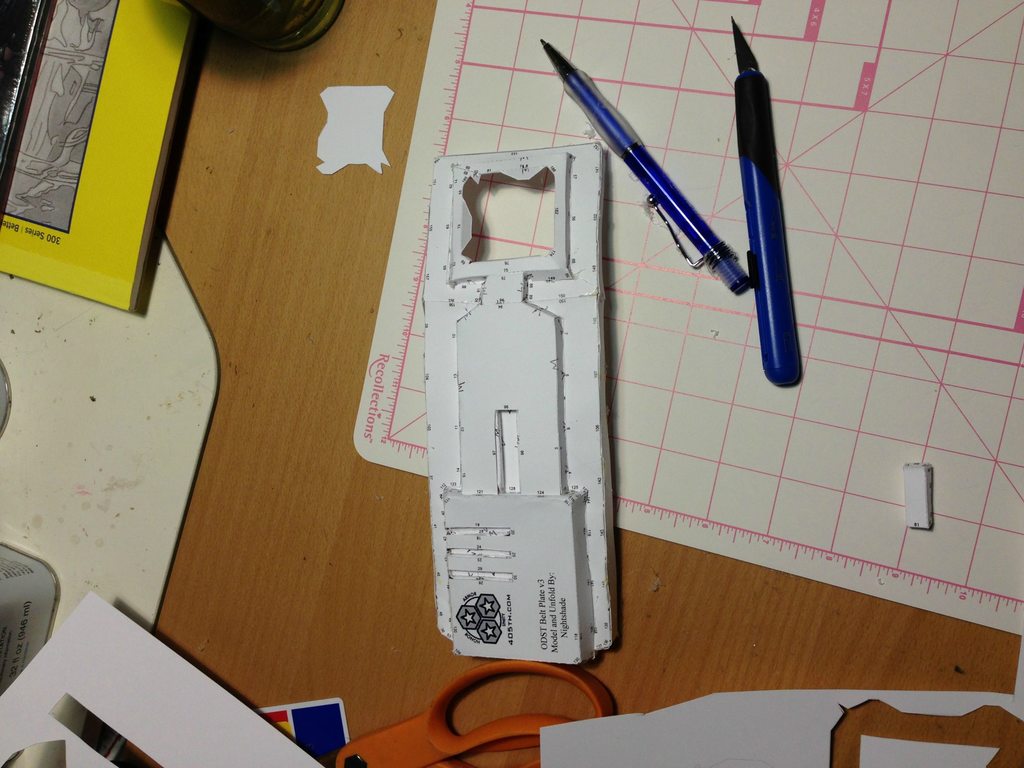

Making a side plate and marking out where to 'rondo'

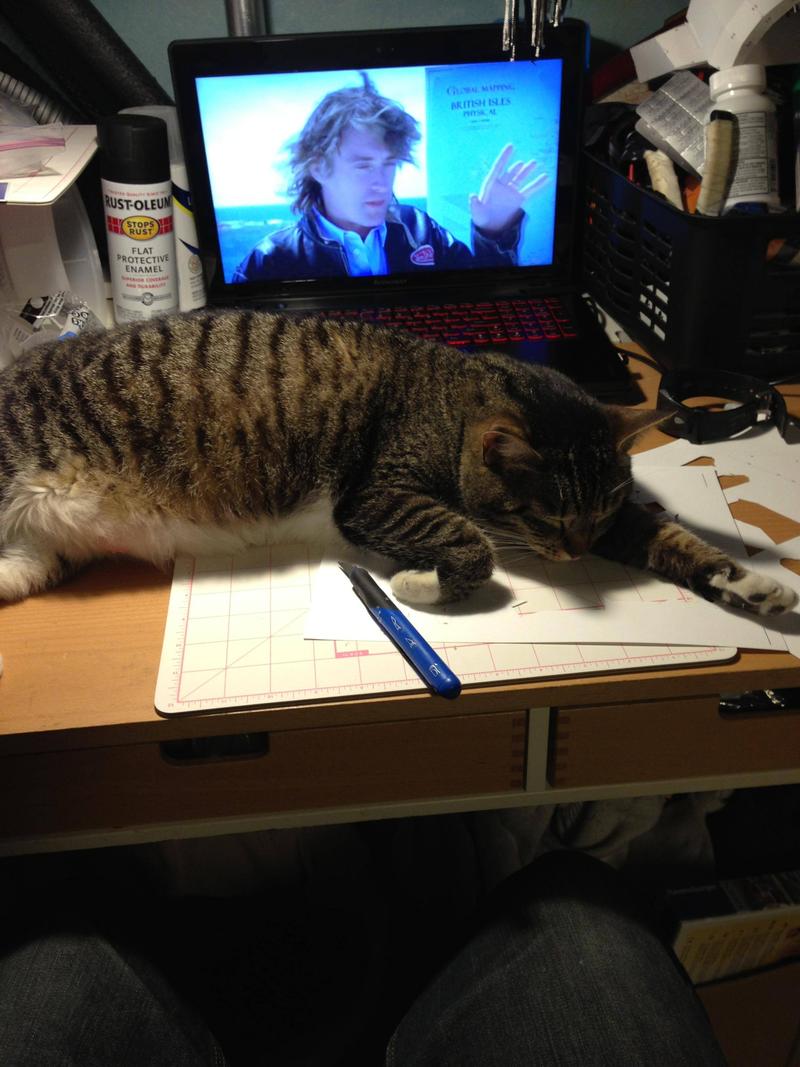

Running into a snag. Also, it appears Richard Hammond is attempting to pet my cat

At work, I quickly decided I needed a way to keep track of what I had done and what I needed to do

I had no set order of completing parts. All I know is I wanted to save the helmet for last so that I would hopefully work out all my kinks and be good at fiberglassing and bondoing by then. Here are some pieces after being resined and hung to keep them from fusing themselves to the newspaper I left them on. The fiberglassing method quickly becomes one of my least favorite. The process is supposed to be cutting out small-ish amounts of cloth to apply to the inside of all the parts. After brushing down a layer of fiberglass resin, I found out just how sticky the resin is when I tried to dip cloth in the resin and apply it to the inside. HOWEVER, one of my biggest tips is this take the extra time to cut smaller pieces. The bigger the pieces, the more likely you are to form air bubbles and air bubbles will seriously compromise the strength of your pieces. Especially on edges and sharp curves

After some mild bondo, one of my first attempts at primering/sanding. The bondoing process is also kind of frustrating. The bondo is like clay, but it dries very quickly. After you mix the putty with the hardener, you have but a few minutes to work with it. I used popsicle sticks and gloved hands to apply the bondo but you will typically end up with the bondo drying with pits and uneveness. Multiple layers are almost always required but be patient and don't try to mix more bondo than you can use before it dries! It's a waste

While making my first gauntlet, it appears I have inadvertently made an owl with some intense eyebrows

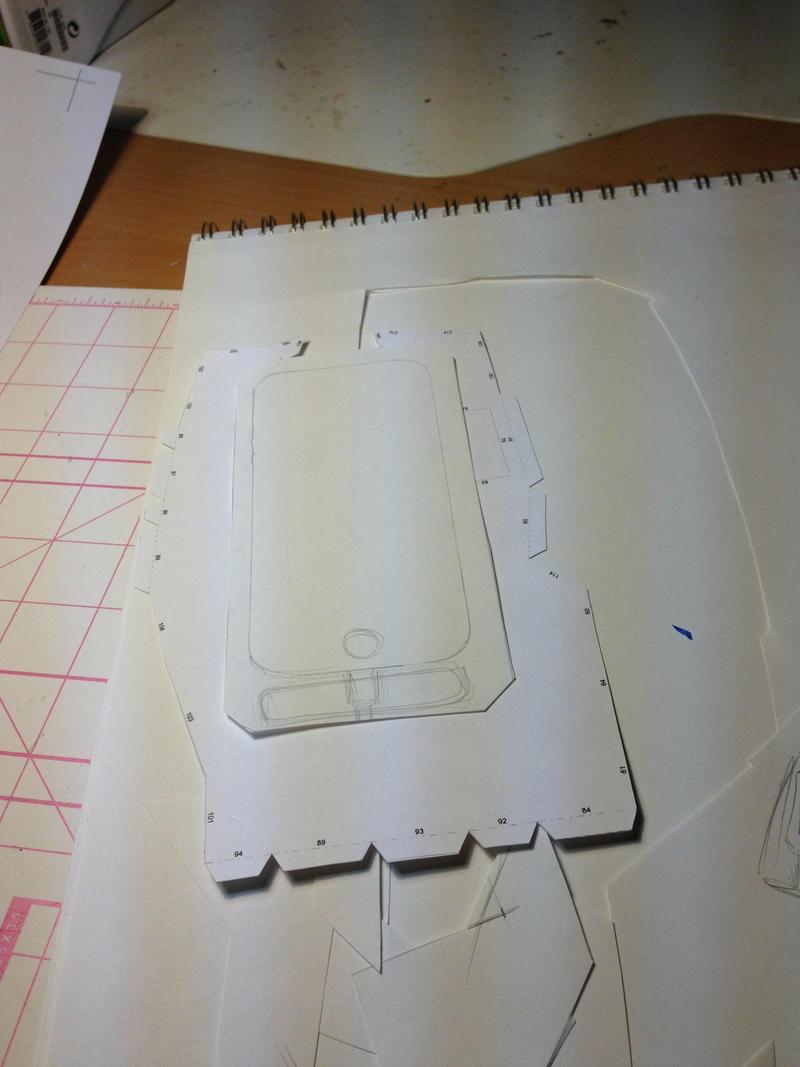

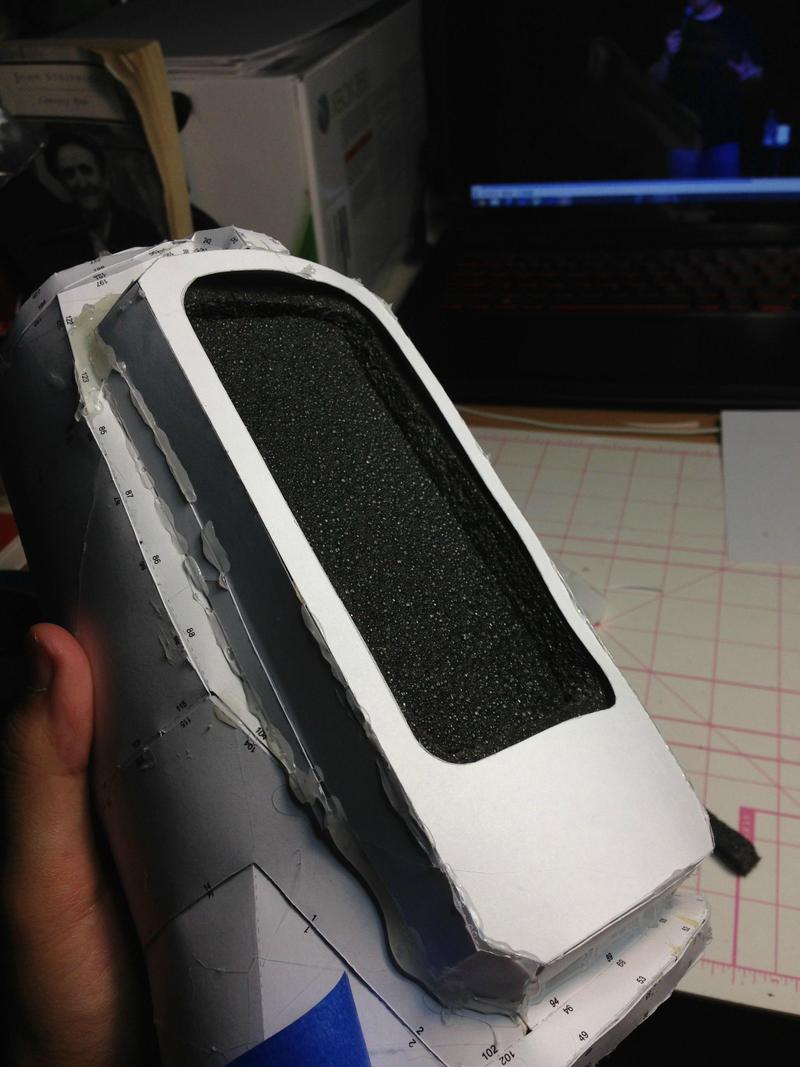

For my 2nd gauntlet, I wanted to add a phone receiver as well as drill a hole in the holder to accept a charging cable that would lead to a charging brick inside my gauntlet. Here's my original mock up

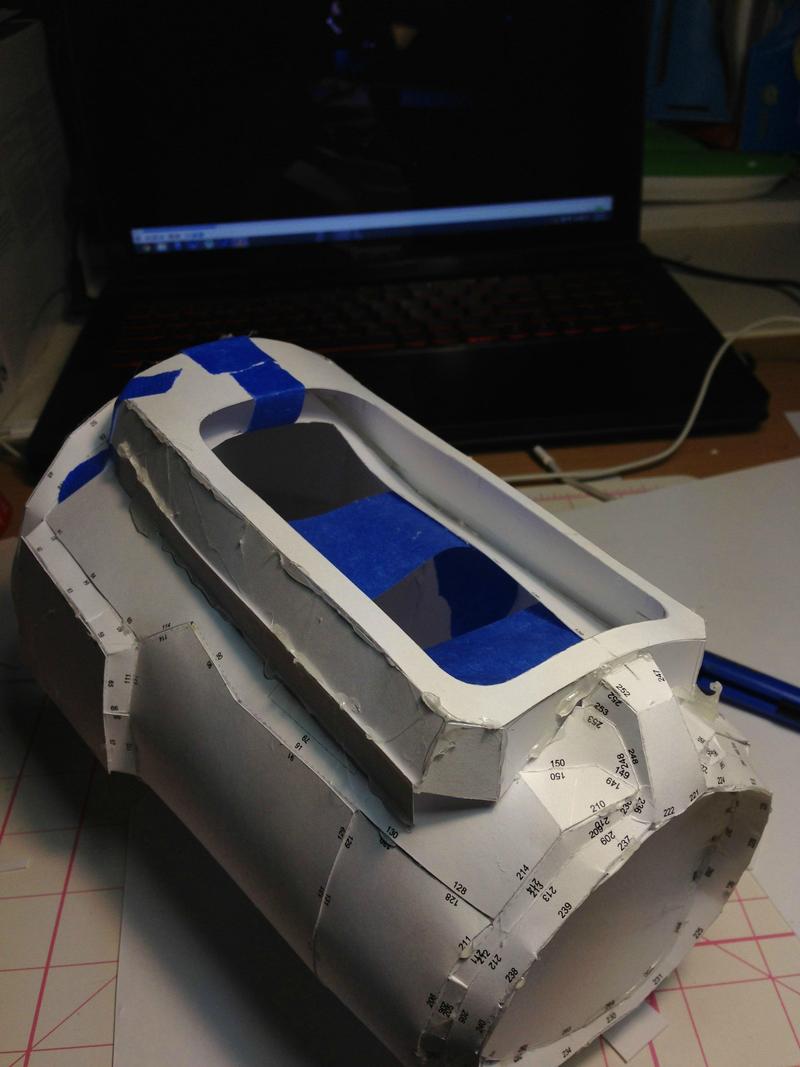

I shimmyed up a holder and some walls for it

annnnd essentially willed it to fit

Quickly cut up some foam to see how I could fit the phone in

After about 2 months, I completed the ODST costume I embarked on starting May 5th and finished a few hours before San Diego comic con. I wish I had had more time because I had a lot of sleepless nights, cancelled plans and I also didn't do as good of a job as I think I could have if I had allotted myself more time. I had lots of fun, frustration and satisfaction making this build and really the most I hope for out of this post is to help encourage people to go out and try to make a costume! With no formal training other than a job where I paint a lot, I was a complete newbie to absolutely every technique and procedure but I ended up with a half decent costume and a lot of hope for the future in improving it and even starting new ones.

I'b be more than happy to answer any questions about the procedure (although not claiming to be an expert, but sometimes an amateur mind is helpful to newcomers). I'll go over as much helpful stuff as I can without trying to bore anyone.

I'll start with the finished product and go through the steps of the build which took just over 2 months. My friend (Dutch) started his at the same time but didn't have time to make a helmet so here we are at Comic con

I'd also like to personally thank all the members of the 405th at comic con that we met up with. They were VERY kind, welcoming, helpful and enjoyable. They encouraged us newcomers to keep up with our work and were a blast to hang out with.

Here we go

The basics - I'm from San Francisco, with no modeling background whatsoever. I have a flair for artistry but no real training on anything that would help me with this project. I'm just over 5'10" and 175lb making me just about exactly average for this project. Also, I'd be horribly short for a Spartan.

I chose to go with the fiberglass/resin/bondo method because of a few simple reasons. I felt it would last longer, be stronger and I liked the look of finished costumes vs foam. More or less, it was all personal preference that lead me to this but I would certainly like to try the foam approach on a future project as I would like to have one of both to compare them. Initial thoughts was the fiberglass was itchy, messy, took longer to form (especially when an area needed lots of bondo) but was very strong, solid and took/held paint very well.

I found essentially every pepakura file I ever needed on the 405th database. A very minimal amount of web searching was needed to find a few more obscure items that were 'Mickey' specific. After a lot of research on things like how to bondo, rondo, fiberglass, sanding tricks, mounting tricks and things of that nature, I dove in, making an expensive trip to Home Depot, Osh hardware, Tap Plastics and Auto Zone. At the end of this project, all said and done, I spent about $700. I had most of the necessary tools already such as my dremel, electric sander, drill and glue gun.

Pardon the large amount of pictures. I'll try to bold the areas where I offer my amateur advice and explanation of the process for any newcomers that may be reading!

Step 1 - Start somewhere

After downloading all the proper paper files and reading about how to scale them, I dove into cutting a few pieces and gluing them together. It took awhile to get an effective cutting, scoring and gluing method down.

After many hours of cutting and gluing, the chest and belts were done and got resined.

Making a side plate and marking out where to 'rondo'

Running into a snag. Also, it appears Richard Hammond is attempting to pet my cat

At work, I quickly decided I needed a way to keep track of what I had done and what I needed to do

I had no set order of completing parts. All I know is I wanted to save the helmet for last so that I would hopefully work out all my kinks and be good at fiberglassing and bondoing by then. Here are some pieces after being resined and hung to keep them from fusing themselves to the newspaper I left them on. The fiberglassing method quickly becomes one of my least favorite. The process is supposed to be cutting out small-ish amounts of cloth to apply to the inside of all the parts. After brushing down a layer of fiberglass resin, I found out just how sticky the resin is when I tried to dip cloth in the resin and apply it to the inside. HOWEVER, one of my biggest tips is this take the extra time to cut smaller pieces. The bigger the pieces, the more likely you are to form air bubbles and air bubbles will seriously compromise the strength of your pieces. Especially on edges and sharp curves

After some mild bondo, one of my first attempts at primering/sanding. The bondoing process is also kind of frustrating. The bondo is like clay, but it dries very quickly. After you mix the putty with the hardener, you have but a few minutes to work with it. I used popsicle sticks and gloved hands to apply the bondo but you will typically end up with the bondo drying with pits and uneveness. Multiple layers are almost always required but be patient and don't try to mix more bondo than you can use before it dries! It's a waste

While making my first gauntlet, it appears I have inadvertently made an owl with some intense eyebrows

For my 2nd gauntlet, I wanted to add a phone receiver as well as drill a hole in the holder to accept a charging cable that would lead to a charging brick inside my gauntlet. Here's my original mock up

I shimmyed up a holder and some walls for it

annnnd essentially willed it to fit

Quickly cut up some foam to see how I could fit the phone in