(Update on page 2)

Greetings 405th! I've been a long-time lurker, but it's finally time to post my first replica build - the Halo 3 variant of the tried-and-true Magnum. I've completed the initial prototype, but my end goal for this project is to create a highly reproduce-able, highly accurate replica that i can modify with each new version; varied accessories, attachments, paint schemes, electronics... whatever. Time for some process!

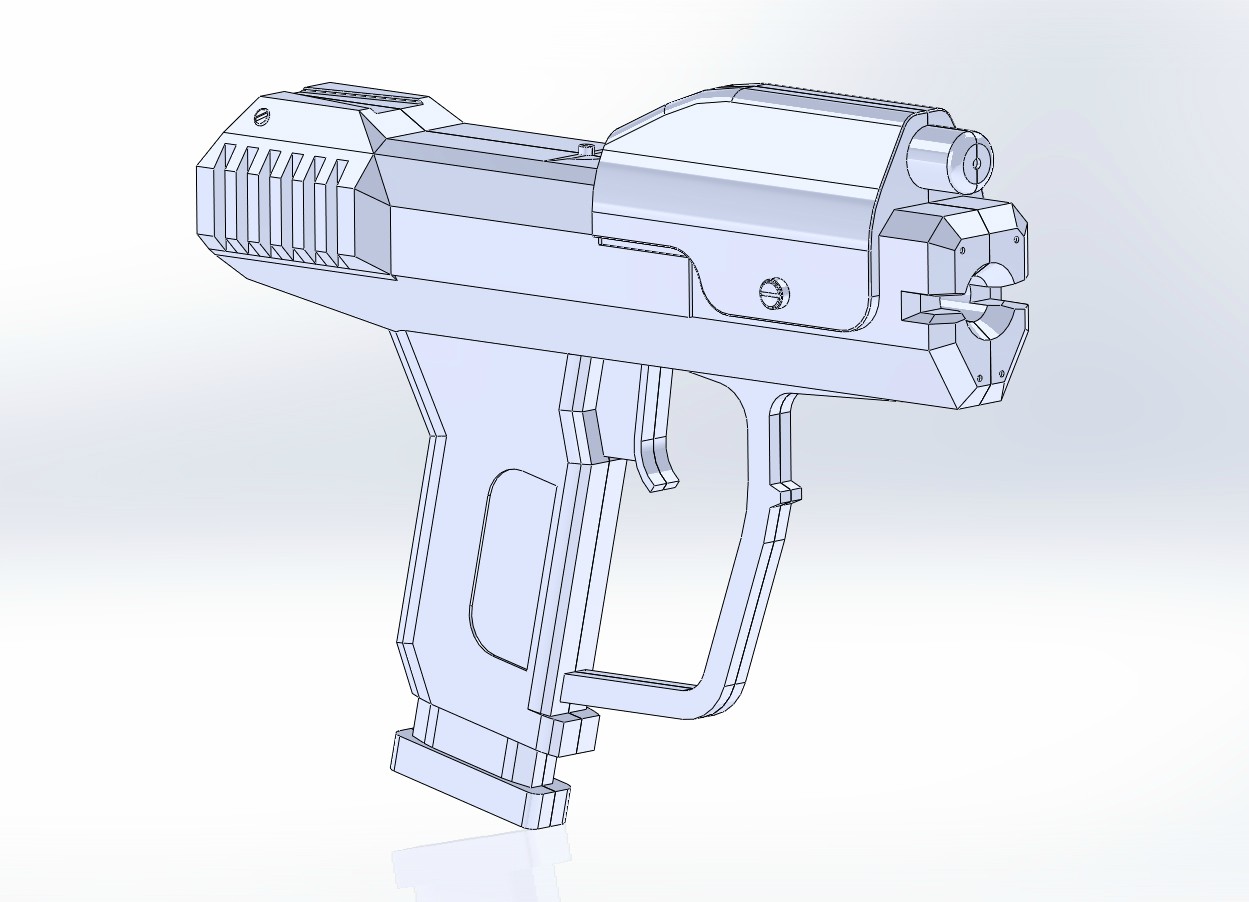

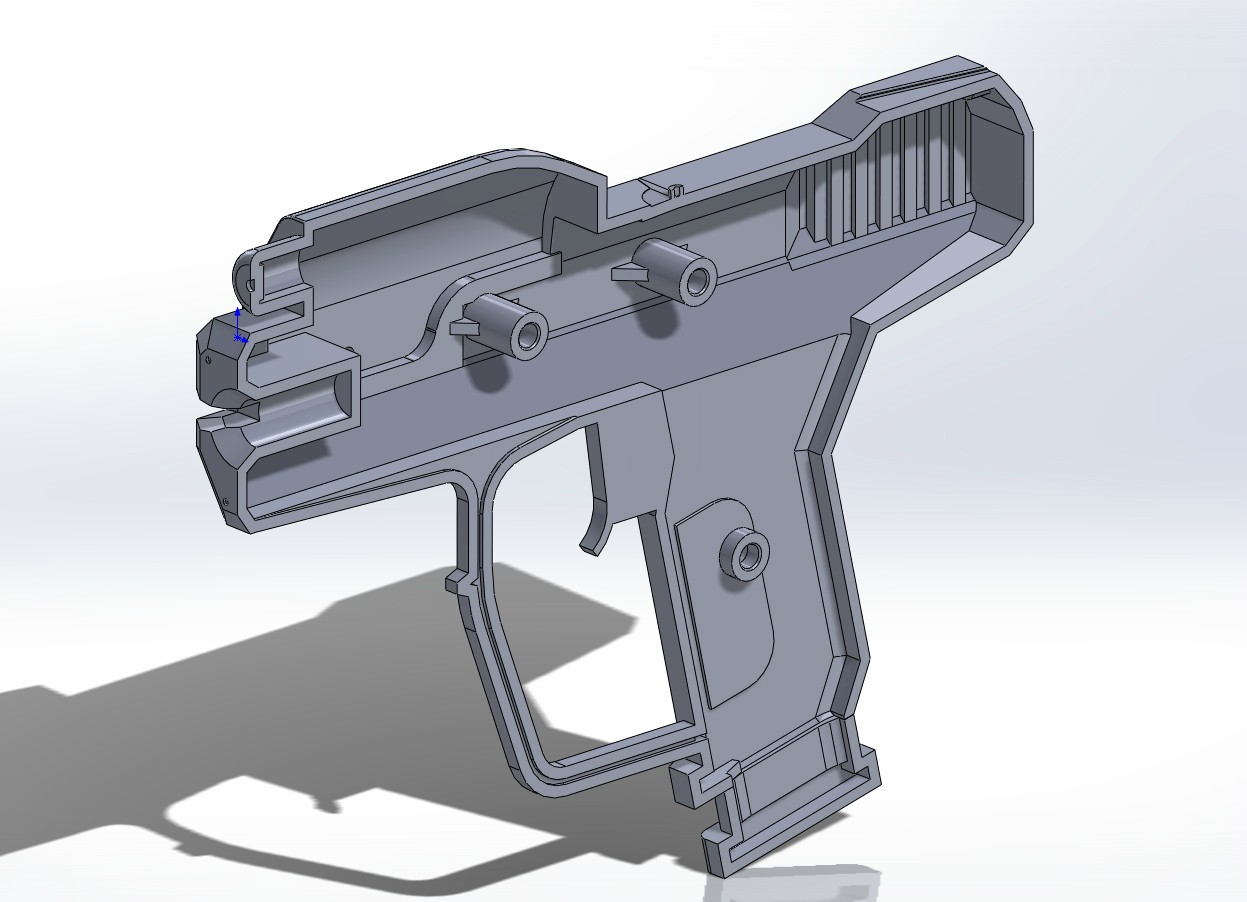

I started in Solidworks, my 3D program of choice. I modeled the gun as accurately as I could, carefully shelling the piece and eliminating under-cuts for the molding process. I decided to go with a two-piece clamshell design both to minimize material used and to provide internal space for whatever electronics or mechanisms I may want to incorporate further down the line:

I wanted the final product to be person, not Spartan-sized, so I reduced the scale from 117% to 100%, and added standoffs and ribbing to help with final assembly.

After some printer-specific modification, it was into the MakerBot Replicator 2.0:

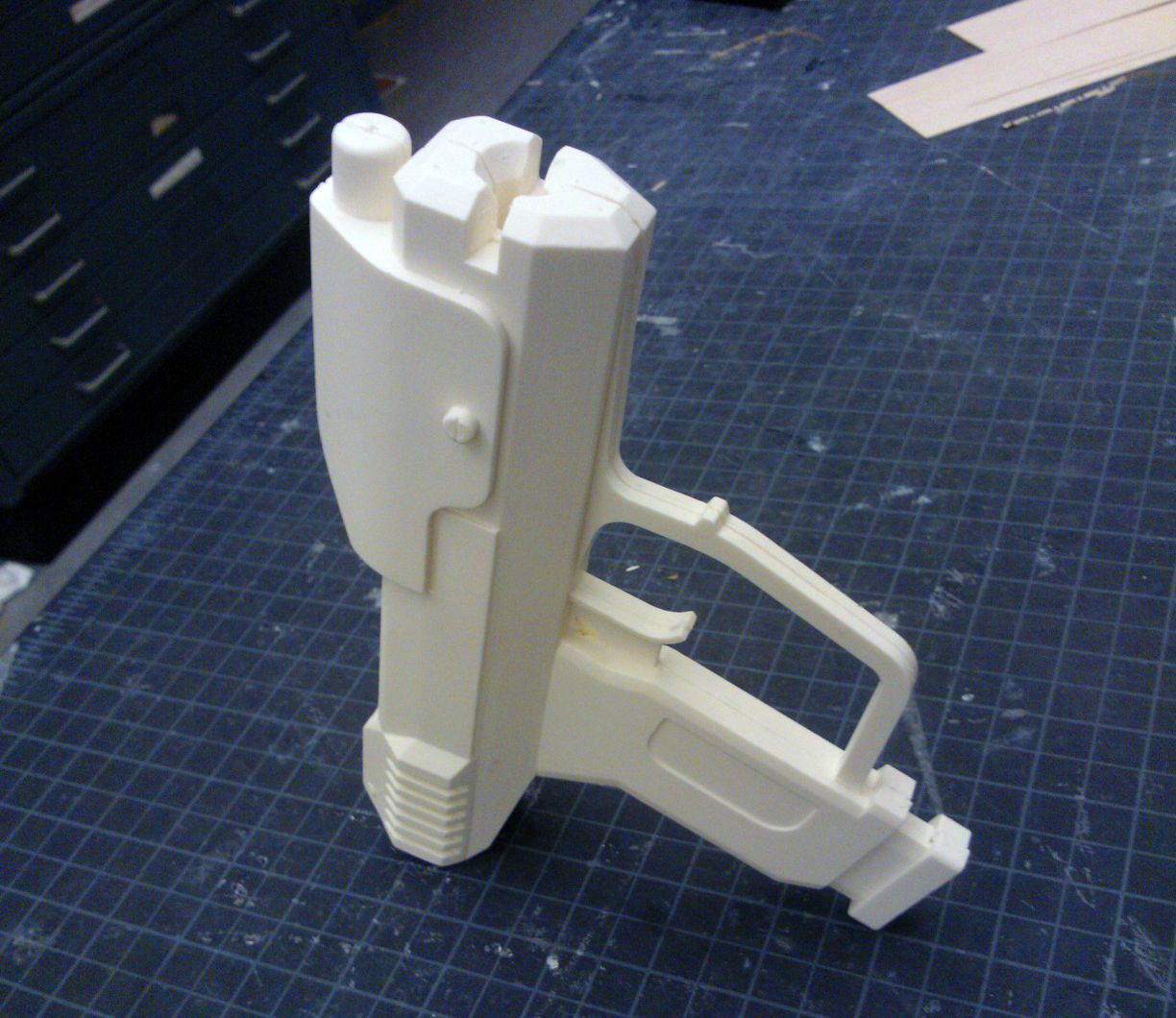

19 hours of printing and about 6 hours of cleaning later:

I then took my prints and spent a considerable amount of time doing the sanding, filling, and priming dance. These guys needed to be as perfect as possible as they would become my masters in the mold-making process:

Once I was happy with them, it was time for silicone. I went with a 2-piece block mold for each half of the clamshell (out of Smooth-On Mold Star 16 Fast). Maybe not the cheapest option, but they're very robust, durable and will allow me to make many, many castings. Because of the thin shell thickness and the detail required, the pour/ breather holes took quite some tweaking in order to eliminate bubbles, and I even had to manually trim the male halves of the mold to thicken things up a bit:

Not the quickest process, but once they were done I could finally start pouring some Smooth-On Smooth-Cast 320 into my new molds. Again, the shelled nature of the cavity made it quite difficult, and I eventually developed a process involving injecting the un-cured resin into the mold via syringe, and incorporating lots of movement to get those darn bubbles out.

At long last, some decent castings (standing on the sprues created by the various breather and pour holes built in to the molds):

At this point I wanted to take the project all the way to a complete prototype (the stock M6G) as a proof-of-concept, so I took those first two successful casts and began assembly, using styrene dowels in the internal standoffs to align the two halves. Excitement ensues!:

Back to the priming, sanding, and filling grind to mask the seam down the middle of the gun, and after painting, weathering, and applying a laser-cut textured rubber grip, I have Magnum #1!

Next step: Production! The infrastructure is complete, and I know it all works. Now it's time to get really creative. I'm thinking silencers, muzzle breaks, scopes, extended clips, crazy colorways, LED's, sound systems, laser pointers, anything really. If all goes well, I will be updating this post periodically as I cast more shells and assemble different variants. Please let me know what you think and thanks for checking this out!

Greetings 405th! I've been a long-time lurker, but it's finally time to post my first replica build - the Halo 3 variant of the tried-and-true Magnum. I've completed the initial prototype, but my end goal for this project is to create a highly reproduce-able, highly accurate replica that i can modify with each new version; varied accessories, attachments, paint schemes, electronics... whatever. Time for some process!

I started in Solidworks, my 3D program of choice. I modeled the gun as accurately as I could, carefully shelling the piece and eliminating under-cuts for the molding process. I decided to go with a two-piece clamshell design both to minimize material used and to provide internal space for whatever electronics or mechanisms I may want to incorporate further down the line:

I wanted the final product to be person, not Spartan-sized, so I reduced the scale from 117% to 100%, and added standoffs and ribbing to help with final assembly.

After some printer-specific modification, it was into the MakerBot Replicator 2.0:

19 hours of printing and about 6 hours of cleaning later:

I then took my prints and spent a considerable amount of time doing the sanding, filling, and priming dance. These guys needed to be as perfect as possible as they would become my masters in the mold-making process:

Once I was happy with them, it was time for silicone. I went with a 2-piece block mold for each half of the clamshell (out of Smooth-On Mold Star 16 Fast). Maybe not the cheapest option, but they're very robust, durable and will allow me to make many, many castings. Because of the thin shell thickness and the detail required, the pour/ breather holes took quite some tweaking in order to eliminate bubbles, and I even had to manually trim the male halves of the mold to thicken things up a bit:

Not the quickest process, but once they were done I could finally start pouring some Smooth-On Smooth-Cast 320 into my new molds. Again, the shelled nature of the cavity made it quite difficult, and I eventually developed a process involving injecting the un-cured resin into the mold via syringe, and incorporating lots of movement to get those darn bubbles out.

At long last, some decent castings (standing on the sprues created by the various breather and pour holes built in to the molds):

At this point I wanted to take the project all the way to a complete prototype (the stock M6G) as a proof-of-concept, so I took those first two successful casts and began assembly, using styrene dowels in the internal standoffs to align the two halves. Excitement ensues!:

Back to the priming, sanding, and filling grind to mask the seam down the middle of the gun, and after painting, weathering, and applying a laser-cut textured rubber grip, I have Magnum #1!

Next step: Production! The infrastructure is complete, and I know it all works. Now it's time to get really creative. I'm thinking silencers, muzzle breaks, scopes, extended clips, crazy colorways, LED's, sound systems, laser pointers, anything really. If all goes well, I will be updating this post periodically as I cast more shells and assemble different variants. Please let me know what you think and thanks for checking this out!

Attachments

-

cOTJJ3e.jpg108.2 KB · Views: 1,457

cOTJJ3e.jpg108.2 KB · Views: 1,457 -

0p7b5u2.jpg122 KB · Views: 602

0p7b5u2.jpg122 KB · Views: 602 -

eesqcoO.jpg228.4 KB · Views: 353

eesqcoO.jpg228.4 KB · Views: 353 -

HOin5Ym.jpg204.7 KB · Views: 353

HOin5Ym.jpg204.7 KB · Views: 353 -

Yz2YLS6.jpg179.2 KB · Views: 349

Yz2YLS6.jpg179.2 KB · Views: 349 -

vAO7NRN.jpg256.2 KB · Views: 338

vAO7NRN.jpg256.2 KB · Views: 338 -

fUjx2Re.jpg166.5 KB · Views: 364

fUjx2Re.jpg166.5 KB · Views: 364 -

1oNZafq.jpg169.2 KB · Views: 317

1oNZafq.jpg169.2 KB · Views: 317 -

jSgRvKj.jpg143.3 KB · Views: 333

jSgRvKj.jpg143.3 KB · Views: 333 -

neDaaBJ.jpg238.5 KB · Views: 308

neDaaBJ.jpg238.5 KB · Views: 308 -

IX5uIIq.jpg97.5 KB · Views: 413

IX5uIIq.jpg97.5 KB · Views: 413 -

mvpL54l.jpg166.8 KB · Views: 645

mvpL54l.jpg166.8 KB · Views: 645 -

OyDhXIA.jpg92.5 KB · Views: 380

OyDhXIA.jpg92.5 KB · Views: 380 -

i9hXn6L.jpg88.9 KB · Views: 317

i9hXn6L.jpg88.9 KB · Views: 317 -

XqNZumY.gif2 MB · Views: 527

XqNZumY.gif2 MB · Views: 527