ComanderXXY

New Member

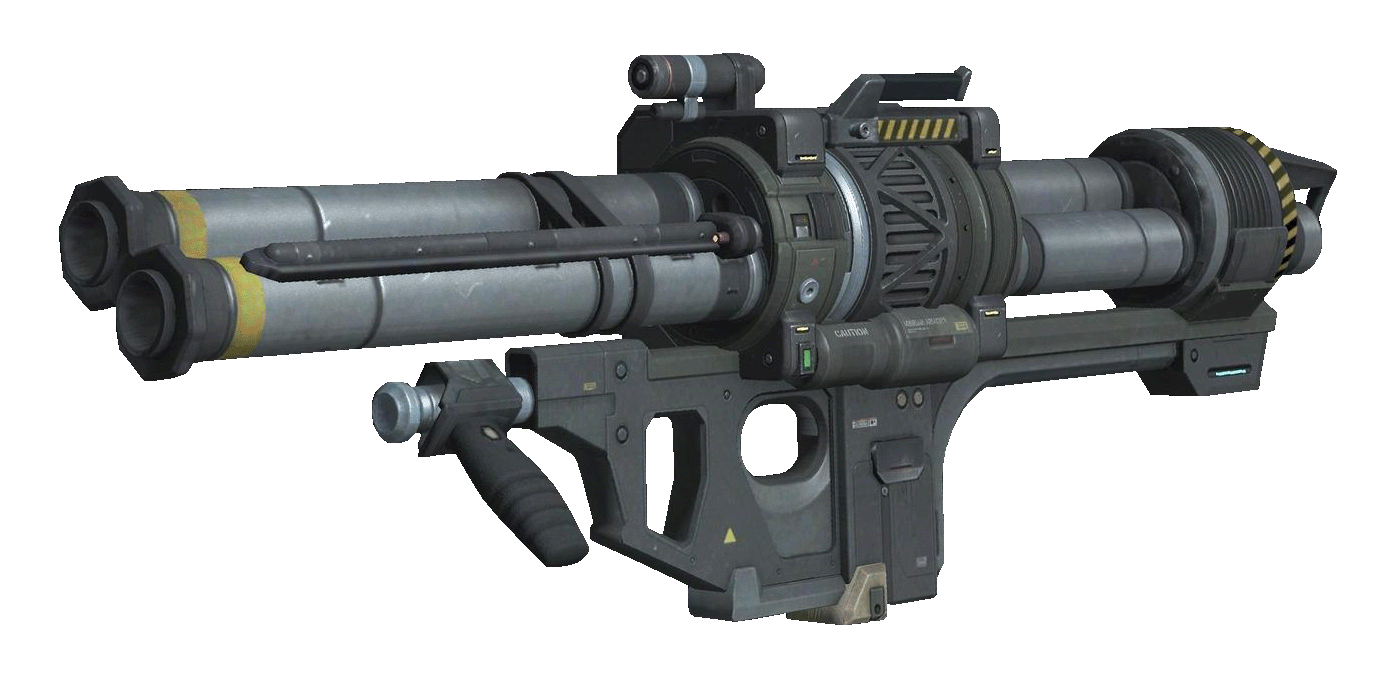

I'm designing and printing a 3D-Printable SPNKR.

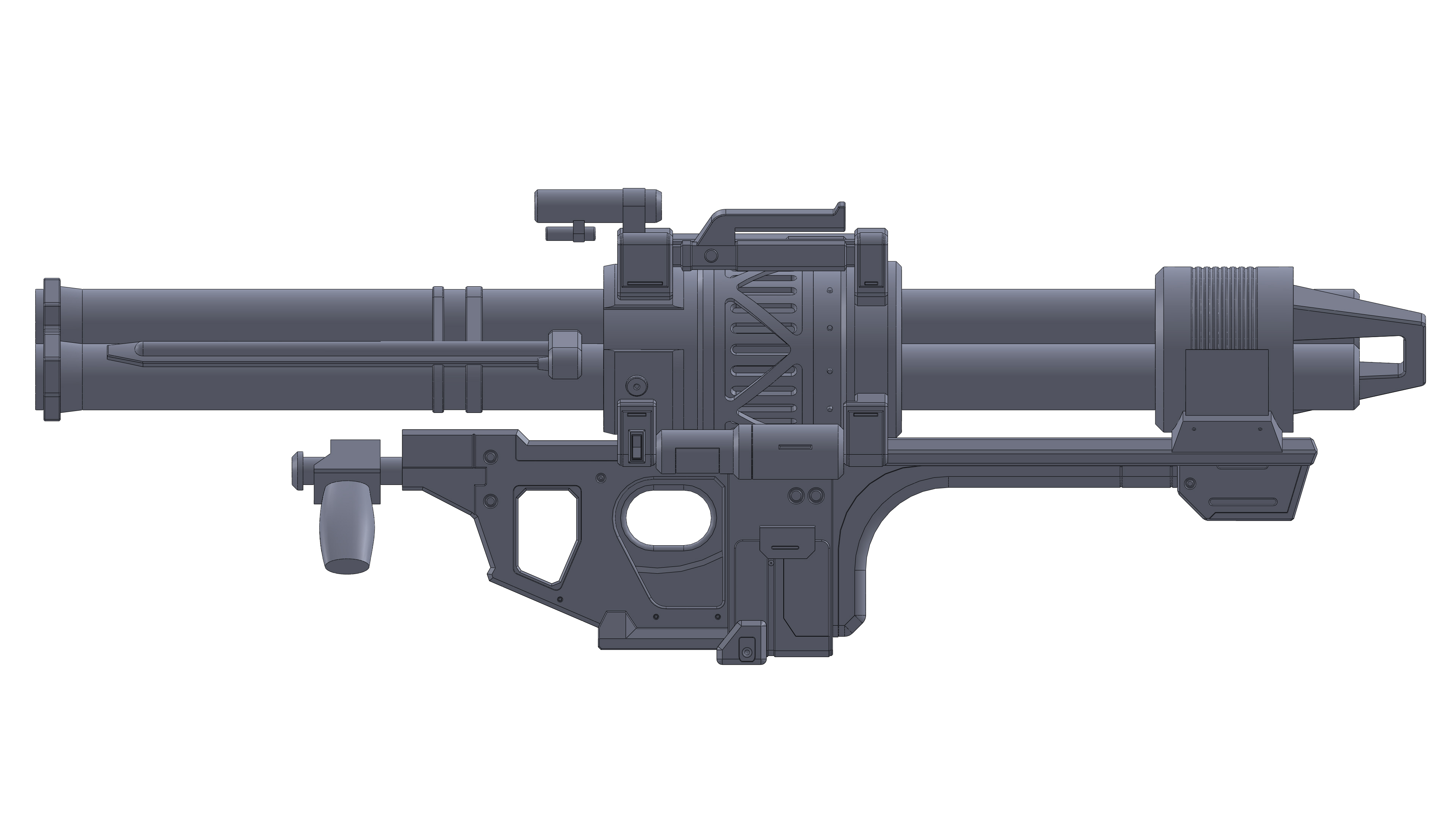

The Base Model is already finished:

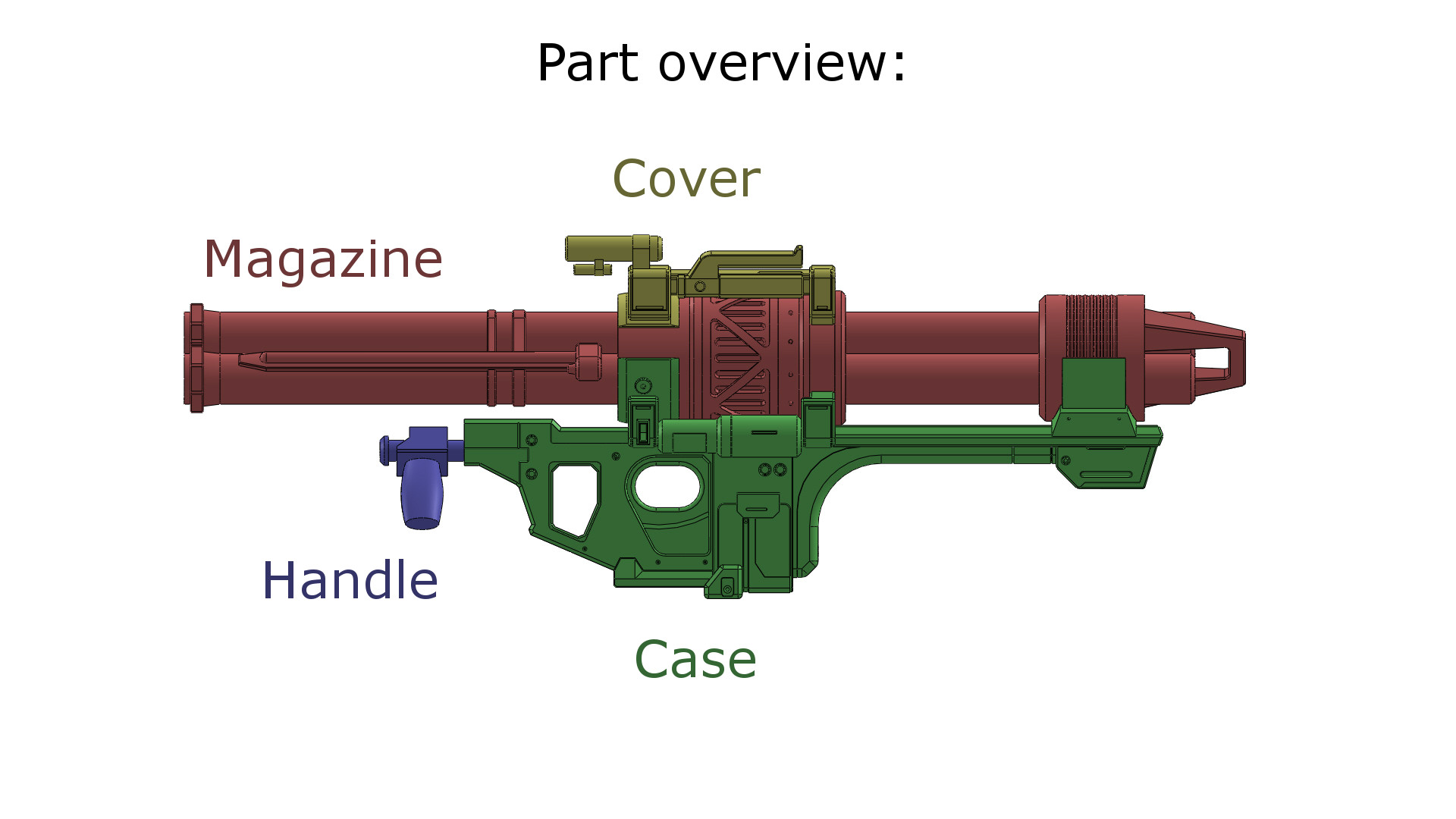

It will consist of 4 main parts:

For 3D-Printing I'll cut two shafts into the Case and Cover Parts, so I can lock the Magazine between with a latch:

That is what I have completed already

At the moment I'm cutting the parts into printable pieces for my "Creality cr-10" printer.

Of course I'll print it in real size (1,2 m tube length)

If you whant to inspect the parts, I've uploaded some stl-files of the bease model.

Edit: the Files are changing slightly during the build, let me know if you wish to have files of the latest version (any file Format I can create with SolidWorks).

The Base Model is already finished:

It will consist of 4 main parts:

For 3D-Printing I'll cut two shafts into the Case and Cover Parts, so I can lock the Magazine between with a latch:

That is what I have completed already

At the moment I'm cutting the parts into printable pieces for my "Creality cr-10" printer.

Of course I'll print it in real size (1,2 m tube length)

If you whant to inspect the parts, I've uploaded some stl-files of the bease model.

Edit: the Files are changing slightly during the build, let me know if you wish to have files of the latest version (any file Format I can create with SolidWorks).

Attachments

Last edited: