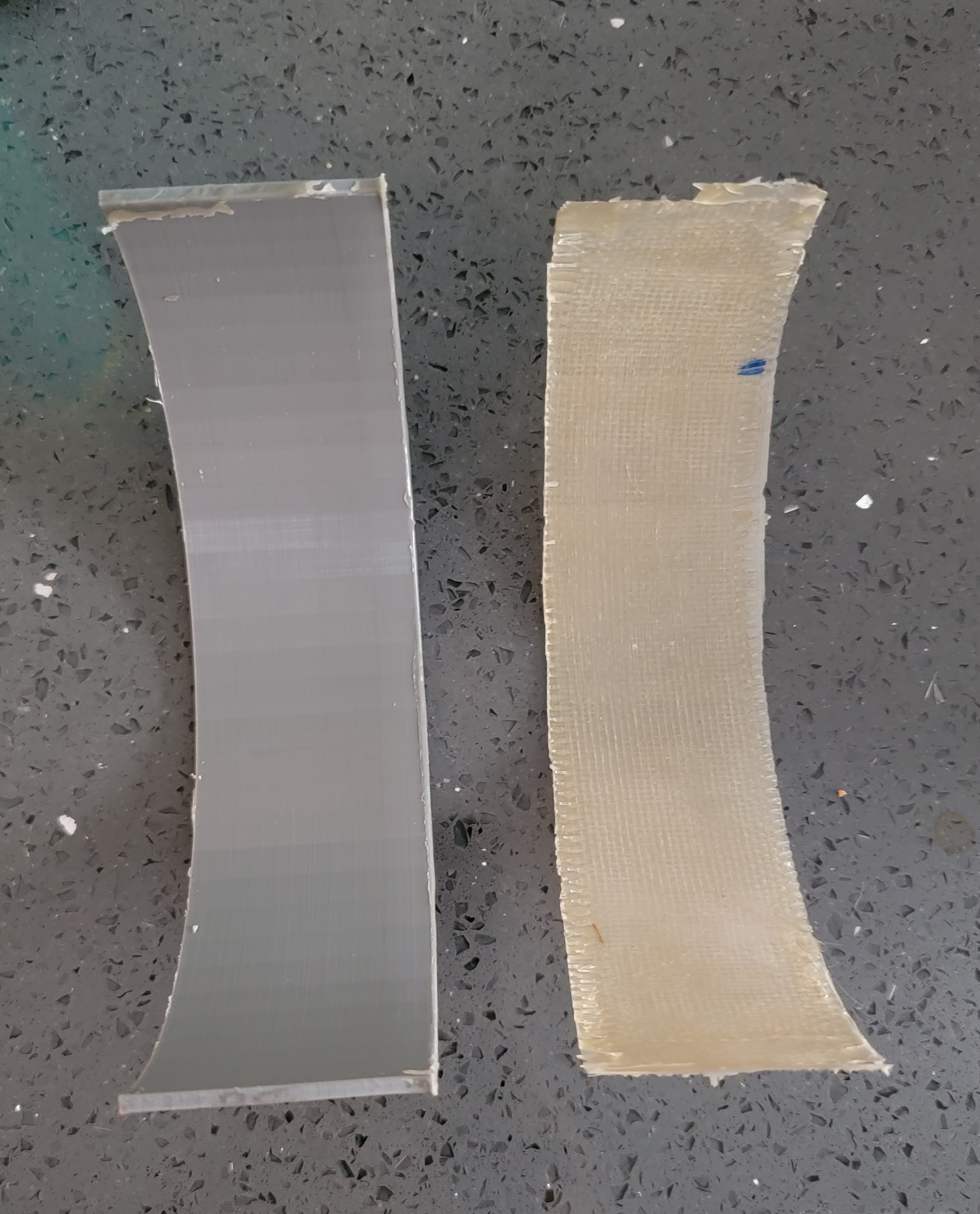

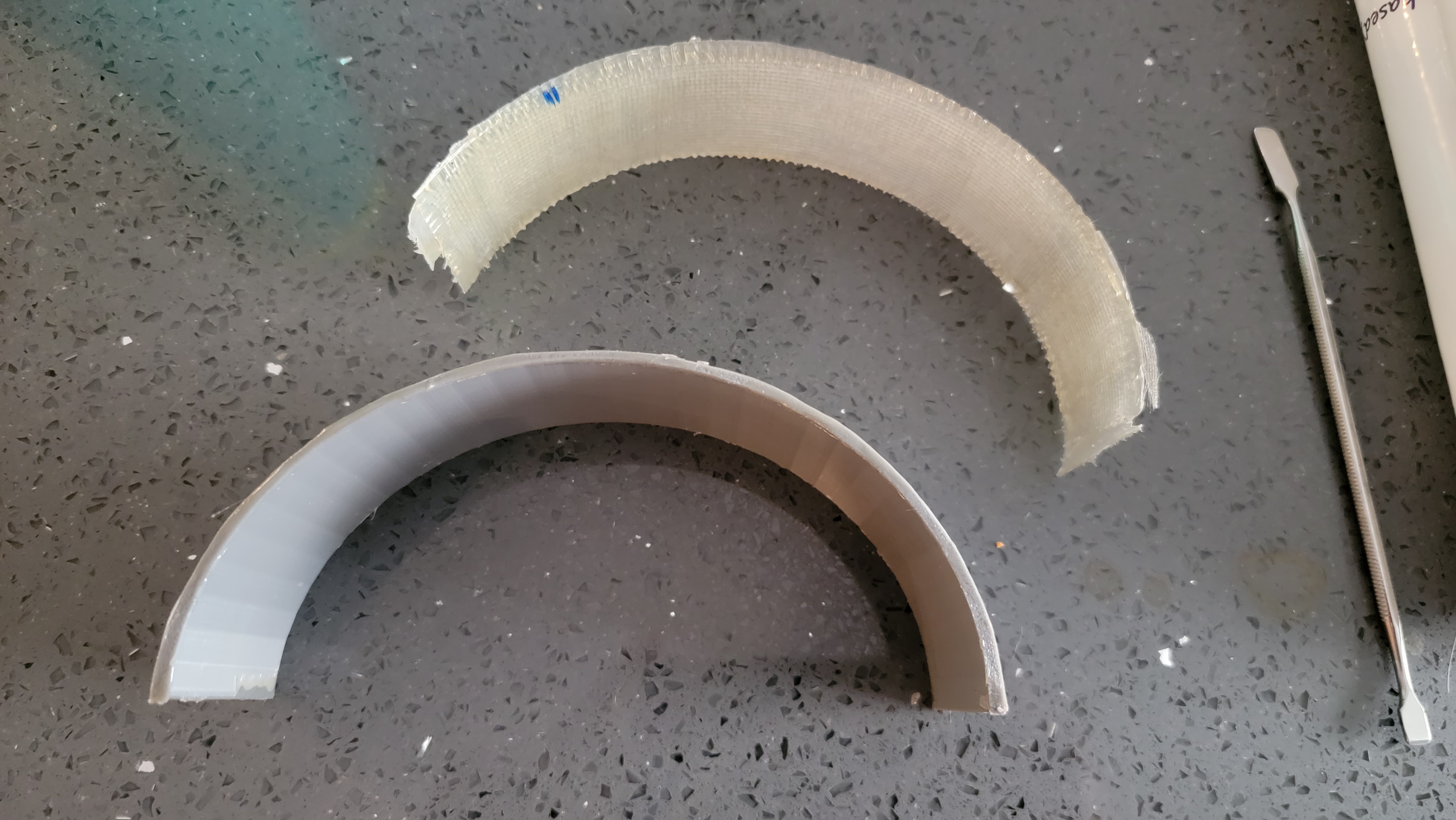

So I am running a test to check a few things in using fiberglass cloth and resin to reinforce the inside of armor pieces I am working on, and found that when cured, the fiberglass seems to not adhere very well to the 3D print, so poorly that i was able to pull it off almost like a casting. Just curious if this is normal, or if there is some other step I need to take to make sure it adheres well? This started as an air pocket that formed after I flexed it a bit to test, and with some minor flexing and prying it popped off.

For reference, this test piece wasn't sanded at all, however I don't plan on sanding the inside faces of the armor that this was going to reinforce. The resin was cured properly with enough hardener as well. The armor will have some nooks and crannies that I think will give this more teeth, so maybe it's just the shape of the piece I tested, but I'm curious to see what others think and if there are any tips for working with fiberglass and resin to reinforce prints. Granted I coaxed this along a bit, but that's part of what I'm testing as well. I feel like with natural movement this could have happened over time, and what it tells me is it really wasn't doing much to reinforce, but maybe that's just my unfamiliarity with the technique and product.

For reference, this test piece wasn't sanded at all, however I don't plan on sanding the inside faces of the armor that this was going to reinforce. The resin was cured properly with enough hardener as well. The armor will have some nooks and crannies that I think will give this more teeth, so maybe it's just the shape of the piece I tested, but I'm curious to see what others think and if there are any tips for working with fiberglass and resin to reinforce prints. Granted I coaxed this along a bit, but that's part of what I'm testing as well. I feel like with natural movement this could have happened over time, and what it tells me is it really wasn't doing much to reinforce, but maybe that's just my unfamiliarity with the technique and product.