MartinSpartan

New Member

I'm designing a working model of the M6G v2546 (Reach Magnum) designed to fire caps. It will use 3D printed cartridges that hold a cap in the rear and allow it to be fired (think like revolver cap gun cylinder, except for only one cap). The power contained in the cap should be enough to get the slide of the pistol to cycle and chamber the next cartridge.

To make the parts move properly so the pistol can function,I need to make changes to the appearance here and there (as well as some changes for practicality) and I wanted some feedback from you all to know what you think can and should not be changed in order to get this model working, because I plan to release the 3D files when I am finished and you are all welcome to 3D print or make your own with the models. (WARNING: This will not be a real firearm, do not load live ammunition into it)

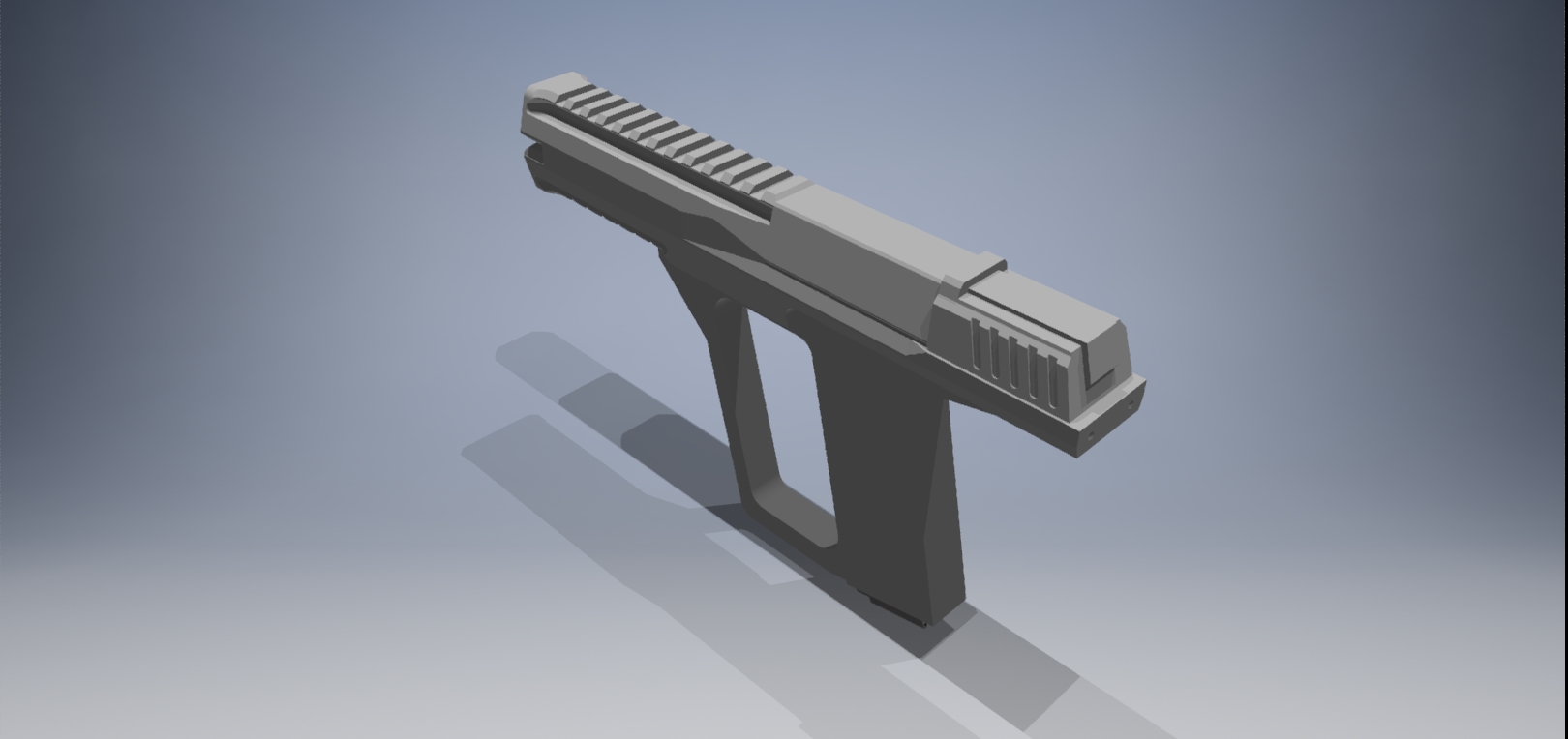

Pictured below is the original model, the original model without the smart link aiming modules, and then my WIP model, which I will be adding the smart link modules to:

The changes I've made (so far) are:

1. This is a change to canon more than appearance, but the magazine and cap-cartridge is modelled of .50 GI, not .50 AE (which is probably the closest to the canonical round used). This is because .50 AE is too long and I would have to change the appearance too much, the downside though, is that .50 GI is not a magnum cartridge.

2. There is no attachment method for the smart link aiming modules, and while it is never seen in game without them attached, other versions such as the M6C are, and I wanted a way of attaching them securely such that you could still put other attachments on as well, so I have made the top and bottom of the front end Piccatiny/NATO standard rails. Only the edges of these should be visible with the modules on, but it changes the look a lot with it off, is there a better attachment method?

3. I have changed the shape of the frame near the chamber, this was stepped but is now inclined, this will not be visible under the aiming modules.

4. I have centred the cut at the muzzle, and standardised the angled sections on the frame, such that the barrel is centred and front section is relatively symmetrical top-to-bottom, at most I have moved parts by 3mm and 5deg. (Ignore the size of the new barrel, that will be changed)

5. The chamber end of the barrel no longer sticks out the end of the frame, this was done to ensure the cartridges could clear the slide and frame, it is only noticeable with the slide reward.

6. I have rounded many of the measurements to within 0.1-1.0mm and 0.1-1deg

Would love to hear what you guys think and whether you think it would be better to have the surfaces and shapes slightly off but correctly aligned centred, or whether you think it's better as close to the original as possible.

To make the parts move properly so the pistol can function,I need to make changes to the appearance here and there (as well as some changes for practicality) and I wanted some feedback from you all to know what you think can and should not be changed in order to get this model working, because I plan to release the 3D files when I am finished and you are all welcome to 3D print or make your own with the models. (WARNING: This will not be a real firearm, do not load live ammunition into it)

Pictured below is the original model, the original model without the smart link aiming modules, and then my WIP model, which I will be adding the smart link modules to:

The changes I've made (so far) are:

1. This is a change to canon more than appearance, but the magazine and cap-cartridge is modelled of .50 GI, not .50 AE (which is probably the closest to the canonical round used). This is because .50 AE is too long and I would have to change the appearance too much, the downside though, is that .50 GI is not a magnum cartridge.

2. There is no attachment method for the smart link aiming modules, and while it is never seen in game without them attached, other versions such as the M6C are, and I wanted a way of attaching them securely such that you could still put other attachments on as well, so I have made the top and bottom of the front end Piccatiny/NATO standard rails. Only the edges of these should be visible with the modules on, but it changes the look a lot with it off, is there a better attachment method?

3. I have changed the shape of the frame near the chamber, this was stepped but is now inclined, this will not be visible under the aiming modules.

4. I have centred the cut at the muzzle, and standardised the angled sections on the frame, such that the barrel is centred and front section is relatively symmetrical top-to-bottom, at most I have moved parts by 3mm and 5deg. (Ignore the size of the new barrel, that will be changed)

5. The chamber end of the barrel no longer sticks out the end of the frame, this was done to ensure the cartridges could clear the slide and frame, it is only noticeable with the slide reward.

6. I have rounded many of the measurements to within 0.1-1.0mm and 0.1-1deg

Would love to hear what you guys think and whether you think it would be better to have the surfaces and shapes slightly off but correctly aligned centred, or whether you think it's better as close to the original as possible.

Last edited: