Aoiken

New Member

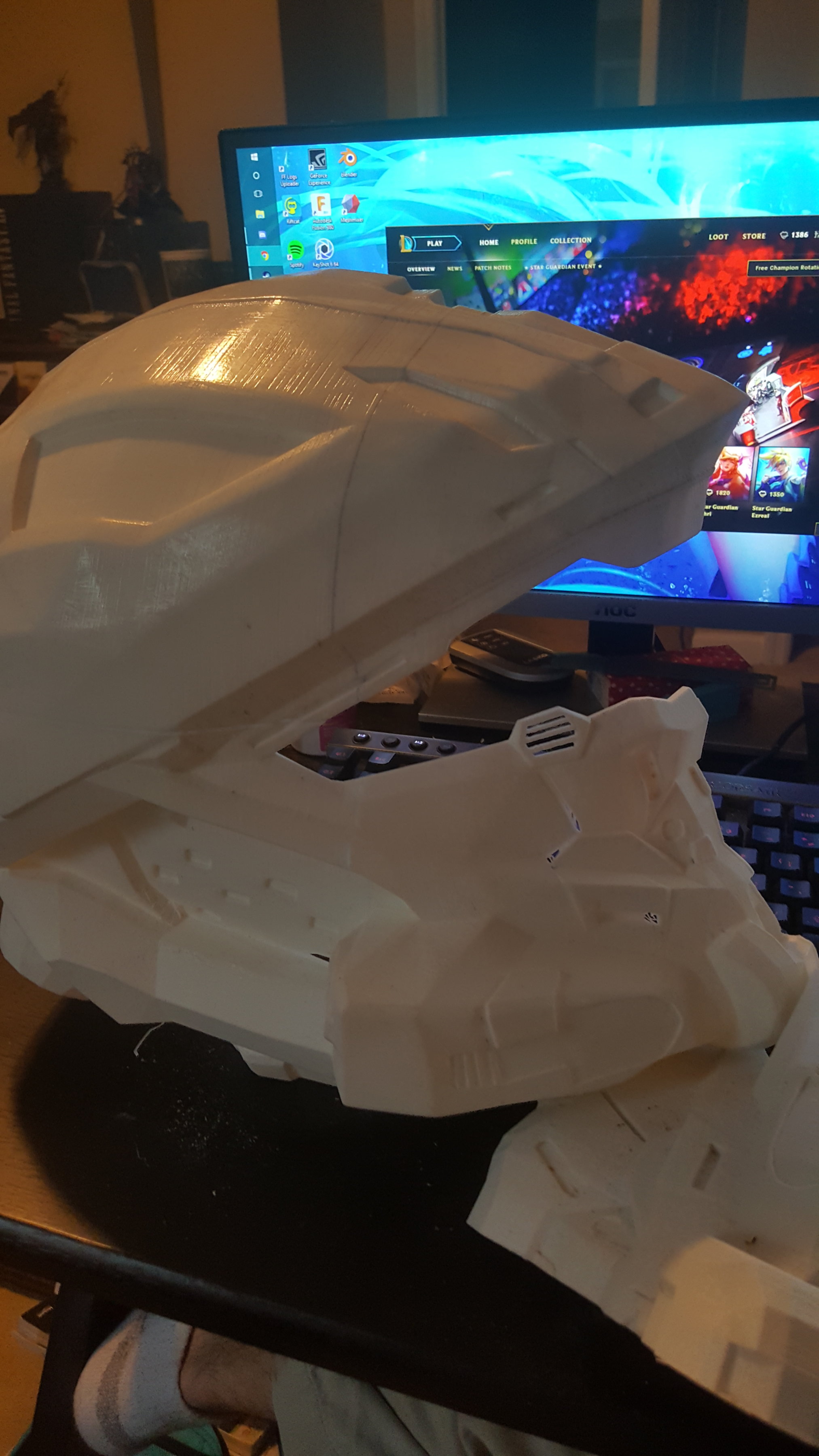

So I got the file to a point where I was happy with it, tried my best at scaling, and then split the helmet into parts sized to my print bed. Ive printed out a little over half of the helmet, and I think I may have scaled it to big lol.

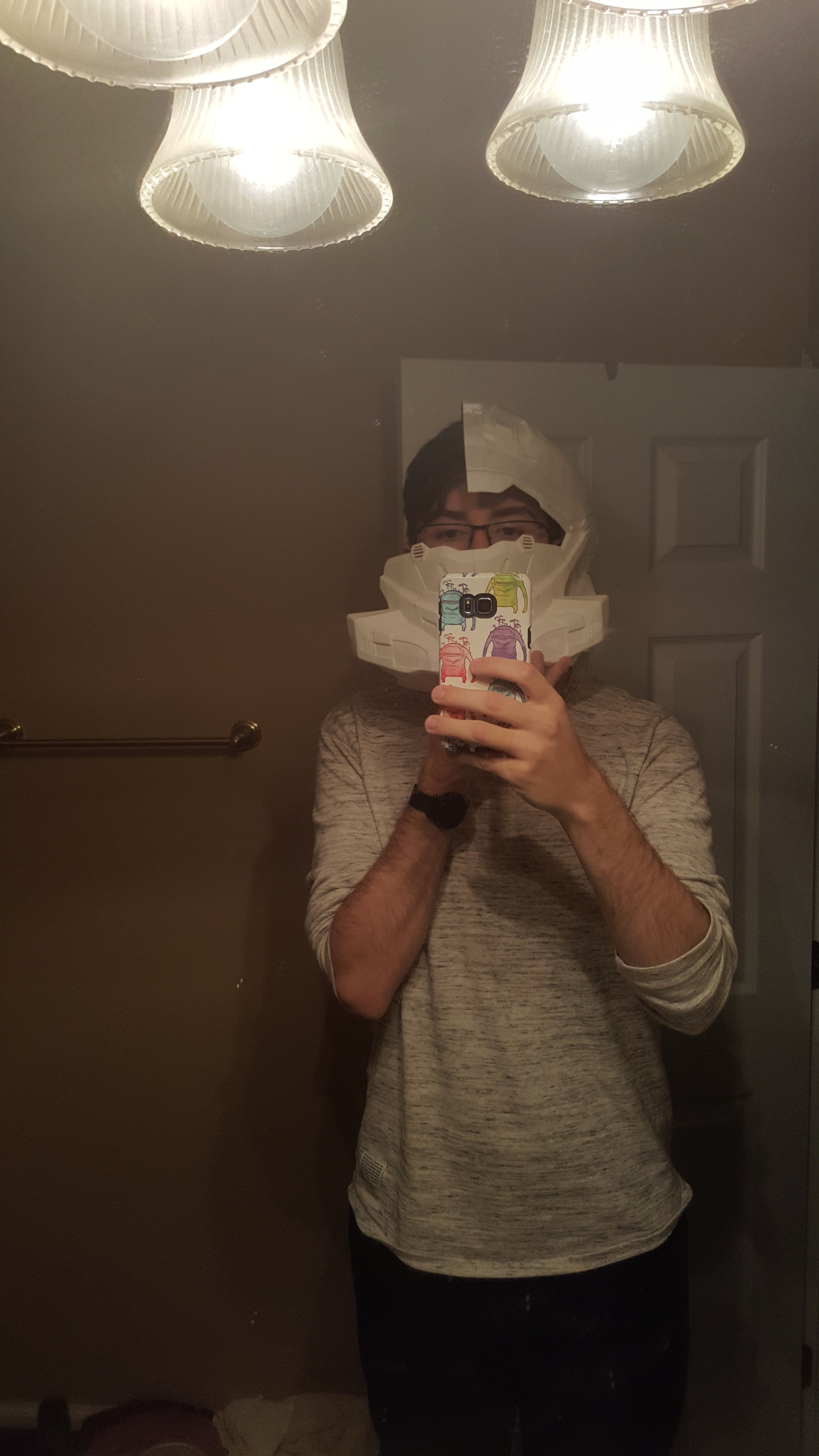

Does this look right to you guys? It looks kind of big on me when I look in the mirror, but It is a close fit getting it onto my head. Once its on Ive got a good amount of room, which I was expecting to an extent as I wanted to add padding and such.

Thanks!

Does this look right to you guys? It looks kind of big on me when I look in the mirror, but It is a close fit getting it onto my head. Once its on Ive got a good amount of room, which I was expecting to an extent as I wanted to add padding and such.

Thanks!