Hi guys&girls.

As I mentioned before, I used this helmet, originally designed by Jeffrey "DutchProps" Tabben as a material study and size reference. As the ODST helmet is rather pointy-looking, it's a disaster for people condemned to wearing glasses. In fact, I know a couple of people having this helmet (or comparable ones) who complain about this issue, so I wanted to test it myself on my own head and see what I had to change/make bigger to have a comfortable fit.

Again : I'm just the printer engineer on this. Jeff did a great job on this model, and I think he doesn't get nearly enough credit for making this accessible for everyone.

But it's not just a "I printed this". There's a bit more info ... albeit somewhat naughty one,

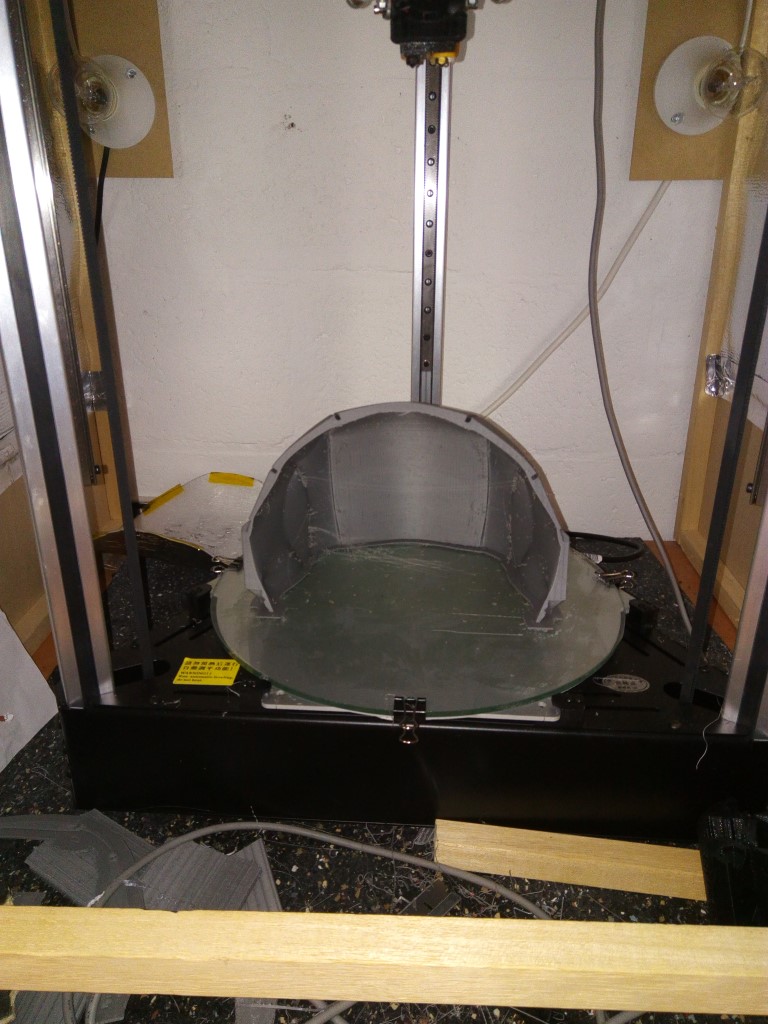

Anyhow. I took his model, sliced it up into 8 parts (first booboo, I'll explain later why) and started printing it on a Hatchbox clone, using ABS+, 0.15layer, 25% infill, 3 Shell exterior wall, 5 bottom, 5 top, eSun running at 245°C (eSun ABS seems to dislike the more typical higher temps of other brands, Angus at Makers' Muse reported something similar) and 115°C bed tem inside a heated enclosure.

Now my first booboo ? Printing this In 8 parts ? No. With a little luck, doing it in 4 parts is perfectly possible. Also while the slicer I used insisted I needed about 50% of the total filament as SUPPORT structure, I decided to use .... no supports _at all_. The only thing I used was a raft, as the relatively thin wall, large distance heated bed would give issues otherwise.

The only thing I used was a raft, as the relatively thin wall, large distance heated bed would give issues otherwise.

Why you ask ?

Well, in the ideal world, heatbeds warm up uniformly. But in the real world, temperature variations of 10 degrees and higher accross a larger printbed are no exception.

This temperature difference WILL get you into troubles with either warp, expansion or curling one way or the other, certainly if you're doing massive large, rather thin walled parts like this.

Enough of the blabber. PICTURES or it didn't happen.

So, you have that large printer now and your slicer tells you you need 1.4kg of filament to print that top part, but only 800 grams would be used for the actual part ?

What do you do ? Throw tons of support structures at it because YOUR SLICER tells you to do so ? Weep about how you don't have dual extruder that would allow easy PVA support (printed paterial that disolves in hot water, perfect for easy removable supports) .... ?

Or you use a bit of logic, saying, wait, back in the middle ages, people already understood how stress calculations should help you to produce a supportless dome.

So ... unless you have a REALLY odd shaped head, you're creating a dome when making a helmet. So "support OFF". "the hell with gravity".

Results ? (if anyone is still reading of course ?)

Look mama ! No hands. No support wheels. Just plastic and air.

But Kaween, what about the front ?

Was still busy, but this is an nice pic : a supportless bridge on a support-free part.

That this kind of printing saves a ton in terms of filament and time should be clear to everyone.

So how did it look like in the end ? Well, I'm not going to assemble this one myself : it is being shipped of to a good friend who'll give it the TLC it deserves.

But even totally raw, of the bed, no afterwork at all, it already looks "rather nice".

Considering the handbook tells us ABS is bad for details, doesn't allow sharp and clean edges and what do I know, I'd say this is a respectable result as far as a raw print goes.

I'd die a million times before I could ever do this in foam, I fear. Which is why i totally repect those who can ! (and there are many !!).

But, what about the naughty stuff, Kris ? Ah well, normally I would keep that as last, but in this case, I'll shove it in the middle. Enough boring stuff already.

Enough boring stuff already.

AIRSOFT related info removed by specific request of staff. Apparantly, saying "i would never condone using it" wasn't clear enough.

Hence the thread is now "naughty free". Sorry people.

Coming to repairs :

While I know acetone and ABS are seen by some as a fast shortcut to avoid the sanding process (and hated by others for doing so as that kind of smoothing often destroys a lot of delicate surface details) I don't like to use acetone for that. Most of the parts I do are still hand-sanded, but I DO use acetone for a very light cold vapor smooth : just to let the layers bond extra, but not more than that. Cold vapor smoothing only needs your part (duh), acetone (really ?) and a preferably transparant sealed container where you can check on the parts' progress.

I tend to take out the part the moment the surface is starting to become shiny. As the smoothing process does continu for some time after that point, I noticed that for me, that point would result in a much stronger surface, yet keeping all the small details in tact. This can take an hour or 2, depending on the used material (not all filaments act the same way), temperature, size ... ect ect.

No sure way to tell, hence the advise to use a transparant container.

But, repair. Here's a cracked part, the result of printing WITHOUT raft and without the realisation that big parts on a non-uniform heated bed will cause thermal stress.

Nasty no ? Super glue yes ? *beeeep* wrong.

Mix up your repair material (use scrap ABS and acetone, keep mixing til you get a consistency you like to work with)

Smear it on and in the damaged area

After it has hardened (takes about 30 minutes for a larger surface, take an hour to be really sure), sand it down just like you would on a normal undamaged piece.

And after about 10 mintues, no one can tell the seam from the material by just feeling over it ...

Paint that up ? No one will ever know. Darth Vader would be proud.

Anyhow, hope some of you are still awake, and at least a couple of you will find something useful in this post. :

As always, all views are strictly personal opinion, but rooted in reproducable, controllable conditions. No "i read on google that.....". This is all done here and now.

Also, important : ABS+ doesn't disolve completly like normal ABS does. No doubt, the manufacturers mix the ABS up with other stuff to get a different behavior of the ABS (ABS+ does NOT STINK during print, it doesn't shrink/curl/warp nearly as bad as normal ABS would), and that "other stuff" does NOT disolve in acetone.

Please be aware of that if you're looking to make stuff like, say, ABS glue.

As I mentioned before, I used this helmet, originally designed by Jeffrey "DutchProps" Tabben as a material study and size reference. As the ODST helmet is rather pointy-looking, it's a disaster for people condemned to wearing glasses. In fact, I know a couple of people having this helmet (or comparable ones) who complain about this issue, so I wanted to test it myself on my own head and see what I had to change/make bigger to have a comfortable fit.

Again : I'm just the printer engineer on this. Jeff did a great job on this model, and I think he doesn't get nearly enough credit for making this accessible for everyone.

But it's not just a "I printed this". There's a bit more info ... albeit somewhat naughty one,

Anyhow. I took his model, sliced it up into 8 parts (first booboo, I'll explain later why) and started printing it on a Hatchbox clone, using ABS+, 0.15layer, 25% infill, 3 Shell exterior wall, 5 bottom, 5 top, eSun running at 245°C (eSun ABS seems to dislike the more typical higher temps of other brands, Angus at Makers' Muse reported something similar) and 115°C bed tem inside a heated enclosure.

Now my first booboo ? Printing this In 8 parts ? No. With a little luck, doing it in 4 parts is perfectly possible. Also while the slicer I used insisted I needed about 50% of the total filament as SUPPORT structure, I decided to use .... no supports _at all_.

Why you ask ?

Well, in the ideal world, heatbeds warm up uniformly. But in the real world, temperature variations of 10 degrees and higher accross a larger printbed are no exception.

This temperature difference WILL get you into troubles with either warp, expansion or curling one way or the other, certainly if you're doing massive large, rather thin walled parts like this.

Enough of the blabber. PICTURES or it didn't happen.

So, you have that large printer now and your slicer tells you you need 1.4kg of filament to print that top part, but only 800 grams would be used for the actual part ?

What do you do ? Throw tons of support structures at it because YOUR SLICER tells you to do so ? Weep about how you don't have dual extruder that would allow easy PVA support (printed paterial that disolves in hot water, perfect for easy removable supports) .... ?

Or you use a bit of logic, saying, wait, back in the middle ages, people already understood how stress calculations should help you to produce a supportless dome.

So ... unless you have a REALLY odd shaped head, you're creating a dome when making a helmet. So "support OFF". "the hell with gravity".

Results ? (if anyone is still reading of course ?)

Look mama ! No hands. No support wheels. Just plastic and air.

But Kaween, what about the front ?

Was still busy, but this is an nice pic : a supportless bridge on a support-free part.

That this kind of printing saves a ton in terms of filament and time should be clear to everyone.

So how did it look like in the end ? Well, I'm not going to assemble this one myself : it is being shipped of to a good friend who'll give it the TLC it deserves.

But even totally raw, of the bed, no afterwork at all, it already looks "rather nice".

Considering the handbook tells us ABS is bad for details, doesn't allow sharp and clean edges and what do I know, I'd say this is a respectable result as far as a raw print goes.

I'd die a million times before I could ever do this in foam, I fear. Which is why i totally repect those who can ! (and there are many !!).

But, what about the naughty stuff, Kris ? Ah well, normally I would keep that as last, but in this case, I'll shove it in the middle.

AIRSOFT related info removed by specific request of staff. Apparantly, saying "i would never condone using it" wasn't clear enough.

Hence the thread is now "naughty free". Sorry people.

Coming to repairs :

While I know acetone and ABS are seen by some as a fast shortcut to avoid the sanding process (and hated by others for doing so as that kind of smoothing often destroys a lot of delicate surface details) I don't like to use acetone for that. Most of the parts I do are still hand-sanded, but I DO use acetone for a very light cold vapor smooth : just to let the layers bond extra, but not more than that. Cold vapor smoothing only needs your part (duh), acetone (really ?) and a preferably transparant sealed container where you can check on the parts' progress.

I tend to take out the part the moment the surface is starting to become shiny. As the smoothing process does continu for some time after that point, I noticed that for me, that point would result in a much stronger surface, yet keeping all the small details in tact. This can take an hour or 2, depending on the used material (not all filaments act the same way), temperature, size ... ect ect.

No sure way to tell, hence the advise to use a transparant container.

But, repair. Here's a cracked part, the result of printing WITHOUT raft and without the realisation that big parts on a non-uniform heated bed will cause thermal stress.

Nasty no ? Super glue yes ? *beeeep* wrong.

Mix up your repair material (use scrap ABS and acetone, keep mixing til you get a consistency you like to work with)

Smear it on and in the damaged area

After it has hardened (takes about 30 minutes for a larger surface, take an hour to be really sure), sand it down just like you would on a normal undamaged piece.

And after about 10 mintues, no one can tell the seam from the material by just feeling over it ...

Paint that up ? No one will ever know. Darth Vader would be proud.

Anyhow, hope some of you are still awake, and at least a couple of you will find something useful in this post. :

As always, all views are strictly personal opinion, but rooted in reproducable, controllable conditions. No "i read on google that.....". This is all done here and now.

Also, important : ABS+ doesn't disolve completly like normal ABS does. No doubt, the manufacturers mix the ABS up with other stuff to get a different behavior of the ABS (ABS+ does NOT STINK during print, it doesn't shrink/curl/warp nearly as bad as normal ABS would), and that "other stuff" does NOT disolve in acetone.

Please be aware of that if you're looking to make stuff like, say, ABS glue.

Last edited by a moderator: