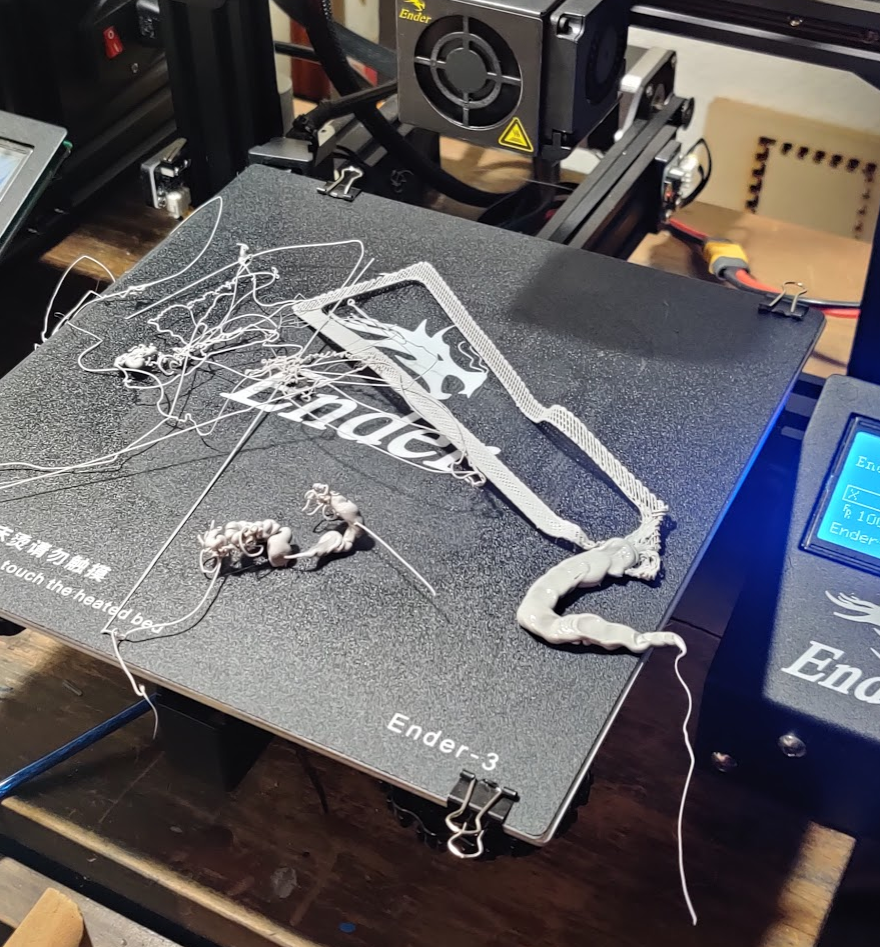

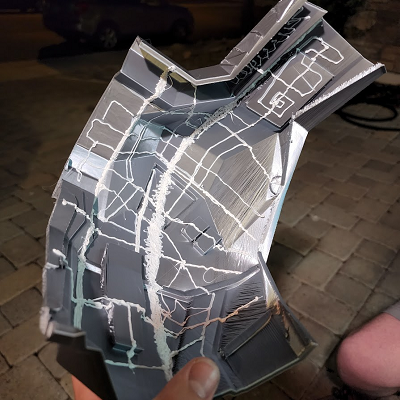

Been having lots of printer issues, it looks like bad adhesion but it's actually severe under-extruding in disguise. I had followed a guide to better calibrate my printer and tweak my flow rate and it has ruined the first layers and made all my prints super brittle since, so I'm probably not gonna keep the setting. Also had the filament spool fall onto a printer mid print in the second pic lol

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1st Build 3D Printed Reach Spartan ft. AKIS

- Thread starter spitzkitz

- Start date

- Status

- Not open for further replies.

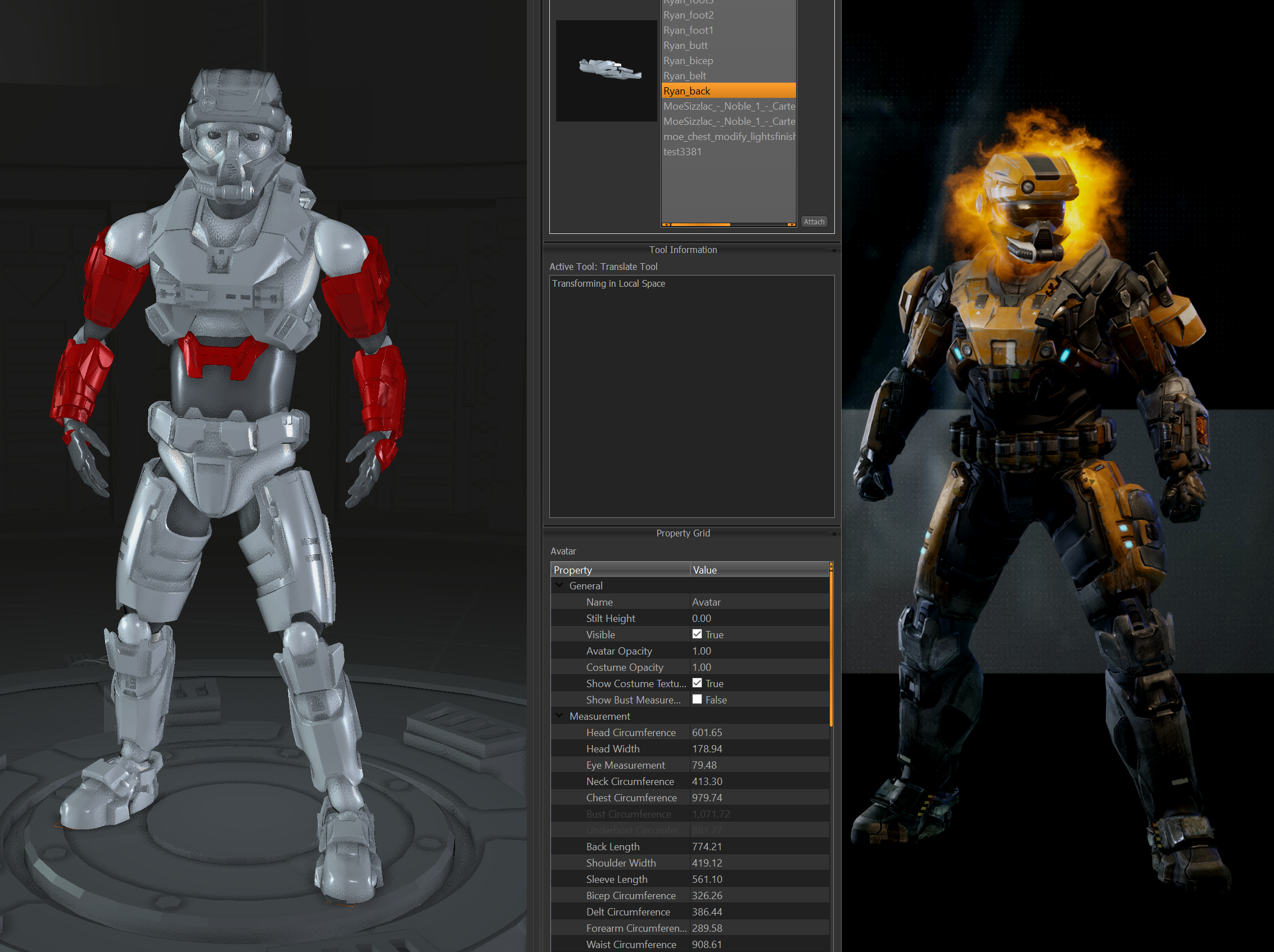

Updated my armorsmith scaling and posed it a little to get an idea of whether or not it actually looks proportional, and I think it's spot on! (Other than the reach spartans being kinda vertically squashed)

Now I just need to decide what pieces to print next lol.

Now I just need to decide what pieces to print next lol.

I hope I'm wrong but do you have two left biceps printed? It could just be the angle of the picture?Yo! All issues remedied, been grinding out on some lab research stuff but in the meantime I managed to sneak in a few smaller, less fun pieces to get out of the way.

(Abs, spine)

Here's everything so far

View attachment 304788

Everything looks great though!

You are not wrong-- I am a certified moron! I hoped nobody would notice. It'll be the last piece I do lol but hey extra pieces for practice!I hope I'm wrong but do you have two left biceps printed? It could just be the angle of the picture?

Everything looks great though!

Thanks though

Use it for stress tests and stuff! Ive broken a sweat running to my printer because I've started the same part before!You are not wrong-- I am a certified moron! I hoped nobody would notice. It'll be the last piece I do lol but hey extra pieces for practice!

Thanks though

Lol yeah could do. I was thinking of using it for painting tests and the likeUse it for stress tests and stuff! Ive broken a sweat running to my printer because I've started the same part before!

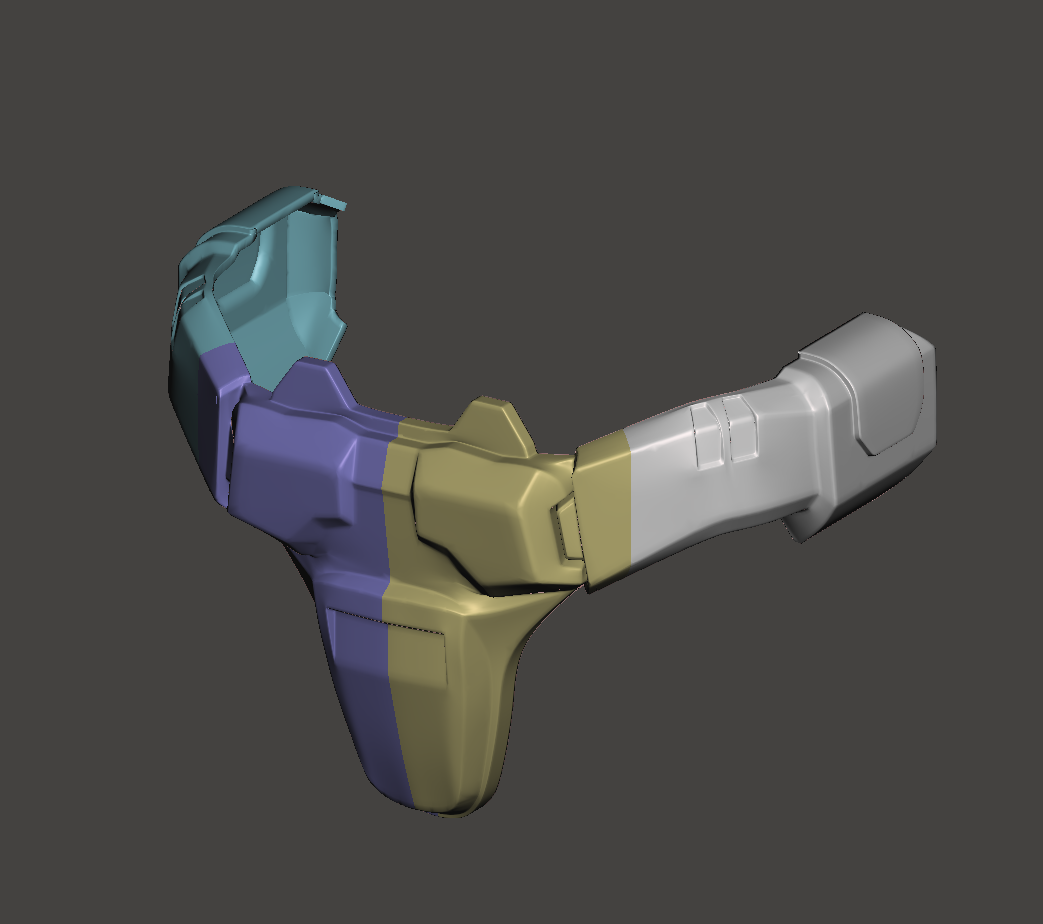

Even more issues! Hurray! I tried to print the remaining portion (turns out that it actually just fell off the build plate and was completely OK to use the rest of) but I am having some random issues cropping up... so in the meantime, here is a cut up codpiece in case anybody looks for a good way to cut it in the future. I can't help but see that a lot of builds skip the "slicing my parts into smaller chunks" step so if you're like me and looking for some good "tried and true" ways of chopping bits up, here ya go. I'll probably do this for the rest of my pieces just so people can reference it in the future

Normally split in half this would be fine, but it just barely fits past the buildplate so yeaaahhh.

also-- just finished my lab work as well so I have lots of free printing time! woo!

Normally split in half this would be fine, but it just barely fits past the buildplate so yeaaahhh.

also-- just finished my lab work as well so I have lots of free printing time! woo!

Yeah! Back on the grind!

Went ahead and edited MoeSizzlac's reach thigh model so that I can make the inner thigh from foam. Hopefully this will give me more flexibility and reduce print time/material usage.

Also if you saw my Modeling Quest thread, I went ahead and did the Mark V B helmet as well. Still debating whether to do that or AKIS as my helmet...

My inner debate is this: Doing an entirely default Noble 6 would be awesome and recognizable, buuuuut I like the AKIS a lot. It's got that mythos going on yaknow? And that would at least let me make some other armor bits (though this would add time of course, and im not sure if that's what I want LOL)

Went ahead and edited MoeSizzlac's reach thigh model so that I can make the inner thigh from foam. Hopefully this will give me more flexibility and reduce print time/material usage.

Also if you saw my Modeling Quest thread, I went ahead and did the Mark V B helmet as well. Still debating whether to do that or AKIS as my helmet...

My inner debate is this: Doing an entirely default Noble 6 would be awesome and recognizable, buuuuut I like the AKIS a lot. It's got that mythos going on yaknow? And that would at least let me make some other armor bits (though this would add time of course, and im not sure if that's what I want LOL)

- Member DIN

- S505

Yeah looks like a quick rubbing alcohol wipe would help haha. Also I know you said you were saving PLA+ for the helmet, but it does also have nice adhesionspaghetti for breakfast :C

View attachment 305744

View attachment 305745

gonna have to increase my adhesion somehow, I think dust has been gathering. A good clean will do the trick.

The actual issue turned out to be adhesion not onto the bed, but on the print itself. It appears that they ALL fell off of their own rafts, so I will probably need to change the air gap (though Im thinking it could just have been a failure from a particularly cold night in my garage...)Yeah looks like a quick rubbing alcohol wipe would help haha. Also I know you said you were saving PLA+ for the helmet, but it does also have nice adhesion

And yeah, PLA+ goin to the helmet for sure.

Well! It has certainly been a hot minute, hasn't it!

As I finished college and started grad school, I have been pretty busy. However, I just got the summer off so it's build time baby.

Lately I have been having some build days with tahu505, and then I got a hold of a bunch of electric sanders which made our lives MUCH easier. Using these and other methods we discovered the absolute magic that is sanding raw PLA before you filler primer it etc.,. Since I'd like to write a more detailed post on this (as mentioned in other threads we are calling it the Angus method lol) and also show the results, I'm gonna spare those details for now and instead show off what I was working on today:

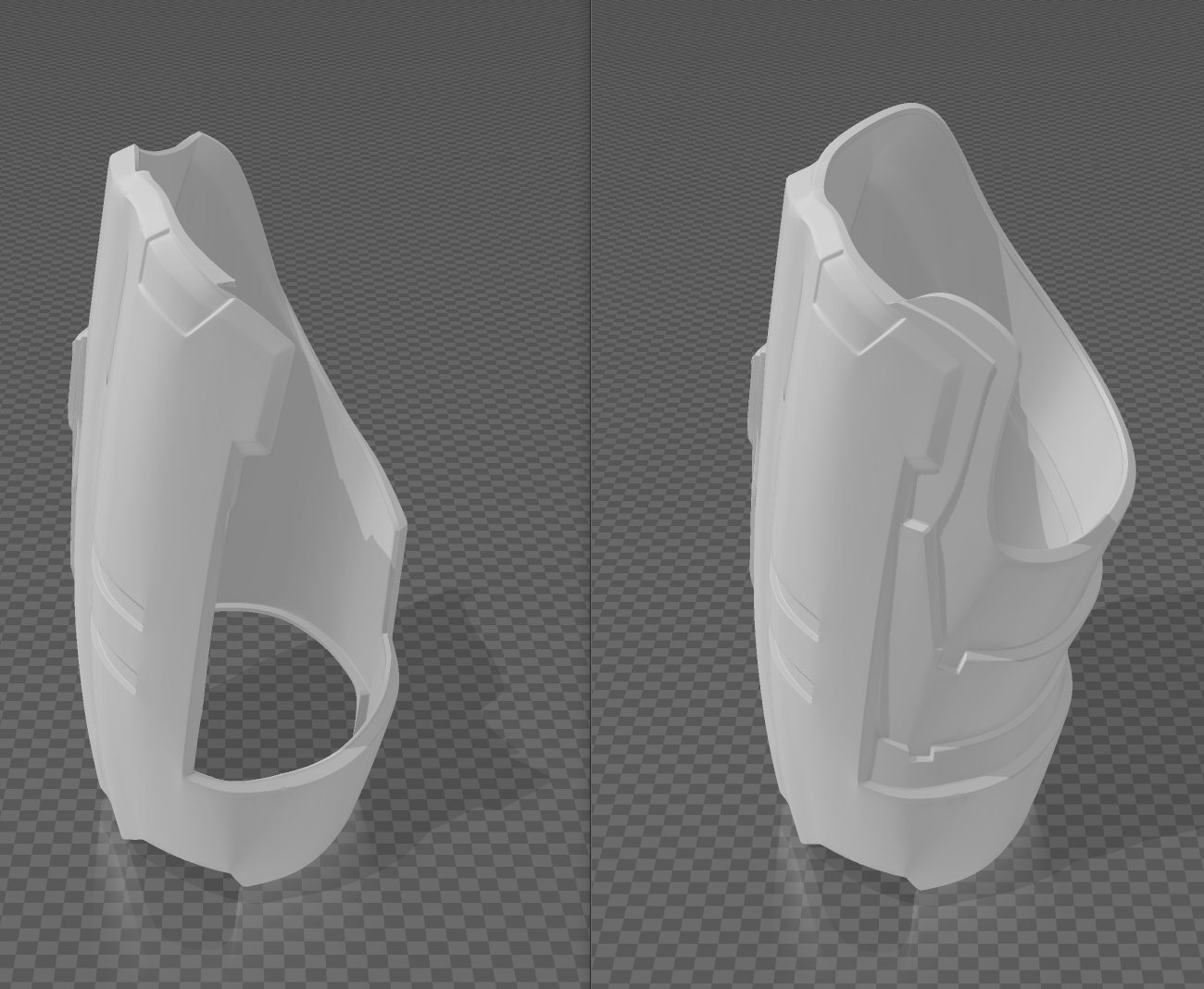

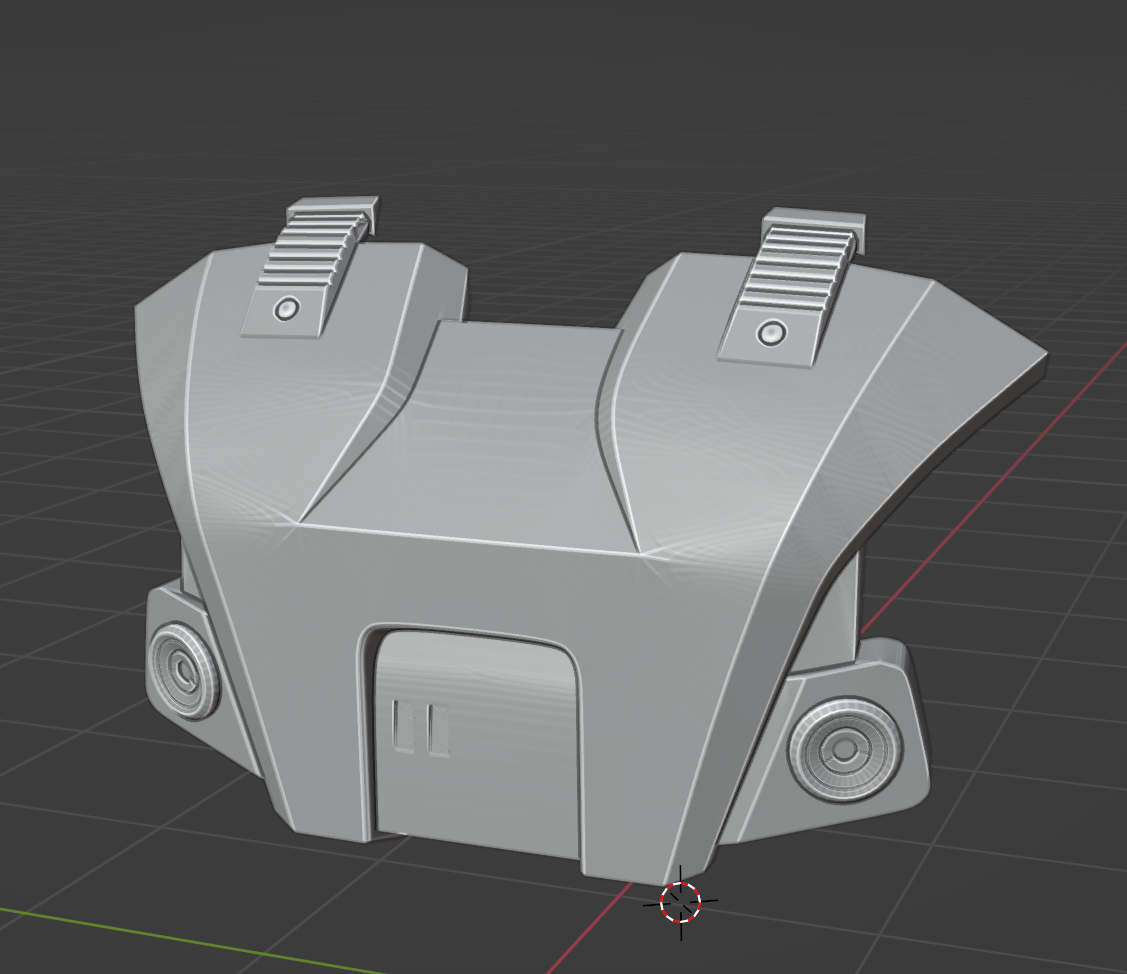

Yep! More modeling. Anyhow, I decided to change sorta last minute the chestplate I wanted to make to the base security. I was going to do the parafoil, but since I'm a big fan of the vertical striping on reach armor I just had to use this chestplate since it has one prominently on the right side. This matches the AKIS helmet well, too. Speaking of I haven't shown any images of it, but it is fully printed and partially sanded. I'll go through some photos here soon and post them, but for now just know it's almost there

And with that, I bring you an updated view of armorsmith featuring all the parts I have printed in red:

So obviously that leaves me with printing the chestplate, torso, kneepads, and the codpiece. The boot covers we decided would be best in foam.

I'm debating whether to merge the chestplate with the torso and print it as one piece, or if I will install magnets so I can swap it out and make it modular, but I'm not sure yet. If anyone has any ideas or warnings please do let me know what you think!!

I'll be updating this thread with some more photos later as I get the chance to take them. Until then!

As I finished college and started grad school, I have been pretty busy. However, I just got the summer off so it's build time baby.

Lately I have been having some build days with tahu505, and then I got a hold of a bunch of electric sanders which made our lives MUCH easier. Using these and other methods we discovered the absolute magic that is sanding raw PLA before you filler primer it etc.,. Since I'd like to write a more detailed post on this (as mentioned in other threads we are calling it the Angus method lol) and also show the results, I'm gonna spare those details for now and instead show off what I was working on today:

Yep! More modeling. Anyhow, I decided to change sorta last minute the chestplate I wanted to make to the base security. I was going to do the parafoil, but since I'm a big fan of the vertical striping on reach armor I just had to use this chestplate since it has one prominently on the right side. This matches the AKIS helmet well, too. Speaking of I haven't shown any images of it, but it is fully printed and partially sanded. I'll go through some photos here soon and post them, but for now just know it's almost there

And with that, I bring you an updated view of armorsmith featuring all the parts I have printed in red:

So obviously that leaves me with printing the chestplate, torso, kneepads, and the codpiece. The boot covers we decided would be best in foam.

I'm debating whether to merge the chestplate with the torso and print it as one piece, or if I will install magnets so I can swap it out and make it modular, but I'm not sure yet. If anyone has any ideas or warnings please do let me know what you think!!

I'll be updating this thread with some more photos later as I get the chance to take them. Until then!

Wow! It's con crunch time!

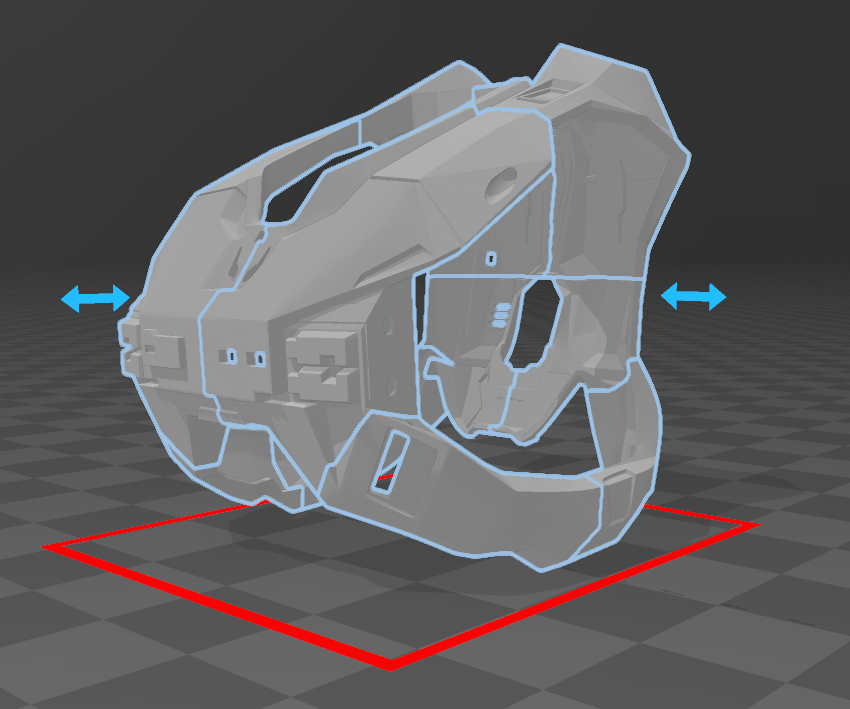

With only 5 days sorta left, I have decided to finally start printing the torso. So, after pulling my hair out, I sliced it up like so:

This will be all parts on Ender 3's except the front two bits which will fit easily on a CR10S5 and take about a day and a half each. Most ender parts take 1 day, with the smaller ones being 8 hours.

So, ideally, I will have the torso assembled and ready to sand in two/three days which means I will be ready to basically paint my suit in four. cutting it close!!

Now, time to start printing

With only 5 days sorta left, I have decided to finally start printing the torso. So, after pulling my hair out, I sliced it up like so:

This will be all parts on Ender 3's except the front two bits which will fit easily on a CR10S5 and take about a day and a half each. Most ender parts take 1 day, with the smaller ones being 8 hours.

So, ideally, I will have the torso assembled and ready to sand in two/three days which means I will be ready to basically paint my suit in four. cutting it close!!

Now, time to start printing

Howdy everyone! It's been a long time since I last posted. As it turns out, grad school is difficult (who knew). Also, I keep getting busy halfway through writing my posts and end up forgetting to finish... but anyway, here we are!

I also realized I never really posted the "finished" helmet, as well as all the progress since last year. I had a huge con crunch back in June when I last posted and was so focused on results I didn't post (BUT I DID TAKE PICS).

I ended up utilizing my helmet model and even managed to recreate the visor details. My first attempt, I successfully made and pulled a visor from my custom buck. Surprisingly, this stuff is just Hatchbox PLA, with 3 walls and 10% lines infill. I just used regular post-processing steps (sand, filler primer, sand again). The visor was vacuum formed from PETG which was warmed at some arbitrary temperature (sorry) and pulled for about 3 seconds using my university's vacuum former.

Buck next to the finished pull. Decent, actually.

And then, the machine we used (actually showing tahu505 's buck inside right before tragically melting, rip):

This thing is honestly a nice little former and I would definitely use it again. Just need to figure out where they moved the darn thing...

Then, somehow, in a matter of 3 days I managed to prime, sand, and paint the base coats on literally every single piece except the belt. Many energy drinks were crushed.

Before:

After:

Also, something I want to share with everyone is strengthening large (or weak) 3D printed parts. I know the traditional method is to coat the inside with fiberglass and/or resin, but I have actually found excellent success with utilizing a 3D pen to reinforce perpendicular to the layer lines. I just crank the temp, use the same filament as the print, then slowly ooze over the lines in a lattice shape.

Check out below how I salvaged this horrible, somewhat brittle torso piece into something actually quite strong:

I went a little crazy with the lines (the thickest one is along a crack that formed after removing from the bed) and some of the zany swirls was because I had extra filament to kill (lol). But ultimately, this results in some great reinforcement with minimal effort. Also, bonding together parts this way works way better than glue, though this isn't really new information. That's how I went about bonding all my parts together, for reference.

So, then I painted, weathered, and assembled the entire helmet overnight just in time for Denver FanExpo and wore it!

I ended up covering up most of the ugly under/overspray with a mixture of black sharpie, gentle sanding, and some hand painting with black acrylics (thanks MDB for the help!).

And the final result, huzzah!

Silver Rub 'n Buff, silver Sharpie, an acrylic paint-soaked rag, and some 4000-grit sandpaper were my best friends during the weathering stage.

Also, I painted the interior of the visor with some (very) gentle coats of both silver and gold chrome spraypaint. It's really easy to see out of and looks just like the default visor color. Also, the camera is a resin print that I just used silver rub-n-buff on to accentuate the details. Looks just like a real lens.

So, what's next?

I need to re-sand and repaint the torso, big time. It has ugly marks everywhere. And the belt/cod needs to be printed/etc. Also, I have masked off and painted lots of my parts for their secondary/primary colors on each piece, so check back in to see that! I am going to try and finish it before next week because there's a Halloween party coming up >

More results soon!

I also realized I never really posted the "finished" helmet, as well as all the progress since last year. I had a huge con crunch back in June when I last posted and was so focused on results I didn't post (BUT I DID TAKE PICS).

I ended up utilizing my helmet model and even managed to recreate the visor details. My first attempt, I successfully made and pulled a visor from my custom buck. Surprisingly, this stuff is just Hatchbox PLA, with 3 walls and 10% lines infill. I just used regular post-processing steps (sand, filler primer, sand again). The visor was vacuum formed from PETG which was warmed at some arbitrary temperature (sorry) and pulled for about 3 seconds using my university's vacuum former.

Buck next to the finished pull. Decent, actually.

And then, the machine we used (actually showing tahu505 's buck inside right before tragically melting, rip):

This thing is honestly a nice little former and I would definitely use it again. Just need to figure out where they moved the darn thing...

Then, somehow, in a matter of 3 days I managed to prime, sand, and paint the base coats on literally every single piece except the belt. Many energy drinks were crushed.

Before:

After:

Also, something I want to share with everyone is strengthening large (or weak) 3D printed parts. I know the traditional method is to coat the inside with fiberglass and/or resin, but I have actually found excellent success with utilizing a 3D pen to reinforce perpendicular to the layer lines. I just crank the temp, use the same filament as the print, then slowly ooze over the lines in a lattice shape.

Check out below how I salvaged this horrible, somewhat brittle torso piece into something actually quite strong:

I went a little crazy with the lines (the thickest one is along a crack that formed after removing from the bed) and some of the zany swirls was because I had extra filament to kill (lol). But ultimately, this results in some great reinforcement with minimal effort. Also, bonding together parts this way works way better than glue, though this isn't really new information. That's how I went about bonding all my parts together, for reference.

So, then I painted, weathered, and assembled the entire helmet overnight just in time for Denver FanExpo and wore it!

I ended up covering up most of the ugly under/overspray with a mixture of black sharpie, gentle sanding, and some hand painting with black acrylics (thanks MDB for the help!).

And the final result, huzzah!

Silver Rub 'n Buff, silver Sharpie, an acrylic paint-soaked rag, and some 4000-grit sandpaper were my best friends during the weathering stage.

Also, I painted the interior of the visor with some (very) gentle coats of both silver and gold chrome spraypaint. It's really easy to see out of and looks just like the default visor color. Also, the camera is a resin print that I just used silver rub-n-buff on to accentuate the details. Looks just like a real lens.

So, what's next?

I need to re-sand and repaint the torso, big time. It has ugly marks everywhere. And the belt/cod needs to be printed/etc. Also, I have masked off and painted lots of my parts for their secondary/primary colors on each piece, so check back in to see that! I am going to try and finish it before next week because there's a Halloween party coming up >

More results soon!

- Member DIN

- S505

I didn't know you took a picture of my visor pull lmaoHowdy everyone! It's been a long time since I last posted. As it turns out, grad school is difficult (who knew). Also, I keep getting busy halfway through writing my posts and end up forgetting to finish... but anyway, here we are!

I also realized I never really posted the "finished" helmet, as well as all the progress since last year. I had a huge con crunch back in June when I last posted and was so focused on results I didn't post (BUT I DID TAKE PICS).

I ended up utilizing my helmet model and even managed to recreate the visor details. My first attempt, I successfully made and pulled a visor from my custom buck. Surprisingly, this stuff is just Hatchbox PLA, with 3 walls and 10% lines infill. I just used regular post-processing steps (sand, filler primer, sand again). The visor was vacuum formed from PETG which was warmed at some arbitrary temperature (sorry) and pulled for about 3 seconds using my university's vacuum former.

View attachment 337125View attachment 337126

Buck next to the finished pull. Decent, actually.

And then, the machine we used (actually showing tahu505 's buck inside right before tragically melting, rip):

View attachment 337127

This thing is honestly a nice little former and I would definitely use it again. Just need to figure out where they moved the darn thing...

Then, somehow, in a matter of 3 days I managed to prime, sand, and paint the base coats on literally every single piece except the belt. Many energy drinks were crushed.

Before:

View attachment 337130

After:

View attachment 337128

Also, something I want to share with everyone is strengthening large (or weak) 3D printed parts. I know the traditional method is to coat the inside with fiberglass and/or resin, but I have actually found excellent success with utilizing a 3D pen to reinforce perpendicular to the layer lines. I just crank the temp, use the same filament as the print, then slowly ooze over the lines in a lattice shape.

Check out below how I salvaged this horrible, somewhat brittle torso piece into something actually quite strong:

View attachment 337129

I went a little crazy with the lines (the thickest one is along a crack that formed after removing from the bed) and some of the zany swirls was because I had extra filament to kill (lol). But ultimately, this results in some great reinforcement with minimal effort. Also, bonding together parts this way works way better than glue, though this isn't really new information. That's how I went about bonding all my parts together, for reference.

So, then I painted, weathered, and assembled the entire helmet overnight just in time for Denver FanExpo and wore it!

View attachment 337131 View attachment 337132

View attachment 337133

I ended up covering up most of the ugly under/overspray with a mixture of black sharpie, gentle sanding, and some hand painting with black acrylics (thanks MDB for the help!).

And the final result, huzzah!

View attachment 337134

View attachment 337135

Silver Rub 'n Buff, silver Sharpie, an acrylic paint-soaked rag, and some 4000-grit sandpaper were my best friends during the weathering stage.

Also, I painted the interior of the visor with some (very) gentle coats of both silver and gold chrome spraypaint. It's really easy to see out of and looks just like the default visor color. Also, the camera is a resin print that I just used silver rub-n-buff on to accentuate the details. Looks just like a real lens.

So, what's next?

I need to re-sand and repaint the torso, big time. It has ugly marks everywhere. And the belt/cod needs to be printed/etc. Also, I have masked off and painted lots of my parts for their secondary/primary colors on each piece, so check back in to see that! I am going to try and finish it before next week because there's a Halloween party coming up >

More results soon!

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 1,783

- Replies

- 8

- Views

- 571

- Replies

- 8

- Views

- 1,974