- Member DIN

- S128

It seems that despite years of 3d printers helping our members produce high quality props and armor they still seem to take flack for being "the easy way out"

I've spent 500 hours crafting a fully Pepakura Spartan, 200 hours making a foam and fabric Marine and 200 hours on a leather Skyrim cosplay. Just like those builds I'll document everything here and we'll find out together if this 3d printing really is easy or not. Granted, I am only making a helmet here and not a full suit, but hopefully my credentials show I can make an accurate analysis.

**Let's also be real clear for a minute. This thread is just for fun and potentially educate someone who wants to know the differences and similarities between 3d printing and other methods. No one method should be called better or worse than another. We are all here for one thing: to have cool Halo stuff. It shouldn't matter what a member makes or how they make it, we should always encourage people to push through challenges and try new things.

The Goal:

*RESERVED FOR FINISHED PHOTO*

Materials/Tools:

- printing -

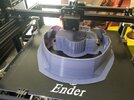

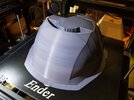

Haunted Helmet STL file - $28

Armorsmith - $20

Cura Slicer - free

Creality Ender 5 plus 3d Printer - $600

PLA+ Filament - $24

- assembling -

Pliers or screwdriver

Box cutter or utility knife

Round and square files

deburring tool

Sandpaper

I've spent 500 hours crafting a fully Pepakura Spartan, 200 hours making a foam and fabric Marine and 200 hours on a leather Skyrim cosplay. Just like those builds I'll document everything here and we'll find out together if this 3d printing really is easy or not. Granted, I am only making a helmet here and not a full suit, but hopefully my credentials show I can make an accurate analysis.

**Let's also be real clear for a minute. This thread is just for fun and potentially educate someone who wants to know the differences and similarities between 3d printing and other methods. No one method should be called better or worse than another. We are all here for one thing: to have cool Halo stuff. It shouldn't matter what a member makes or how they make it, we should always encourage people to push through challenges and try new things.

The Goal:

*RESERVED FOR FINISHED PHOTO*

Materials/Tools:

- printing -

Haunted Helmet STL file - $28

Armorsmith - $20

Cura Slicer - free

Creality Ender 5 plus 3d Printer - $600

PLA+ Filament - $24

- assembling -

Pliers or screwdriver

Box cutter or utility knife

Round and square files

deburring tool

Sandpaper

Last edited: