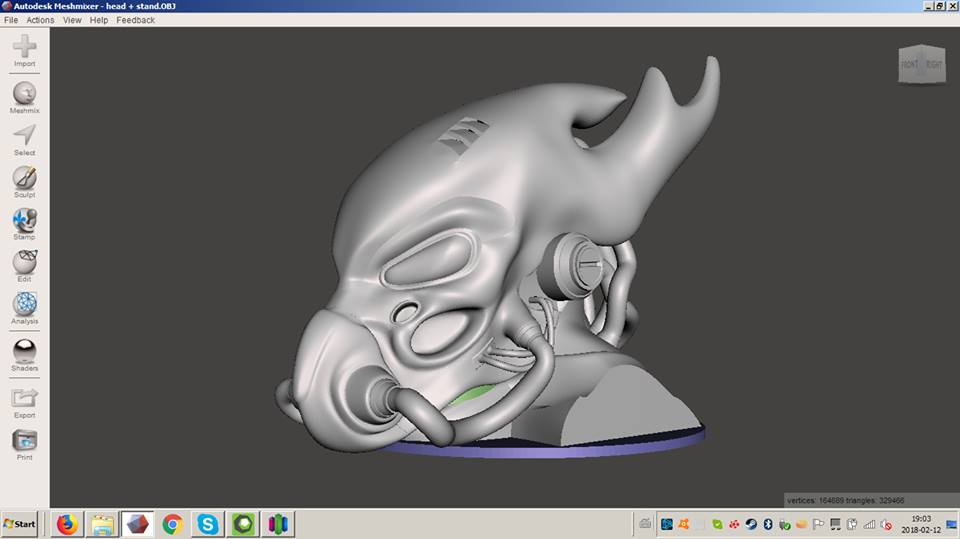

ohh dear lets try to answer everything in one post

As apposed to......any other time of the year w/ the same condition you are afflicted with?

Seriously though...If this come out 1/2 as good as your projected piece.....its going to be one bad-ass suit.

hoping it will, i always try my best when it comes to my projects whch most can be seen on

https://www.facebook.com/NerdArmoury/

Good point

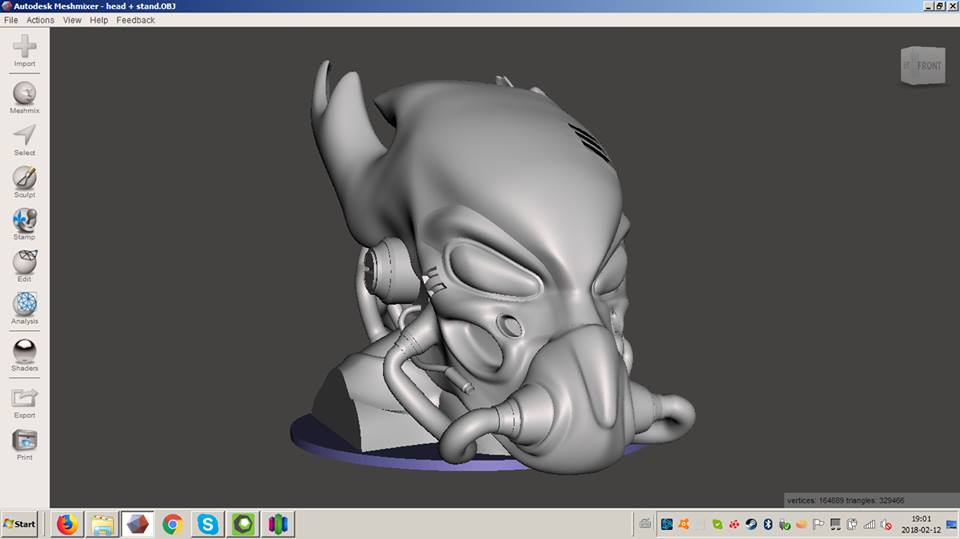

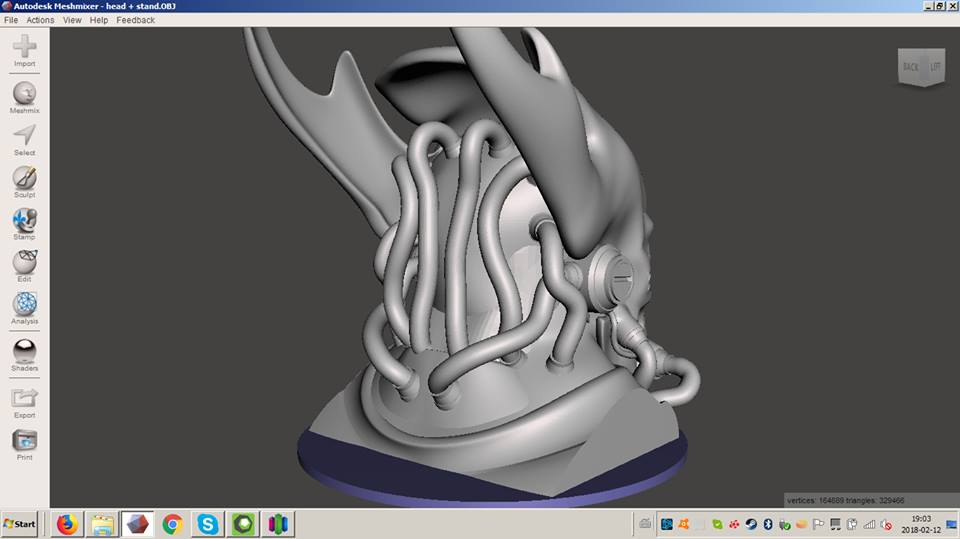

TurboCharizard but if someone grabs the helmet by those hoses in the back the print will probably break, unless you've got good printing skills to make sure it's strong.

mblackwell1002 might be able to weigh in too.

When do you think you'll start printing

Lyhtem ? I like your idea to give the tubes function. Also, I was referring to how hard it would be to sand the helmet *under* the tubes, not sanding the tubes themselves... But that it will be impossible to get your fingers in behind them or even risk breaking the tubes.

no worries about it breaking, if You familiar with printing, helmet will be done on 4 perimeter shells and 25-30% infill to give it more strength, and then just in case layer of poured polyurethane resin inside to give it extra strength, as for time frame, first print which will be the head on the stand will be done in next two weeks, after that i have to finish two projects for other people and one for myself, and then i`m good to go propper full time printing will probably start around end of march beginning of april

I've seen some of the work that

Lyhtem puts out and I can see him knocking this project out of the park no matter which way he goes about it and print structure and durability isn't really a concern here.

A good option for hose connections would be ABS sprinkler system fittings with an ABS filament that could be welded together with either a sprinkler system epoxy or an ABS slurry made from print scraps and acetone to make the off the shelf fittings and the print effectively the same part and reduce chance of shearing. I dunno mang. I'm just spitballing ideas.

Thank You

and yes sprinklers connectors are exactly what i was thinking about also a good idea are those, not sure whats those are called in english but i used similar stuff for my previous build, another idea is to actually print them and cast them in metal

Lyhtem, if you're going for the realistic look, I think some plastic ribbed pool hoses would give you a nice look and really sell the realism. I noticed the game models have some ribbing on the hoses, so it would be easy to replicate the look.

If you could find some pool hoses with wide ribbing, you'll be golden. If you have access to an airbrush, you can really make this bad boy pop with some brown and black weathering to simulate rust.

Also, a side note...is your OS Windows 4.5?

pool hoses or real gas mask hoses, also cable masking hoses and something different

SHOWER HOSE ;D unfortunately no airbrush but heres the fun part

i have a Car Paint Shop next to me and a guy that owns it will help me paint the whole thing for a couple of prints

as for weathering already started to make some real rust

5kg of iron nails sitting in a bucket with a bit of salt water

why simulate if You can go real

Side answer

nope its Windows 7 with classic Windows theme and all the other "freworks" switched of, unfortunately i have to work on a crappy old ass laptop which barely handles my design and printing software, so trying to save up the ram and everything else as much as i can

things i still have to figure out, COOLING system possibly will be installed in chest piece two fans at the front and two on the back but that's getting wayyy into the future

glad to hear any other suggestions and ideas

and if You want to check my other stuff

https://www.facebook.com/NerdArmoury/

PS: need to sort out my forum skills and check how to tag people