- Member DIN

- S358

This is kinda an after action report for now as I don't have a proper space at the moment to do bondo work. Long and short of it is...I wanted to actually see how difficult it would be to make a H4 helmet, as I've heard mixed stories about the difficulty. It doesn't help that I was bored and wanted something to do. Many thanks to SpartanSonny and Zercon.

Anyways, without further ado...

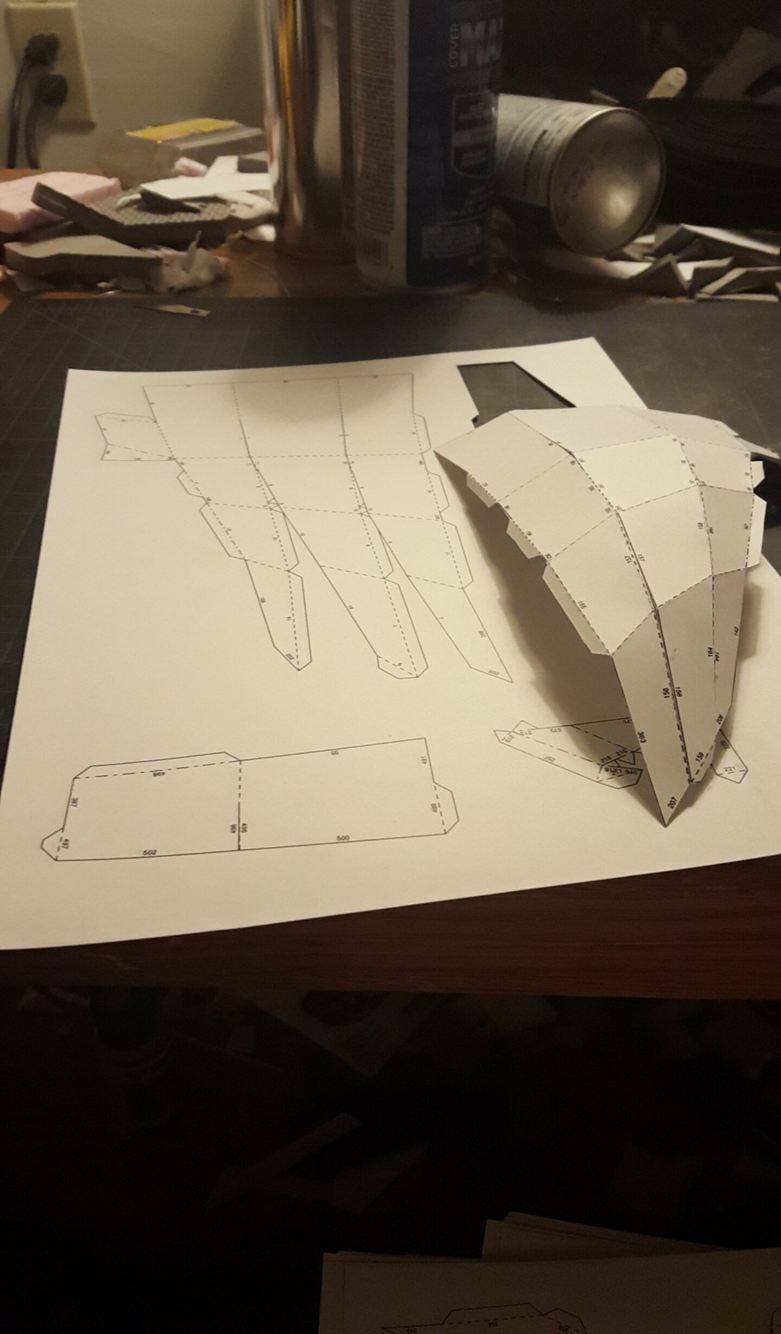

The beginning of the process. First piece and gluing.

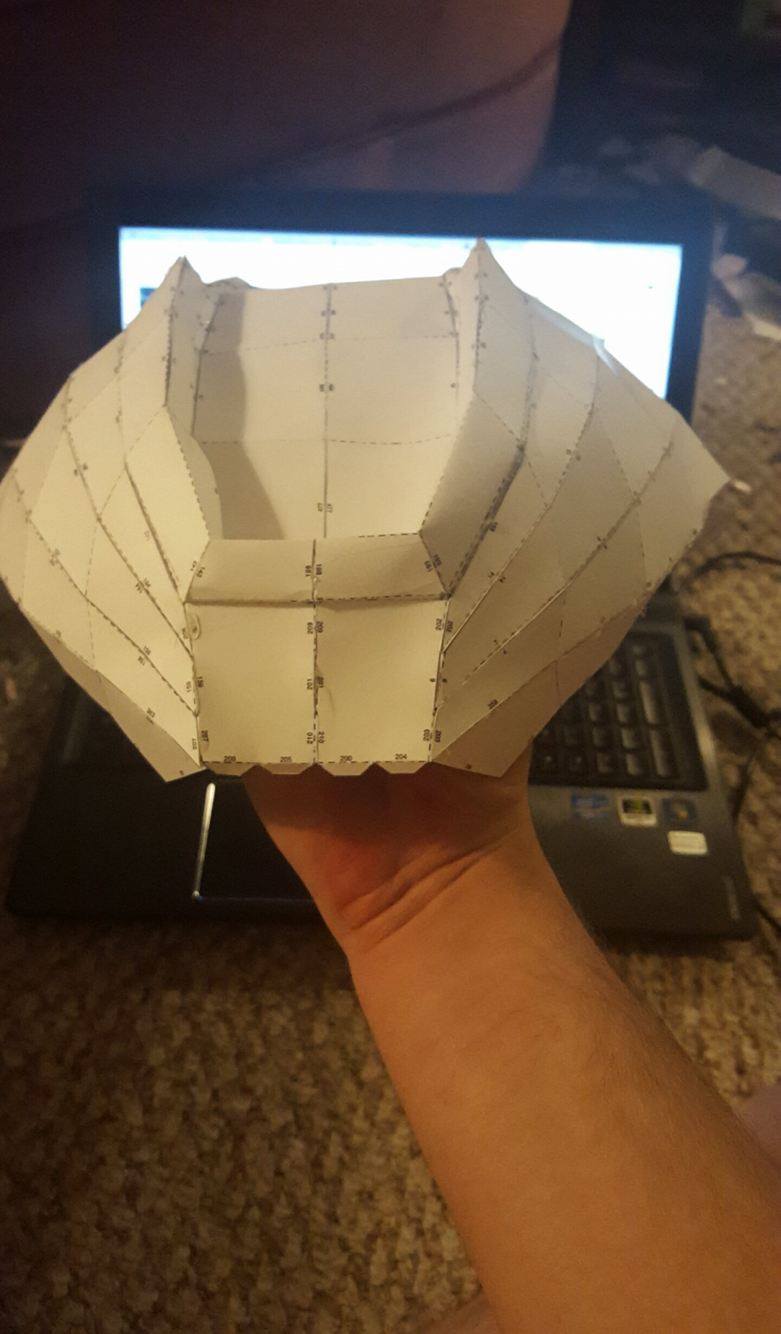

Very top completed...and even for once!

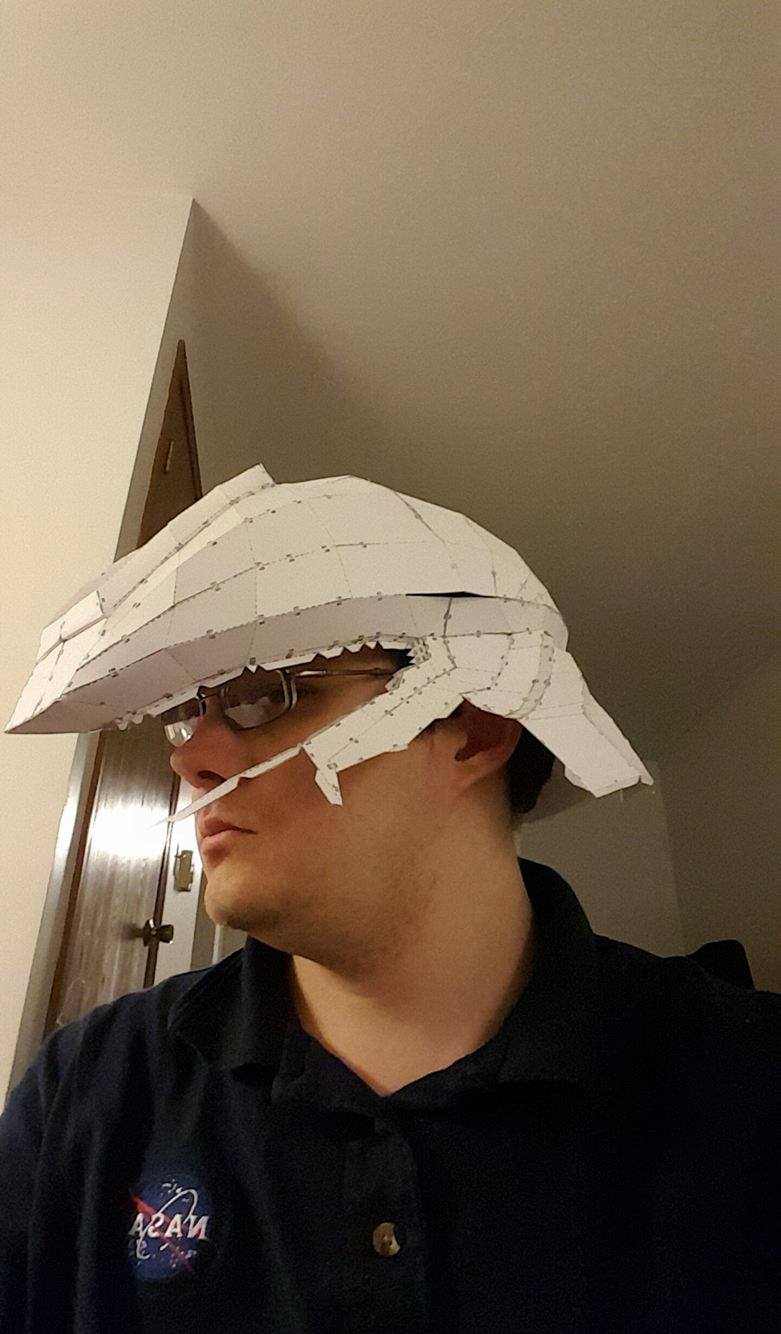

Sizing looks about right, width wise with my glasses. Also, fiddly bits are fiddly.

And here's the current product! Hardened with smooth-cast 65D. I know it's supposed to be for casting helmets and the like, but it works exceptionally well for hardening. Much quicker cure time compared to my envirotech lite that I would use otherwise.

I hope to add more pictures as this comes along in the near future! I'm not sure exactly what I want to do...although I have been considering molding it to potentially sell in the future...but that's not set in stone. In either case, I'm happy with how well it turned out. Any feedback would certainly be appreciated!

Anyways, without further ado...

The beginning of the process. First piece and gluing.

Very top completed...and even for once!

Sizing looks about right, width wise with my glasses. Also, fiddly bits are fiddly.

And here's the current product! Hardened with smooth-cast 65D. I know it's supposed to be for casting helmets and the like, but it works exceptionally well for hardening. Much quicker cure time compared to my envirotech lite that I would use otherwise.

I hope to add more pictures as this comes along in the near future! I'm not sure exactly what I want to do...although I have been considering molding it to potentially sell in the future...but that's not set in stone. In either case, I'm happy with how well it turned out. Any feedback would certainly be appreciated!