Woah man that's looking hot. Everything looks so dang clean. I'm proud of you, and you got this, you're in the final stretch.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Foam KaeSpoon's Halo Reach Marine Foam Build

- Thread starter KaeSpoon

- Start date

-

- Tags

- foam foamsmithing haloreach marine

- Member DIN

- S226

And... Done!

(Photos by Futuristicfembot, TheDukeofMayo and Zero Serenity)

I finally have armor and I'm thrilled about it. What was supposed to be a speed build ended up being something I put a lot of effort into, sometimes more than I should of, but it was all worth it. I do plan to make some shins eventually and replace a few straps and such, maybe 3d print the thighs so they look better, but I'm proud of myself and all the obstacles I've overcome to get this build done, and I got it done just in time for Dragoncon!

Thank you 405th for standing by my side and cheering me on with this suit, couldn't have done it without you guys. You all know what's next ; )

(Photos by Futuristicfembot, TheDukeofMayo and Zero Serenity)

I finally have armor and I'm thrilled about it. What was supposed to be a speed build ended up being something I put a lot of effort into, sometimes more than I should of, but it was all worth it. I do plan to make some shins eventually and replace a few straps and such, maybe 3d print the thighs so they look better, but I'm proud of myself and all the obstacles I've overcome to get this build done, and I got it done just in time for Dragoncon!

Thank you 405th for standing by my side and cheering me on with this suit, couldn't have done it without you guys. You all know what's next ; )

Last edited:

- Member DIN

- S222

without a doubt the cleanest foam work I’ve seen

I still can’t believe you made this out of foam, these are genuinely the cleanest seams I’ve seen. Would you give me some tips for getting my seams as clean as that? It’s unbelievable.

Amazing job man, can’t wait to see what else you make!

Amazing job man, can’t wait to see what else you make!

- Member DIN

- S226

Thank you folks!

Hmm.. Foam clay? X)I still can’t believe you made this out of foam, these are genuinely the cleanest seams I’ve seen. Would you give me some tips for getting my seams as clean as that? It’s unbelievable.

Amazing job man, can’t wait to see what else you make!

- Member DIN

- S128

You've come so far! I love the new armor.

- Member DIN

- S226

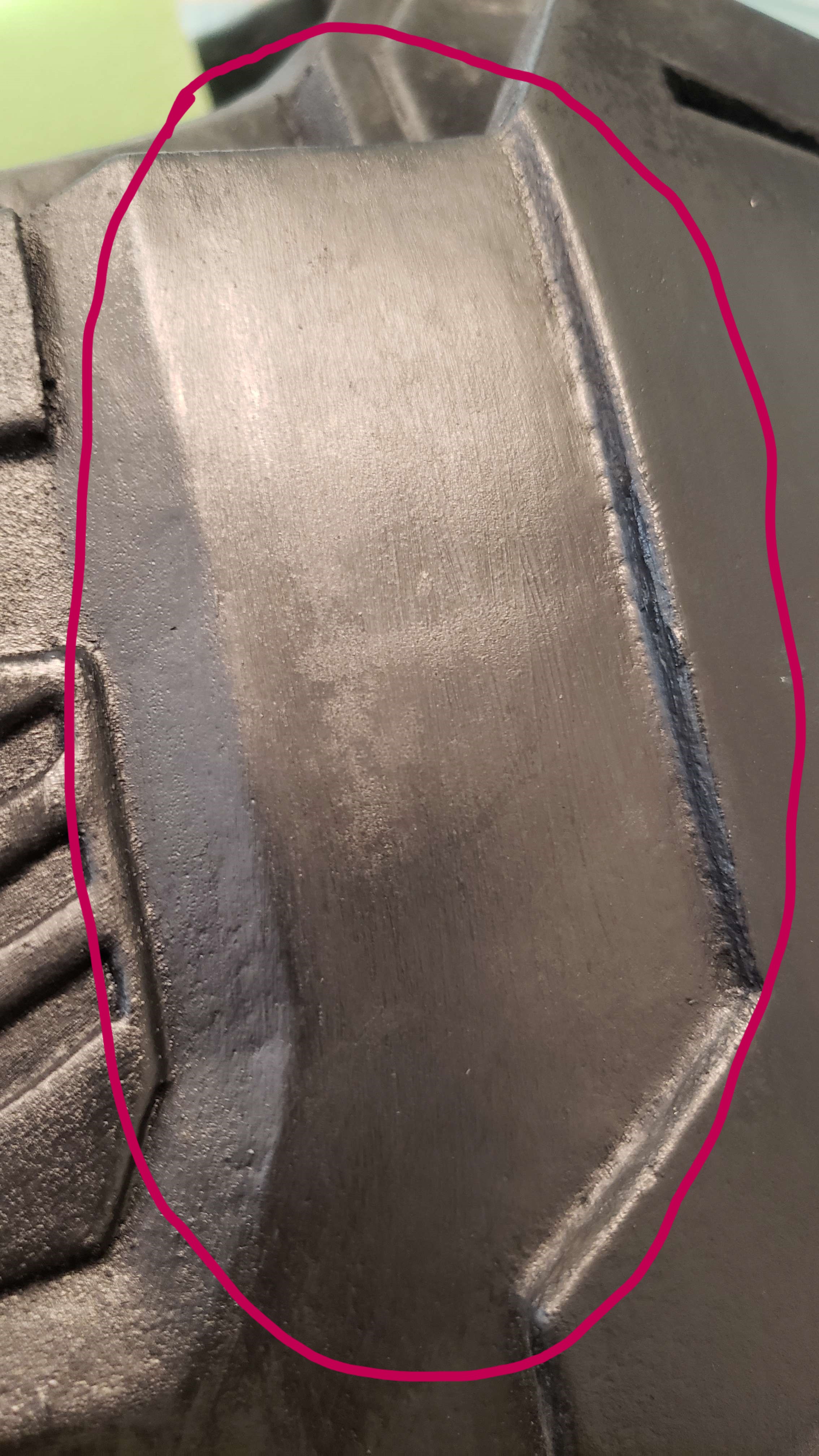

I wanted to include a trick I used on my armor before the thread got locked due to inactivity.

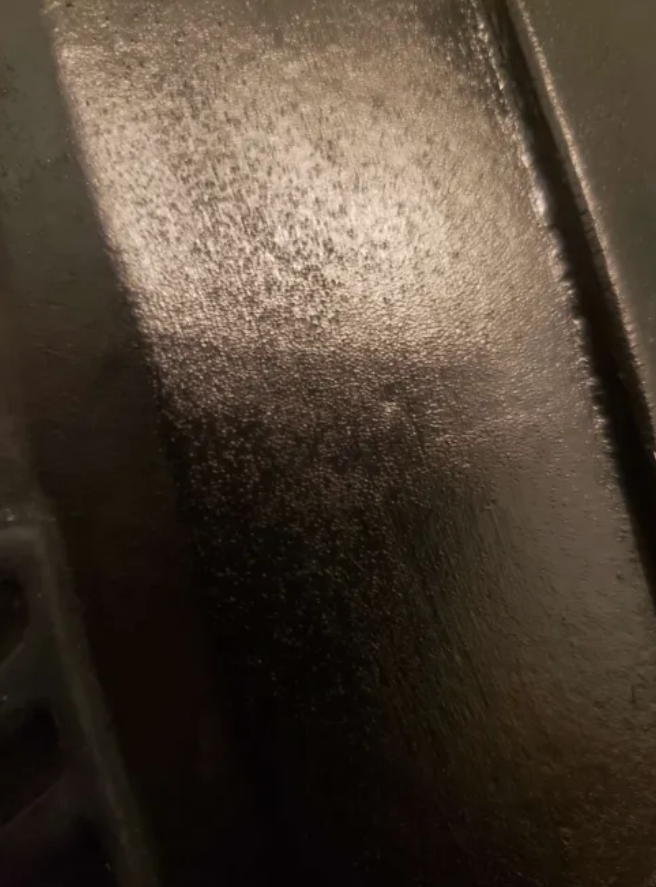

Due to so much sanding to fix the rough texture of the leak seal, it exposed little pinpoint air bubbles everywhere. These tiny holes made the chest vary in sheen and texture, and were very noticeable from a distance when the light hit.

How I fixed it? Your cheap art store acrylic paint.

(I swear it said "sandable" somewhere.)

(I swear it said "sandable" somewhere.)

Lots of hand-brushed layers and high-grit sandpaper. Very time-consuming, but the extra work boosted my confidence on my build.

I am not certain how this method would turn out on high-flex areas, but so far I've had no cracking.

Thought I would share this little trick up my sleeve, Marine shins coming soon. (Hopefully)

Due to so much sanding to fix the rough texture of the leak seal, it exposed little pinpoint air bubbles everywhere. These tiny holes made the chest vary in sheen and texture, and were very noticeable from a distance when the light hit.

How I fixed it? Your cheap art store acrylic paint.

Lots of hand-brushed layers and high-grit sandpaper. Very time-consuming, but the extra work boosted my confidence on my build.

I am not certain how this method would turn out on high-flex areas, but so far I've had no cracking.

Thought I would share this little trick up my sleeve, Marine shins coming soon. (Hopefully)

Dude this is amazing. I tried to do a foam marine but I didn’t have the patience for it. I’m really excited to see how it turns out, and it’s making me want to start working on mine againHello, been awhile friends! Welcome to KaeSpoon’s Marine build thread!

This has been a build in progress since January that I never got around to making a thread for. It was originally planned to be due by HCS Charlotte, but I ran out of time and took a break.

Why the marine? Wasn’t I already building a Spartan?

Some health issues have resulted in a long pause on the Spartan build, so I picked a marine because I thought it would be “easier” to make and fit. It was also a build that would allow me to participate in 405th events while my Spartan is still a work in progress/on hold.

View attachment 333028Mockup and fitting

Shoulder

View attachment 332995View attachment 332996View attachment 332997 View attachment 333039

Wish I had more photos of the build progress, this shoulder was a tough and tedious one! You can tell I went a little nuts on the foam clay afterwards, something I'm working on NOT doing. The bolts of the shoulder will be 3d printed.

Chest

View attachment 333000View attachment 333001View attachment 333003View attachment 333004

Paper and cardboard holders to keep the foam in the correct shape (using measurements) while I hot glue and shoegoo.

I ended up restarting the chest after this progress due to being unhappy with it and thinking it might be too small.

View attachment 333012View attachment 333013View attachment 333016

Doing the same thing with the paper and cardboard as above!

View attachment 333018View attachment 333019

View attachment 333020View attachment 333022

Test gasket with sample upper and lower strapping. I went into Blender and modeled my own gasket and then transferred it into a pattern. Lower strapping and details for that done and then the permanent gasket was installed! All that planning sometimes leads to battle scars...

View attachment 333023View attachment 333024

Scarring the backplate picked up thanks to the hot glue I used to hold the temporary straps, thankfully foam clay exists and the damaged areas will get covered up anyway! Don't be afraid to use foam clay to save your sanity. I did the backplate details by freehanding a pattern on tape and then using 2mm foam in layers.

View attachment 333026

View attachment 333027View attachment 333035

An example of how I freehanded some details using painter's tape, tedious and took a few tries but it was worth it!

View attachment 333030View attachment 333031

View attachment 333033View attachment 333034View attachment 333036

More details...

View attachment 333037View attachment 333038

STOP. COLLAR TIME. I made it in two parts so it could be magnetic!

View attachment 333040

Size comparison between my first Marine's (LA) Lower belt and my newer one.

View attachment 333041

Quick builds of the thigh UA's for the marine, these patterns were made by me. I am not very pleased with how they turned out, but they are good enough for now and I will remake them from the armory files at some point.

View attachment 333042

Test fit and finishing touches with foam clay, fixing a few seams and imperfections. I was pretty nervous at this stage, things were looking messy and not as clean as I'd hope; but sometimes things can look grim but end up turning out okay at the end.

I made the chest in a span of 5 weeks, but at the cost of extreme burnout and months without touching foam afterwards. Pace yourself friends!

Continuation below....

Impressive! My helmet off to you; the patience for foam is something I lack severely.Leak seal time! unfortunately I had a hard time when applying leakseal to the chest, there was a lot of details and layers that made application difficult. It also left a textured look to my armor that required a lot of sanding. Though its still not perfect and I wish the application was better, its good enough.

View attachment 333043View attachment 333044View attachment 333046

Sometimes you have to take a leap of faith and keep going.

View attachment 333047View attachment 333048

Lots and lots of sanding...

I ended up using Plastidip on the midsection of the chest, but wasn't happy with the results either, it pulled seams apart but overall had a cleaner application.

Semi-Finished chest: (Still needs more sanding, coat of paint, etc)

View attachment 333051View attachment 333052

View attachment 333053View attachment 333054View attachment 333055View attachment 333056

View attachment 333057View attachment 333058

I do plan on making this a hybrid build and finally put that MK V(B) that was too small for my spartan to some good use! I was worried the chest ended up too big, but with a BDU it SHOULD be okay. If not, I'll just be extra tanky.

So far, this build has been a TON of work, I was very ambitious and went overboard on details. I've learned a lot and can't wait to put what I've learned to good use with my Spartan build!

That being said, you've inspired me to give it another go.

Baron

- Member DIN

- S226

Thank you; I appreciate the kind words! I'm glad I could help you reconsider foamsmithing. I will be watching with great interest to see what you build.Impressive! My helmet off to you; the patience for foam is something I lack severely.

That being said, you've inspired me to give it another go.

Baron

- Member DIN

- S226

I'm genuinely in awe of your foam work. You've done an incredible job with this costume, and I can't wait to see what you do moving forward.

Thank you for the wonderful compliments. It's an overwhelming feeling to know I've inspired others with my build. I can't wait to see what you two have cooking up for the future!Dude this is amazing. I tried to do a foam marine but I didn’t have the patience for it. I’m really excited to see how it turns out, and it’s making me want to start working on mine again

- Member DIN

- S222

This stuff is the truth! And it’s surpsingly durable tooI wanted to include a trick I used on my armor before the thread got locked due to inactivity.

Due to so much sanding to fix the rough texture of the leak seal, it exposed little pinpoint air bubbles everywhere. These tiny holes made the chest vary in sheen and texture, and were very noticeable from a distance when the light hit.

View attachment 341404

How I fixed it? Your cheap art store acrylic paint. View attachment 341405(I swear it said "sandable" somewhere.)

View attachment 341407View attachment 341409

Lots of hand-brushed layers and high-grit sandpaper. Very time-consuming, but the extra work boosted my confidence on my build.

I am not certain how this method would turn out on high-flex areas, but so far I've had no cracking.

Thought I would share this little trick up my sleeve, Marine shins coming soon. (Hopefully)

- Member DIN

- S127

This build is so cool and your foam work is absolutely beautiful!! You should be so proud!

- Member DIN

- S226

Its been 84 years... But I finished shins in time for HWC.

I grabbed the stl of the armory file shin by Satchmo III and altered it by hand in Blender to make it look more like the female shin in Reach, then I added layer details.

These shins were by far the hardest part of the build due to their intricacy and shape, I hope I will never have to make a second pair of these again. They could have looked better, but they are going to get beat up anyway. In fact, they did so during HCS and needed some repairs. They still need their strapping, but I'll get to that eventually.

Kneegaurds next.

I grabbed the stl of the armory file shin by Satchmo III and altered it by hand in Blender to make it look more like the female shin in Reach, then I added layer details.

These shins were by far the hardest part of the build due to their intricacy and shape, I hope I will never have to make a second pair of these again. They could have looked better, but they are going to get beat up anyway. In fact, they did so during HCS and needed some repairs. They still need their strapping, but I'll get to that eventually.

Kneegaurds next.

- Member DIN

- S226

Ah, hiccups.

The shins won't fit in my tote if my kneegards are glued onto them, so I did some janky work... It will do for now. I will add extra Velcro straps to hold it on, but the rods do the majority of the work

.

As I'm doing this on the first shin I built, the shin itself is a little lop-sided so one of the sticks will be exposed to keep everything balanced. It shouldn't be noticeable once the sticks are painted.

Cheers!

The shins won't fit in my tote if my kneegards are glued onto them, so I did some janky work... It will do for now. I will add extra Velcro straps to hold it on, but the rods do the majority of the work

.

As I'm doing this on the first shin I built, the shin itself is a little lop-sided so one of the sticks will be exposed to keep everything balanced. It shouldn't be noticeable once the sticks are painted.

Cheers!