thatdecade

Well-Known Member

A piece of plexiglass in the center?? I hadn't considered that. Sounds like it would look really cool !

I originally had a hole in the center but was worried about fabrication difficulties. Currently, I am bringing the hole back. The overlapping drill hits don't seem to be a problem with my fab shop's DRC bot.

BatchPCB FAQ - Can I route exotic shapes?

They do make sideways RGB smd LEDs. With one color LEDs you can just use regular ones and mount them sideways. I am in the process of simplifying everything, speed production and keep costs down. RCB was the first thing to go.

At the time I wrote the 7 io comment I had 5 LEDs, one in the center and four on the sides. Pic below shows 10 LEDs driven by 5 channels.

No transistors needed. AVR chips can provide a maximum of 40mA per channel. I have no intention of going over that.

ATTiny25 Datasheet - Page 166

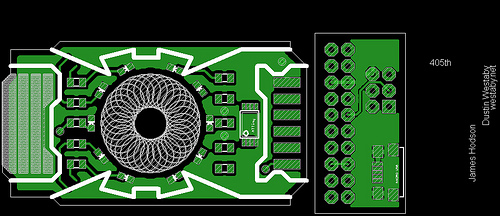

Slot holder is demonstrated below. USB connector has been moved off board. Switch removed, insert the card to light it up. The 10 blue LEDs are in a circle pattern and can do a neat spinning circle for a loading animation, then fade in and out after startup for an idling animation.

top_copper_silk_4 by thatdecade, on Flickr

The second board on the right is the connector board. Has an avr 6 pin programmer header and usb power connector. The 10x2 header is the connector shown below.

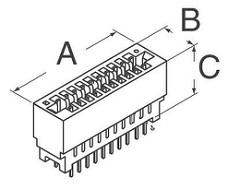

A29114_M10X2 by thatdecade, on Flickr

Still on my todo list.

I originally had a hole in the center but was worried about fabrication difficulties. Currently, I am bringing the hole back. The overlapping drill hits don't seem to be a problem with my fab shop's DRC bot.

BatchPCB FAQ - Can I route exotic shapes?

They do make sideways RGB smd LEDs. With one color LEDs you can just use regular ones and mount them sideways. I am in the process of simplifying everything, speed production and keep costs down. RCB was the first thing to go.

At the time I wrote the 7 io comment I had 5 LEDs, one in the center and four on the sides. Pic below shows 10 LEDs driven by 5 channels.

No transistors needed. AVR chips can provide a maximum of 40mA per channel. I have no intention of going over that.

ATTiny25 Datasheet - Page 166

Slot holder is demonstrated below. USB connector has been moved off board. Switch removed, insert the card to light it up. The 10 blue LEDs are in a circle pattern and can do a neat spinning circle for a loading animation, then fade in and out after startup for an idling animation.

top_copper_silk_4 by thatdecade, on Flickr

The second board on the right is the connector board. Has an avr 6 pin programmer header and usb power connector. The 10x2 header is the connector shown below.

A29114_M10X2 by thatdecade, on Flickr

Still on my todo list.

- Finish routing traces.

- Add a switch connect upon insertion (inserting cortana board can complete a circuit to turn on other lights in suit).

- Add a battery power connection (alternative to usb)

- Construct a prototype version of the circuit

- Program some light animations

- Order parts and do test fitting on 1:1 print out of the pcb

- Some design work on the outer shell. (something like this)