Still working on this advanced knife. I have a journeyman smith coaching me through this one, but unfortunately he can't be with me all the time to hover over my work. Much of it I have to work out for myself. Forged into shape, pre-heat treat grind, heat treated and tempered. I got it to hardness 59 rockwell. In the middle of post heat treat grinding now and taking it very carefully.

I also had to make a custom machete to smash down the blackberry I am constantly blocked by on my prospecting trips.

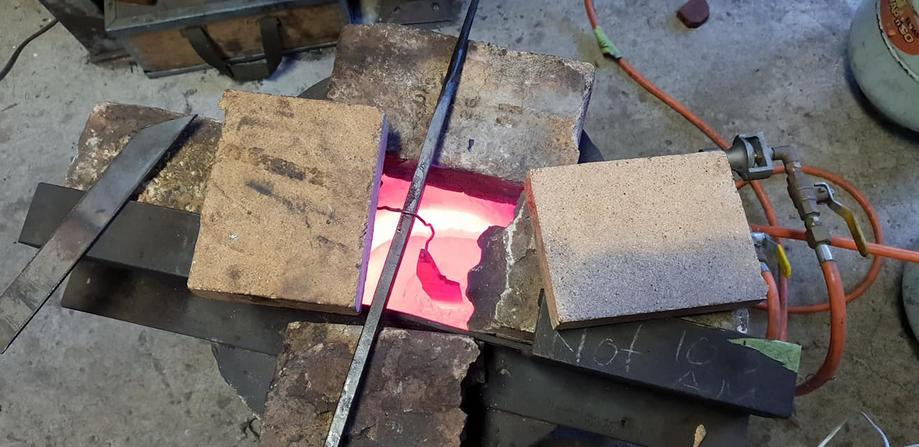

High carbon steel, hardened and tempered as per normal, but afterwards, given a spring temper by submerging the cutting edge in water and using a propane torch to blue the back. This one didn't have to look pretty, just do the job. I took it up to the goldfields last weekend and smashed my way through to the creek. Works a treat!

I also had to make a custom machete to smash down the blackberry I am constantly blocked by on my prospecting trips.

High carbon steel, hardened and tempered as per normal, but afterwards, given a spring temper by submerging the cutting edge in water and using a propane torch to blue the back. This one didn't have to look pretty, just do the job. I took it up to the goldfields last weekend and smashed my way through to the creek. Works a treat!