- Member DIN

- S980

This update is focused on the nose area and looking ahead to the mods needed to not only hide the airsoft components in here, but be able to access and service them post construction. We have already seen that there is not a lot of front to back space to install components. There are also width concerns as well.

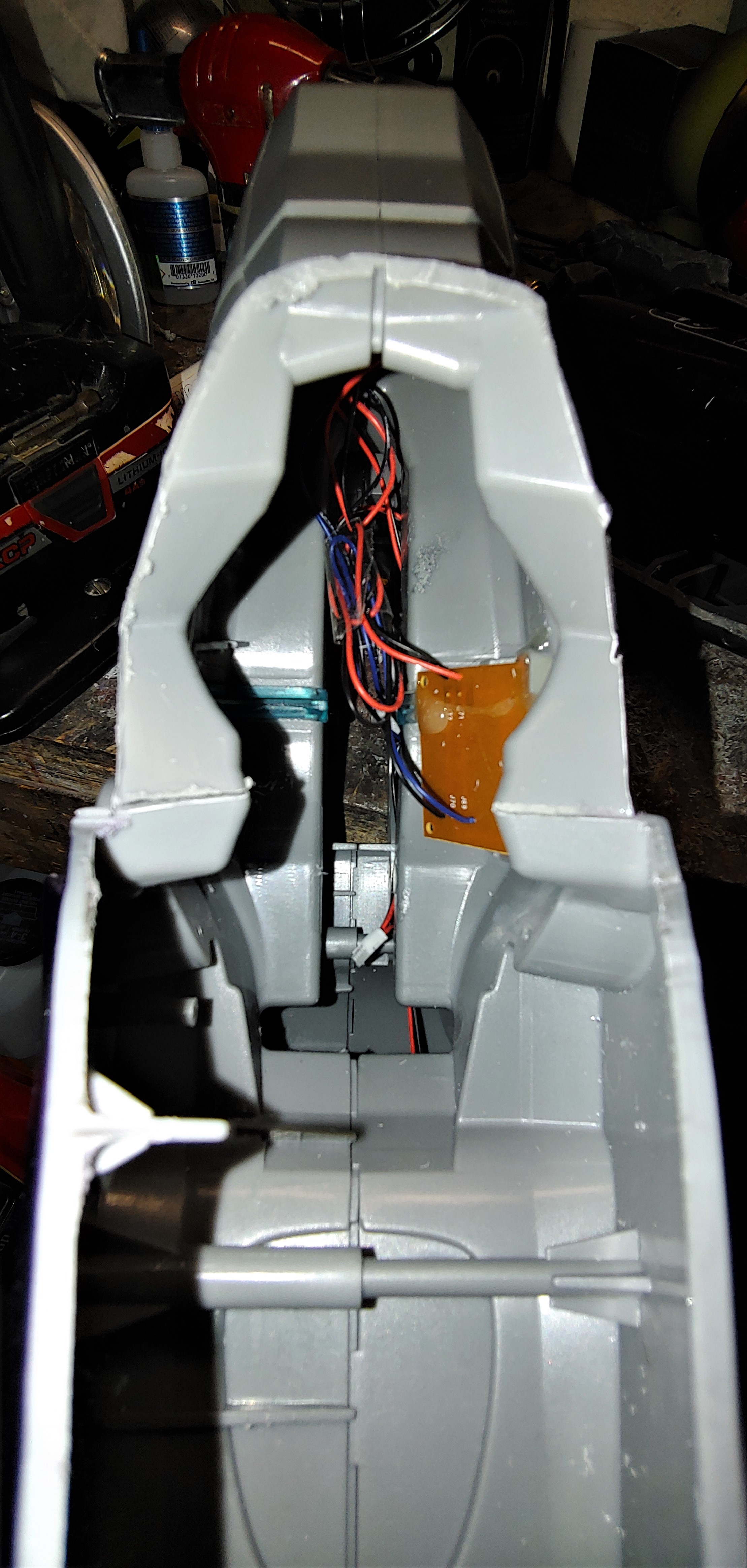

Starting at the bottom, there is not a lot of room for electronics and the air hose to pass up to the cylinder chamber and barrel. After taking a look, I determined that although it is pretty tight, there is enough room here.

View from the underside looking up. The gap at the top of the photo is where the air hose and electronics harness will access the actual firing components. The area at the bottom of the picture is where the regulator (attached to the high-pressure air bottle) will occupy. The battery and Arduino components will likely also reside in this space as it is the only significant space not already taken.

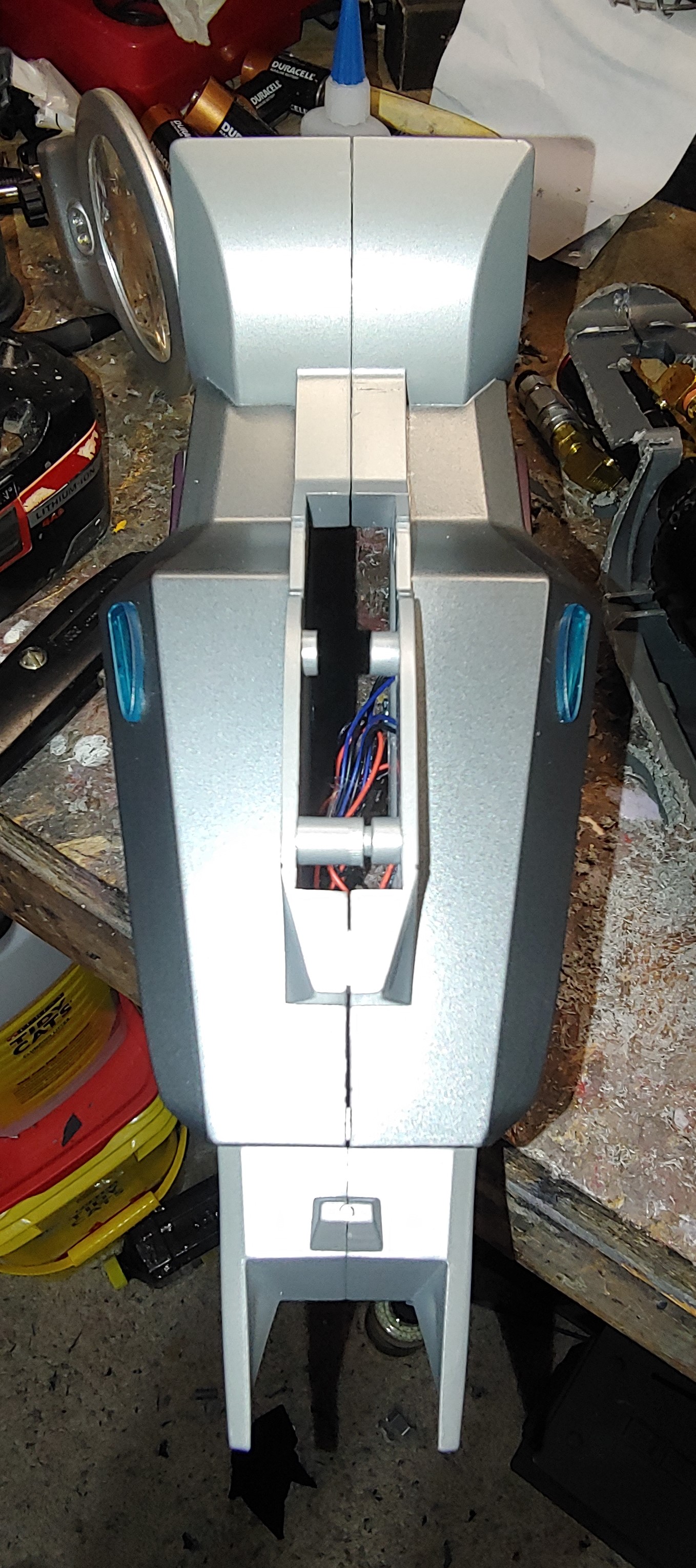

Viewed from above, the narrowness of the channel is apparent. So is the awfulness of the seams. These will go away as this becomes a one-piece assembly. The struts and pegs for screws will go away as well to give more space.

View of the bottom section from above. The halves will be bonded together permanently and strengthened.

There is a cluster of seven lights that dominated the space and the back of the center section. This was very effectively glued on by NECA. I'll need this to remain removable in the future as it will give the best access to the back end of the airsoft components including the air hose attachment. I will probably use just magnets to hold the light cluster in place.

A view from the back of the nose section. the narrowest point is too small for the airsoft components so I will have to widen it slightly. The slot at the bottom on the photo is where the pistol grip attaches to the lower section. This will become a permanent attachment and strengthened as this was a major source of flex and noise as originally constructed.

The front of the nose piece shows the massive gaps at the seams and the inconsistent depth of the molded details. It won't be hard to improve the look of this area. Once joined into a single piece and the seams filled, I'll sandblast it all and coat it with a slurry of epoxy and aluminum powder that will be buffed into a polished metal surface that is tough enough to not chip even when struck by high-velocity BBs.

View from the front. Lots of seams to be eliminated and details to be sharpened.

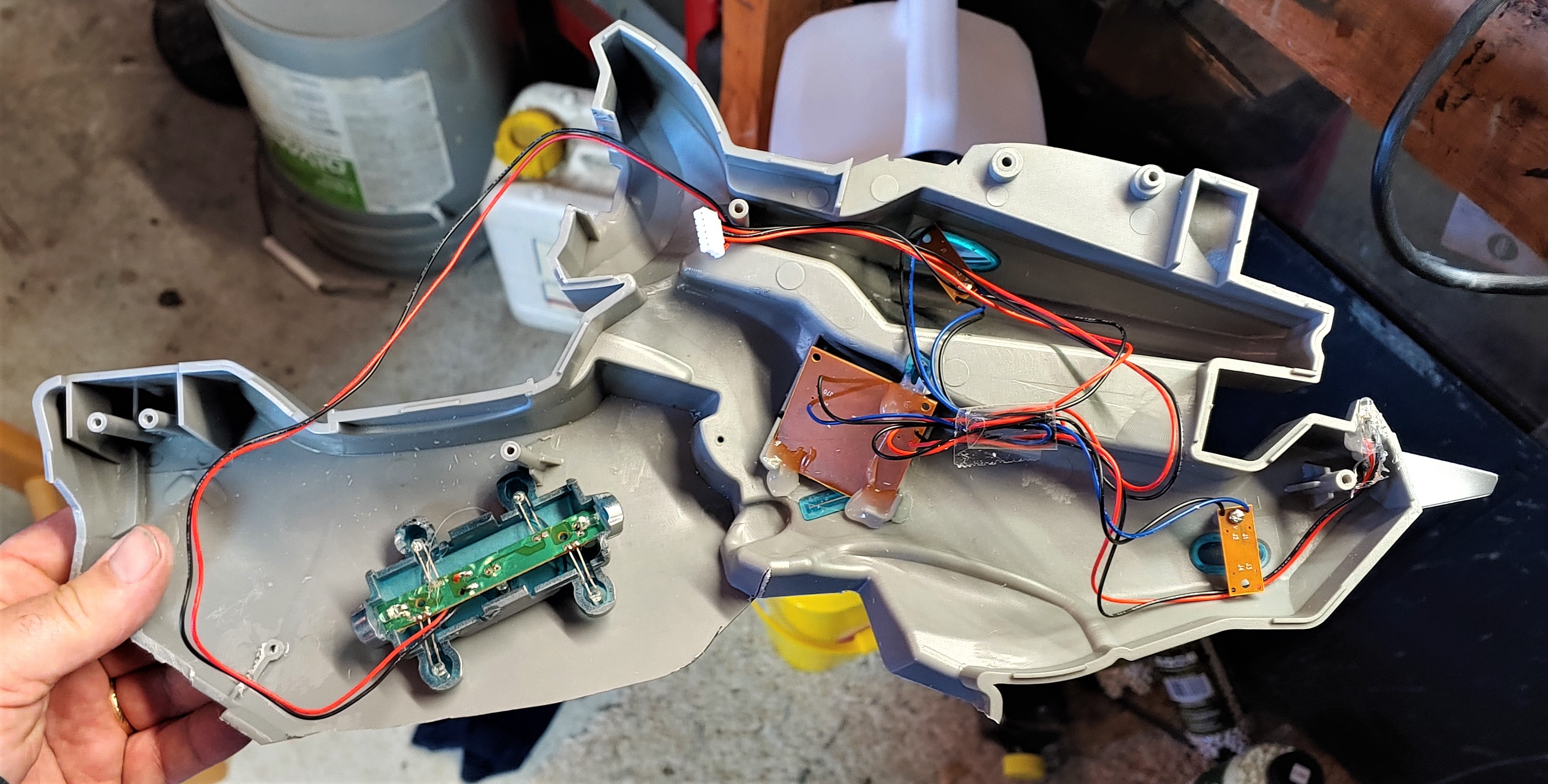

With the nose section apart, more hot glue is the theme. The tininess of the space is very evident. The diamond-shaped area will need to be removable to access the hop-up adjustment and barrel mechanics. The rat's nest of wires will need to be cleaned up as the LEDs are converted to pink.

Left side of the nose assembly. The first modification will be to cut away the diamond-shaped area.

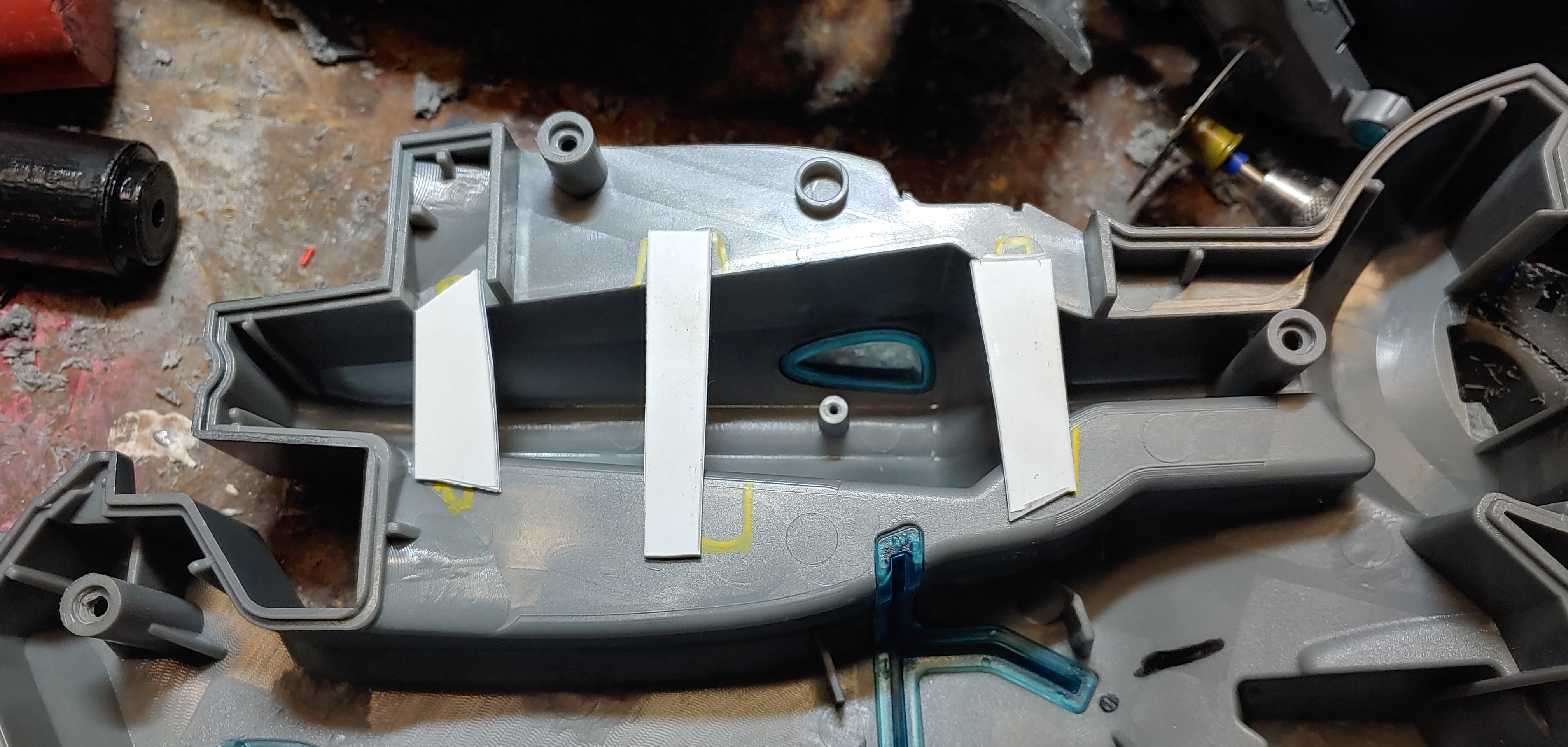

In order to preserve the spatial relationship of the upper and lower components while the emitter area is cut away, I glued in strips of styrene. This whole area will need to be subtly-widened at the rear to accommodate the width of the cylinder. All pegs for screws will be eliminated when the halves are fiberglassed together.

Styrene strips to hold components in alignment after cuts are made.

I got really busy with the Dremel saw and cut away the emitter section and the side walls of the nose section. This will allow me to widen the area slightly by moving the side walls outward. The emitter section halves will be joined and will be removable to permit servicing airsoft and electronics components inside.

Horrid picture of the sad remains of the emitter section. No going back now!

Most of the major disassembly is behind me know. Here is what the state of the disassembled components looks like now. Notice how many components are not broken along their factory seams.

Pretty cool display of all the parts. A lot of work to get to this point. And a lot of planning.

Next up: Final disassembly. I'm excited to turn the corner from disassembly to construction.

Redshirt

Guess who's not coming back from the Slayer match--the guy in the Red Shirt

Signature Project: Halo 3 Working Airsoft Spartan Laser in Metal & Fiberglass

Starting at the bottom, there is not a lot of room for electronics and the air hose to pass up to the cylinder chamber and barrel. After taking a look, I determined that although it is pretty tight, there is enough room here.

View from the underside looking up. The gap at the top of the photo is where the air hose and electronics harness will access the actual firing components. The area at the bottom of the picture is where the regulator (attached to the high-pressure air bottle) will occupy. The battery and Arduino components will likely also reside in this space as it is the only significant space not already taken.

Viewed from above, the narrowness of the channel is apparent. So is the awfulness of the seams. These will go away as this becomes a one-piece assembly. The struts and pegs for screws will go away as well to give more space.

View of the bottom section from above. The halves will be bonded together permanently and strengthened.

There is a cluster of seven lights that dominated the space and the back of the center section. This was very effectively glued on by NECA. I'll need this to remain removable in the future as it will give the best access to the back end of the airsoft components including the air hose attachment. I will probably use just magnets to hold the light cluster in place.

A view from the back of the nose section. the narrowest point is too small for the airsoft components so I will have to widen it slightly. The slot at the bottom on the photo is where the pistol grip attaches to the lower section. This will become a permanent attachment and strengthened as this was a major source of flex and noise as originally constructed.

The front of the nose piece shows the massive gaps at the seams and the inconsistent depth of the molded details. It won't be hard to improve the look of this area. Once joined into a single piece and the seams filled, I'll sandblast it all and coat it with a slurry of epoxy and aluminum powder that will be buffed into a polished metal surface that is tough enough to not chip even when struck by high-velocity BBs.

View from the front. Lots of seams to be eliminated and details to be sharpened.

With the nose section apart, more hot glue is the theme. The tininess of the space is very evident. The diamond-shaped area will need to be removable to access the hop-up adjustment and barrel mechanics. The rat's nest of wires will need to be cleaned up as the LEDs are converted to pink.

Left side of the nose assembly. The first modification will be to cut away the diamond-shaped area.

In order to preserve the spatial relationship of the upper and lower components while the emitter area is cut away, I glued in strips of styrene. This whole area will need to be subtly-widened at the rear to accommodate the width of the cylinder. All pegs for screws will be eliminated when the halves are fiberglassed together.

Styrene strips to hold components in alignment after cuts are made.

I got really busy with the Dremel saw and cut away the emitter section and the side walls of the nose section. This will allow me to widen the area slightly by moving the side walls outward. The emitter section halves will be joined and will be removable to permit servicing airsoft and electronics components inside.

Horrid picture of the sad remains of the emitter section. No going back now!

Most of the major disassembly is behind me know. Here is what the state of the disassembled components looks like now. Notice how many components are not broken along their factory seams.

Pretty cool display of all the parts. A lot of work to get to this point. And a lot of planning.

Next up: Final disassembly. I'm excited to turn the corner from disassembly to construction.

Redshirt

Guess who's not coming back from the Slayer match--the guy in the Red Shirt

Signature Project: Halo 3 Working Airsoft Spartan Laser in Metal & Fiberglass