You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reach Shotgun - The molding process

- Thread starter Brandon McClain

- Start date

- Status

- Not open for further replies.

the rice shield

New Member

I was wondering, where do you get mixing containers that are that big that have the measurements on the side?

Thanks for the comments everyone, it keeps me going! And to answer your question rice shield, I got the measuring cups at Walmart, they are just 500ml (2 cup) liquid measuring cups from the baking aisle.

Well, time for another update. Work has keeping me far to busy to be able to do much. 14+ hours 5-6 days a week doesn't leave much time for anything. Anyway, I got a couple more parts clayed up (I still need to do the barrel assemble, the pump, and the little bits), so all of the rest of the main body is ready to throw under rubber. I also picked up a couple gallons of Moldstar30, I want to see if it works better than the rebound. I also picked up various other products for casting and finishing up my other projects. Let's just say smooth on put a serious dent in my checking account.

See!!

And the clayed up pieces:

Forward lower reciever

The grip etc. This will be a 3 part mold. The large clay are will eventually be filled with rubber so as to allow for the trigger assembly to be installed

The stock. The Lego is to cut down on the volume of rubber I use. Filling the entire area is just a waste of rubber.

Well, time for another update. Work has keeping me far to busy to be able to do much. 14+ hours 5-6 days a week doesn't leave much time for anything. Anyway, I got a couple more parts clayed up (I still need to do the barrel assemble, the pump, and the little bits), so all of the rest of the main body is ready to throw under rubber. I also picked up a couple gallons of Moldstar30, I want to see if it works better than the rebound. I also picked up various other products for casting and finishing up my other projects. Let's just say smooth on put a serious dent in my checking account.

See!!

And the clayed up pieces:

Forward lower reciever

The grip etc. This will be a 3 part mold. The large clay are will eventually be filled with rubber so as to allow for the trigger assembly to be installed

The stock. The Lego is to cut down on the volume of rubber I use. Filling the entire area is just a waste of rubber.

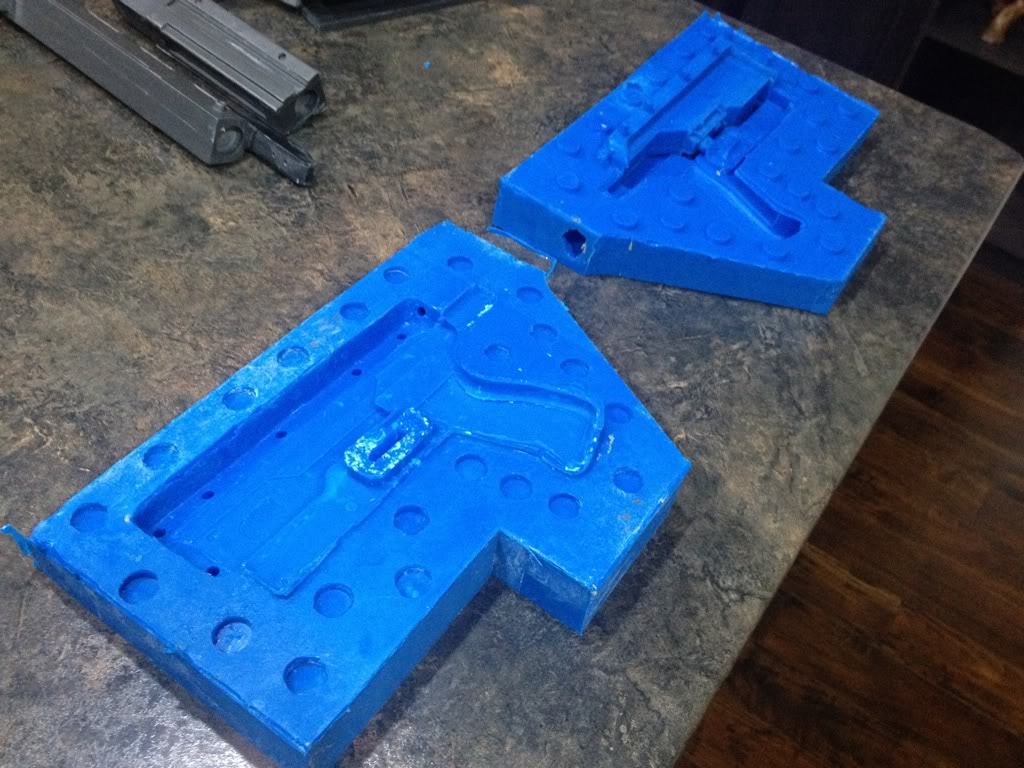

Okay, small update. Laying out the rubber has taken a little longer than planned, but it's coming. Let me start by saying that I am in love withe the new moldstar30. It is sooo much nicer than rebound for making box molds. It self degasses and it is marvelous. Plus its such a purdy shade of blue! For anyone looking to make box molds, don't go with anything else. Seriously. As far as pictures, I will only be posting a teaser. I still need to mold the small bits, the pump and the barrel assembly. The full upper, lower and buttstock are all done being molded. The grip is a 3 part mold, I will have more pictures of that later. In the meantime here is a picture of the front lower receiver mold:

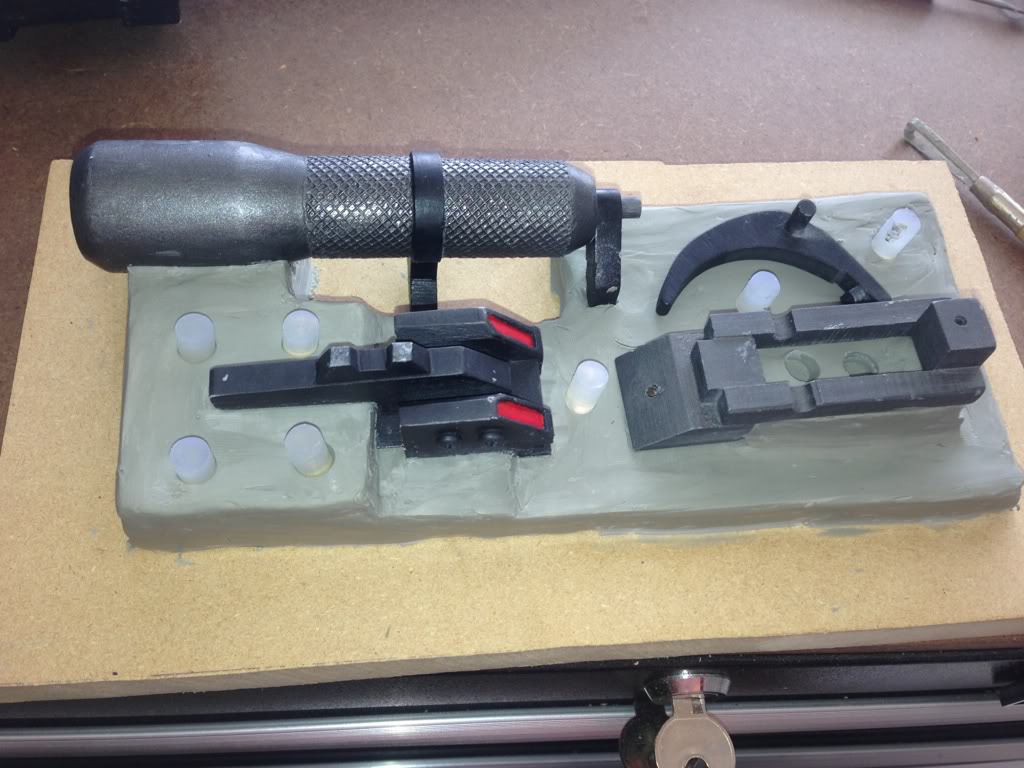

And another teaser, here is the next molding project once the shotty is completed

And another teaser, here is the next molding project once the shotty is completed

Brandon, may I know who's the creator of that Magnum? I must say his/her work is amazing!

That would be me!

Thanks!

sooooooooooooooooooooo beautiful..love the pistol

That would be me!

Thanks!

You never cease to amaze me! Great job on the Magnum!

TheReconSpartan

Active Member

I'm going to cast my Halo 4 Battle Rifle and i know some about molding guns but not all of it, can i get some advise from you on how to do it? The gun also has a retractable magazine and i don't know how to handle that issue...Help?

Valiathon13

New Member

PLEEEEEASE send me a PM on pricing information for this beautiful work of art.

Well I suppose it's time to repost the updates that were lost in the reversion. I will try and space them out to give people time to respond and ask any questions they may have about methodology. Here goes:

I was thinking somewhere around $$$ for a kit, it depends on how much resin and other material it takes to do the final casting. I've already spent and ungodly amount on rubber. In other news, some progress has been made in the molding process, which I hope to complete this weekend.

This is the mold for the grip. In this picture it looks like a standard two part mold, but there is in fact an insert that enables the interior of the grip to be hollow to hold the trigger, spring and etc.

These two pictures show the same side of the mold, the first with the insert in place, the second with it removed. I isolated the insert with clay, including the sprue on top when pouring the two halves. I then removed the clay and poured the insert.

The insert:

Next up is the buttstock:

After this all that is left is the pump, barrel assembly and small bits.

I was thinking somewhere around $$$ for a kit, it depends on how much resin and other material it takes to do the final casting. I've already spent and ungodly amount on rubber. In other news, some progress has been made in the molding process, which I hope to complete this weekend.

This is the mold for the grip. In this picture it looks like a standard two part mold, but there is in fact an insert that enables the interior of the grip to be hollow to hold the trigger, spring and etc.

These two pictures show the same side of the mold, the first with the insert in place, the second with it removed. I isolated the insert with clay, including the sprue on top when pouring the two halves. I then removed the clay and poured the insert.

The insert:

Next up is the buttstock:

After this all that is left is the pump, barrel assembly and small bits.

No questions? Okay, the here we go again:

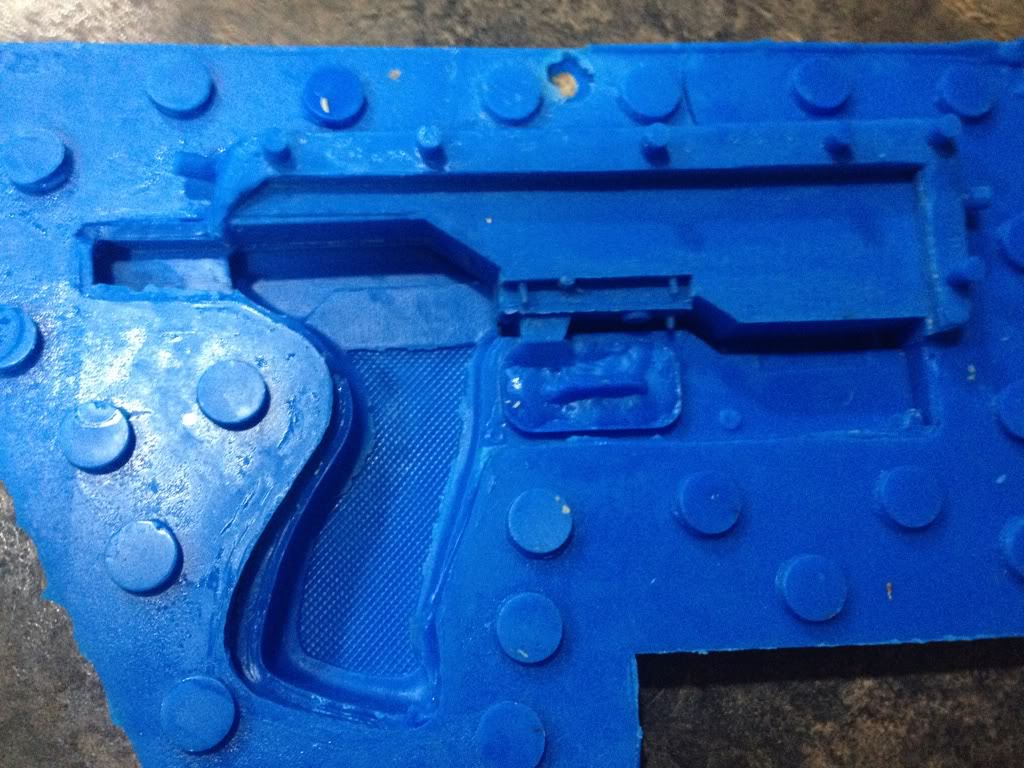

Next up was prepping the small bits for molding, there is the sight, trigger, trigger keeper and the flashlight. I laid down a base of clay and filled in around the parts. The registration keys were then added. All of the sprues will be added in between pours of the two halves.

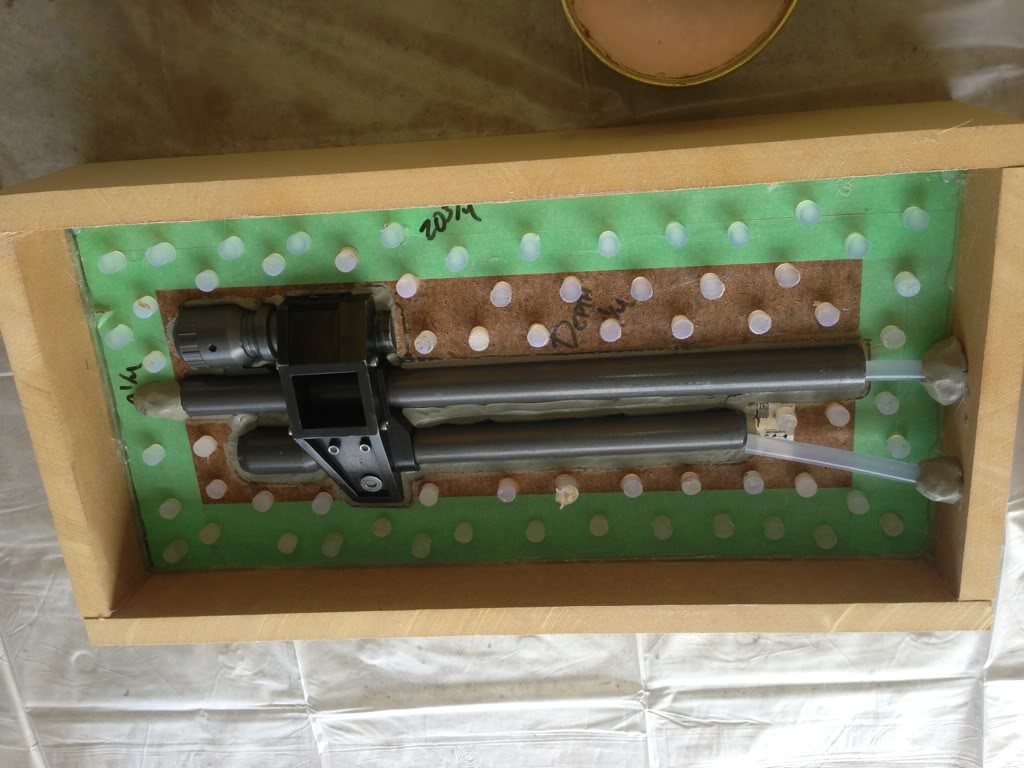

Finally comes the barrel assembly. The procedure was much same with the other box molds. I had cut out the hard board the serves as a barrier between the two halves. The came filling the gaps with clay. I filled the back side first to provide a solid structure and good bass for filling in the gaps. This way no clay with pop out and let rubber leak. Once again, lessons learned the hard way. Once the back had all be filled, I cleaned up the front added clay in the gaps and using my sculpting tools I made sure that the gaps were smoothed out. All that remains is to cut the rim boards for the two molds? Wax and spray with release and they are ready for rubber. Once the rubber is down she is all done

Next up was prepping the small bits for molding, there is the sight, trigger, trigger keeper and the flashlight. I laid down a base of clay and filled in around the parts. The registration keys were then added. All of the sprues will be added in between pours of the two halves.

Finally comes the barrel assembly. The procedure was much same with the other box molds. I had cut out the hard board the serves as a barrier between the two halves. The came filling the gaps with clay. I filled the back side first to provide a solid structure and good bass for filling in the gaps. This way no clay with pop out and let rubber leak. Once again, lessons learned the hard way. Once the back had all be filled, I cleaned up the front added clay in the gaps and using my sculpting tools I made sure that the gaps were smoothed out. All that remains is to cut the rim boards for the two molds? Wax and spray with release and they are ready for rubber. Once the rubber is down she is all done

Spartan 150

New Member

This looks amazing. I mean really the people on here are making chief proud . Keep it up.

Okay, time for another update. Made some serious headway through the weekend and the week. Finished all of the prep and poured the rubber for the barrel assembly, small parts, and half of the pump mold. Here's the pics:

Completed box mold for the small parts:

The barrel assembly:

Sans registration keys

With registration keys. The usual glue stick bits were used for keys. You can also see the pouring sprues and vents.

Next I poured an initial pseudo print layer. This is less about preserving detail than it is about sealing around the part to prevent leakage. It locks the part in place and ensures that all of the cracks are closed up. I let it sit for an hour or two and then pour over top of it.

Just a shot of where I am working in my garage.

The initial layers on the pump and small bits. On the pump I made sure to pour over the front where the recesses were first to ensure that no large air bubbles were trapped.

What the work space looks like after a while of pouring rubber

After the first half was cured I pulled the clay barrier from the small parts and removed the hard board and the clay from the Sam on the barrel assembly. I then proceeded to spray down the whole thing with release agent being very liberal, you want to ensure that the two sides are not going to stick together, so you really can't use too much release agent. I then poured the initial layer, following it up by pouring the rest of the second halves for the barrel assembly and small parts.

So, once again, lots of pics, but I hope the process helps a bit. There is a ton of rubber in all of the various molds, once these are all cured I will get a shot of all of them together.

Once all of the rubber is cured I have to cut the backing boards for all of the parts, but that goes fairly quickly.

Completed box mold for the small parts:

The barrel assembly:

Sans registration keys

With registration keys. The usual glue stick bits were used for keys. You can also see the pouring sprues and vents.

Next I poured an initial pseudo print layer. This is less about preserving detail than it is about sealing around the part to prevent leakage. It locks the part in place and ensures that all of the cracks are closed up. I let it sit for an hour or two and then pour over top of it.

Just a shot of where I am working in my garage.

The initial layers on the pump and small bits. On the pump I made sure to pour over the front where the recesses were first to ensure that no large air bubbles were trapped.

What the work space looks like after a while of pouring rubber

After the first half was cured I pulled the clay barrier from the small parts and removed the hard board and the clay from the Sam on the barrel assembly. I then proceeded to spray down the whole thing with release agent being very liberal, you want to ensure that the two sides are not going to stick together, so you really can't use too much release agent. I then poured the initial layer, following it up by pouring the rest of the second halves for the barrel assembly and small parts.

So, once again, lots of pics, but I hope the process helps a bit. There is a ton of rubber in all of the various molds, once these are all cured I will get a shot of all of them together.

Once all of the rubber is cured I have to cut the backing boards for all of the parts, but that goes fairly quickly.

Thank you for such a thorough guide on how you have done all this. Although I knew how to already it's good to have all the info and huge array of pictures to work from as reference when I do the box moulds for a gun I want to make in the future.

Keep up the amazing work man

Keep up the amazing work man

I'm glad some are finding this helpful. For the sake of preserving the purpose of demonstrating the dos and donts of the molding process let me show you my screw up:

If you notice, the pump is out of it's box, off to the side, covered in rubber. It was an expensive goof to say the least. In the case where you are pouring over a part, ensure that you have secured the part securely to the base over which you are pouring. I only tacked it down with hot glue. I should have glued it down more securely. The reason I didn't is that I was concerned that in removing the base to pour the rest of the rubber I would unseat the pump from the rubber which would create a lot of problems. (You almost never want to remove the part from the mold until all rubber has been poured, it never goes back in perfectly. There are tiny gaps that the rubber will find. Nightmare. Once again lesson I learned the hard way). The end result is that the pump floated off its base up through the 3/4 gallon of rubber I had poured over it. This could also have been prevented if I had left the initial/sealer layer cute longer until it was mostly hard. Sadly my impatience got the better of me. Now some might say why don't you just try glueing it down again and re-pour it: well, the rubber the cured against the mdf sort of seals the "pores" of the wood, and the glue won't really stick to it. How do I know that. Because silly me, like most other lessons learned, I tried it, and no dice. Now, one more lesson to learn from my screw up: the rubber isn't a complete waste. You can't cut it up and mix it with fresh rubber and it becomes a viable filler. Awesome when you are pouring large box molds like these. I was able to reuse pretty much all of my excess rubber from previous screw ups.

If you notice, the pump is out of it's box, off to the side, covered in rubber. It was an expensive goof to say the least. In the case where you are pouring over a part, ensure that you have secured the part securely to the base over which you are pouring. I only tacked it down with hot glue. I should have glued it down more securely. The reason I didn't is that I was concerned that in removing the base to pour the rest of the rubber I would unseat the pump from the rubber which would create a lot of problems. (You almost never want to remove the part from the mold until all rubber has been poured, it never goes back in perfectly. There are tiny gaps that the rubber will find. Nightmare. Once again lesson I learned the hard way). The end result is that the pump floated off its base up through the 3/4 gallon of rubber I had poured over it. This could also have been prevented if I had left the initial/sealer layer cute longer until it was mostly hard. Sadly my impatience got the better of me. Now some might say why don't you just try glueing it down again and re-pour it: well, the rubber the cured against the mdf sort of seals the "pores" of the wood, and the glue won't really stick to it. How do I know that. Because silly me, like most other lessons learned, I tried it, and no dice. Now, one more lesson to learn from my screw up: the rubber isn't a complete waste. You can't cut it up and mix it with fresh rubber and it becomes a viable filler. Awesome when you are pouring large box molds like these. I was able to reuse pretty much all of my excess rubber from previous screw ups.

- Status

- Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 832

- Replies

- 16

- Views

- 2,541