You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Revenant1988's MK V Build (WIP)

- Thread starter Revenant1988

- Start date

- Status

- Not open for further replies.

acasualbanana

Jr Member

That is amazing!! O.O

I can only hope to arise to that level. Hats off to you!

I can only hope to arise to that level. Hats off to you!

BLACKULA727

Well-Known Member

Very well done! Looks like you did a lot of proper planning and your results were fantastic. I can't wait to see future builds of yours. Keep up the great work and thanks for the kudos  . Now you can Inspire others!

. Now you can Inspire others!

-TOny

-TOny

just out of curiosity what did you scale the helmet at?

The helmet is scaled at 292.679. The native scale of the file is 268.384. I don't have a very big head, and I'd had some practice at this point but I got the helmet right on the first try. No splitting was necessary to get it on either, I only dremel'd the thin lip away on the bottom so my ears didn't catch. I have a pic below to better explain. The part in green is the part that was removed.

Very well done! Looks like you did a lot of proper planning and your results were fantastic. I can't wait to see future builds of yours. Keep up the great work and thanks for the kudos. Now you can Inspire others!

-TOny

Haha I have some plans, but right now I have no money to fund them until the holidays are over. Your tut was a huge help. I'll have some pics up for how I used it soon.

@CasualBanana- Thanks for the compliment! My build is nothing special, and with patience you can easily surpass me

CUSTOM ALTERATIONS

More updates to share!

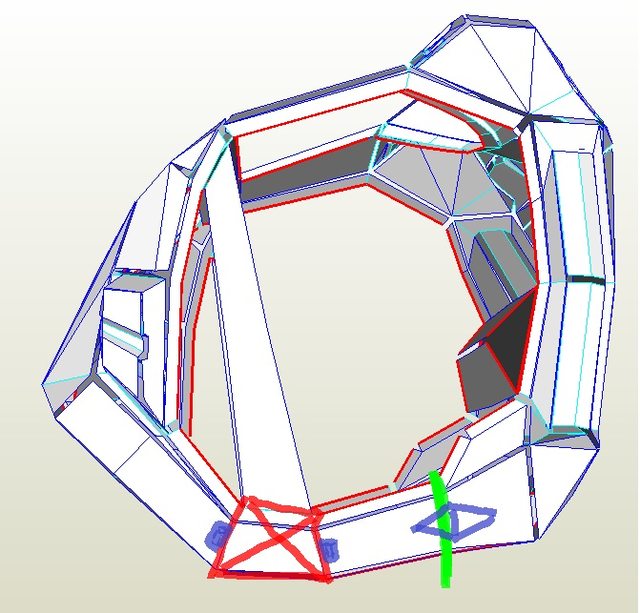

Ok, so I mentioned early on that I had to alter Rhinoc's pep files a bit (not that there was anything wrong with them, I would have had to make changes to the pieces regardless) and that was mostly removing excess during the pep stage.

While everything was scaled to my height correctly, the depth tended to leave large areas that did not fit me; for instance, my calf muscle is NOT jutting out 10inches behind my skinny leg, so I had to remove parts.

In the picture above, the green lines represent parts of the pep file I removed to make it fit the circumference of my leg better.

I found this technique to be very effective. By doing it early in the pep stage, I ensured that when it was time to resin and glass that I had a piece that would fit. Had I waited to split the pieces during fiberglassing it would have been hart to even out the pieces and they may not have fitted right anyway (warping). Since it was just paper, all I had to do was join the new edges together with another piece of paper!

Here are some shots of the other pieces where I did the same thing

Thigh:

Now the Chest was something different.... same thing, I had to remove a section along the bottom that wraps around your sides. I didn't have to remove this piece, but since I did the chest sits more flat against my actual chest instead of bulging out. It basically makes the MK 5 look a bit more like the MK 6 in that sense.

The red section is the part I removed, The green section is where I made the split for the hinges, and the Blue represents this actual hinge and magnet locations

In the next post I'll have some better pics of how I set that up.

More updates to share!

Ok, so I mentioned early on that I had to alter Rhinoc's pep files a bit (not that there was anything wrong with them, I would have had to make changes to the pieces regardless) and that was mostly removing excess during the pep stage.

While everything was scaled to my height correctly, the depth tended to leave large areas that did not fit me; for instance, my calf muscle is NOT jutting out 10inches behind my skinny leg, so I had to remove parts.

In the picture above, the green lines represent parts of the pep file I removed to make it fit the circumference of my leg better.

I found this technique to be very effective. By doing it early in the pep stage, I ensured that when it was time to resin and glass that I had a piece that would fit. Had I waited to split the pieces during fiberglassing it would have been hart to even out the pieces and they may not have fitted right anyway (warping). Since it was just paper, all I had to do was join the new edges together with another piece of paper!

Here are some shots of the other pieces where I did the same thing

Thigh:

Now the Chest was something different.... same thing, I had to remove a section along the bottom that wraps around your sides. I didn't have to remove this piece, but since I did the chest sits more flat against my actual chest instead of bulging out. It basically makes the MK 5 look a bit more like the MK 6 in that sense.

The red section is the part I removed, The green section is where I made the split for the hinges, and the Blue represents this actual hinge and magnet locations

In the next post I'll have some better pics of how I set that up.

Last edited by a moderator:

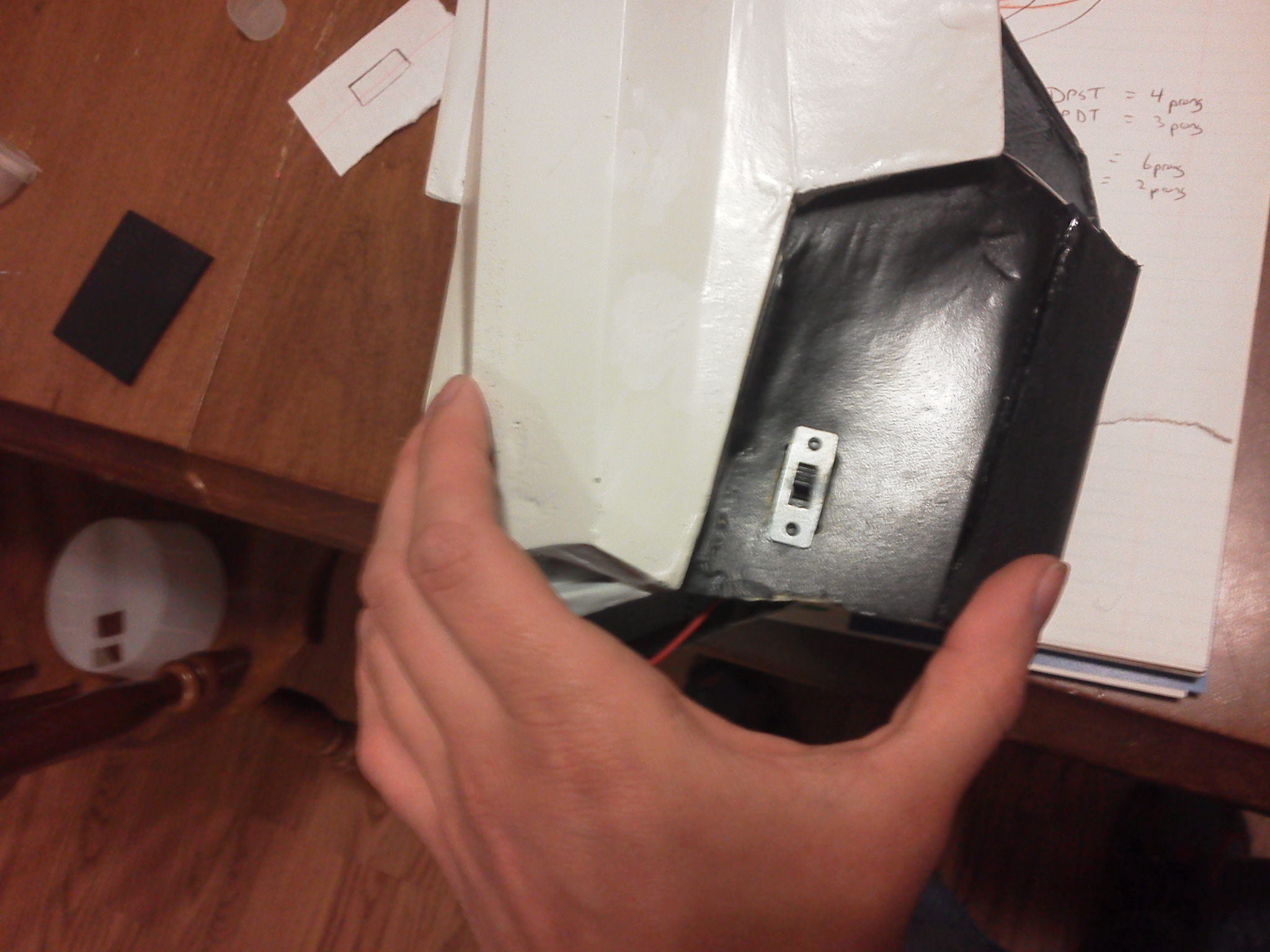

CHEST

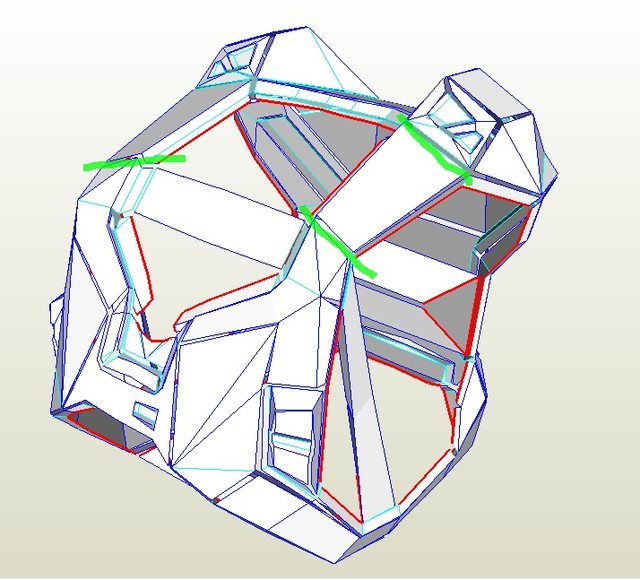

As I mentioned above, the chest piece was done a little differently than what is normally done here on the 405th, at least from what I've seen over the years. Most people split the chest in 4 places: 2 at the top, 2 at the bottom and then join them together via magnets, clips, or even a lock and key setup (or puzzle piece). I saw that another member here had an even better idea, and just spit it only on the bottom. I decided to do the same thing but with different pieces.

The green lines in the picture above represent 2 places where people usually cut the chest, and then once on the bottom to match.

I still made 4 cuts on my chest, but I made them on the bottom only. This allowed me simply flip out the sections and then simply drop it on top of my shoulders, like you would a shirt or football pads.

Before I made the cuts on the bottom, I had to reinforce the top of the chest that normally would have seen a cut. I had to do this because the top of the shoulders would now see more stress without the bottom being solid. To avoid the possibility of it bending or cracking, I just epoxy'd some glue to a couple pieces of wood. It worked very well!!

The JB weld epoxy sets in about 5 min, but it takes a few hours to cure fully. Once that was done, it was time to make the cuts, and drill some holes.

Attaching the hinge was pretty straight forward. The hinge is a simple one from Lowes...cost about $3. I wanted a triangular one since they are stronger when compared to a square or rectangle.

I held the hinge where I wanted it and then just marked with a sharpie where I needed to drill the holes. From there, I just have a couple of nuts with some thread locker on the ends to keep them in place.

Here is what it looked like when it was split out. You may also notice the door latches in the bottom of the pic. Well, that didn't work out how I wanted. I think these would have worked if I had a more flat surface area to attach them to, but I didn't so I had to use magnets.

Attaching the magnets.... I did not go out and get any fancy ones or anything, there were actually just generic ones from walmart for cabinets and such. I marked where they needed to sit, and then just epoxy'd them down. They don't sit as even as I would like when they are closed, but they still lock very well. Next time, I'll add some guide pins to make sure they sync up even better.

Here are the results:

When I'm wearing it, you can see where the split is, like a car door. I really don't care about this. If I've noticed anything when I'm in it, its that no one notices that stuff. In fact, all the things I spent hours on trying to perfect, normal people don't even see... like they don't notice or care haha. Oh well. I guess you all know what I mean though; While it may not bother them or they don't know about it- WE know about so it eats at us haha!

EDIT:

OH! one other thing I forgot. So JB weld actually does contain bits of metal! I found this out when I was epoxying the magnets in place; the epoxy would react to the magnet like a small screw, it was really cool! If I wasn't sure about it being held in place before, I wasn't worried after that!!

As I mentioned above, the chest piece was done a little differently than what is normally done here on the 405th, at least from what I've seen over the years. Most people split the chest in 4 places: 2 at the top, 2 at the bottom and then join them together via magnets, clips, or even a lock and key setup (or puzzle piece). I saw that another member here had an even better idea, and just spit it only on the bottom. I decided to do the same thing but with different pieces.

The green lines in the picture above represent 2 places where people usually cut the chest, and then once on the bottom to match.

I still made 4 cuts on my chest, but I made them on the bottom only. This allowed me simply flip out the sections and then simply drop it on top of my shoulders, like you would a shirt or football pads.

Before I made the cuts on the bottom, I had to reinforce the top of the chest that normally would have seen a cut. I had to do this because the top of the shoulders would now see more stress without the bottom being solid. To avoid the possibility of it bending or cracking, I just epoxy'd some glue to a couple pieces of wood. It worked very well!!

The JB weld epoxy sets in about 5 min, but it takes a few hours to cure fully. Once that was done, it was time to make the cuts, and drill some holes.

Attaching the hinge was pretty straight forward. The hinge is a simple one from Lowes...cost about $3. I wanted a triangular one since they are stronger when compared to a square or rectangle.

I held the hinge where I wanted it and then just marked with a sharpie where I needed to drill the holes. From there, I just have a couple of nuts with some thread locker on the ends to keep them in place.

Here is what it looked like when it was split out. You may also notice the door latches in the bottom of the pic. Well, that didn't work out how I wanted. I think these would have worked if I had a more flat surface area to attach them to, but I didn't so I had to use magnets.

Attaching the magnets.... I did not go out and get any fancy ones or anything, there were actually just generic ones from walmart for cabinets and such. I marked where they needed to sit, and then just epoxy'd them down. They don't sit as even as I would like when they are closed, but they still lock very well. Next time, I'll add some guide pins to make sure they sync up even better.

Here are the results:

When I'm wearing it, you can see where the split is, like a car door. I really don't care about this. If I've noticed anything when I'm in it, its that no one notices that stuff. In fact, all the things I spent hours on trying to perfect, normal people don't even see... like they don't notice or care haha. Oh well. I guess you all know what I mean though; While it may not bother them or they don't know about it- WE know about so it eats at us haha!

EDIT:

OH! one other thing I forgot. So JB weld actually does contain bits of metal! I found this out when I was epoxying the magnets in place; the epoxy would react to the magnet like a small screw, it was really cool! If I wasn't sure about it being held in place before, I wasn't worried after that!!

Last edited by a moderator:

Fudz073

Active Member

I guess you all know what I mean though; While it may not bother them or they don't know about it- WE know about so it eats at us haha!

I completely understand. When I mounted the visor on my mk V helmet, I had to use two small screws to keep the contours correct. And even after painting them black, It just bothered me. Funnily enough, NO one else noticed them. It's just how it is when you put your sweat blood and tears into project.

Anywho, I love the way you set up the chest piece. The hinges are a VERY nice touch as well as the magnets. I think I'm going to go this route when I redo my chest piece (Too big). Very innovative. Still love the suit!!!

HELMET (still W I P)

My helmet still has lots of work to be done on it. I still need to put LED's and a fan in, as well as the foam around my head. I have some in there temporarily, but I need a more final solution. I also need to make a few revisions to the visor, and fill the gaps.

First off, a BIG thank you to BLACKULA for his visor tutorial. It was very helpful to me. If you have not seen it, check out my first post in this thread for the link. -WELL WORTH YOUR TIME.

Helmet went like this:

Bondo'd to my liking > visor test fit > cut visor > test fit > more cuts > Epoxy in the bases for the screw posts > put in screw posts > Epoxy over them > mark and drill holes on visor > push into place > Put on screws > verify position and decide if I like it > Make adjustments > remove visor > Prime helmet > Paint helmet > Clear coat helmet > Attach visor.

Take visor and cover it in plastic wrap and masking tape, then trace the outline of the visor using the one I cut out of the glassed helmet

Cut it so it fits into place as good as the helmet allows

Epoxy in the bases so the screws have something to grab to (I have 3 on top, 1 on bottom as thats what spacing allowed).

Kind of a bad shot, but it has all 4 posts.

I used mighty putty as was recommended, and then I put JB weld on top. I just liked using it better to get the posts in. The mighty putty was wayyyyy better to use as a sculpting agent.

Here's what it looks like on the inside of my helmet with the screws in.

As Fudz can tell you in his thread, the Bubble visor just completes the look of the MK 5 so much better than a flat motorcycle visor. I got mine off ebay. Just search Bubble visor. The only drawback to that visor is that it doesn't quite fit around the side of the helmet all the way... there is a gap, and its not exactly small

Now, I was short on time so to get around this dilemma, I just took a couple pieces of craft foam and used double sided tap to pold them against the visor and the gap.

This is a close up shot, so it looks kinda bad here but if you look at my first post with me wearing it you can't tell.

What I plan to do to fix this is try to fit the gap with another piece of that same type visor. I will order another one here when I have the cash and just cut the pieces to fit, and screw them in the same way I did above. I can use a small amount of glue on the seam to make it look more natural. If that does not work, then I'll try what fudz did with styrene, or I will try to re-do what I have with the foam.

That's my last update for the evening. I'll post what I did for my harness setup and what I used soon. After that, I won't have anything new for a while until the holidays are over and I can spend time (and money) working on it again.

My helmet still has lots of work to be done on it. I still need to put LED's and a fan in, as well as the foam around my head. I have some in there temporarily, but I need a more final solution. I also need to make a few revisions to the visor, and fill the gaps.

First off, a BIG thank you to BLACKULA for his visor tutorial. It was very helpful to me. If you have not seen it, check out my first post in this thread for the link. -WELL WORTH YOUR TIME.

Helmet went like this:

Bondo'd to my liking > visor test fit > cut visor > test fit > more cuts > Epoxy in the bases for the screw posts > put in screw posts > Epoxy over them > mark and drill holes on visor > push into place > Put on screws > verify position and decide if I like it > Make adjustments > remove visor > Prime helmet > Paint helmet > Clear coat helmet > Attach visor.

Take visor and cover it in plastic wrap and masking tape, then trace the outline of the visor using the one I cut out of the glassed helmet

Cut it so it fits into place as good as the helmet allows

Epoxy in the bases so the screws have something to grab to (I have 3 on top, 1 on bottom as thats what spacing allowed).

Kind of a bad shot, but it has all 4 posts.

I used mighty putty as was recommended, and then I put JB weld on top. I just liked using it better to get the posts in. The mighty putty was wayyyyy better to use as a sculpting agent.

Here's what it looks like on the inside of my helmet with the screws in.

As Fudz can tell you in his thread, the Bubble visor just completes the look of the MK 5 so much better than a flat motorcycle visor. I got mine off ebay. Just search Bubble visor. The only drawback to that visor is that it doesn't quite fit around the side of the helmet all the way... there is a gap, and its not exactly small

Now, I was short on time so to get around this dilemma, I just took a couple pieces of craft foam and used double sided tap to pold them against the visor and the gap.

This is a close up shot, so it looks kinda bad here but if you look at my first post with me wearing it you can't tell.

What I plan to do to fix this is try to fit the gap with another piece of that same type visor. I will order another one here when I have the cash and just cut the pieces to fit, and screw them in the same way I did above. I can use a small amount of glue on the seam to make it look more natural. If that does not work, then I'll try what fudz did with styrene, or I will try to re-do what I have with the foam.

That's my last update for the evening. I'll post what I did for my harness setup and what I used soon. After that, I won't have anything new for a while until the holidays are over and I can spend time (and money) working on it again.

Last edited by a moderator:

It's been a while since I've had any updates on my suit- the Weather here has been much nicer and I finally have some space to start working again.

-I just ordered LEDs for my suit and I will give it a shot wiring them myself

-I still need to adjust strapping and document it here to share

-My helmet visor has an issue... the mighty putty separated from the fiberglass and is not anchoring the visor to the helmet in one spot. This sounds bad but now that I've looked at it I see where I went wrong. I put too much stress on that point and it just couldn't hold it. If I can add more anchor screws or find a way to adhere it in a few more places, it should work much better.

I'm ready for spring! I have so much to dooooooooooooo!!

-I just ordered LEDs for my suit and I will give it a shot wiring them myself

-I still need to adjust strapping and document it here to share

-My helmet visor has an issue... the mighty putty separated from the fiberglass and is not anchoring the visor to the helmet in one spot. This sounds bad but now that I've looked at it I see where I went wrong. I put too much stress on that point and it just couldn't hold it. If I can add more anchor screws or find a way to adhere it in a few more places, it should work much better.

I'm ready for spring! I have so much to dooooooooooooo!!

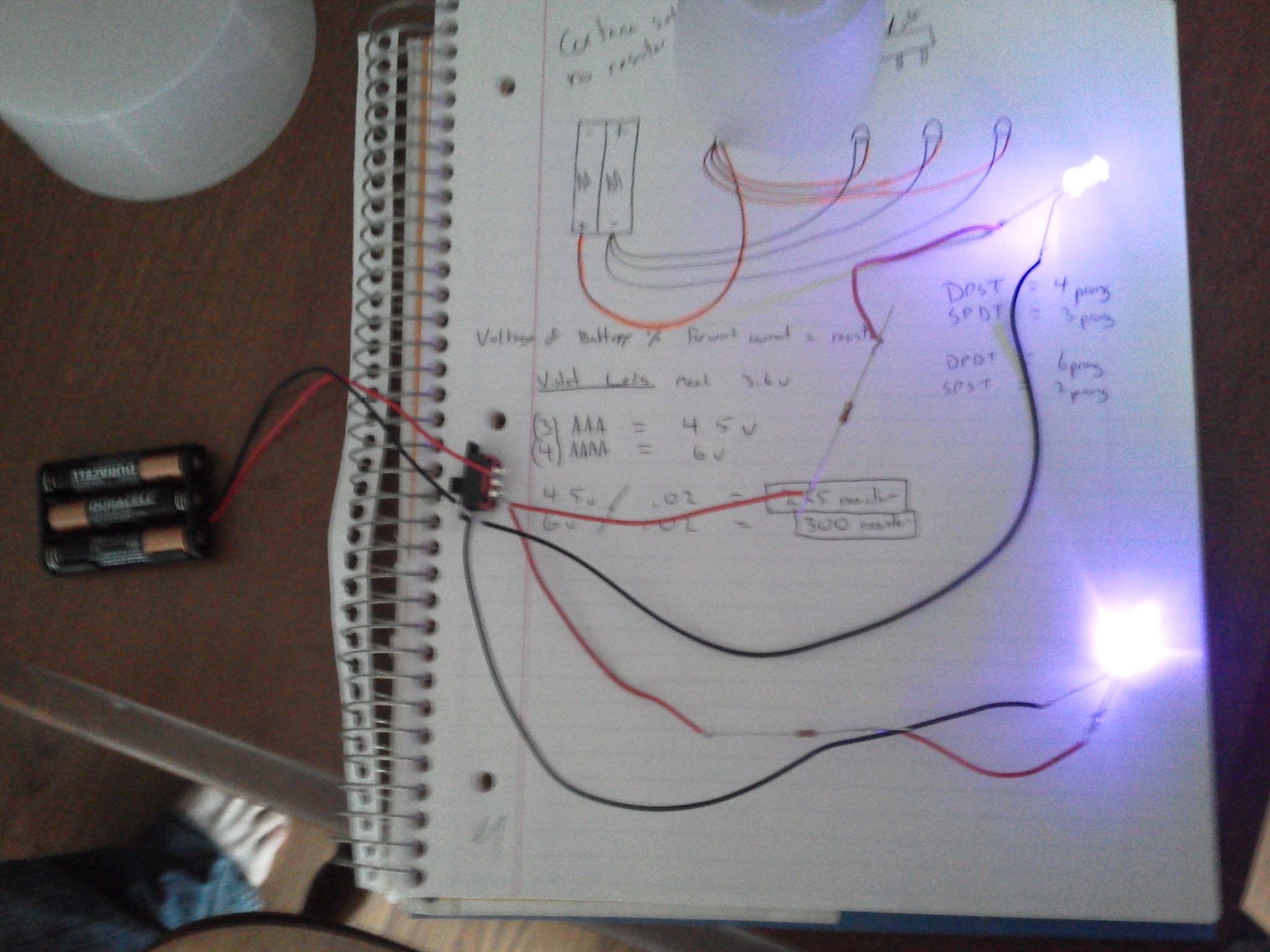

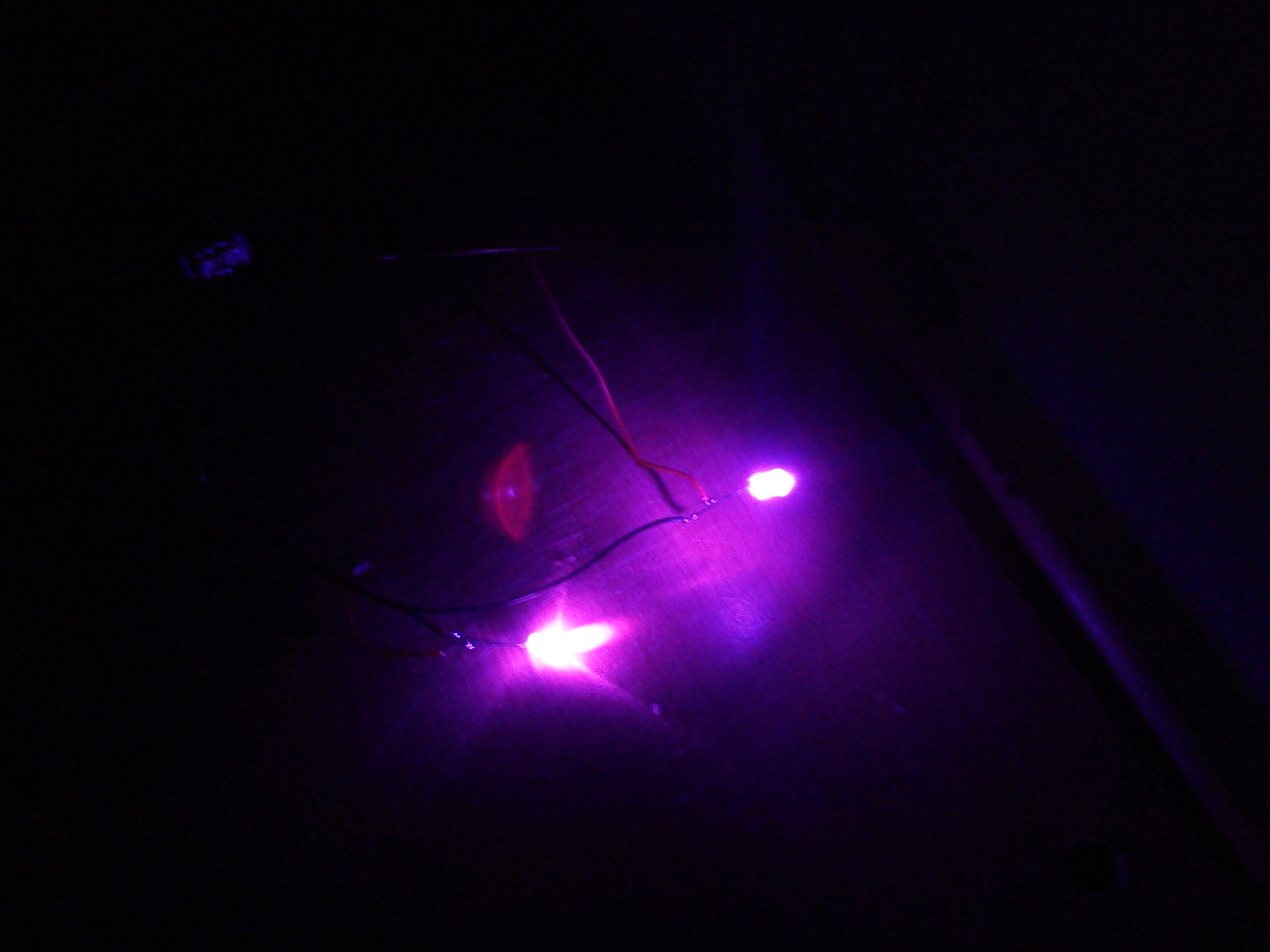

Small but important update: My LEDs have arrived and I've been experimenting with them. So far, I've only fried 2 and I found the mistake I was making. The smell of a burning LED is.... odd.

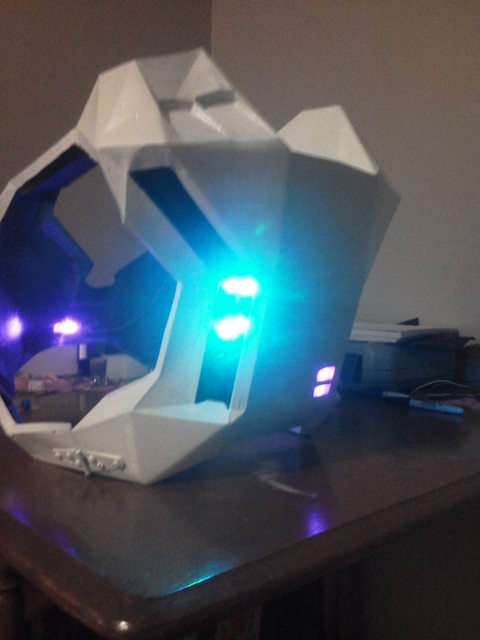

Throughout my suit, my lights will be violet. I decided on violet because I wanted to do something different than what you normally see in 405 builds, and I also think the violet is a nice compliment to my white suit. I'll have a couple of blue and green ones on the back.

Here is a basic circuit I made to see what they could look like- I still need to start installing them into the suit.

Throughout my suit, my lights will be violet. I decided on violet because I wanted to do something different than what you normally see in 405 builds, and I also think the violet is a nice compliment to my white suit. I'll have a couple of blue and green ones on the back.

Here is a basic circuit I made to see what they could look like- I still need to start installing them into the suit.

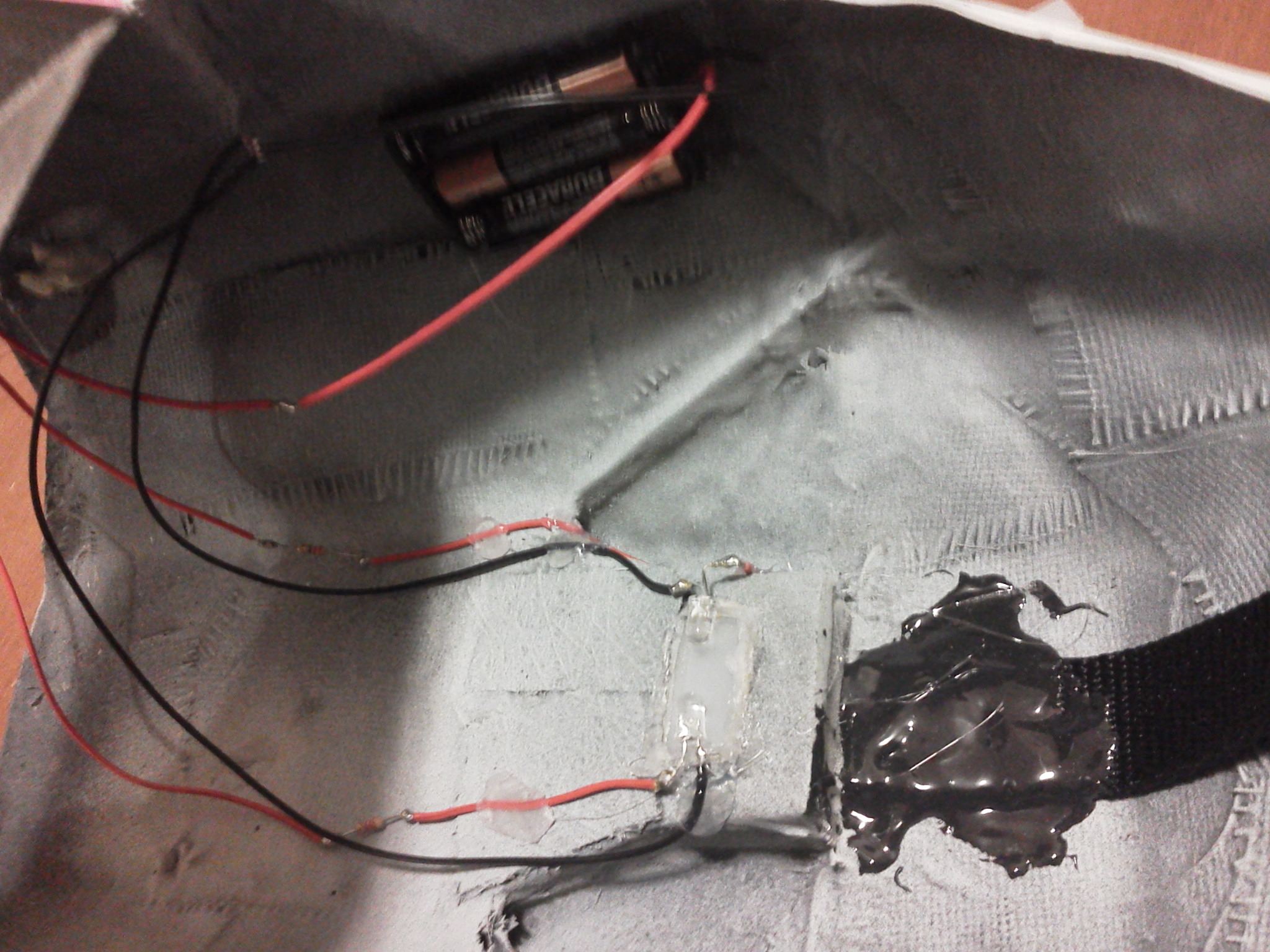

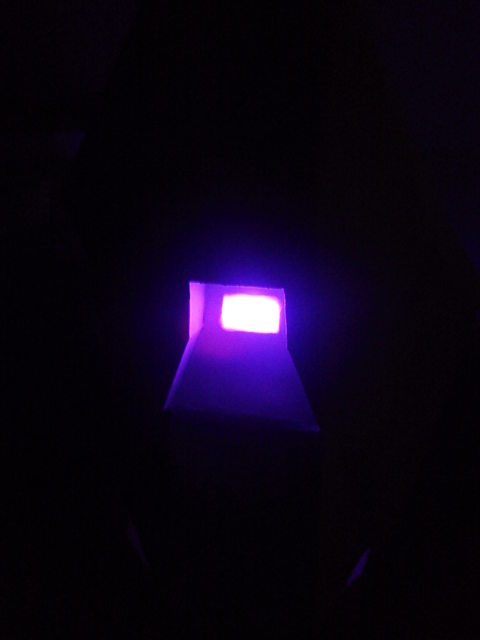

I finished a shoulder piece last night. I wired in 2 violet LEDs for the light and it looks pretty sweet. I was fretting over what to use for the "window" that all the lights will shine through and then it hit me that I could just cut up the caps from the Bondo containers. They diffuse the light just right!

I hot glued a batter pack (3 AAA) into the piece and then soldered the LEDs, resistors, and a slide switch to the assembly.

I put the slide switch on the front so I could easily switch it on/off myself. I thought about hiding it, but then I'd have to have someone else switch it for me. It's not noticeable where I have it so I happy with it.

Here is what it looks like when switched on ( I know the piece is dirty, I need to wash it )

)

Here is what it looks like in the dark with my cell camera

Lol right now my thread is all me replying to me

I will keep posting these updates because it helps to keep me going, but if you read this and have any comments or suggestions, I would love to hear them!!

I hot glued a batter pack (3 AAA) into the piece and then soldered the LEDs, resistors, and a slide switch to the assembly.

I put the slide switch on the front so I could easily switch it on/off myself. I thought about hiding it, but then I'd have to have someone else switch it for me. It's not noticeable where I have it so I happy with it.

Here is what it looks like when switched on ( I know the piece is dirty, I need to wash it

Here is what it looks like in the dark with my cell camera

Lol right now my thread is all me replying to me

I will keep posting these updates because it helps to keep me going, but if you read this and have any comments or suggestions, I would love to hear them!!

i think the purple LEDs look awesome. i've never seen them in purple before. if i ever make a covie helmet of some sort i may have to look them up, they have a more unearthly colour to them than the standard blue/green/white LEDs that you see in almost every hobby store. like Kyre said, they really do compliment your suit, and makes it just so much more customized and personal. at least you'll have fewer ignorant people confusing you for a stormtrooper  ...

...

moar lights!

Haha Thanks guys! It's nice to get some comments on this. I'm not sure if it will help with the storm trooper thing, but I can live with it. I think that moment when someone sees you in your suit and they just stop and go "wow!!" is such a great feeling, to know that you've captivated someone for a moment.

It's been a little while since I've had an update- I've been wiring the other pieces and felt it wasn't worth rehashing the same piece again. This time though, I finished wiring the chest, and I LOVE IT. I wish I would have used a couple more lights in it

The front is one single violet led

The sides are harder to show off, they are just too bright for my cell camera to separate.

They are staggered like this:

G___ B

_ UV

G

__ B

The two windows on the back each have 1 purple led (non ultra violet)

The wiring wasn't too complicated, but the soldering was tricky since I ran out of thin wire and had to use a slightly higher gauge that was harder to bend with my fingers. The switch is in the front vent, and it's powered by 3 C batteries. If anyone is interested, I will post a wiring diagram for how I set this one up.

Next, I wire the helmet and then start to re pad my suit for a convention in June.

Haha Thanks guys! It's nice to get some comments on this. I'm not sure if it will help with the storm trooper thing, but I can live with it. I think that moment when someone sees you in your suit and they just stop and go "wow!!" is such a great feeling, to know that you've captivated someone for a moment.

It's been a little while since I've had an update- I've been wiring the other pieces and felt it wasn't worth rehashing the same piece again. This time though, I finished wiring the chest, and I LOVE IT. I wish I would have used a couple more lights in it

The front is one single violet led

The sides are harder to show off, they are just too bright for my cell camera to separate.

They are staggered like this:

G___ B

_ UV

G

__ B

The two windows on the back each have 1 purple led (non ultra violet)

The wiring wasn't too complicated, but the soldering was tricky since I ran out of thin wire and had to use a slightly higher gauge that was harder to bend with my fingers. The switch is in the front vent, and it's powered by 3 C batteries. If anyone is interested, I will post a wiring diagram for how I set this one up.

Next, I wire the helmet and then start to re pad my suit for a convention in June.

Last edited by a moderator:

Hey Thorn thanks! Hearing that from you is quite a compliment. I'll be posting some more updates here soon, I've got a convention I'm wearing it at this weekend. I'm pretty much done with it at this point. I've made a ton of mistakes but I've learned a lot and I plan on remaking it, but with foam to see if that improves anything.

GANGST3RGAM3R

New Member

Awesome Progress

Nice Job man. I am makin a halo mk. v helmet, but not the hd one. great job man. good luck.

Nice Job man. I am makin a halo mk. v helmet, but not the hd one. great job man. good luck.

Nice Job man. I am makin a halo mk. v helmet, but not the hd one. great job man. good luck.

Thanks for the compliment! I really like the MK V and it's good to see that people are still interested in making it.

Update time!

Well it's been a while but I've finally had time to get some of my content uploaded to share with you all. I recently went to a Haunters convention here in my home town and used the opportunity to show off my suit. At this point, my suit is 99% done- there isn't really another level I can take this specific build to at this point without remaking the suit completely. I've learned quite a bit for when I want to remake it. I still plan to post at least a few more updates to this thread regarding how I wired my suit, and how I did the strapping and packing.

Oh, one other thing I learned is to have someone take moar pictures of me when I'm walking around! Lol for most of the ones I have to share I'm in the same position- this is accidental! My girlfriend only had her cell phone to take pictures with and 1/2 of them didn't come out good (naturally, these are the ones where I'm posed different). So here's what I got, lights and all!

So, when the convention arrived I realized I needed a way to move my armor, all of it at once. This is one of those things I bet a lot of people don't think about when traveling with it but I think I came to a pretty elegant solution:

I wanted everything to look official, even the cases. It took me a while to find one that would hold the entire chest piece (mine is not split). I didn't purchase these all at once, that is why they are not the same. The larger boxes were clear, so I got some spray paint specifically for plastic and painted the inside, I think the effect is great! it looks just like the ones from Reach. I found some custom stickers from a seller on etsy.com and bought a bunch to complete the look. I also LOVE the ONI logo haha. Add a couple of ratchet straps and a folding dolly and BAM, I can transport this all at once.

The girlfriend and I

One of my friends

Another one of my friends who had never seen any of my build

^^ I got this look a lot from people, and that was pretty frickin cool. When a little kid spots you and and their jaws drop and they say "Wow!!!!!!" you know you've done a good job. I had a small army of kids following me though the floor for a while lol.

This humvee was bad-ass. They offered to let me climb into the gunner seat and I really, really, REALLY wanted to but I couldn't fit

The hummer was decked out with a couple of machine guns on the hood and all kinds of zombie stuff. It was from a haunted house somewhere in Ohio.

Also got a pic with Nix Herrera (A special effects artist who was recently on the SCI-FI show "Face Off"). My girlfriend is pretty good friends with him. His mustache is epic.

So I decided I wanted in on it

I didn't wear the cod piece when I was out. I found that it really restricted my movement, and honestly no one really noticed anyway. In my next build, I'm going to try to improve on it so that I can wear it, but I won't do the space diaper. I don't see the point, and I like the Reach style belt/cod better so I'll make it look like that I think.

That's all I have for this post. I need to start remembering to get more content when I'm out wearing it. I'm still waiting for pics from some other people I know who took some but I haven't seen them yet. I also have a couple of small video clips to add in another post but they are not very long and there is no sound from me ripping them from my droid. I'll have them up soon.

Thanks for looking!

Skinny ODST Boy

New Member

Amazing work, Revenant. The old boots REALLY bothered me, glad you changed them. Nice moostash, BTW!

You couldn't get in the Humvee? Bet you were like this guy =>

You couldn't get in the Humvee? Bet you were like this guy =>

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 1,146