Re: RobotChicken's Halo 3 Mk VI Master Chief, Ultra Detail, First Build WIP (many pic

The last print is finished and I'm now ready to share some photos of how things turned out. They're not perfect, but I think they're probably good enough for costume parts. First, here is the original UD hand plate pepped and resined:

At first I was trying to print the model horizontally and it just wasn't working due to where all the sharp angles ended up. Simplify3D technical support recommended printing this model upside-down so its flat topside could rest directly on the build platform. That ended in disaster after 19 hours of printing with the supports fused to the model and I gave up with trying to remove them:

So I then went about experimenting with different orientations and support structures to achieve the best results in Simplify3D's slicing preview. Its 5-second slicing time was indispensable compared against Dremel's 45 minutes. Suffice it to say, I will not be using the Dremel software anymore for printing. After about a day of tinkering with different model orientations and support schemes I came up with a print job using 6 meters less filament and 9 hours build time. Here is the second attempt, raw and not cleaned up yet:

It does have some defects near the back due to not enough support material, but I think I'll still use it anyway and inherit the "combat damage" if it ends up not getting cleaned up with Bondo. I revised the supports arrangement and came up with this:

Oddly, with the additional supports added, build time was reduced to roughly 8 and a half hours. Here is how the final one turned out, again raw and not cleaned up yet:

It too has a few defect areas and will take some Bondo work but overall I'm happy with the result and I didn't have to pep it - it printed through the night while I was sleeping. What would have taken me several weeks to pep (I don't get much time each day for working on this) got printed in 2 days and I get to skip the resin and fiberglassing steps.

Incidentally, perhaps you noticed the filament color. I chose to print these using silver filament. That's my clever idea for saving a few steps in the finishing process. After sanding and painting these parts they won't be dry-brushed with silver for weathering - they'll get abused and roughed up to reveal the silver base material under the paint before adding a clear coat. Later, any damage incurred while the kid's wearing it will just end up showing more silver instead of white (or some other color) interior.

I'll get the STL file uploaded later this week after I take care of some modeling on the cod project.

The last print is finished and I'm now ready to share some photos of how things turned out. They're not perfect, but I think they're probably good enough for costume parts. First, here is the original UD hand plate pepped and resined:

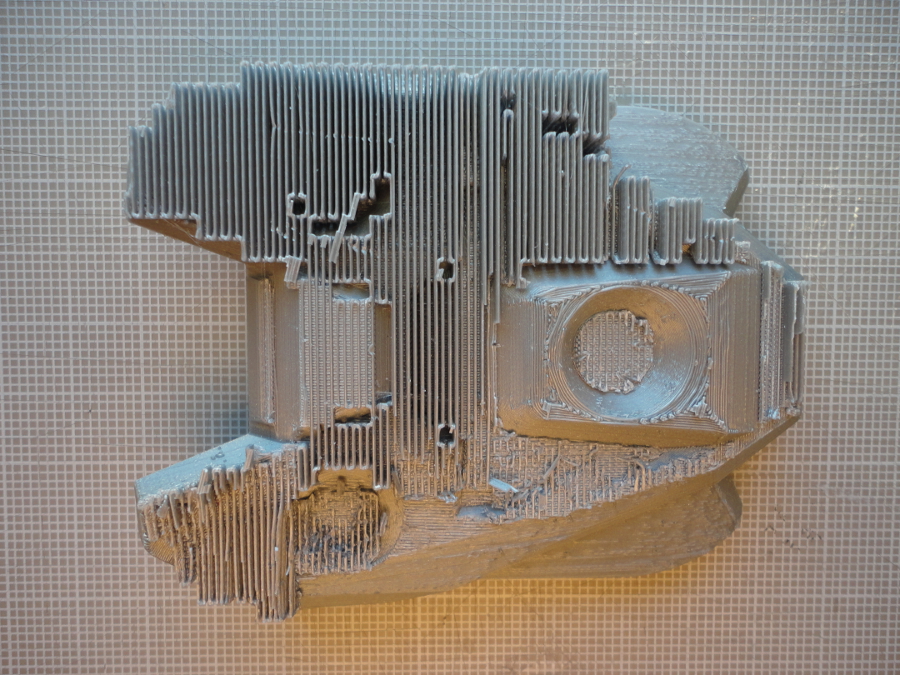

At first I was trying to print the model horizontally and it just wasn't working due to where all the sharp angles ended up. Simplify3D technical support recommended printing this model upside-down so its flat topside could rest directly on the build platform. That ended in disaster after 19 hours of printing with the supports fused to the model and I gave up with trying to remove them:

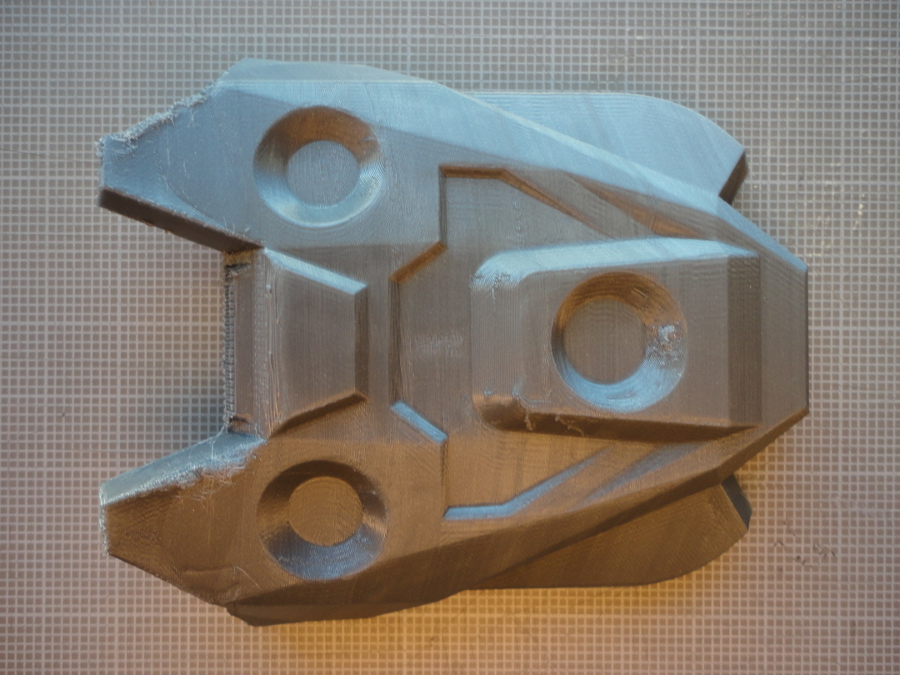

So I then went about experimenting with different orientations and support structures to achieve the best results in Simplify3D's slicing preview. Its 5-second slicing time was indispensable compared against Dremel's 45 minutes. Suffice it to say, I will not be using the Dremel software anymore for printing. After about a day of tinkering with different model orientations and support schemes I came up with a print job using 6 meters less filament and 9 hours build time. Here is the second attempt, raw and not cleaned up yet:

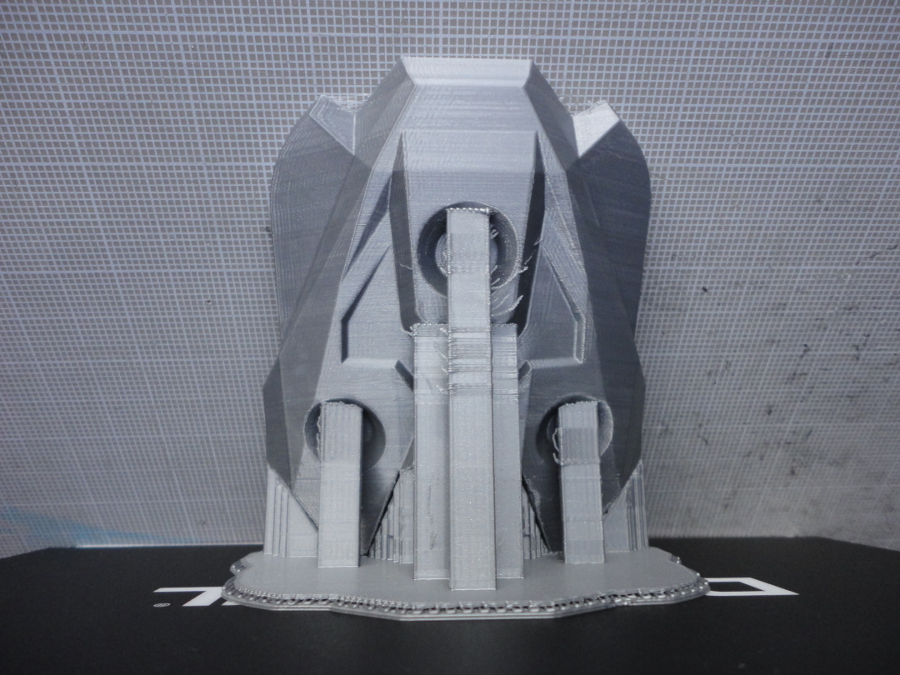

It does have some defects near the back due to not enough support material, but I think I'll still use it anyway and inherit the "combat damage" if it ends up not getting cleaned up with Bondo. I revised the supports arrangement and came up with this:

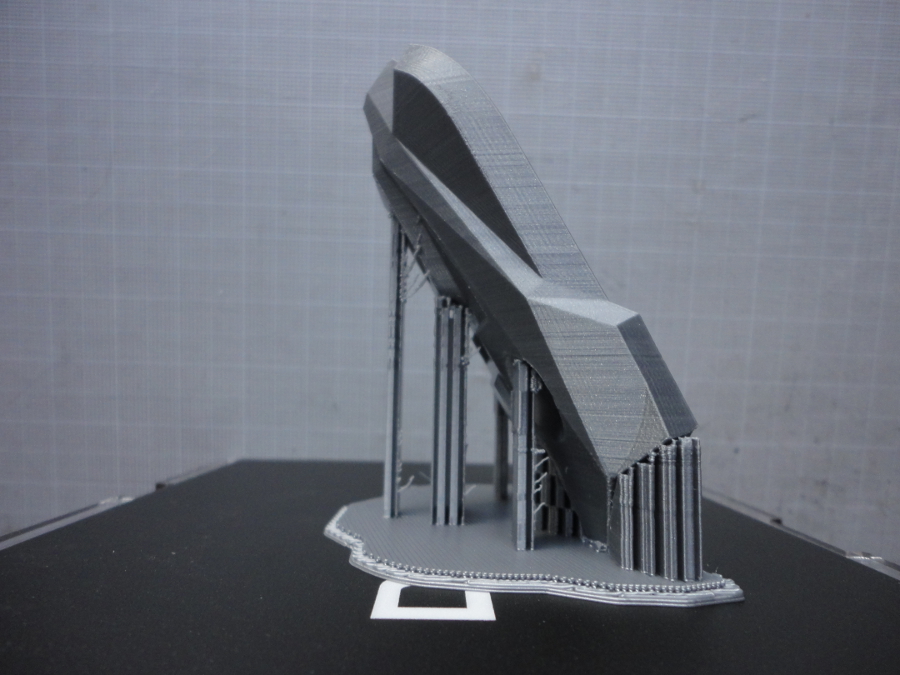

Oddly, with the additional supports added, build time was reduced to roughly 8 and a half hours. Here is how the final one turned out, again raw and not cleaned up yet:

It too has a few defect areas and will take some Bondo work but overall I'm happy with the result and I didn't have to pep it - it printed through the night while I was sleeping. What would have taken me several weeks to pep (I don't get much time each day for working on this) got printed in 2 days and I get to skip the resin and fiberglassing steps.

Incidentally, perhaps you noticed the filament color. I chose to print these using silver filament. That's my clever idea for saving a few steps in the finishing process. After sanding and painting these parts they won't be dry-brushed with silver for weathering - they'll get abused and roughed up to reveal the silver base material under the paint before adding a clear coat. Later, any damage incurred while the kid's wearing it will just end up showing more silver instead of white (or some other color) interior.

I'll get the STL file uploaded later this week after I take care of some modeling on the cod project.