Is leak seal flexible?Not quite. Once it cures, it's done. No going back.

Also, try out LeakSeal as a coating. Does way better than plastidip, and is sandable.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TurboCharizard's Halo Reach CQB Build Log

- Thread starter TurboCharizard

- Start date

- Status

- Not open for further replies.

Yup. It's like this hybrid plasti dip-truck bed liner sort of thing. It's not as flexible as plasti dip, but it is fairly easy to sand. If you get wrinkles in some foam that is coated in leak seal, hit the coating with a heatgun. Wrinkles begin to vanish. Let it sit for 12 hours for them to be completely gone. The finish is similar to plasti dip, but with less bubbles when applied properly. (thin coats)Is leak seal flexible?

I can show some pics later.

- Member DIN

- S068

Yup. It's like this hybrid plasti dip-truck bed liner sort of thing. It's not as flexible as plasti dip, but it is fairly easy to sand. If you get wrinkles in some foam that is coated in leak seal, hit the coating with a heatgun. Wrinkles begin to vanish. Let it sit for 12 hours for them to be completely gone. The finish is similar to plasti dip, but with less bubbles when applied properly. (thin coats)

I can show some pics later.

The super goo from Woodland Scenics will be here in two weeks time, I have PlastiDip and Leak Seal is at Home Depot five minutes from home, should I just add a bunch of different things to the test bed for science?

I don't see why not!The super goo from Woodland Scenics will be here in two weeks time, I have PlastiDip and Leak Seal is at Home Depot five minutes from home, should I just add a bunch of different things to the test bed for science?

- Member DIN

- S068

[SLIPSPACE RUPTURE DETECTED]

[SLIPSPACE RUPTURE DETECTED]

[SLIPSPACE RUPTURE DETECTED]

ahem...

[PHOTO DUMP INBOUND]

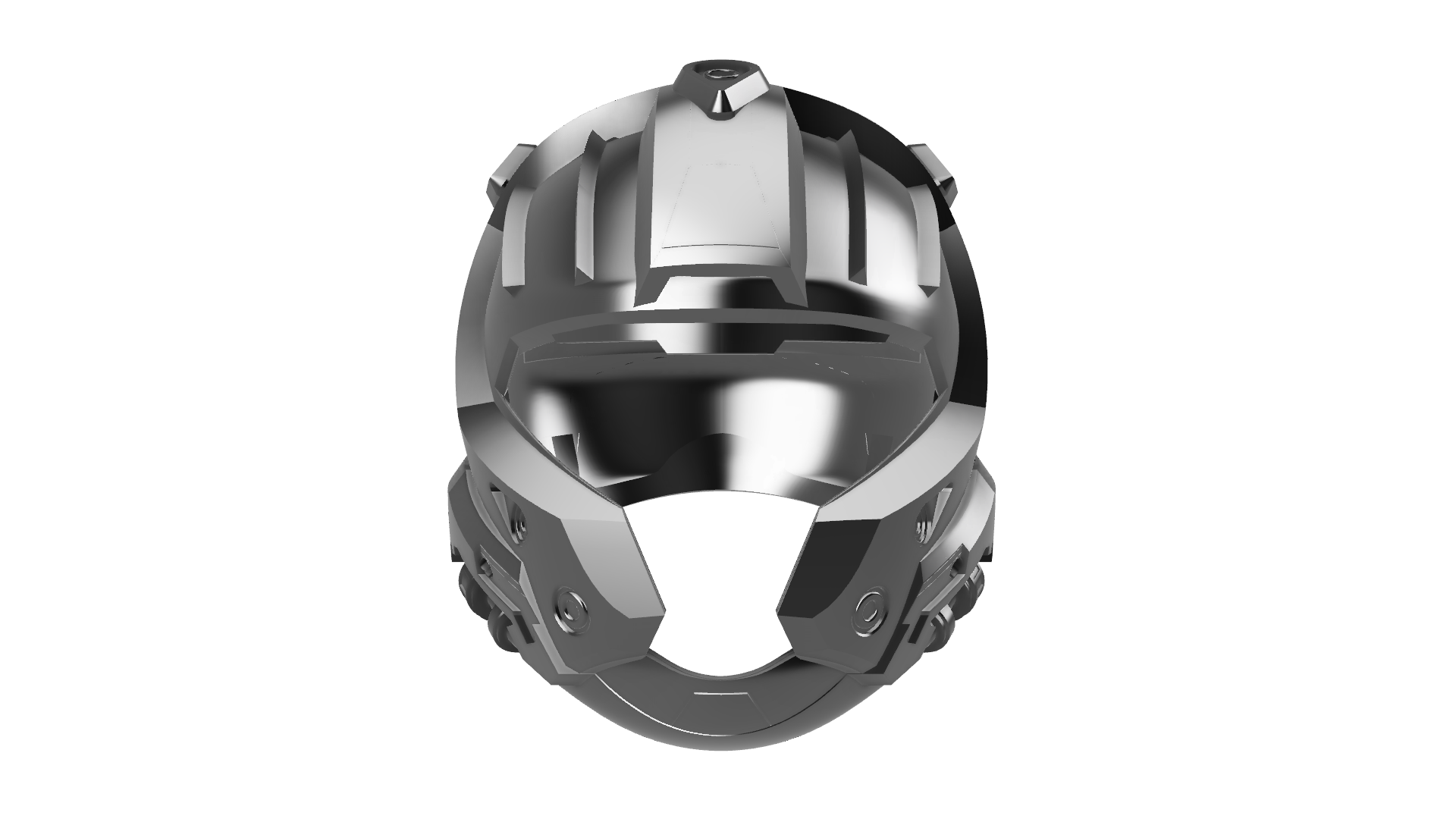

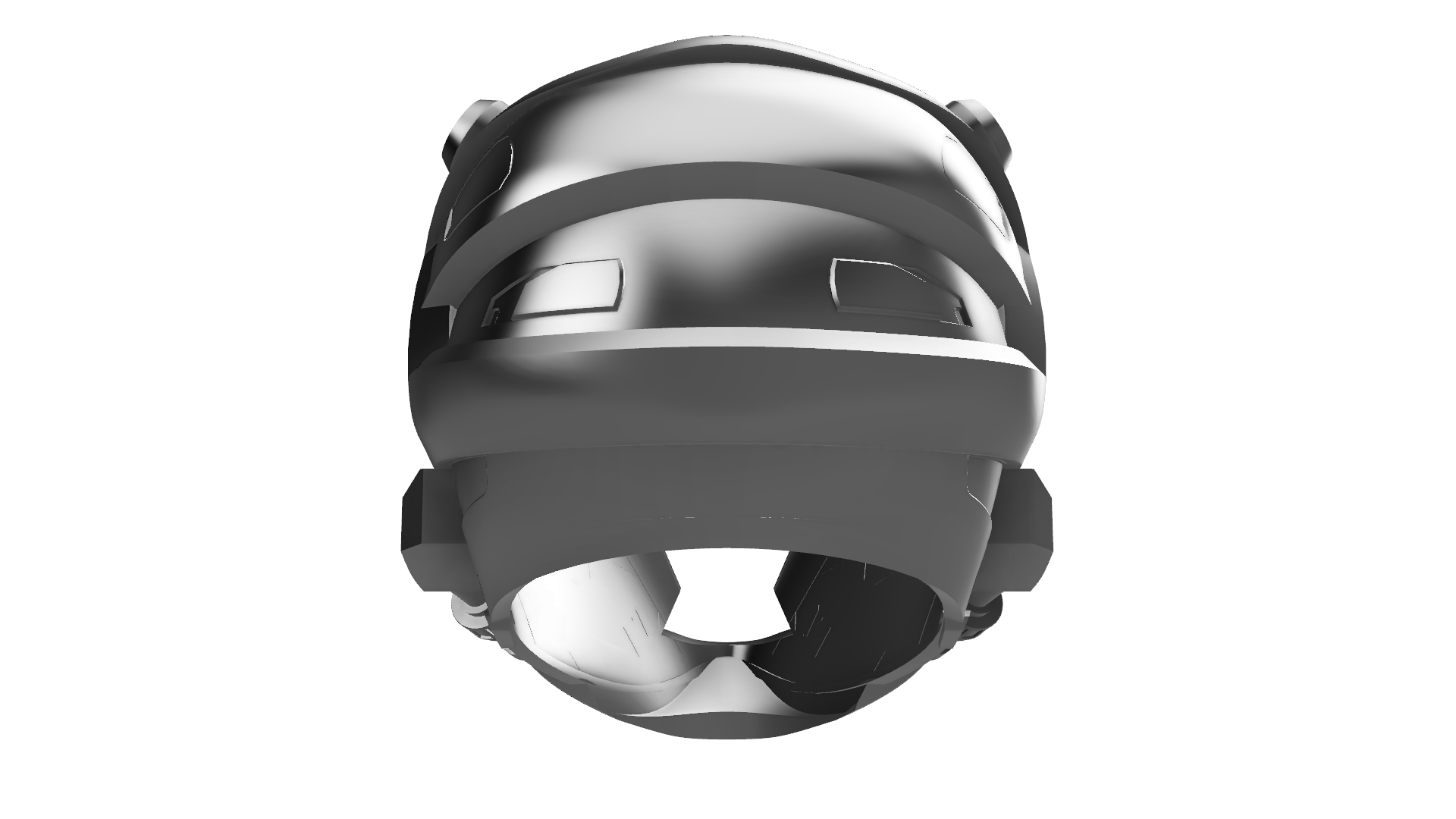

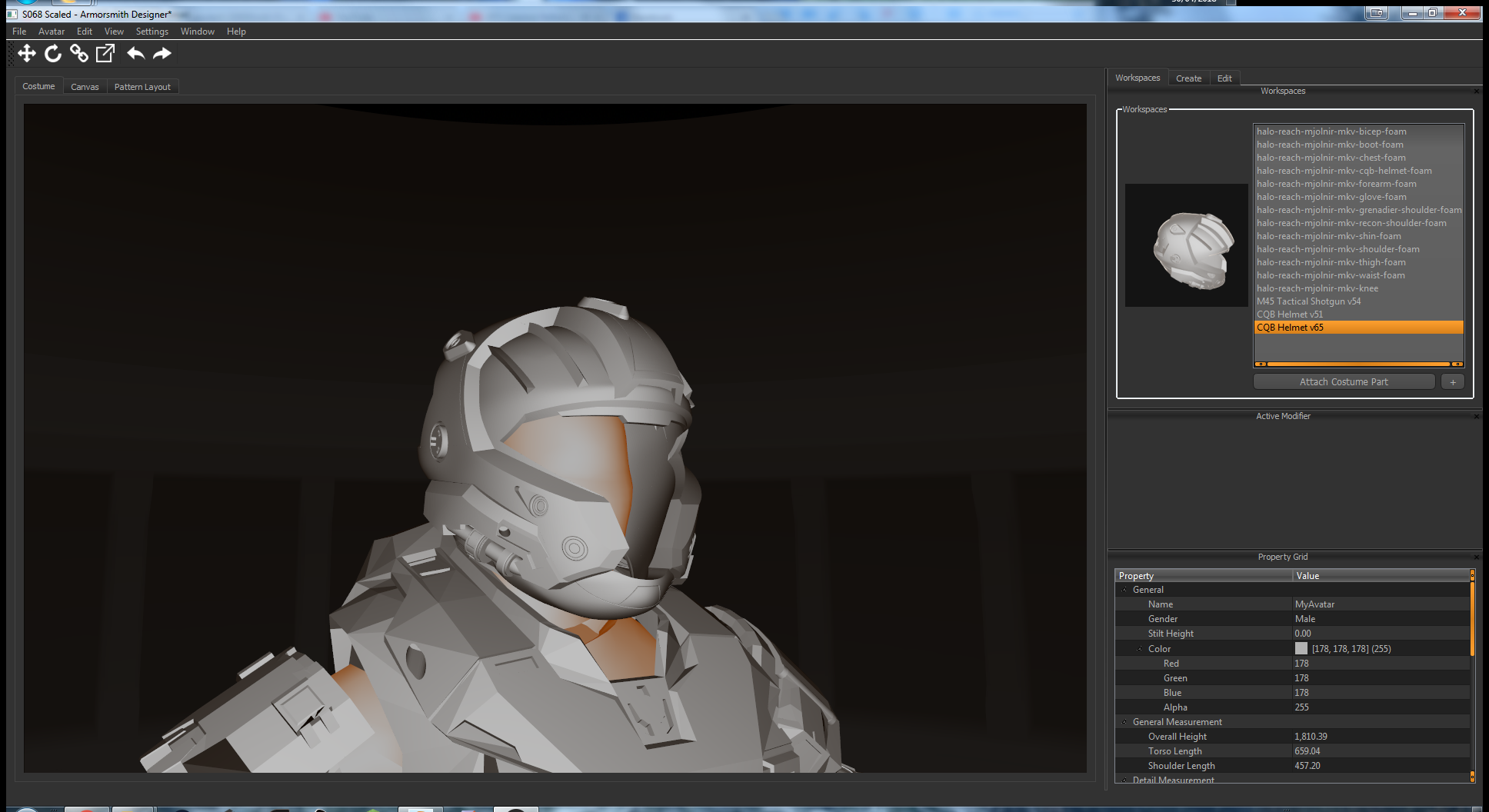

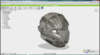

I've gone over every possible reference image I can find at this point and I think the only thing that has more detail than my model at this point is the original concept art with some small panel divides on the top three ports that I wasn't digging. So here it is. The only things missing at this point are some flexible hose to cover over piping on the side panels, two small aluminum tubing and four spacers or gaskets which I decided to add after as non printed parts to make printing easier.

Fancy pictures? Fancy Pictures.

Not bad for about ten hours work. Tomorrow I go wandering around the electronics store to figure out cooling fans and a light bar for inside the fin. I leave you with one last image, gorram pride. This thing isn't even made yet and it has me all giddy with how cool everything is going to look.

[SLIPSPACE RUPTURE DETECTED]

[SLIPSPACE RUPTURE DETECTED]

ahem...

[PHOTO DUMP INBOUND]

I've gone over every possible reference image I can find at this point and I think the only thing that has more detail than my model at this point is the original concept art with some small panel divides on the top three ports that I wasn't digging. So here it is. The only things missing at this point are some flexible hose to cover over piping on the side panels, two small aluminum tubing and four spacers or gaskets which I decided to add after as non printed parts to make printing easier.

Fancy pictures? Fancy Pictures.

Not bad for about ten hours work. Tomorrow I go wandering around the electronics store to figure out cooling fans and a light bar for inside the fin. I leave you with one last image, gorram pride. This thing isn't even made yet and it has me all giddy with how cool everything is going to look.

- Member DIN

- S240

Amazing work...... someday I will get around to actually learning how to model. Really dampens your 3d printing capabilities when you aren’t able to model something from scratch.

- Member DIN

- S068

Yes I amMy, My, aren't you a pretty little thing.

Amazing work...... someday I will get around to actually learning how to model. Really dampens your 3d printing capabilities when you aren’t able to model something from scratch.

Sit down with TinkerCAD for a bit and work through their tutorials to get a head space for combining shapes and doing 3D operations. I'm a fan of Fusion 360 but it's definitely not the end all be all of design suites, take a look around at a few different options and work with what feels good.

- Member DIN

- S068

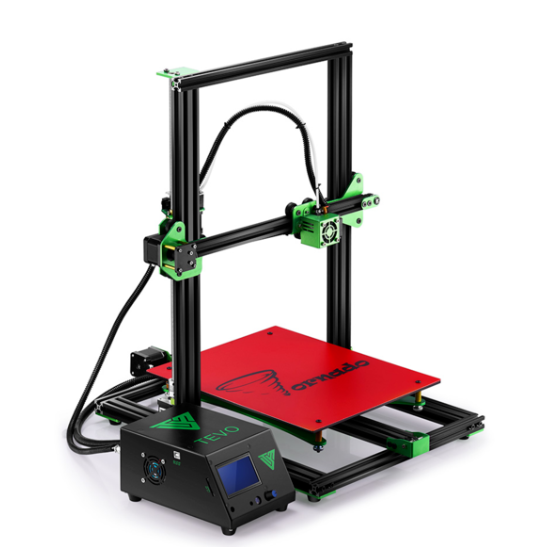

So um... Uh... I might have bought a second printer.

This one can pretty much print helmets in one go, no splitting. Dear 300mm x 300mm x 400mm build volume, my body is ready. I think the maiden voyage of the Tevo Tornado (still unnamed) will be the M45 in significantly fewer parts than on my Wanhao.

Also, 47 hours into printing the helmet, we're a quarter of the way there. Test pieces are looking jawesome and the fit will be snug but easy to slip on, I'm freaking excited. Only 9 more days of continuous printing to go!

This one can pretty much print helmets in one go, no splitting. Dear 300mm x 300mm x 400mm build volume, my body is ready. I think the maiden voyage of the Tevo Tornado (still unnamed) will be the M45 in significantly fewer parts than on my Wanhao.

Also, 47 hours into printing the helmet, we're a quarter of the way there. Test pieces are looking jawesome and the fit will be snug but easy to slip on, I'm freaking excited. Only 9 more days of continuous printing to go!

- Member DIN

- S240

Not trying to derail anything here I’m just curious. I haven’t look into printers lately, how does this compare with the cr10? I’m assuming you’ve done a little research. This appears similar in design and price. I’ve just heard of older Tevos having power supply problems and catching fireSo um... Uh... I might have bought a second printer.

View attachment 255180

This one can pretty much print helmets in one go, no splitting. Dear 300mm x 300mm x 400mm build volume, my body is ready. I think the maiden voyage of the Tevo Tornado (still unnamed) will be the M45 in significantly fewer parts than on my Wanhao.

Also, 47 hours into printing the helmet, we're a quarter of the way there. Test pieces are looking jawesome and the fit will be snug but easy to slip on, I'm freaking excited. Only 9 more days of continuous printing to go!

- Member DIN

- S068

Not trying to derail anything here I’m just curious. I haven’t look into printers lately, how does this compare with the cr10? I’m assuming you’ve done a little research. This appears similar in design and price. I’ve just heard of older Tevos having power supply problems and catching fire

From the Canadian suppliers the Tevo is cheaper than the comparable CR-10 but has several parts that are machined aluminum on the Tornado as opposed to plastic on the CR-10 (places like the lead screw supports and a few others). The heated bed is also set up differently using a separate circuit from the rest of the controller and has an insulated coil that halves the warm up time. Also, Creality has done some semi-shady things with regards to their OpenGL license and /may/ get in a bit of poo or the owners of machines may just suffer a bit because of it and I wanted to avoid that. There's a few other things different between the two but from what I can tell the Tevo is a clone that is cheaper but has improvements on the material it's copying so everything is awesome.

With regards to fires, that's pretty much the risk anyone who leaves a machine running hot for hours on end really. I'm going to be starting to build a new printer station to house both the new printer and the old one. Benefit to the new station being that it'll have better insulation than sitting on a table beside my desk and there'll be a smoke detector in the unit as opposed to in the hallway adjacent along with a fire extinguisher on a wall mounted bracket within reach.

AM I DOING THINGS RIGHT? I DON'T KNOW. I'M KIND OF JUST FAKING IT 'TIL I MAKE IT TO BE HONEST.

Ninja Edit

There's going to be sanding for sure but damn is this thing looking rad.

Last edited:

- Member DIN

- S128

Sounds pretty right to me. I'm gonna be mounting a fire extinguisher next to my printer after reading this.

- Member DIN

- S068

So. Yes, I did fall off the face of the earth for a bit. I may have been quiet on the forums for about two weeks but a lot has happened both in build, in my personal life and a bunch of other chaos that has led to a very sleepy TurboCharizard. Anyway, progress photos because that's what you folks like!

The foamsmithing has gone well during the time I was able to get to it, I managed to build to finish off the lower half of the Spartan armour and have worked my way toward the top, this week will be a sprint through the last of the upper body before attempting to build a torso over the course of a few days next week so that I can catch up to the schedule that I set for myself. I likely will not have the M45 or Gravity Hammer finished for the convention I was hoping to debut the costume at (I'd have to skip a week or two at work to get everything done(not happening)) but I may be able to print off an M6G and finish it while working on the helmet.

I made a Spartan Diaper with removable buttplate for ease of changing and the possibility of bathroom breaks while in costume.

I took the pepakura files for the MkV knees and modified them to work with foam since I couldn't find a foam pep in the pack I downloaded from the Armoury. I could be dumb, but I couldn't find it. I'm probably dumb.

The gauntlets were... fun. I've got a small bit of gap filling to do and with a bit of edge grinding and cleanup with the Dremel everything will be good to go.

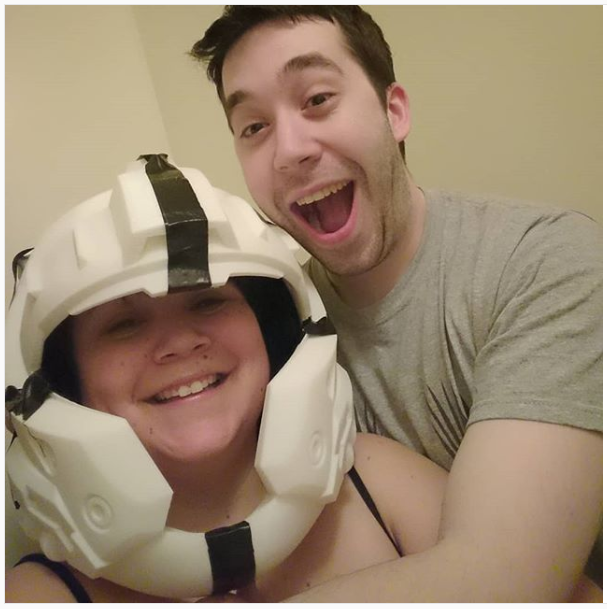

Luckily the helmet didn't require too much hands on effort after the design stage and I could just let the printer do it's thing for a week and a half while I dealt with other more pressing matters. This new bucket is my pride and joy right now and I can't wait until I can get it all prepped for paint. I did a size test to make sure it fit over my melon and kept within scale of my shoulders. Everything seemed good and not too bobble-heady, at least for me with the padding. For her, heh.

Last little bit to update is that I built a little vacuum forming box to do up the visor on. Once the visor is finished I'll be doing a full post on the process from making the model, buck, vacuum former box and visor colouring.

It's a bit of a small post but I hope it'll tide you over until I get back cracking at full tilt.

The foamsmithing has gone well during the time I was able to get to it, I managed to build to finish off the lower half of the Spartan armour and have worked my way toward the top, this week will be a sprint through the last of the upper body before attempting to build a torso over the course of a few days next week so that I can catch up to the schedule that I set for myself. I likely will not have the M45 or Gravity Hammer finished for the convention I was hoping to debut the costume at (I'd have to skip a week or two at work to get everything done(not happening)) but I may be able to print off an M6G and finish it while working on the helmet.

I made a Spartan Diaper with removable buttplate for ease of changing and the possibility of bathroom breaks while in costume.

I took the pepakura files for the MkV knees and modified them to work with foam since I couldn't find a foam pep in the pack I downloaded from the Armoury. I could be dumb, but I couldn't find it. I'm probably dumb.

The gauntlets were... fun. I've got a small bit of gap filling to do and with a bit of edge grinding and cleanup with the Dremel everything will be good to go.

Luckily the helmet didn't require too much hands on effort after the design stage and I could just let the printer do it's thing for a week and a half while I dealt with other more pressing matters. This new bucket is my pride and joy right now and I can't wait until I can get it all prepped for paint. I did a size test to make sure it fit over my melon and kept within scale of my shoulders. Everything seemed good and not too bobble-heady, at least for me with the padding. For her, heh.

Last little bit to update is that I built a little vacuum forming box to do up the visor on. Once the visor is finished I'll be doing a full post on the process from making the model, buck, vacuum former box and visor colouring.

It's a bit of a small post but I hope it'll tide you over until I get back cracking at full tilt.

One would think the gauntlets would be relatively simple to make. Make it out of foam though... head scratching starts and then eventually turns to hair pulling. The most annoying parts are the tiny little bits that require a bevel to get the angles right.The gauntlets were... fun. I've got a small bit of gap filling to do and with a bit of edge grinding and cleanup with the Dremel everything will be good to go.

- Member DIN

- S068

One would think the gauntlets would be relatively simple to make. Make it out of foam though... head scratching starts and then eventually turns to hair pulling. The most annoying parts are the tiny little bits that require a bevel to get the angles right.

I think that the hardest part of them is the slight concave form in certain places which requires leaving extra foam in place to create a bevel that the part that joins to it has a proper mating surface for gluing. There was a bit of that in the Spartan Diaper and shins but nowhere near as small and fiddly.

Oh well, everything fits and has minimal cleanup so I'm a happy chappy. and ready to move on to the next pieces. In other news the foam putty and visor tint arrived in the mail while I was out of town for a bit and THE NEW PRINTER IS OUT FOR DELIVERY.

- Member DIN

- S068

CAFFEINE FUELED PHOTO DUMP

So I've run out of glue and the only store that carries the kind I like is 60km away over a mountain range, so I'll be working on foam stuff later this week, that being said I had the perfect excuse today to assemble the helmet. It started just like every good Canadian Saturday Timmies in hand and in the workshop.

Also, this is a post all about fun chemicals and spinning tools so this is an important reminder.

When working with epoxies, resins, dust and a whole bunch of other stuff that's off-gassing and making a bunch of stuff that'll make your lungs cry, wear your paint and pesticide rated respirator and save yourself some trouble when it comes to dinner time by wearing nitrile gloves. When working with sanders for long periods of time, throw on those ear defenders and if you're using them for any amount of time safety glasses to protect from kicked up debris.

Using a five minute epoxy and almost every clamp that I have in my shop, I started piecing together the eight pieces of the helmet. I started from the top and then worked down and to the back to allow room for clamping, if I had worked in the opposite direction I would have needed a bar clamp of some sort and pressure applied from the inside of the helmet, always plan your order of operations kiddos!

With the epoxy set and the clamps removed it was time to assess how bad the alignment was due to slight peel up of one of the parts from the print bed. There was a little gap filling to be done but nothing a little Bondo couldn't fix. I did a quick sand with a mouse sander to clean up the surface a bit and see what other spots needed a bit of patching or extra care. When filling in gaps in seams and low spots I like to go a bit crazy with Bondo and not worry about applying too much. I layer it on, smooth it out with a tool and any extra that's left there I come back to after about 15 minutes once the Bondo is halfway set and carve it away carefully with a razor. This saves a lot of time sanding and more importantly, sandpaper and sanding pads/sponges. You can use a thin 9mm snap off blade to match the curvature of parts which makes sure you don't take off too much.

After a snack break to let the Bondo fully cure it was MORE SANDING to blend all the seams. All low spots were identified and then filled with a spot putty. Then more sanding and because the weather is nice enough a first coat of filler primer.

But as you know, there is no such thing as too much sanding, I went and did another full pass with a higher grit. Also out of curiosity I wanted to test fit the visor buck into the helmet which makes for a good teaser of my visor making post which will be done in the next couple of days.

It still looks a bit rough but most parts are passing the fingernail scratch test on the helmet and the buck has XTC-3D over it which makes some interesting patterns with the sanded and prepped form below. Another two cycles of filler primer and sanding and this should be nice, glossy and ready for painting. Eight to ten hours well spent today I'd say.

So I've run out of glue and the only store that carries the kind I like is 60km away over a mountain range, so I'll be working on foam stuff later this week, that being said I had the perfect excuse today to assemble the helmet. It started just like every good Canadian Saturday Timmies in hand and in the workshop.

Also, this is a post all about fun chemicals and spinning tools so this is an important reminder.

When working with epoxies, resins, dust and a whole bunch of other stuff that's off-gassing and making a bunch of stuff that'll make your lungs cry, wear your paint and pesticide rated respirator and save yourself some trouble when it comes to dinner time by wearing nitrile gloves. When working with sanders for long periods of time, throw on those ear defenders and if you're using them for any amount of time safety glasses to protect from kicked up debris.

Using a five minute epoxy and almost every clamp that I have in my shop, I started piecing together the eight pieces of the helmet. I started from the top and then worked down and to the back to allow room for clamping, if I had worked in the opposite direction I would have needed a bar clamp of some sort and pressure applied from the inside of the helmet, always plan your order of operations kiddos!

With the epoxy set and the clamps removed it was time to assess how bad the alignment was due to slight peel up of one of the parts from the print bed. There was a little gap filling to be done but nothing a little Bondo couldn't fix. I did a quick sand with a mouse sander to clean up the surface a bit and see what other spots needed a bit of patching or extra care. When filling in gaps in seams and low spots I like to go a bit crazy with Bondo and not worry about applying too much. I layer it on, smooth it out with a tool and any extra that's left there I come back to after about 15 minutes once the Bondo is halfway set and carve it away carefully with a razor. This saves a lot of time sanding and more importantly, sandpaper and sanding pads/sponges. You can use a thin 9mm snap off blade to match the curvature of parts which makes sure you don't take off too much.

After a snack break to let the Bondo fully cure it was MORE SANDING to blend all the seams. All low spots were identified and then filled with a spot putty. Then more sanding and because the weather is nice enough a first coat of filler primer.

But as you know, there is no such thing as too much sanding, I went and did another full pass with a higher grit. Also out of curiosity I wanted to test fit the visor buck into the helmet which makes for a good teaser of my visor making post which will be done in the next couple of days.

It still looks a bit rough but most parts are passing the fingernail scratch test on the helmet and the buck has XTC-3D over it which makes some interesting patterns with the sanded and prepped form below. Another two cycles of filler primer and sanding and this should be nice, glossy and ready for painting. Eight to ten hours well spent today I'd say.

- Member DIN

- S240

Helmets looks amazing!!

- Member DIN

- S2424

How the hell do you get such crisp edges? And the indented areas....? FANTASTIC work!!!!

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 129

- Replies

- 6

- Views

- 510