I’ve been fooling around with the idea of making a suit for a few years now, and figured now’s probably the best time for it – so here goes!

Special kit at my disposal – My days are consumed with architecture and my nights with architectural model making, so I’ve got some special stuff to play with. I have access to laser cutters, 3D printers, and the cherry on top – the university I attend has a composite laboratory which I have access to – meaning I can build a carbon fibre Mjolnir suit – which may very well be the final material.

My background in architecture and model making means I’m good with my hands, and I can provide DWG’s or PDF’s of the suit for you guys to make, (cut and score/fold lines) and give you guys access to free CAD software to scale the suit to your bodies, I may even write a short document on how to use the programs and how to deal with referenced scaling to fit as you.

Update posts will be pretty few and far between, working on PhD stuffs and many other things, but when the end goal will be (hopefully) a gnarly suit made of carbon fibre, they will be worth it. Expecting this build to be a year, possibly 18 months.

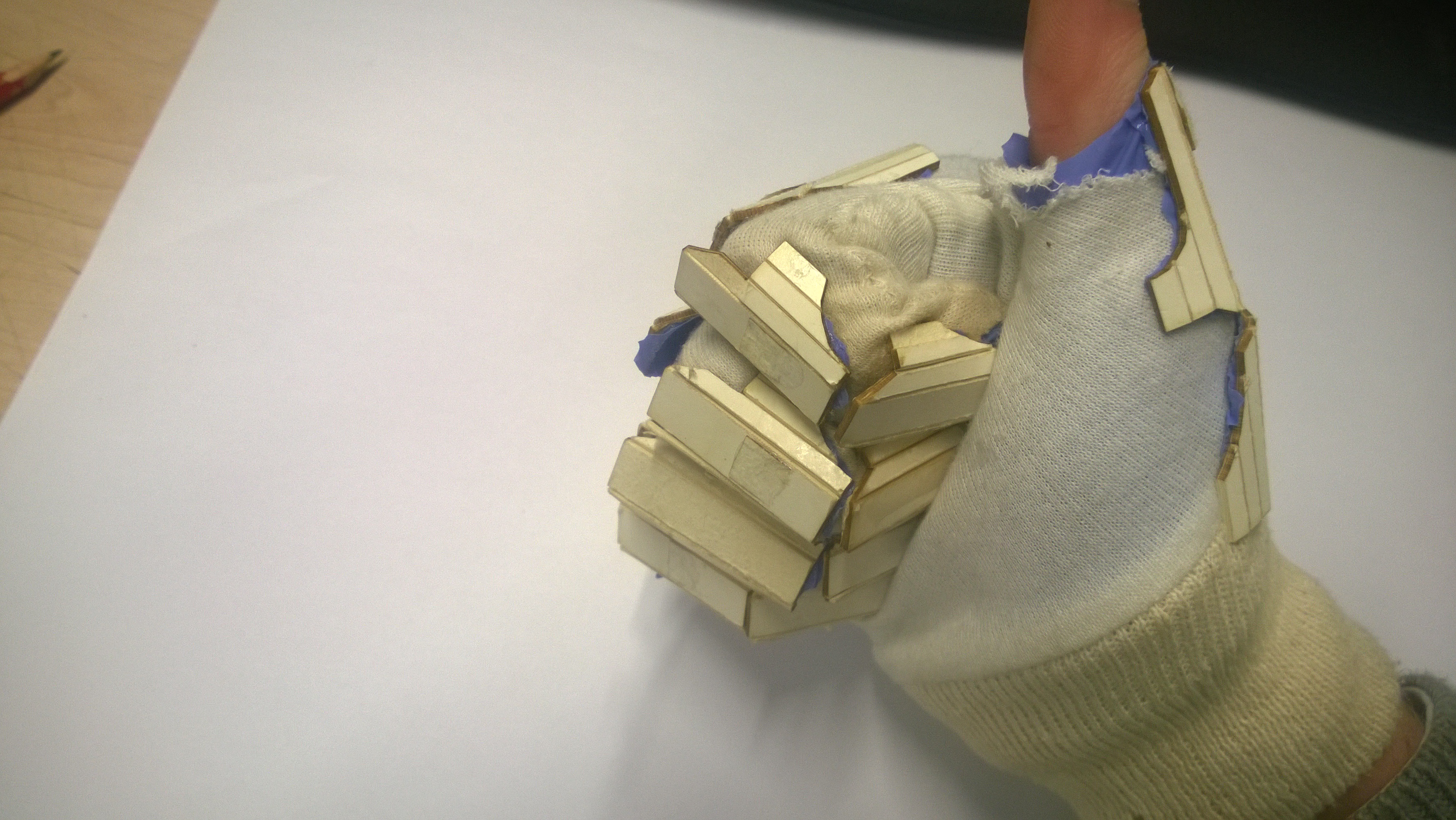

So to start, here’s a glove, made with just some forming card, laser cut and one coat of polyurethane resin kiln cured, resin glued to an old woodworking cotton glove lined with latex to get a rough idea of how it’s going to feel and look – which may change from the chief’s suit, design student, I like to change and improve where I can.

And a little sample of a composite material, stuff is hard

View attachment 246372

View attachment 246376

View attachment 246376

Special kit at my disposal – My days are consumed with architecture and my nights with architectural model making, so I’ve got some special stuff to play with. I have access to laser cutters, 3D printers, and the cherry on top – the university I attend has a composite laboratory which I have access to – meaning I can build a carbon fibre Mjolnir suit – which may very well be the final material.

My background in architecture and model making means I’m good with my hands, and I can provide DWG’s or PDF’s of the suit for you guys to make, (cut and score/fold lines) and give you guys access to free CAD software to scale the suit to your bodies, I may even write a short document on how to use the programs and how to deal with referenced scaling to fit as you.

Update posts will be pretty few and far between, working on PhD stuffs and many other things, but when the end goal will be (hopefully) a gnarly suit made of carbon fibre, they will be worth it. Expecting this build to be a year, possibly 18 months.

So to start, here’s a glove, made with just some forming card, laser cut and one coat of polyurethane resin kiln cured, resin glued to an old woodworking cotton glove lined with latex to get a rough idea of how it’s going to feel and look – which may change from the chief’s suit, design student, I like to change and improve where I can.

And a little sample of a composite material, stuff is hard

View attachment 246372

Last edited: