That's what I was doing at first - using the pliers that came with my printer (well, a set of pliers - I've owned a total of four printers [two were the same model], so I have quite a collection of pliers). It worked well enough to begin with, but there are some spots where I can't get a grip on the pieces to pull it off, so I guess sandpaper is Plan B. What grit would you suggest?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1st Build Cody's ODST Build Thread

- Thread starter ODSTCody

- Start date

- Status

- Not open for further replies.

- Member DIN

- S970

On the raw print 60 grit. Just be really careful you don't start sanding the print itself with 60 grit, It'll chew right through it.That's what I was doing at first - using the pliers that came with my printer (well, a set of pliers - I've owned a total of four printers [two were the same model], so I have quite a collection of pliers). It worked well enough to begin with, but there are some spots where I can't get a grip on the pieces to pull it off, so I guess sandpaper is Plan B. What grit would you suggest?

Another status update inbound, with some major changes to my overall build - both in digital concepts and actual physical progress in realizing said concepts.

Some might notice that I renamed the thread, which was because this is no longer a radio operator build, but is still an ODST costume project that I'm still adamant on finishing. I guess my current concept could be described as a "recon scout" - still using the hexagonal camo pattern (because I am crazy enough to try that), but now with four possible color variants (pictured below - my favorites are #3 and #4, but I'm curious what others think).

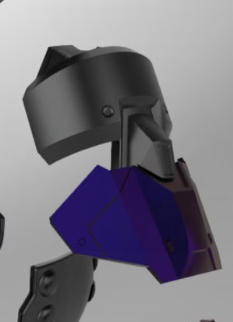

At its core, the recon scout is basically the sharpshooter ODST BDU (worn by Romeo in Halo 3: ODST), but with the addition of a custom right shoulder. I saw this possible combo of shoulder pieces from AguilarWorkshop's ODST set, the upper half of Mickey's CQB shoulder and then a standard lower half, and to me, that makes for a good "light" ODST shoulder - the kind of thing an operator would requisition if he/she needed shoulder protection on both arms, but needed something a little lighter and less bulky/edged than the stock ODST shoulder.

Last part is a sneak preview, a work in progress, of me doing more than just sharing concept art: with the power vested in me by my new-ish Ender 3, I've been printing pieces of the ODST sniper helmet. 6/8 from the helmet itself (not counting the two halves of the O/I device as well as the visor buck). The front upper left piece took about a day and a half, and I haven't attached it due to desiring to attach the mirrored half to it, and then put those two merged parts on the main body of the helmet.

The discolored brown stuff is the same brand of body filled I used before - the reason it's on there was because, like the original helmet I showed off, I printed and assembled the lower half of the helmet first, and I figured that I could make productive use of my time by getting to work on the body filler while that aft upper left part was printing, rather than just sit there doing nothing. While I'm printing the last two upper pieces, I'll continue to apply spot putty and then sand it down, and then once the upper half of the helmet is done, I'll then just attach it, and spot putty the equator and upper half.

That's all for now. I'll keep further progress on the helmet a surprise until a major milestone is achieved, like having the whole thing primed and ready to paint.

Some might notice that I renamed the thread, which was because this is no longer a radio operator build, but is still an ODST costume project that I'm still adamant on finishing. I guess my current concept could be described as a "recon scout" - still using the hexagonal camo pattern (because I am crazy enough to try that), but now with four possible color variants (pictured below - my favorites are #3 and #4, but I'm curious what others think).

At its core, the recon scout is basically the sharpshooter ODST BDU (worn by Romeo in Halo 3: ODST), but with the addition of a custom right shoulder. I saw this possible combo of shoulder pieces from AguilarWorkshop's ODST set, the upper half of Mickey's CQB shoulder and then a standard lower half, and to me, that makes for a good "light" ODST shoulder - the kind of thing an operator would requisition if he/she needed shoulder protection on both arms, but needed something a little lighter and less bulky/edged than the stock ODST shoulder.

Last part is a sneak preview, a work in progress, of me doing more than just sharing concept art: with the power vested in me by my new-ish Ender 3, I've been printing pieces of the ODST sniper helmet. 6/8 from the helmet itself (not counting the two halves of the O/I device as well as the visor buck). The front upper left piece took about a day and a half, and I haven't attached it due to desiring to attach the mirrored half to it, and then put those two merged parts on the main body of the helmet.

The discolored brown stuff is the same brand of body filled I used before - the reason it's on there was because, like the original helmet I showed off, I printed and assembled the lower half of the helmet first, and I figured that I could make productive use of my time by getting to work on the body filler while that aft upper left part was printing, rather than just sit there doing nothing. While I'm printing the last two upper pieces, I'll continue to apply spot putty and then sand it down, and then once the upper half of the helmet is done, I'll then just attach it, and spot putty the equator and upper half.

That's all for now. I'll keep further progress on the helmet a surprise until a major milestone is achieved, like having the whole thing primed and ready to paint.

- Member DIN

- S970

I vote #3 and the helmet is coming together great!Another status update inbound, with some major changes to my overall build - both in digital concepts and actual physical progress in realizing said concepts.

Some might notice that I renamed the thread, which was because this is no longer a radio operator build, but is still an ODST costume project that I'm still adamant on finishing. I guess my current concept could be described as a "recon scout" - still using the hexagonal camo pattern (because I am crazy enough to try that), but now with four possible color variants (pictured below - my favorites are #3 and #4, but I'm curious what others think).

View attachment 328300

At its core, the recon scout is basically the sharpshooter ODST BDU (worn by Romeo in Halo 3: ODST), but with the addition of a custom right shoulder. I saw this possible combo of shoulder pieces from AguilarWorkshop's ODST set, the upper half of Mickey's CQB shoulder and then a standard lower half, and to me, that makes for a good "light" ODST shoulder - the kind of thing an operator would requisition if he/she needed shoulder protection on both arms, but needed something a little lighter and less bulky/edged than the stock ODST shoulder.

View attachment 328301

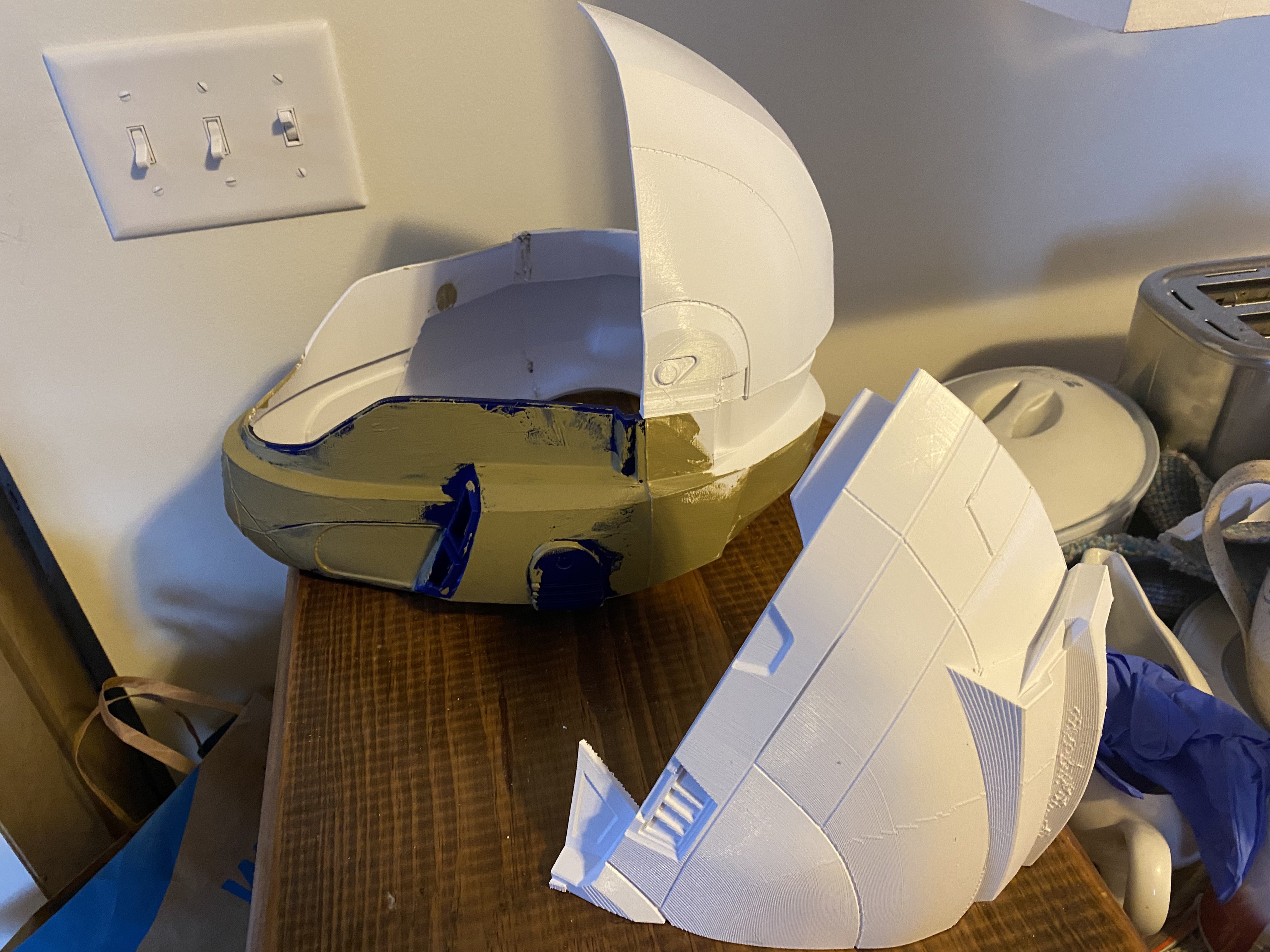

Last part is a sneak preview, a work in progress, of me doing more than just sharing concept art: with the power vested in me by my new-ish Ender 3, I've been printing pieces of the ODST sniper helmet. 6/8 from the helmet itself (not counting the two halves of the O/I device as well as the visor buck). The front upper left piece took about a day and a half, and I haven't attached it due to desiring to attach the mirrored half to it, and then put those two merged parts on the main body of the helmet.

The discolored brown stuff is the same brand of body filled I used before - the reason it's on there was because, like the original helmet I showed off, I printed and assembled the lower half of the helmet first, and I figured that I could make productive use of my time by getting to work on the body filler while that aft upper left part was printing, rather than just sit there doing nothing. While I'm printing the last two upper pieces, I'll continue to apply spot putty and then sand it down, and then once the upper half of the helmet is done, I'll then just attach it, and spot putty the equator and upper half.

View attachment 328302

View attachment 328303

That's all for now. I'll keep further progress on the helmet a surprise until a major milestone is achieved, like having the whole thing primed and ready to paint.

Thanks, DeltaAlphaZulu!

As a side note, a mini-status update I want to share is that when I woke up today, I got a message from the Etsy seller who's printing the rest of my armor. He said that most of it has been printed, with only the larger leg parts (one of the thighs [he's already printed one of the two] and then the shin armor), as well as the prop weapons, remaining. With any luck, the helmet will be good to go (minus the visor) by the time the rest of the costume arrives, at which point I can get painting, get the visor made and installed, and then put it all together.

I'm also wondering what I should do for the two lens of the O/I attachment - they're really small, and as much as I want to dye them, I don't wish for them to warp, or fall in the dye vat and be unretrievable, or something along the lines of that. Any suggestions on how to dye those, assuming I shouldn't just paint them?

As a side note, a mini-status update I want to share is that when I woke up today, I got a message from the Etsy seller who's printing the rest of my armor. He said that most of it has been printed, with only the larger leg parts (one of the thighs [he's already printed one of the two] and then the shin armor), as well as the prop weapons, remaining. With any luck, the helmet will be good to go (minus the visor) by the time the rest of the costume arrives, at which point I can get painting, get the visor made and installed, and then put it all together.

I'm also wondering what I should do for the two lens of the O/I attachment - they're really small, and as much as I want to dye them, I don't wish for them to warp, or fall in the dye vat and be unretrievable, or something along the lines of that. Any suggestions on how to dye those, assuming I shouldn't just paint them?

- Member DIN

- S953

Imma big fan of 3, and best of luck with the camo u a legend for doin that!!Another status update inbound, with some major changes to my overall build - both in digital concepts and actual physical progress in realizing said concepts.

Some might notice that I renamed the thread, which was because this is no longer a radio operator build, but is still an ODST costume project that I'm still adamant on finishing. I guess my current concept could be described as a "recon scout" - still using the hexagonal camo pattern (because I am crazy enough to try that), but now with four possible color variants (pictured below - my favorites are #3 and #4, but I'm curious what others think).

View attachment 328300

At its core, the recon scout is basically the sharpshooter ODST BDU (worn by Romeo in Halo 3: ODST), but with the addition of a custom right shoulder. I saw this possible combo of shoulder pieces from AguilarWorkshop's ODST set, the upper half of Mickey's CQB shoulder and then a standard lower half, and to me, that makes for a good "light" ODST shoulder - the kind of thing an operator would requisition if he/she needed shoulder protection on both arms, but needed something a little lighter and less bulky/edged than the stock ODST shoulder.

View attachment 328301

Last part is a sneak preview, a work in progress, of me doing more than just sharing concept art: with the power vested in me by my new-ish Ender 3, I've been printing pieces of the ODST sniper helmet. 6/8 from the helmet itself (not counting the two halves of the O/I device as well as the visor buck). The front upper left piece took about a day and a half, and I haven't attached it due to desiring to attach the mirrored half to it, and then put those two merged parts on the main body of the helmet.

The discolored brown stuff is the same brand of body filled I used before - the reason it's on there was because, like the original helmet I showed off, I printed and assembled the lower half of the helmet first, and I figured that I could make productive use of my time by getting to work on the body filler while that aft upper left part was printing, rather than just sit there doing nothing. While I'm printing the last two upper pieces, I'll continue to apply spot putty and then sand it down, and then once the upper half of the helmet is done, I'll then just attach it, and spot putty the equator and upper half.

View attachment 328302

View attachment 328303

That's all for now. I'll keep further progress on the helmet a surprise until a major milestone is achieved, like having the whole thing primed and ready to paint.

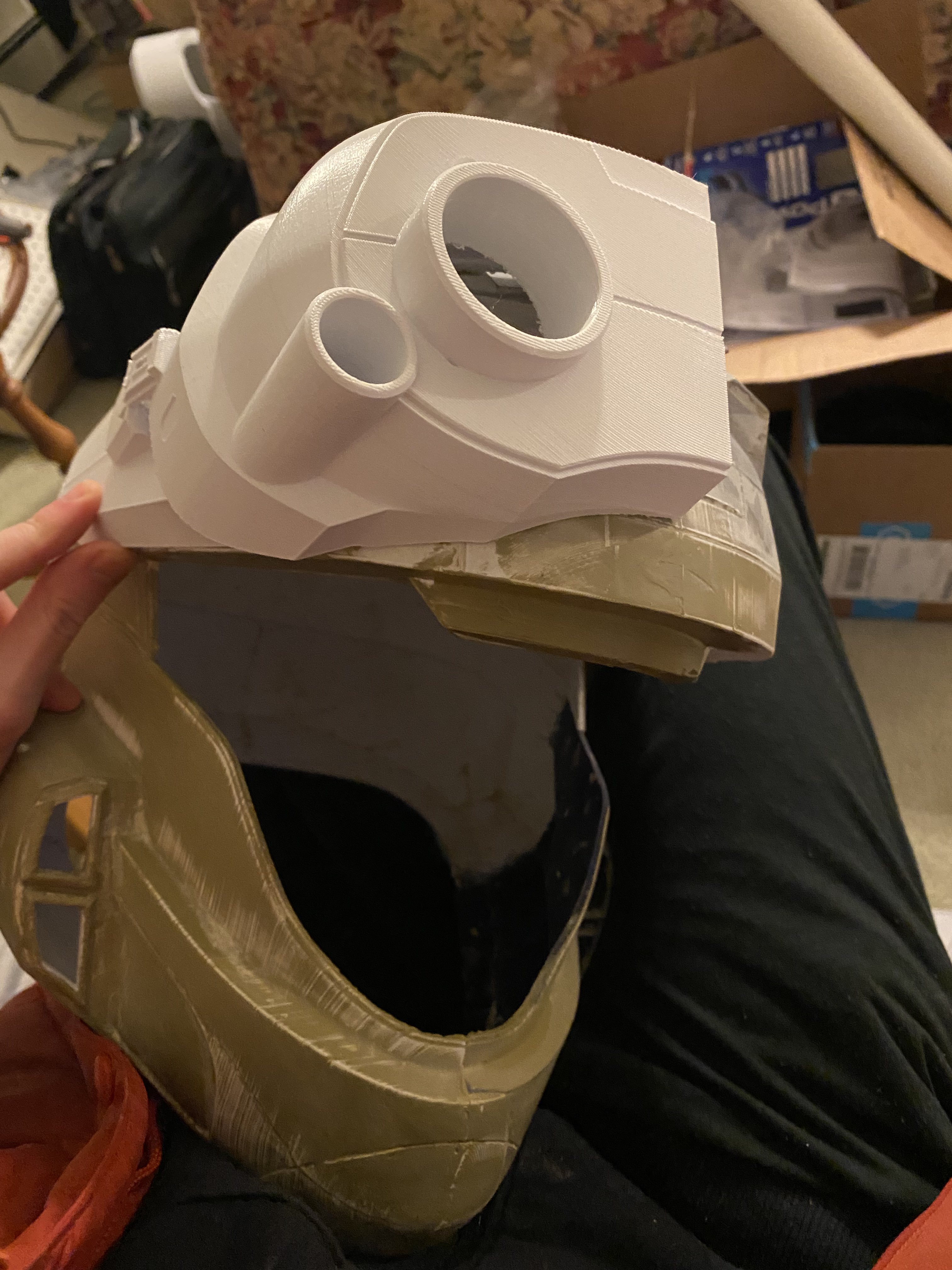

So, uh, I lied when I said I'd wait for the new helmet to be fully primed before making a status update. I'm in the process of priming it, and I'm in the home stretch of finishing it. Enough progress has been made to where I'm going back on what I said before to show it off.

It's worth mentioning that although you can see lines (as sort of an image texture, not a physical one), you can't feel them due to the fact that spot putty and/or filler primer has filled in those gaps, and therefore they won't show through paint - at least, I hope that's what it is.

Though I won't be attaching it until both it and the helmet are fully painted, I also got started with printing the helmet's O/I device, the flip-down binoculars (that realistically wouldn't be able to flip down given the way they're modeled and attached, if Romeo's character model in Halo 3: ODST is any indication). The right half was time-consuming to print (due to printing it vertically to preserve the detail), but it printed relatively fine.

As for the armor, the most recent status update I've received from the Etsy guy I hired to print my suit for me was that by this point, the base suit is completed - now all that he has left to print is the guns that I ordered (the H2A shotgun and a pair of H2A pistols), a visor buck, and the unique shoulders (Mickey and Romeo), so I'm nearing the point where all that stuff will be in my possession. My personal goal is to have the helmet ready to go before it arrives, so I can do all my painting in one go.

It's worth mentioning that although you can see lines (as sort of an image texture, not a physical one), you can't feel them due to the fact that spot putty and/or filler primer has filled in those gaps, and therefore they won't show through paint - at least, I hope that's what it is.

Though I won't be attaching it until both it and the helmet are fully painted, I also got started with printing the helmet's O/I device, the flip-down binoculars (that realistically wouldn't be able to flip down given the way they're modeled and attached, if Romeo's character model in Halo 3: ODST is any indication). The right half was time-consuming to print (due to printing it vertically to preserve the detail), but it printed relatively fine.

As for the armor, the most recent status update I've received from the Etsy guy I hired to print my suit for me was that by this point, the base suit is completed - now all that he has left to print is the guns that I ordered (the H2A shotgun and a pair of H2A pistols), a visor buck, and the unique shoulders (Mickey and Romeo), so I'm nearing the point where all that stuff will be in my possession. My personal goal is to have the helmet ready to go before it arrives, so I can do all my painting in one go.

- Member DIN

- S410

Lots of progress since that last time i checked in. Looks good!

If you're note sure the layer lines are completely hidden, spray the helmet with a sandable primer before you paint. If you can't see the lines, you're good! If you can, it will be much easier to work with sandable primer rather than paint that gums up your sandpaper.

If you're note sure the layer lines are completely hidden, spray the helmet with a sandable primer before you paint. If you can't see the lines, you're good! If you can, it will be much easier to work with sandable primer rather than paint that gums up your sandpaper.

- Member DIN

- S935

I'd also suggest using the "paint seams" feature a lot of slicers have, it allows you to have your Z seam at the back of the print where it wont be seen, so it is not an extra thing to sand away each time tooThis afternoon, I used the uppermost part of the shoulder as a test subject for this really interesting video I saw on using acetone to thin out Bondo filler and make it thin enough to just spread on with a paintbrush. I tried that, and my results were nothing short of fantastic.

A status update on the helmet - it's not finished, because on one hand, I lost a lot of progress, but on the other hand, I made a lot of progress. I shall explain:

What set me back a bit was a staged accident - I did a drop test of sorts, where I had my helmet sitting on a pile of clothes on my couch, and to see just how sturdy it was, I pushed it off. It fell two feet onto a carpeted floor and the top half broke off from the bottom half.

I'm still more horrified than you, the reader, hearing me say that. It took a lot of guts, but it was a good test to perform and actually enabled me to see that the soldering method I use for connecting parts isn't as invincible as I once thought (but it still beats superglue, which is barely better than duct taping it together). It also makes finishing/sanding the two separate halves considerably easier.

Now, to rectify this, I opted to try out a product that was showcased in one of DeltaAlphaZulu's more recent videos, of using my ancient enemy (superglue) and plastic bonder, the latter of which I hadn't used before. I had actually originally planned to test it with the O/I helmet device (which, as you'll see, I did) first, but then this became the real test. Having since used it, I'll say that it's sort of annoying to sand, but from what I can tell after another "two foot drop" test with the lower half of the helmet, it held the parts together (but then again, it did also have a stronger/better solder weld than the top half's parts did, so I don't know if that's the example or the exception), so I think that going forward, glue and plastic bonding might at the very least supplement my soldering work, or perhaps I'll solder, then plastic bond.

As for the O/I attachment:

Lastly, the best part - the upper half of the helmet isn't flawlessly smooth, but quite close to flawless, and I've reached the point where I don't think there's anything else I can (or want) to do with it until the time comes to paint it (but if there's any step between priming and painting that I need to know about, feel free to inform me). It's shiny, and it's substantially smoother than my previous Helljumper helmet (at one point, I think I actually generated a very mild static charge from rubbing it). Even my dog is entranced by how shiny and near-perfect it is.

As if that wasn't exciting enough, it gets better - the bottom half of the helmet is hot on the upper half's heels with regards to completion. I didn't think to snap a photo of it at the time, but I can say this much: after a bunch of sanding, I've applied the first coat of filler primer to the entirety of the lower half of the helmet, and I'll eventually get around to sanding it and, without any doubt, exposing more areas with little craters and bubbles, because a uniform silver coat of filler primer is very good at doing that.

Lastly, with all of the helmet parts (minus the two lens of the O/I module) finally finished (I can hardly believe it myself), I've started printing the parts to that customized shoulder design I shared a screenshot of earlier. I started with the upper half first, just to get the biggest time and filament hog out of the way before working on smaller parts that wouldn't be as disastrous in time and materials wasted in the event of something like a spool running out, or a power outage, or something like that. When those shoulder parts are printed, I'll give an update on them.

By the way, as a side note, part of why I give these kinds of detailed status updates is because I'm attempting to break the cycle of build threads I've read that mainly just show off neat tricks and finished parts, and not the sacrifices made to achieve those results. I just want to help people see what sort of stuff can happen and how to go about fixing it.

Anyway, that's all for now.

What set me back a bit was a staged accident - I did a drop test of sorts, where I had my helmet sitting on a pile of clothes on my couch, and to see just how sturdy it was, I pushed it off. It fell two feet onto a carpeted floor and the top half broke off from the bottom half.

I'm still more horrified than you, the reader, hearing me say that. It took a lot of guts, but it was a good test to perform and actually enabled me to see that the soldering method I use for connecting parts isn't as invincible as I once thought (but it still beats superglue, which is barely better than duct taping it together). It also makes finishing/sanding the two separate halves considerably easier.

Now, to rectify this, I opted to try out a product that was showcased in one of DeltaAlphaZulu's more recent videos, of using my ancient enemy (superglue) and plastic bonder, the latter of which I hadn't used before. I had actually originally planned to test it with the O/I helmet device (which, as you'll see, I did) first, but then this became the real test. Having since used it, I'll say that it's sort of annoying to sand, but from what I can tell after another "two foot drop" test with the lower half of the helmet, it held the parts together (but then again, it did also have a stronger/better solder weld than the top half's parts did, so I don't know if that's the example or the exception), so I think that going forward, glue and plastic bonding might at the very least supplement my soldering work, or perhaps I'll solder, then plastic bond.

As for the O/I attachment:

Lastly, the best part - the upper half of the helmet isn't flawlessly smooth, but quite close to flawless, and I've reached the point where I don't think there's anything else I can (or want) to do with it until the time comes to paint it (but if there's any step between priming and painting that I need to know about, feel free to inform me). It's shiny, and it's substantially smoother than my previous Helljumper helmet (at one point, I think I actually generated a very mild static charge from rubbing it). Even my dog is entranced by how shiny and near-perfect it is.

As if that wasn't exciting enough, it gets better - the bottom half of the helmet is hot on the upper half's heels with regards to completion. I didn't think to snap a photo of it at the time, but I can say this much: after a bunch of sanding, I've applied the first coat of filler primer to the entirety of the lower half of the helmet, and I'll eventually get around to sanding it and, without any doubt, exposing more areas with little craters and bubbles, because a uniform silver coat of filler primer is very good at doing that.

Lastly, with all of the helmet parts (minus the two lens of the O/I module) finally finished (I can hardly believe it myself), I've started printing the parts to that customized shoulder design I shared a screenshot of earlier. I started with the upper half first, just to get the biggest time and filament hog out of the way before working on smaller parts that wouldn't be as disastrous in time and materials wasted in the event of something like a spool running out, or a power outage, or something like that. When those shoulder parts are printed, I'll give an update on them.

By the way, as a side note, part of why I give these kinds of detailed status updates is because I'm attempting to break the cycle of build threads I've read that mainly just show off neat tricks and finished parts, and not the sacrifices made to achieve those results. I just want to help people see what sort of stuff can happen and how to go about fixing it.

Anyway, that's all for now.

- Member DIN

- S410

I've seen a lot of people recommend that soldering method saying it's stronger than glue, but in my experience that is not the case at all. Soldering just makes a very thin connection between pieces. I haven't tried that plastic bond stuff, personally i use CA glue with activator. If I drop a prop, the plastic will break before the glue breaks. Either way, I try to treat my 3d printed things like they're the body of a car. I never throw it or toss it on the ground. The 3d printed shell can be a bit weak sometimes and can crack if something falls on it.

I wish I had made a more detailed build thread when I built my suit. I will certainly have to do that for my next build! It's nice to go back and remember what you did in detail.

Progress look good!

I wish I had made a more detailed build thread when I built my suit. I will certainly have to do that for my next build! It's nice to go back and remember what you did in detail.

Progress look good!

- Member DIN

- S970

I've seen a lot of people recommend that soldering method saying it's stronger than glue, but in my experience that is not the case at all. Soldering just makes a very thin connection between pieces. I haven't tried that plastic bond stuff, personally i use CA glue with activator. If I drop a prop, the plastic will break before the glue breaks. Either way, I try to treat my 3d printed things like they're the body of a car. I never throw it or toss it on the ground. The 3d printed shell can be a bit weak sometimes and can crack if something falls on it.

I wish I had made a more detailed build thread when I built my suit. I will certainly have to do that for my next build! It's nice to go back and remember what you did in detail.

Progress look good!

I agree, in my experience even with really well done seams 3D prints are predisposed to breaks along any layer line so if you're worried about breaks make sure to back a majority of your print with something like fiberglass or even a bunch of hot glue and strapping may be better than nothing, although I haven't tested this method. Also I can't wait to see a build thread by you!

Your seam backing looks great. The plastic bonder is incredibly difficult to sand, that's why I tend to do heavy layers on the back and only really light layers on the front. I don't think I really used any on the outside of the helmet I put together with that method, but I really should have!A status update on the helmet - it's not finished, because on one hand, I lost a lot of progress, but on the other hand, I made a lot of progress. I shall explain:

What set me back a bit was a staged accident - I did a drop test of sorts, where I had my helmet sitting on a pile of clothes on my couch, and to see just how sturdy it was, I pushed it off. It fell two feet onto a carpeted floor and the top half broke off from the bottom half.

View attachment 328814

I'm still more horrified than you, the reader, hearing me say that. It took a lot of guts, but it was a good test to perform and actually enabled me to see that the soldering method I use for connecting parts isn't as invincible as I once thought (but it still beats superglue, which is barely better than duct taping it together). It also makes finishing/sanding the two separate halves considerably easier.

Now, to rectify this, I opted to try out a product that was showcased in one of DeltaAlphaZulu's more recent videos, of using my ancient enemy (superglue) and plastic bonder, the latter of which I hadn't used before. I had actually originally planned to test it with the O/I helmet device (which, as you'll see, I did) first, but then this became the real test. Having since used it, I'll say that it's sort of annoying to sand, but from what I can tell after another "two foot drop" test with the lower half of the helmet, it held the parts together (but then again, it did also have a stronger/better solder weld than the top half's parts did, so I don't know if that's the example or the exception), so I think that going forward, glue and plastic bonding might at the very least supplement my soldering work, or perhaps I'll solder, then plastic bond.

View attachment 328815

As for the O/I attachment:

View attachment 328816

View attachment 328817

View attachment 328818

Lastly, the best part - the upper half of the helmet isn't flawlessly smooth, but quite close to flawless, and I've reached the point where I don't think there's anything else I can (or want) to do with it until the time comes to paint it (but if there's any step between priming and painting that I need to know about, feel free to inform me). It's shiny, and it's substantially smoother than my previous Helljumper helmet (at one point, I think I actually generated a very mild static charge from rubbing it). Even my dog is entranced by how shiny and near-perfect it is.

View attachment 328819

As if that wasn't exciting enough, it gets better - the bottom half of the helmet is hot on the upper half's heels with regards to completion. I didn't think to snap a photo of it at the time, but I can say this much: after a bunch of sanding, I've applied the first coat of filler primer to the entirety of the lower half of the helmet, and I'll eventually get around to sanding it and, without any doubt, exposing more areas with little craters and bubbles, because a uniform silver coat of filler primer is very good at doing that.

Lastly, with all of the helmet parts (minus the two lens of the O/I module) finally finished (I can hardly believe it myself), I've started printing the parts to that customized shoulder design I shared a screenshot of earlier. I started with the upper half first, just to get the biggest time and filament hog out of the way before working on smaller parts that wouldn't be as disastrous in time and materials wasted in the event of something like a spool running out, or a power outage, or something like that. When those shoulder parts are printed, I'll give an update on them.

By the way, as a side note, part of why I give these kinds of detailed status updates is because I'm attempting to break the cycle of build threads I've read that mainly just show off neat tricks and finished parts, and not the sacrifices made to achieve those results. I just want to help people see what sort of stuff can happen and how to go about fixing it.

Anyway, that's all for now.

Your build so far is looking great! I can't wait to see that helmet all put together!

Yeah, that's part of why I can't bring myself to put it on the outside - I'm assuming I'd have to sand down all the filler primer and spot putty to be able to apply it, and the fact that I would have to sand it all off, then put on the plastic bonder, then sand that, then put the putty/primer back on, and then sand that is significantly discouraging, so that's not happening. When the glue and plastic bonder arrive (ETA Saturday), I'm just doing the inside, and then making a conscious effort to avoid dropping the helmet again - that, or I might take a page out of my old playbook and put thermoplastic backing plates along major corners (as in where corners of different pieces meet) within the helmet to make it even sturdier.

Thanks for the kind words, as always.

The next day...

So in addition to finally being accepted into the Colonial Regiment, I've got slight news to share: the pieces for my custom "light" shoulder are finished printing, so I'll be working on those in tandem with my helmet's binocular attachment. The pieces are surprisingly large at base size - I put it next to the SkookumProps shoulder I was working on months back for a sense of scale.

Thanks for the kind words, as always.

The next day...

So in addition to finally being accepted into the Colonial Regiment, I've got slight news to share: the pieces for my custom "light" shoulder are finished printing, so I'll be working on those in tandem with my helmet's binocular attachment. The pieces are surprisingly large at base size - I put it next to the SkookumProps shoulder I was working on months back for a sense of scale.

Last edited:

Some major progress has been made, though not by me directly. The Etsy fella who's been printing my suit for me informed me that he's finished printing all of the parts to my suit; all that's left to print now, according to him, is just the buck for my helmet's visor, and the pieces of my shotgun. I was originally going to have a pair of pistols printed, but I ultimately couldn't go through with it for financial reasons, a change in my vision for my suit, and practical reasons (namely A) having a working printer now; and B) realizing that I'll most likely have to have some sort of pouch on my hip and wouldn't have space for the holsters).

Here are the pics he sent me:

Here are the pics he sent me:

- Member DIN

- S970

The ODST thighs have some lovely squares in them the would work very well for magnets to have a magnetic pistol holder on! The SOCOM is also a pretty easy print to do! Also you usually have those flashbangs mounted around where your hip armor is along with the tailbone plate, so there isn't a lot of real estate to put pouches on the waist of a fully armored ODST. I can't wait to see how your finishing and fitment goes!Some major progress has been made, though not by me directly. The Etsy fella who's been printing my suit for me informed me that he's finished printing all of the parts to my suit; all that's left to print now, according to him, is just the buck for my helmet's visor, and the pieces of my shotgun. I was originally going to have a pair of pistols printed, but I ultimately couldn't go through with it for financial reasons, a change in my vision for my suit, and practical reasons (namely A) having a working printer now; and B) realizing that I'll most likely have to have some sort of pouch on my hip and wouldn't have space for the holsters).

Here are the pics he sent me:

View attachment 328884

View attachment 328885

View attachment 328886

View attachment 328887

The weekend, and an update (the start of painting), are here.

An update-within-an-update first: I was given a completion ETA by the Etsy seller - my armor, the visor buck, and the H2A shotgun should all be done by the end of the month (he said two weeks a few days ago, which would more or less line up with the end of March, since we've got two weeks left as of this post). There'll be a big update on that when it's all here, though for now, I want to share what I've been working on.

I briefly went against valued advice and my own better judgment and began painting, though if we were to compare it to combat, it's akin to scouting rather than launching a combined arms assault. I bought these camo colors at Lowe's, and I was determined to see how they'd actually look.

My problem is that I have an inability to really visualize how something looks painted, even if I paint like a scrap piece of foam or plastic and hold it beside a print. So, I got painting with the tan color (my biggest source of concern), and this was the result. I may have gotten carried away with what was basically a tertiary color.

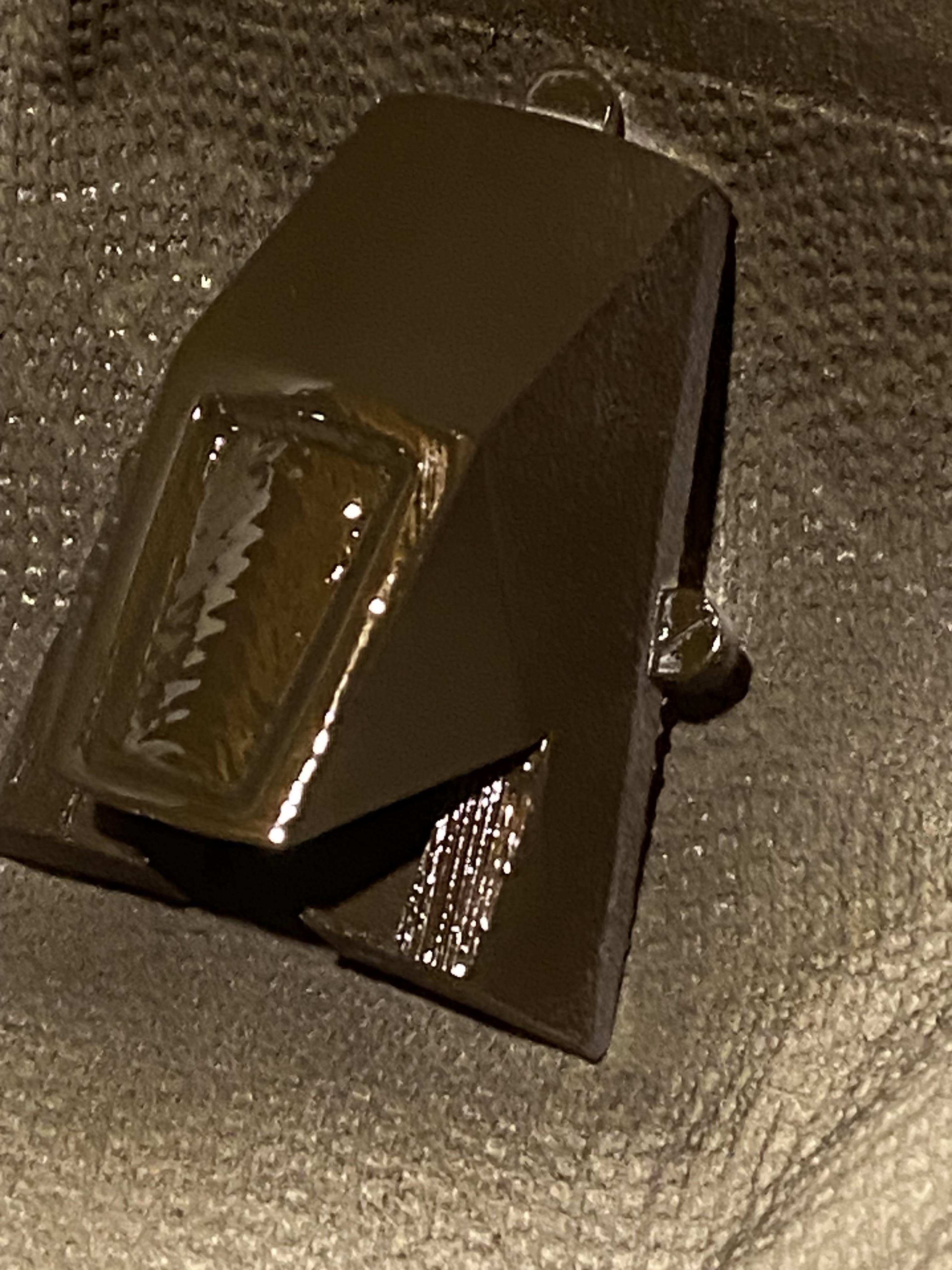

I'll tell you right now that this color is actually a surprisingly good desert tan, though its use is definitely going to be solely for the multi-cam part of the hex camo, which is why I feel like an idiot for using so much of it on the helmet and the O/I device. However, that isn't the only color I tested. Because it would be painted brown either way, I tested the brown color on the middle connector piece of my "light shoulder". It's really zoomed in, and it looks all shiny and weird, but hopefully that will dry and look normal tomorrow.

And speaking of that shoulder piece, this is a "before" photo (I didn't think to take an "after" photo before I painted the middle piece) of the upper and middle shoulder components. Both are primed to my level of acceptable (as you'd see in the nonexistent "after" photo, not this one), though I'm going to hold off on fusing those two parts once all three main components (not counting the locking key) are painted (because I'm attempting to fight off my terrible impulse control in favor of DeltaAlphaZulu's advice to do all of my painting at once - that, and my hex stencil isn't here yet, so I can't do the hex patterns anyway) and ready for installation.

Last thing for now is the same ODST avatar I've shown a few times, this time updated in two ways: the first is that the colors have been altered based on what I've tested (basically, I sprayed those three colors from the first photo, took pictures, color-picked from the photos, and then set the colors in Moho, so they should, at least closely, match what will actually be painted); the second is that I'm now debating visor color again (first time was in the Discord server several weeks ago). I'm torn between green, because I get a death trooper vibe from it, or teal, like General Warfield's visor in StarCraft II.

That's all I've got for now. Any suggestions and questions (if for some reason, any of you have any) are welcome, and either way, until next time, have a good weekend.

An update-within-an-update first: I was given a completion ETA by the Etsy seller - my armor, the visor buck, and the H2A shotgun should all be done by the end of the month (he said two weeks a few days ago, which would more or less line up with the end of March, since we've got two weeks left as of this post). There'll be a big update on that when it's all here, though for now, I want to share what I've been working on.

I briefly went against valued advice and my own better judgment and began painting, though if we were to compare it to combat, it's akin to scouting rather than launching a combined arms assault. I bought these camo colors at Lowe's, and I was determined to see how they'd actually look.

My problem is that I have an inability to really visualize how something looks painted, even if I paint like a scrap piece of foam or plastic and hold it beside a print. So, I got painting with the tan color (my biggest source of concern), and this was the result. I may have gotten carried away with what was basically a tertiary color.

I'll tell you right now that this color is actually a surprisingly good desert tan, though its use is definitely going to be solely for the multi-cam part of the hex camo, which is why I feel like an idiot for using so much of it on the helmet and the O/I device. However, that isn't the only color I tested. Because it would be painted brown either way, I tested the brown color on the middle connector piece of my "light shoulder". It's really zoomed in, and it looks all shiny and weird, but hopefully that will dry and look normal tomorrow.

And speaking of that shoulder piece, this is a "before" photo (I didn't think to take an "after" photo before I painted the middle piece) of the upper and middle shoulder components. Both are primed to my level of acceptable (as you'd see in the nonexistent "after" photo, not this one), though I'm going to hold off on fusing those two parts once all three main components (not counting the locking key) are painted (because I'm attempting to fight off my terrible impulse control in favor of DeltaAlphaZulu's advice to do all of my painting at once - that, and my hex stencil isn't here yet, so I can't do the hex patterns anyway) and ready for installation.

Last thing for now is the same ODST avatar I've shown a few times, this time updated in two ways: the first is that the colors have been altered based on what I've tested (basically, I sprayed those three colors from the first photo, took pictures, color-picked from the photos, and then set the colors in Moho, so they should, at least closely, match what will actually be painted); the second is that I'm now debating visor color again (first time was in the Discord server several weeks ago). I'm torn between green, because I get a death trooper vibe from it, or teal, like General Warfield's visor in StarCraft II.

That's all I've got for now. Any suggestions and questions (if for some reason, any of you have any) are welcome, and either way, until next time, have a good weekend.

- Member DIN

- S970

It's looking good and those colors look great together! If you are going to paint parts at different times and levels just make sure to wipe them off before a new coat with something that doesn't leave lint if they have been sitting for a while, that way you have a nice clean finish free of bumps and such from dust and debris.The weekend, and an update (the start of painting), are here.

An update-within-an-update first: I was given a completion ETA by the Etsy seller - my armor, the visor buck, and the H2A shotgun should all be done by the end of the month (he said two weeks a few days ago, which would more or less line up with the end of March, since we've got two weeks left as of this post). There'll be a big update on that when it's all here, though for now, I want to share what I've been working on.

I briefly went against valued advice and my own better judgment and began painting, though if we were to compare it to combat, it's akin to scouting rather than launching a combined arms assault. I bought these camo colors at Lowe's, and I was determined to see how they'd actually look.

View attachment 329134

My problem is that I have an inability to really visualize how something looks painted, even if I paint like a scrap piece of foam or plastic and hold it beside a print. So, I got painting with the tan color (my biggest source of concern), and this was the result. I may have gotten carried away with what was basically a tertiary color.

View attachment 329135

View attachment 329136

I'll tell you right now that this color is actually a surprisingly good desert tan, though its use is definitely going to be solely for the multi-cam part of the hex camo, which is why I feel like an idiot for using so much of it on the helmet and the O/I device. However, that isn't the only color I tested. Because it would be painted brown either way, I tested the brown color on the middle connector piece of my "light shoulder". It's really zoomed in, and it looks all shiny and weird, but hopefully that will dry and look normal tomorrow.

View attachment 329137

And speaking of that shoulder piece, this is a "before" photo (I didn't think to take an "after" photo before I painted the middle piece) of the upper and middle shoulder components. Both are primed to my level of acceptable (as you'd see in the nonexistent "after" photo, not this one), though I'm going to hold off on fusing those two parts once all three main components (not counting the locking key) are painted (because I'm attempting to fight off my terrible impulse control in favor of DeltaAlphaZulu's advice to do all of my painting at once - that, and my hex stencil isn't here yet, so I can't do the hex patterns anyway) and ready for installation.

View attachment 329138

Last thing for now is the same ODST avatar I've shown a few times, this time updated in two ways: the first is that the colors have been altered based on what I've tested (basically, I sprayed those three colors from the first photo, took pictures, color-picked from the photos, and then set the colors in Moho, so they should, at least closely, match what will actually be painted); the second is that I'm now debating visor color again (first time was in the Discord server several weeks ago). I'm torn between green, because I get a death trooper vibe from it, or teal, like General Warfield's visor in StarCraft II.

View attachment 329139

That's all I've got for now. Any suggestions and questions (if for some reason, any of you have any) are welcome, and either way, until next time, have a good weekend.

As far as visor colors go, I think an amber or black would look pretty cool with the colors you have picked out! I can't wait to see more of your progress!

I've been silent for several weeks, until now, and you're about to see why. This is, to date, the biggest update for this project.

At long last, the first half of my order arrived. "First half" is defined as the entire base suit. The special shoulders (Mickey and Romeo, because although my recon scout will use Romeo's sniper shoulder, I have plans to do a Mickey-like build at some point in the future, because of all of the members of Alpha-Nine, his armor is my favorite) and my M90 shotgun are due to ship out some time this week.

First off, this isn't all of the parts that came; it's just the ones that were still in the box when I took the photo.

The leg armor is marginally too big, so padding is in order (literally, I ordered some upholstery foam originally for my helmet padding, but now also for the legs and forearm gauntlets).

It's truly exhilarating being able to wear cosplay pieces, though since I'm going to be wearing my ODST suit over some fairly tight-fitting clothing, I'm gonna have to pad a fair number of these pieces out, otherwise they'll be shaking around on my legs, and I can't have any of that.

Not long after getting these parts and assembling some of them, I got right to work on painting what I could. I also was set up with a larger work station that would be able to hold the bulk of my pieces, my many cans of paint, extra supplies, etc.

I've saved the best part for last. Bar weathering (which I'm going to do all in one go like a sane person), my helmet is fully painted, and here it is in all its hexagonal glory:

As more stuff comes in, I'll be working on those parts (I can't wait to put the shotgun together... or try to and fail horribly). Other stuff I don't have photos of, but have, include the vacuum former, two packets of iDye Poly, and the PETG sheets for vacuum forming my visors (both for multiple helmets, and also for smaller visors like the lens of Mickey's helmet attachment, and the two sniper lens of Romeo's helmet attachment), so I'm eventually going to move on towards vacuum forming and dying my ODST helmet's visor.

That's all for now, folks. I don't know when my next major status update will be, but I hope this was worth the wait.

At long last, the first half of my order arrived. "First half" is defined as the entire base suit. The special shoulders (Mickey and Romeo, because although my recon scout will use Romeo's sniper shoulder, I have plans to do a Mickey-like build at some point in the future, because of all of the members of Alpha-Nine, his armor is my favorite) and my M90 shotgun are due to ship out some time this week.

First off, this isn't all of the parts that came; it's just the ones that were still in the box when I took the photo.

The leg armor is marginally too big, so padding is in order (literally, I ordered some upholstery foam originally for my helmet padding, but now also for the legs and forearm gauntlets).

It's truly exhilarating being able to wear cosplay pieces, though since I'm going to be wearing my ODST suit over some fairly tight-fitting clothing, I'm gonna have to pad a fair number of these pieces out, otherwise they'll be shaking around on my legs, and I can't have any of that.

Not long after getting these parts and assembling some of them, I got right to work on painting what I could. I also was set up with a larger work station that would be able to hold the bulk of my pieces, my many cans of paint, extra supplies, etc.

I've saved the best part for last. Bar weathering (which I'm going to do all in one go like a sane person), my helmet is fully painted, and here it is in all its hexagonal glory:

As more stuff comes in, I'll be working on those parts (I can't wait to put the shotgun together... or try to and fail horribly). Other stuff I don't have photos of, but have, include the vacuum former, two packets of iDye Poly, and the PETG sheets for vacuum forming my visors (both for multiple helmets, and also for smaller visors like the lens of Mickey's helmet attachment, and the two sniper lens of Romeo's helmet attachment), so I'm eventually going to move on towards vacuum forming and dying my ODST helmet's visor.

That's all for now, folks. I don't know when my next major status update will be, but I hope this was worth the wait.

- Status

- Not open for further replies.