You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Foam Air Assault and Sword Builds for Me and My Girlfriend (Comic-Con 2012/2013)

- Thread starter Spacemeat

- Start date

- Status

- Not open for further replies.

Totally forgot to respond to that! Anyhow, I'm always up for meetups, but I've already preordered my copy at my local gamestop, and I've been going there since Halo 2. Plus, they know to look for the guy in armor already

Wow this build is going so well, I hope you're still doing it! I noticed you're in Irvine and I'm in Thousand Oaks! Maybe a Halo 4 midnight release meet up?

Hey guys! Quick update.

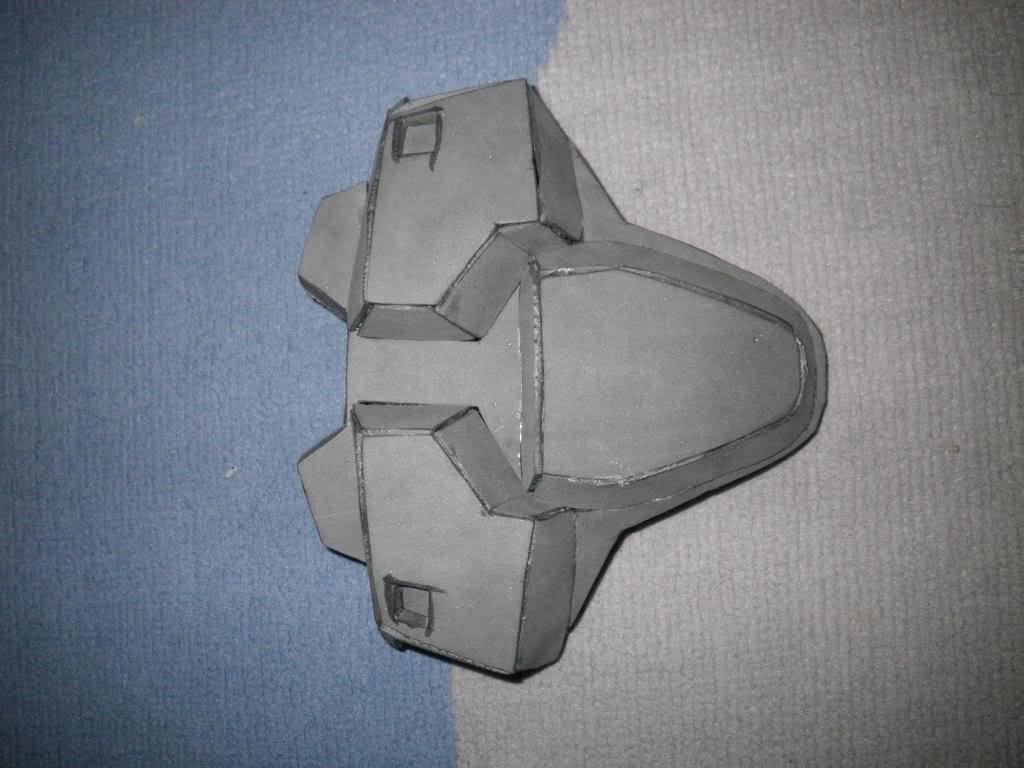

I've done a little work on the codpiece, hopefully get it done by the end of the week:

I finally got some time in to sand and prime the helmets. I'm seeing lots of imperfections, so I'm probably going to give them another once over with some spot putty before the final paint layer

And finally, my failed experiment with sword production. I spent a few hours today trying to bend some acyrillc with my heat gun around the sword blade. The tension from the sheet made it very hard to keep it's shape. Every time I heated up a section to bend, the tension from the rest of the sheet would straighten it out. Plus, I just wasn't getting the detail I wanted from just pressing hot plastic with my (gloved) hands. I guess I'll have to go full on vacuform. My only really stumbling block is that I'm going to need a large oven...

I've done a little work on the codpiece, hopefully get it done by the end of the week:

I finally got some time in to sand and prime the helmets. I'm seeing lots of imperfections, so I'm probably going to give them another once over with some spot putty before the final paint layer

And finally, my failed experiment with sword production. I spent a few hours today trying to bend some acyrillc with my heat gun around the sword blade. The tension from the sheet made it very hard to keep it's shape. Every time I heated up a section to bend, the tension from the rest of the sheet would straighten it out. Plus, I just wasn't getting the detail I wanted from just pressing hot plastic with my (gloved) hands. I guess I'll have to go full on vacuform. My only really stumbling block is that I'm going to need a large oven...

Wiltonican

Jr Member

And finally, my failed experiment with sword production. I spent a few hours today trying to bend some acyrillc with my heat gun around the sword blade. The tension from the sheet made it very hard to keep it's shape. Every time I heated up a section to bend, the tension from the rest of the sheet would straighten it out. Plus, I just wasn't getting the detail I wanted from just pressing hot plastic with my (gloved) hands. I guess I'll have to go full on vacuform. My only really stumbling block is that I'm going to need a large oven...

If you're good with electronics/mechanics, you can make your own "oven" by taking apart a toaster or toaster oven and using the heating elements. If you google DIY vacuforming, I'm sure their setups uses something similar. But, it is dangerous when dealing with these sort of things... so please proceed with caution!

Wow this is really neat!!

I need to stop looking at other peoples builds or I will never finish my current one haha. I am seriously thinking about foam for my next suit. Your thread has been very helpful to show me what it can do.

Good luck with your build and GREAT WORK!

I need to stop looking at other peoples builds or I will never finish my current one haha. I am seriously thinking about foam for my next suit. Your thread has been very helpful to show me what it can do.

Good luck with your build and GREAT WORK!

Hey guys, time a little update:

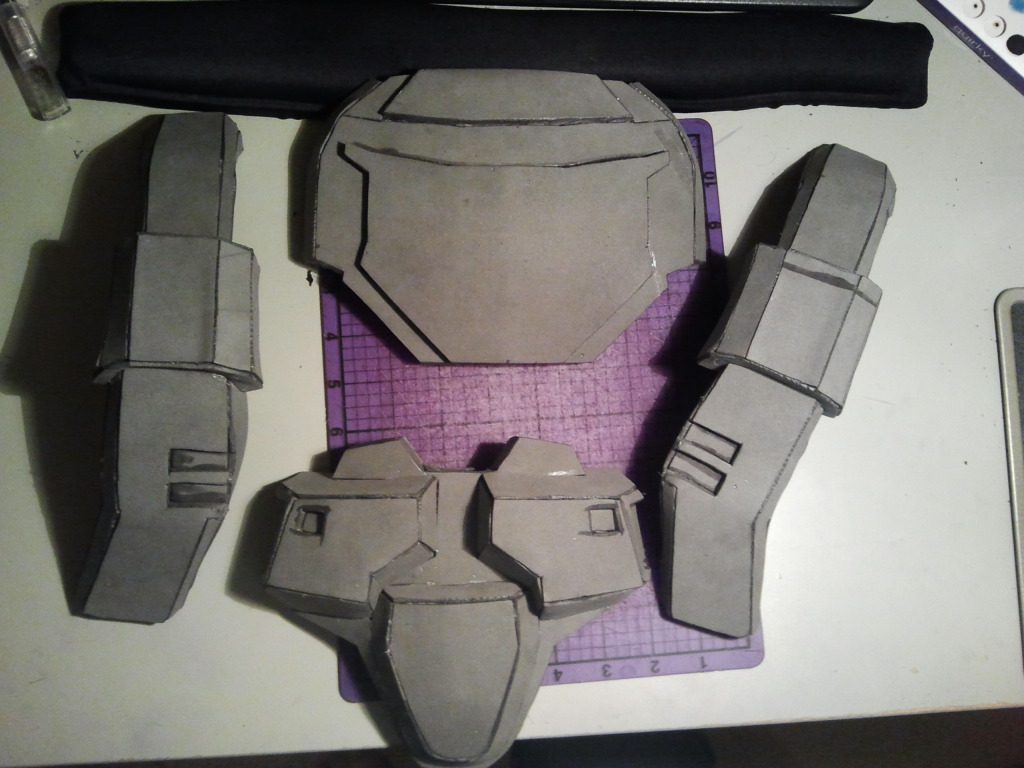

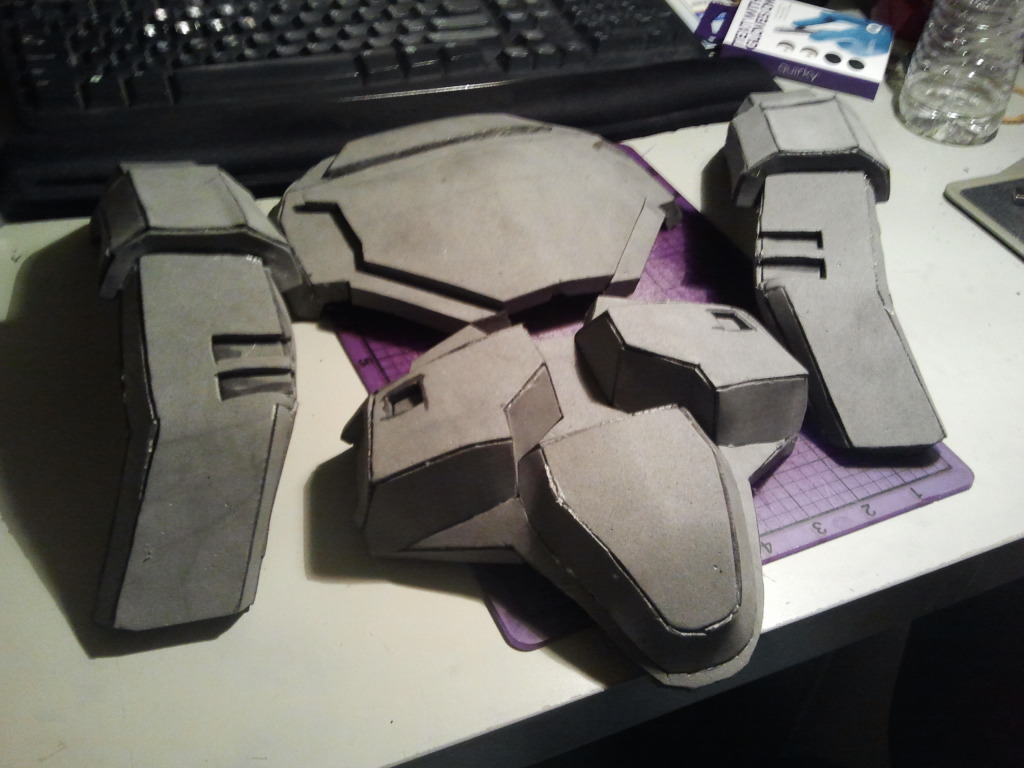

I've been getting jealous of the all the new parts I've been building for my girlfriend. So, I ended up building some new pieces to replace mine!

Of course, I still found the time to finish the cod piece (just need to put some elastic between the pieces after I get some plastidip done.

And I got some shins done today:

Going to moving on to the boots soon. Then I probably do some little pieces like knees and shoulder plates before I finish up with the spine and and ab pieces. Then I get to move on to plastidip and working on the undersuit!

I've been getting jealous of the all the new parts I've been building for my girlfriend. So, I ended up building some new pieces to replace mine!

Of course, I still found the time to finish the cod piece (just need to put some elastic between the pieces after I get some plastidip done.

And I got some shins done today:

Going to moving on to the boots soon. Then I probably do some little pieces like knees and shoulder plates before I finish up with the spine and and ab pieces. Then I get to move on to plastidip and working on the undersuit!

Annanymous

Well-Known Member

WOW you work fast. I had forgotten to sub to this thread so I missed all of your updates from earlier, however I'm subbed now.

It all looks great, are you and your girlfriend going to be matching? Or are you guys going to mess around and do different paint jobs.

Anyway, it all looks like really clean work, can't wait to what you do for the undersuit.

It all looks great, are you and your girlfriend going to be matching? Or are you guys going to mess around and do different paint jobs.

Anyway, it all looks like really clean work, can't wait to what you do for the undersuit.

WOW you work fast. I had forgotten to sub to this thread so I missed all of your updates from earlier, however I'm subbed now.

It all looks great, are you and your girlfriend going to be matching? Or are you guys going to mess around and do different paint jobs.

Anyway, it all looks like really clean work, can't wait to what you do for the undersuit.

Originally I meant just to replace the chest and helmet from my build last year. So the new pieces for my suit are just going to be painted cobalt to match the older pieces.

My girlfriend's armor is still up in the air color wise. She's taken a liking to the Halo 3 zombie color, so I'll be looking into matching that color unless something else catches her fancy.

Wow that is one awesome foam build! What tools do you use to get such clean edges so they line up so nicely?!

The pep patterns quite obviously help with the sizing, but I primarily use a hot knife and a ruler to cut into the foam. I trace out the pattern from the paper pep with marker, then put the ruler along the line and cut with the hot knife. Leads to nice clean cuts

BlueSol

Active Member

The pep patterns quite obviously help with the sizing, but I primarily use a hot knife and a ruler to cut into the foam. I trace out the pattern from the paper pep with marker, then put the ruler along the line and cut with the hot knife. Leads to nice clean cuts

Ahh a hot knife...that seems to be the tool i'm missing

DagothDraal

Member

Wow, I'll probably just pep my helmet, and try foam for the body! Where do you get this foam? Name?

Wow, I'll probably just pep my helmet, and try foam for the body! Where do you get this foam? Name?

The foam comes from Harbor Freight

wow you have made a lot of Kat helmets

everything looks amazing and i really can't wait to see the finished energy sword =D good luck

I certainly have! At this point I know the helmet like the back of my hand and have made a few alterations to the orginal unfold I did last year. I'm guessing I should upload that at some point...

In anycase, update!

I've made the boots. I'm a little unsatisfied with mine, and will probably make the boot cap bigger

I shoved my foot into my girlfriend's shoe and thigh to try to get some scale...

Due to the image limits on posts, I had to split it up...

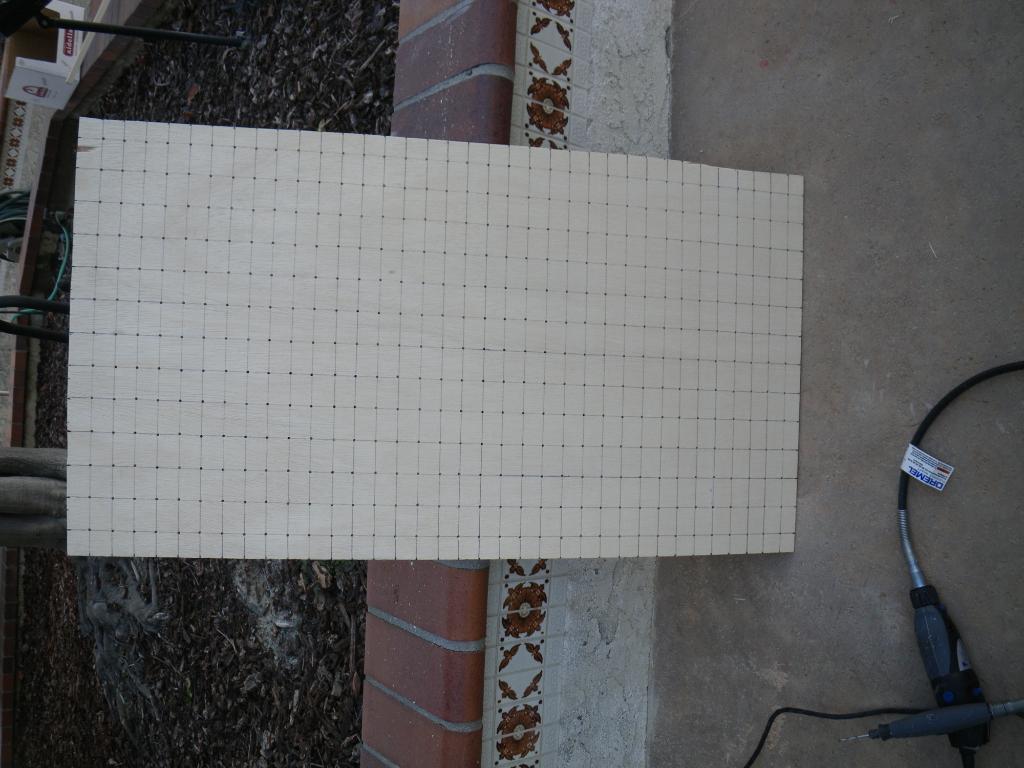

Since we had an extra long weekend, I decided to finally get around to making the vacuform machine...

We all have to start somewhere...

I mounted the sword mold on a board, because one of the blades was bending upward in the back. I was told that the plastic would probably wrap around it and it would be harder to pull the plastic from the mold

Yes, I drilled every one of these holes...

The bottom of the vacuum box, I salvaged a valve from a vacupack bag from harbor freight so I could easily hook up the vacuum to it

Inside of the box, you might notice the rubber seal on the outer edge (it's made from garage door insulation seals that i use for the neck seals on my helmets, I've just got tons of lying around, so I figured I'd make some use of it). The seal is because the top board is removable in case i need to make repairs/adjustments

Fully assembled box, let another seal for when I press the frame against it

Here's the setup, it looks a little flimsy (the other side of the box is held up by flower pots!) so I'll be thinking about a better setup

The frame to hold the plastic, with more rubber seal goodness

As a test, I used a plastic trash bag to see if the whole setup even works

The sword mold on the vacumbox, it's a tight fit!

Vacuum power on. Huzzah! it works! I just pray this applies to when i use a real piece of plasitc

And finally the heating the table. I bought an infrared heater from fry's and I'll be positioning it underneath the plastic. It was getting late, so I'll be attemping the whole thing next weekend

And there you have it! I'll be doing some more foam work during the weekdays and then I'll finally attempt to vacuform a sword on the weekend. Wish me luck!

Since we had an extra long weekend, I decided to finally get around to making the vacuform machine...

We all have to start somewhere...

I mounted the sword mold on a board, because one of the blades was bending upward in the back. I was told that the plastic would probably wrap around it and it would be harder to pull the plastic from the mold

Yes, I drilled every one of these holes...

The bottom of the vacuum box, I salvaged a valve from a vacupack bag from harbor freight so I could easily hook up the vacuum to it

Inside of the box, you might notice the rubber seal on the outer edge (it's made from garage door insulation seals that i use for the neck seals on my helmets, I've just got tons of lying around, so I figured I'd make some use of it). The seal is because the top board is removable in case i need to make repairs/adjustments

Fully assembled box, let another seal for when I press the frame against it

Here's the setup, it looks a little flimsy (the other side of the box is held up by flower pots!) so I'll be thinking about a better setup

The frame to hold the plastic, with more rubber seal goodness

As a test, I used a plastic trash bag to see if the whole setup even works

The sword mold on the vacumbox, it's a tight fit!

Vacuum power on. Huzzah! it works! I just pray this applies to when i use a real piece of plasitc

And finally the heating the table. I bought an infrared heater from fry's and I'll be positioning it underneath the plastic. It was getting late, so I'll be attemping the whole thing next weekend

And there you have it! I'll be doing some more foam work during the weekdays and then I'll finally attempt to vacuform a sword on the weekend. Wish me luck!

Annanymous

Well-Known Member

Hey Space! I really love the boots, and I don't know why you would redo them because they look great to me!

(also I like that futurama reference.)

I can't believe you made that vac. table! It looks super legit and I am excited to see you make an energy sword with it. Are you making one for yourself and one for your girlfriend?

(also I like that futurama reference.)

I can't believe you made that vac. table! It looks super legit and I am excited to see you make an energy sword with it. Are you making one for yourself and one for your girlfriend?

Great looking foam work, and you're Vac table looks sweet.

Hey Space! I really love the boots, and I don't know why you would redo them because they look great to me!

(also I like that futurama reference.)

I can't believe you made that vac. table! It looks super legit and I am excited to see you make an energy sword with it. Are you making one for yourself and one for your girlfriend?

Thanks guys! I'm really hoping the thing actually works though, a garbage is considerably lighter than the sheet of plastic I'm planning on using. The current goal is for both of us to have energy swords. If I can manage it, I'll be making one for my sister too, since she'll be running around with my old helmet painted pink.

As to the shoes, the toe caps I made for mine a simply too small. in the pictures they're just resting on the shoe, but if I were to glue it down, it would get kinda flat and deformed, like my build last year. So I'll be upsizing the boot cap this week

- Status

- Not open for further replies.