You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Halo 4 Mark V Helmet With RUBBER NECK SEALS(Impact Props)

- Thread starter TheBradinator

- Start date

- Status

- Not open for further replies.

TwistedKiwi

New Member

Clean detail, great scale, and it appears to have zero warping. Absolutely exquisite work, Brad! Great job

TheBradinator

Member

Thanks guys! I got an update for YOUUUU!

Let the Pics flowww

Almost done guys! All thats left is some minor sanding, visor, perfecting ect.

Then its of to Sir Tsaboc for some good old fashion moldin.

Let me know what you think!

Brad

Let the Pics flowww

Almost done guys! All thats left is some minor sanding, visor, perfecting ect.

Then its of to Sir Tsaboc for some good old fashion moldin.

Let me know what you think!

Brad

Attachments

-

1BA37880-096D-45E2-BCB6-AE826B353561-12155-00000BD95F5842DB_zps505269a7.jpg57.9 KB · Views: 387

1BA37880-096D-45E2-BCB6-AE826B353561-12155-00000BD95F5842DB_zps505269a7.jpg57.9 KB · Views: 387 -

7B0B1A2E-D66F-4151-8C83-91CA6B3340E7-12155-00000BD9BB479ABA_zpsf376e2aa.jpg50.9 KB · Views: 376

7B0B1A2E-D66F-4151-8C83-91CA6B3340E7-12155-00000BD9BB479ABA_zpsf376e2aa.jpg50.9 KB · Views: 376 -

18D3BE0A-C12E-4205-914E-F12A0D181CA9-12155-00000BD98C2F202B_zps577f9ae6.jpg85 KB · Views: 377

18D3BE0A-C12E-4205-914E-F12A0D181CA9-12155-00000BD98C2F202B_zps577f9ae6.jpg85 KB · Views: 377 -

71B01939-6ED5-4F01-B08A-33D22A497F02-12155-00000BD9756A7955_zps94740691.jpg69.8 KB · Views: 379

71B01939-6ED5-4F01-B08A-33D22A497F02-12155-00000BD9756A7955_zps94740691.jpg69.8 KB · Views: 379 -

2FD0ED29-1A1E-4984-85E8-D33D83A16884-12155-00000BDA13AAB62A_zpsc289ad0f.jpg85.2 KB · Views: 372

2FD0ED29-1A1E-4984-85E8-D33D83A16884-12155-00000BDA13AAB62A_zpsc289ad0f.jpg85.2 KB · Views: 372 -

DE56BE18-943E-4A77-B72D-A149A3BE2F59-12155-00000BD9FD04FF56_zps9e417f29.jpg66.4 KB · Views: 372

DE56BE18-943E-4A77-B72D-A149A3BE2F59-12155-00000BD9FD04FF56_zps9e417f29.jpg66.4 KB · Views: 372 -

B39079C6-8A32-4D14-9FED-DF38E216002A-12155-00000BD9CA2FE010_zps31eef6e2.jpg55.7 KB · Views: 406

B39079C6-8A32-4D14-9FED-DF38E216002A-12155-00000BD9CA2FE010_zps31eef6e2.jpg55.7 KB · Views: 406 -

06B591E5-F4C9-4FE3-ACDB-36A2623C4A3B-12155-00000BDA1E5EE449_zps3f156aad.jpg62.5 KB · Views: 366

06B591E5-F4C9-4FE3-ACDB-36A2623C4A3B-12155-00000BDA1E5EE449_zps3f156aad.jpg62.5 KB · Views: 366 -

8387E9E1-1300-4BB4-9388-1539822D7FCB-12155-00000BDA065ACCA1_zps1f32335d.jpg58.9 KB · Views: 393

8387E9E1-1300-4BB4-9388-1539822D7FCB-12155-00000BDA065ACCA1_zps1f32335d.jpg58.9 KB · Views: 393 -

13A595F1-11D0-4B14-B833-70EAC15153DA-12155-00000BD9DE9027D2_zpsc6578d2f.jpg95.7 KB · Views: 371

13A595F1-11D0-4B14-B833-70EAC15153DA-12155-00000BD9DE9027D2_zpsc6578d2f.jpg95.7 KB · Views: 371

TheBradinator

Member

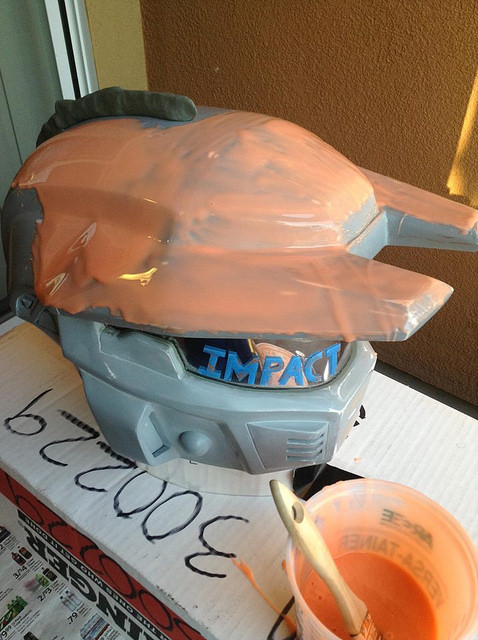

I have another update for you guys!

She is almost ready to mold!

Thanks for looking guys!

She is almost ready to mold!

Thanks for looking guys!

Attachments

-

99D7C969-BD52-4877-8D42-8A37207BFD4A-19656-0000136086977692_zpsefd4ce8b.jpg86.9 KB · Views: 362

99D7C969-BD52-4877-8D42-8A37207BFD4A-19656-0000136086977692_zpsefd4ce8b.jpg86.9 KB · Views: 362 -

8AA1EEF3-5FAF-4B13-BAFA-32686AD00671-19656-00001360688FDD03_zps9f481358.jpg148.2 KB · Views: 372

8AA1EEF3-5FAF-4B13-BAFA-32686AD00671-19656-00001360688FDD03_zps9f481358.jpg148.2 KB · Views: 372 -

81416336-803D-4B44-9704-EBAADBD99861-19656-00001360AAE1939F_zps63881d54.jpg79 KB · Views: 354

81416336-803D-4B44-9704-EBAADBD99861-19656-00001360AAE1939F_zps63881d54.jpg79 KB · Views: 354 -

C4301612-3F3C-4474-B483-B323950BFA0C-19656-00001360B89E112D_zps52333e4b.jpg39.8 KB · Views: 376

C4301612-3F3C-4474-B483-B323950BFA0C-19656-00001360B89E112D_zps52333e4b.jpg39.8 KB · Views: 376 -

C93E01DA-30B1-4E00-AD9B-8DCDF71933B7-19656-00001360A3811040_zpsdc586bfe.jpg81.2 KB · Views: 364

C93E01DA-30B1-4E00-AD9B-8DCDF71933B7-19656-00001360A3811040_zpsdc586bfe.jpg81.2 KB · Views: 364 -

FD125FE4-9910-4A50-B38F-A0B122A76A9A-19656-000013609C4815C5_zps9153157f.jpg86.1 KB · Views: 382

FD125FE4-9910-4A50-B38F-A0B122A76A9A-19656-000013609C4815C5_zps9153157f.jpg86.1 KB · Views: 382 -

539130D3-B57E-4CC4-A129-F7B7BFD85121-19656-00001360787AED1D_zps8ced575b.jpg104.1 KB · Views: 370

539130D3-B57E-4CC4-A129-F7B7BFD85121-19656-00001360787AED1D_zps8ced575b.jpg104.1 KB · Views: 370 -

B7AB9A9B-F6D2-422A-AD7B-19FB5A5336D4-19656-000013607F95D28E_zps5c30ea9f.jpg67.4 KB · Views: 381

B7AB9A9B-F6D2-422A-AD7B-19FB5A5336D4-19656-000013607F95D28E_zps5c30ea9f.jpg67.4 KB · Views: 381

Jessanation

New Member

wow looks great so far!

Sir Tsaboc

Member

Hey guys, I'm following up on this build that Brad and I have been working on!

I put the finishing touches on the helmet and molded it. Casts have been successfully pulled!

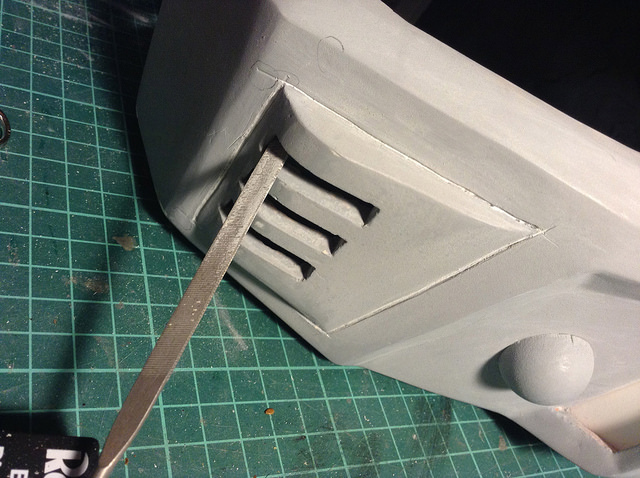

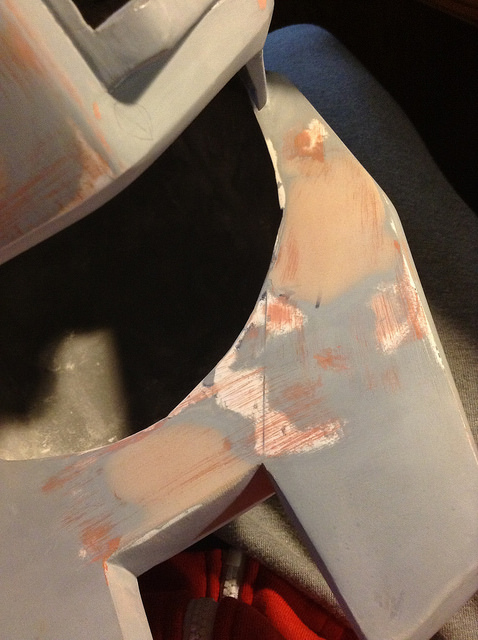

Per ushe, I think pictures speak louder than words so I'll keep the text down to a minimum. The finer details were perfected with needle files and a bunch of spot putty was used for the surface work. I used rebound 25 and free form air from smooth on to create the mold, and poured casts with smoothcast 300.

I put the finishing touches on the helmet and molded it. Casts have been successfully pulled!

Per ushe, I think pictures speak louder than words so I'll keep the text down to a minimum. The finer details were perfected with needle files and a bunch of spot putty was used for the surface work. I used rebound 25 and free form air from smooth on to create the mold, and poured casts with smoothcast 300.

Attachments

-

12260681495_0b7ab680ca_z.jpg118.5 KB · Views: 323

12260681495_0b7ab680ca_z.jpg118.5 KB · Views: 323 -

12261117544_286b6b4b00_z.jpg141.5 KB · Views: 316

12261117544_286b6b4b00_z.jpg141.5 KB · Views: 316 -

12261265636_c078236dbd_z.jpg119.3 KB · Views: 321

12261265636_c078236dbd_z.jpg119.3 KB · Views: 321 -

12260846033_7fa883e282_z.jpg120.4 KB · Views: 312

12260846033_7fa883e282_z.jpg120.4 KB · Views: 312 -

12261116284_d9dcac0bdc_z.jpg121.8 KB · Views: 333

12261116284_d9dcac0bdc_z.jpg121.8 KB · Views: 333 -

12261235576_aa06fdd7e3_z.jpg99.9 KB · Views: 319

12261235576_aa06fdd7e3_z.jpg99.9 KB · Views: 319 -

12493616193_a3f3aecb0f_z.jpg139.3 KB · Views: 324

12493616193_a3f3aecb0f_z.jpg139.3 KB · Views: 324 -

12261245806_a6b42dd815_z.jpg133.9 KB · Views: 317

12261245806_a6b42dd815_z.jpg133.9 KB · Views: 317 -

12526357313_f06b34a5f6_z.jpg143.1 KB · Views: 307

12526357313_f06b34a5f6_z.jpg143.1 KB · Views: 307 -

12553177545_47defc19c4_z.jpg145.4 KB · Views: 343

12553177545_47defc19c4_z.jpg145.4 KB · Views: 343

TheBradinator

Member

Awesome job Brad. Congrats on the move to Elite.

Loved the set of update pics.

How long until you have to be back in Oklahoma for the fall?

How long until you have to be back in Oklahoma for the fall?

TheBradinator

Member

Wow, THANK YOU SO MUCH! This is such an honor, and I'm so happy that the 405th is back!

So, what some people may not know is that this helmet actually has a rubber neck seal on it (the back portion of the helmet). I have incorporated this method on other helmets, but with this helmet, it is absolutely necessary because with the geometry of this helmet, you can barley get your head in without it.

So here is how I did it....

This helmet has a seam line running from the top of the head all the way down the back. So, there was no way I could accomplish this with the original mold. With rubber, you cannot have a seam line because of how hard it is to fix. So, I needed to make a new mold of the back section of the helmet. So I cleaned up the seam line, hit it with a clear coat, then went on to molding!

I decided that I wanted to use Rebound 25 as my mold rubber, and BrushOn 35 as the casting rubber. These two rubbers do not bond together because the Rebound is a Silicon rubber and Brush on is a Urethane Rubber. Also, because brush on 35 is a urethane, it will bond to Smoothcast 300, which is what I cast the hard portions of the helmet.

I used freeform Air for the Mother mold.

And BAM! The mold is done!

Ok, so the next thing that needs to be done before you cast the rubber is you need to Dremel out that back neck part. Then, you coat the rubber mold with a thin dusting of baby powder (a good release agent), Next, you strap on the mold to the back, mix the rubber (ADD BLACK DYE), and paint it in the mold and on the back of the resin surrounding where you cut that resin part out. let that sit for 12 hours, you should get something like this.

The only problem with rubber neck seals is the fact that you can only paint the rubber with latex based paint. But using black dye is very effective!

Thanks for looking, and it is such an honor to be added into the Elite section. Its been a dream of mine ever since I joined!

-Brad!

So, what some people may not know is that this helmet actually has a rubber neck seal on it (the back portion of the helmet). I have incorporated this method on other helmets, but with this helmet, it is absolutely necessary because with the geometry of this helmet, you can barley get your head in without it.

So here is how I did it....

This helmet has a seam line running from the top of the head all the way down the back. So, there was no way I could accomplish this with the original mold. With rubber, you cannot have a seam line because of how hard it is to fix. So, I needed to make a new mold of the back section of the helmet. So I cleaned up the seam line, hit it with a clear coat, then went on to molding!

I decided that I wanted to use Rebound 25 as my mold rubber, and BrushOn 35 as the casting rubber. These two rubbers do not bond together because the Rebound is a Silicon rubber and Brush on is a Urethane Rubber. Also, because brush on 35 is a urethane, it will bond to Smoothcast 300, which is what I cast the hard portions of the helmet.

I used freeform Air for the Mother mold.

And BAM! The mold is done!

Ok, so the next thing that needs to be done before you cast the rubber is you need to Dremel out that back neck part. Then, you coat the rubber mold with a thin dusting of baby powder (a good release agent), Next, you strap on the mold to the back, mix the rubber (ADD BLACK DYE), and paint it in the mold and on the back of the resin surrounding where you cut that resin part out. let that sit for 12 hours, you should get something like this.

The only problem with rubber neck seals is the fact that you can only paint the rubber with latex based paint. But using black dye is very effective!

Thanks for looking, and it is such an honor to be added into the Elite section. Its been a dream of mine ever since I joined!

-Brad!

killerownz11

Member

So how did you get the visor that color? Airbrush? Or special paint..

Brilliant work Brad. This is a great method for difficult to put on helmets.

darthcheeto

New Member

invested in seeing the final product

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 387

- Replies

- 0

- Views

- 646

- Replies

- 1

- Views

- 1,409

Similar threads

- Replies

- 0

- Views

- 646