You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Halo 4 Spartan IV under armor and utility suit

- Thread starter VividT E X

- Start date

- Status

- Not open for further replies.

Sri LanKING

New Member

Couldn't you guys use some kind of cheap wetsuit and put foamies on top of it to achieve details?

example (wetsuit):http://www.ebay.ca/itm/TWF-XT3-Mens...ng_CA&var=&hash=item7dbd1bb570#ht_5094wt_1161

EDIT: here is some neopreme with hexagonal embosing: http://vesde.en.alibaba.com/product/546568981-201834093/Hexagon_Embossing_Neoprene_Sheet.html

I don't know if either idea will work, I'm just spit balling

example (wetsuit):http://www.ebay.ca/itm/TWF-XT3-Mens...ng_CA&var=&hash=item7dbd1bb570#ht_5094wt_1161

EDIT: here is some neopreme with hexagonal embosing: http://vesde.en.alibaba.com/product/546568981-201834093/Hexagon_Embossing_Neoprene_Sheet.html

I don't know if either idea will work, I'm just spit balling

You are the best morphine. Thank you.

Not a problem

Couldn't you guys use some kind of cheap wetsuit and put foamies on top of it to achieve details?

example (wetsuit):http://www.ebay.ca/itm/TWF-XT3-Mens...ng_CA&var=&hash=item7dbd1bb570#ht_5094wt_1161

EDIT: here is some neopreme with hexagonal embosing: http://vesde.en.alibaba.com/product/546568981-201834093/Hexagon_Embossing_Neoprene_Sheet.html

I don't know if either idea will work, I'm just spit balling

The use of neoprene was the first thing I looked at but the problem is the fabric is designed to retain heat and keep you warm. If you're wearing it in summer outdoors, you'll boil like an egg!

The answer is using a fabric that's breathable and wicking to keep cool. If you're cold then you can always wear skins or thermals underneath.

Not a problem

The use of neoprene was the first thing I looked at but the problem is the fabric is designed to retain heat and keep you warm. If you're wearing it in summer outdoors, you'll boil like an egg!

The answer is using a fabric that's breathable and wicking to keep cool. If you're cold then you can always wear skins or thermals underneath.

I know its a shoe but it stretches, it is breathable and sturdy. We just need to find who supplies it.

It is my puma running shoe. It matches the pattern close.

What do you guys think?

check out this site

rainbow dash

Well-Known Member

rainbow dash

Well-Known Member

Thanks to everyone who came up with these awesome ideas for an undersuit.

I personally really like the McDavid sports stuff:

Maybe a combination of these two Hexpad protection clothes will work fine for me

http://www.mcdavid.eu/products/hexpad/soccer/7737/Long-Sleeve-Goalkeeper-Shirt

http://www.mcdavid.eu/products/hexpad/Basketball/7590/HexPad-Wrap:Around-Basketball-Short

I personally really like the McDavid sports stuff:

Maybe a combination of these two Hexpad protection clothes will work fine for me

http://www.mcdavid.eu/products/hexpad/soccer/7737/Long-Sleeve-Goalkeeper-Shirt

http://www.mcdavid.eu/products/hexpad/Basketball/7590/HexPad-Wrap:Around-Basketball-Short

I'll pass ... that's something I'd see some wearing out clubbing, lol!

Thanks to everyone how came up with these awesome ideas for an undersuit.

I personally really like the McDavid sports stuff:

Maybe a combination of these two Hexpad protection clothes will work fine for me

http://www.mcdavid.eu/products/hexpad/soccer/7737/Long-Sleeve-Goalkeeper-Shirt

http://www.mcdavid.eu/products/hexpad/Basketball/7590/HexPad-Wrap:Around-Basketball-Short

Well, my bloody browser ate my post but I'll try post an update tonight when I get home. I've emailed McDavid to see if you can buy Hexpad Lite sheets/rolls.

Pappa Midnight

Jr Member

I did a little shopping on my lunch break and found some "foam glue" that apparently sticks to fabric and is flexible.

I've given my test dyed spandex piece another wash and will look at doing some gluing tests tomorrow with foam (which for the best bond takes 24 hours to cure in a warm area).

Now, after a few hours of painstakingly blowing myself up to try get the best corpse posing possible, I've managed to get some screenshots for those looking for undersuit reference pictures.

It is incredibly difficult to have the body positioned symmetrically (evident in the back / chest pics) but I tried the best I had to work with.

Without further delay, here is the following Imageshack album (which was being a pain in the a$$) with all shots of the undersuit:

http://imageshack.us/g/1/9944769/

Here's a picture from it to give you an idea:

Let me know what you think! Also, if you're after more particular shots of the undersuit, let me know and I'll see what I can do.

Morphine would it be possible to get side, top, and bottom of this full body ( all pics taken from the same frame. also the hands and feet. Im going to model it for pep.

Or even beter can you fileshare the video. Ive been tryining to get a pep file of this undersuit to try out a new method of sizing, peping, and creating it. i got a list of materials that i want to try (most from this thread) but i need a decent pep.

colinmon22

Active Member

As a temporary undersuit, I used my wetsuit under the armour. It actually worked out ok and heat wasn't an issue. Just needing bathroom breaks

Just wondering though, what thickness? I'd imagine my 5:4 would get way too hot, but my 3:2 I figured might work. I'm nowhere near done with my armor, just planning ahead.

Just wondering though, what thickness? I'd imagine my 5:4 would get way too hot, but my 3:2 I figured might work. I'm nowhere near done with my armor, just planning ahead.

Oh hell erm off the top of my head can't remember the exact thickness but its pretty thick. It's a winter wetsuit, the sea round Cornwall gets almost freezing in winter and I can wear it in the sea and not feel the cold at all so it's fairly hefty! I can take a look at thickness if your interested. Just need to take a look when I'm home

Morphine would it be possible to get side, top, and bottom of this full body ( all pics taken from the same frame. also the hands and feet. Im going to model it for pep.

Or even beter can you fileshare the video. Ive been tryining to get a pep file of this undersuit to try out a new method of sizing, peping, and creating it. i got a list of materials that i want to try (most from this thread) but i need a decent pep.

Sure thing, I'll see what I can do tonight. It probably won't be the exact frame as the one pictured, so I'll grab another front-on shot as the same frame as the side, top and bottom.

I'll hopefully be able to post pics of the results of my foam piece gluing as well.

VividT E X

Jr Member

All right here it comes ... Guys ...I don't realy know what to do about all this crap -_- bots totaly just wreck my damned day...

How come people find any plesure in destroying other's every parcelle of proudness, or even just doing what they ever do ? not that I realy want a debat on that, it was more rethorical than anythig xD Now sotp complaining Vivid !

!

Life is great, nobody is cocky but now, should I report him to spase for harasing this thread ? Just end up that I talked to him today

How come people find any plesure in destroying other's every parcelle of proudness, or even just doing what they ever do ? not that I realy want a debat on that, it was more rethorical than anythig xD Now sotp complaining Vivid

Life is great, nobody is cocky but now, should I report him to spase for harasing this thread ? Just end up that I talked to him today

colinmon22

Active Member

Oh hell erm off the top of my head can't remember the exact thickness but its pretty thick. It's a winter wetsuit, the sea round Cornwall gets almost freezing in winter and I can wear it in the sea and not feel the cold at all so it's fairly hefty! I can take a look at thickness if your interested. Just need to take a look when I'm home

Ok, perfect, thats encouraging. Your's is probably a 5:4 or thicker. I'd just heard that they're a bad idea for cons, I'll probably use my 3:2 just to be on the safe side. Its too thin to keep me warm in the summer even! Then again, the Monterey Bay isn't known for warm waters!

I've been counting on using my wetsuit despite what what some people say about them. Now I'm just curious as to how to go about adding detail to one without ruining it.

Ok, perfect, thats encouraging. Your's is probably a 5:4 or thicker. I'd just heard that they're a bad idea for cons, I'll probably use my 3:2 just to be on the safe side. Its too thin to keep me warm in the summer even! Then again, the Monterey Bay isn't known for warm waters!

I've been counting on using my wetsuit despite what what some people say about them. Now I'm just curious as to how to go about adding detail to one without ruining it.

Guess you could add the detail to the exterior using cut pieces from a donor suit or thin neoprene sheeting. Use the correct cement for attachment and the suit should remain quite usable in cool water conditions without sacrificing mobility nor structural integrity. 3:2 would be the best bet for prolonged indoor/all day use.

2nd Monterey Bay being a bit chilly!

Probably the best idea would be to buy a cheap one and then use camping mat foam to add the detail. Just be sure to cut a hole in the crotch and install a zipper. The thing to remember with the suit and wetsuit is, once your in. Your in!

Not quick to get it off again, so make sure you get bathroom breaks covered lol

Not quick to get it off again, so make sure you get bathroom breaks covered lol

Alrighty, so I have finally uploaded some pics with some of the testing I've done in regards to foam and spandex.

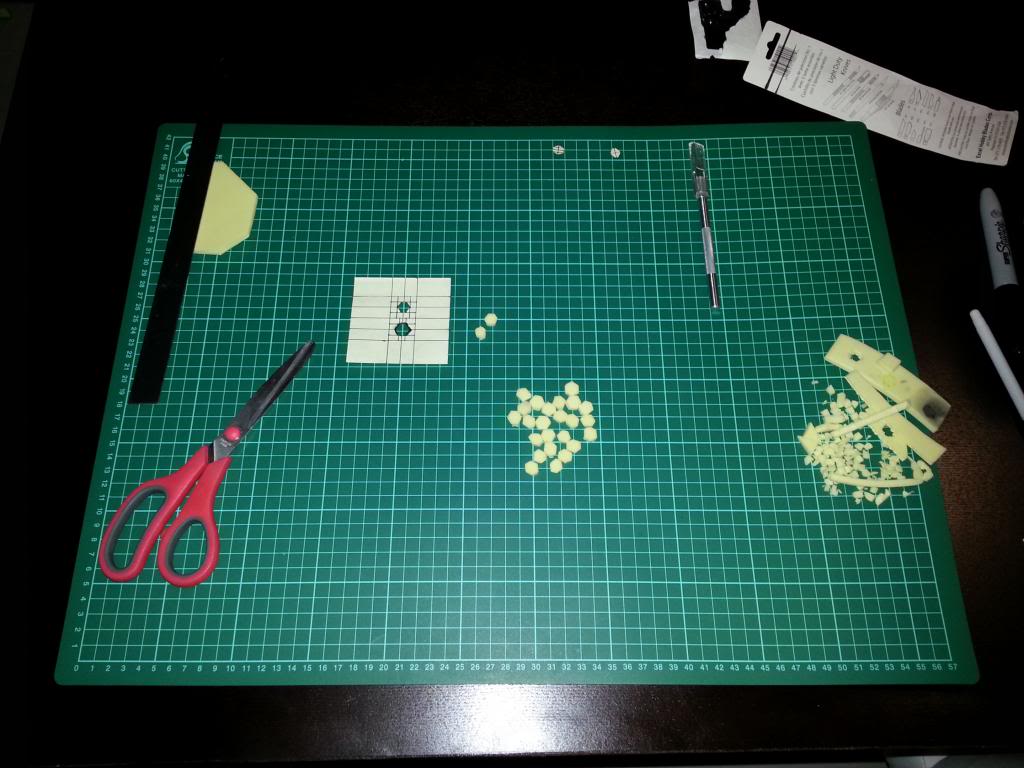

I first started cutting out little hexagon pieces of 8mm foam, not the EVA foam but like a camping mat, which is pretty spongey and not very rigid:

That little square piece of paper I was to try get a hexagon template going, but it's extremely hard not to wreck it if you keep cutting in the middle of it with the x-acto knife. I decided to just freehand little hexagons, measuring around 1cm in width (which is the approximate length of hexagon on the undersuit, I believe anyway). Due to the foam's spongeyness, I found it was easier to cut holding the knive horizontally (like cutting steak) than it was vertically in the template I did. They weren't exactly shaped hexagons, but they did the job for the test I was trying to achieve.

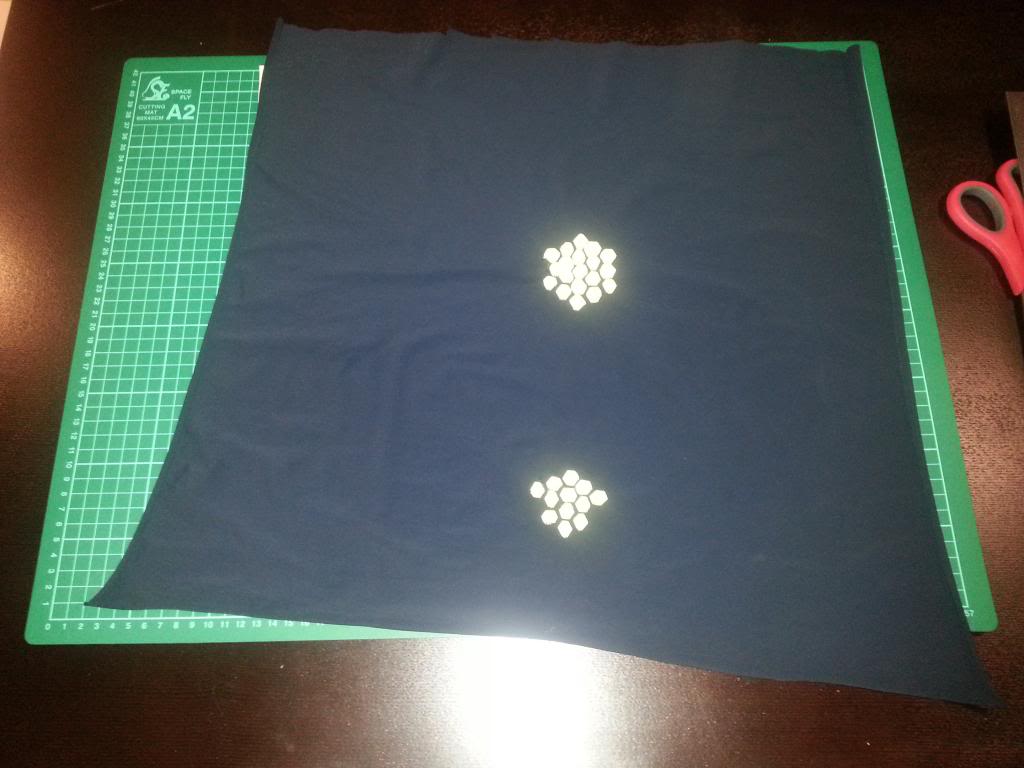

For half of the hexagons, I cut them in half to make it approximately 4mm high, just to see if the depth of foam made a difference when stretching the foam around my body. I then glued all the hexagons in the pattern of the undersuit and attempted to space them 1mm apart from each other:

(Apologies for the glow, as I took the picture at night time)

It was difficult to know how much glue to use so the foam was adequately stuck onto the spandex and would hold properly. Definitely messy work and trying to keep the hexagons close yet still 1mm apart was a challenge as the glue made the spandex surface slippery. The glue was also causing the spandex to stuck to my art mat, so I had to keep moving it without disturbing the hexagon's position.

I then left the fabric on the washing line for the glue to cure (as per the foam glue's instructions) for 24 hours. It seemed to have worked! The glue definitely does provide enough give for the foam to remain stuck on the fabric. I did find that I used too much glue on the thicker 8mm foam bits than the 4mm foam bits, evident in the result shots below:

Thicker 8mm hex foam bits result

Thinner 4mm hex foam bits result

I've stretched the spandex piece around my thigh just to show how it looks with the foam pressing from underneath and the bumpiness I'm trying to achieve. As you can see, there is excess glue that has come through to the surface, but it was only a test piece to see if the glue would hold the foam to the fabric properly.

I think the thicker 8mm provides the bumpy texture a lot better than the 4mm pieces.

I don't have a photo of it, but I have submerged the test piece and the foam bits to see if the foam comes off. This was to simulate a drink spillage or similar. Thankfully, the foam remains glued to the fabric even though the glue is water soluble. I might try keeping it in water a little longer for further research but the signs appear that this method is fit for use.

Although it will be rather tedious and time consuming cutting out and gluing single hex foam pieces to the undersuit, I think the result will be quite rewarding. This in addition to sublimating the fabric with the rubber look (with the addition of scratches and weathering THIS PATTERN that I created is what I'll probably print) I think I'll manage to have a breathable, lightweight undersuit that is still convincing rather than wearing actual furnace-inducing rubber. At the end of the day, I'll probably have little hexagon marks on my skin from the foam pressing in, but it'll be worth it

Let me know what people think and if you have any questions or want more pictures of the test piece.

I first started cutting out little hexagon pieces of 8mm foam, not the EVA foam but like a camping mat, which is pretty spongey and not very rigid:

That little square piece of paper I was to try get a hexagon template going, but it's extremely hard not to wreck it if you keep cutting in the middle of it with the x-acto knife. I decided to just freehand little hexagons, measuring around 1cm in width (which is the approximate length of hexagon on the undersuit, I believe anyway). Due to the foam's spongeyness, I found it was easier to cut holding the knive horizontally (like cutting steak) than it was vertically in the template I did. They weren't exactly shaped hexagons, but they did the job for the test I was trying to achieve.

For half of the hexagons, I cut them in half to make it approximately 4mm high, just to see if the depth of foam made a difference when stretching the foam around my body. I then glued all the hexagons in the pattern of the undersuit and attempted to space them 1mm apart from each other:

(Apologies for the glow, as I took the picture at night time)

It was difficult to know how much glue to use so the foam was adequately stuck onto the spandex and would hold properly. Definitely messy work and trying to keep the hexagons close yet still 1mm apart was a challenge as the glue made the spandex surface slippery. The glue was also causing the spandex to stuck to my art mat, so I had to keep moving it without disturbing the hexagon's position.

I then left the fabric on the washing line for the glue to cure (as per the foam glue's instructions) for 24 hours. It seemed to have worked! The glue definitely does provide enough give for the foam to remain stuck on the fabric. I did find that I used too much glue on the thicker 8mm foam bits than the 4mm foam bits, evident in the result shots below:

Thicker 8mm hex foam bits result

Thinner 4mm hex foam bits result

I've stretched the spandex piece around my thigh just to show how it looks with the foam pressing from underneath and the bumpiness I'm trying to achieve. As you can see, there is excess glue that has come through to the surface, but it was only a test piece to see if the glue would hold the foam to the fabric properly.

I think the thicker 8mm provides the bumpy texture a lot better than the 4mm pieces.

I don't have a photo of it, but I have submerged the test piece and the foam bits to see if the foam comes off. This was to simulate a drink spillage or similar. Thankfully, the foam remains glued to the fabric even though the glue is water soluble. I might try keeping it in water a little longer for further research but the signs appear that this method is fit for use.

Although it will be rather tedious and time consuming cutting out and gluing single hex foam pieces to the undersuit, I think the result will be quite rewarding. This in addition to sublimating the fabric with the rubber look (with the addition of scratches and weathering THIS PATTERN that I created is what I'll probably print) I think I'll manage to have a breathable, lightweight undersuit that is still convincing rather than wearing actual furnace-inducing rubber. At the end of the day, I'll probably have little hexagon marks on my skin from the foam pressing in, but it'll be worth it

Let me know what people think and if you have any questions or want more pictures of the test piece.

Morphine would it be possible to get side, top, and bottom of this full body ( all pics taken from the same frame. also the hands and feet. Im going to model it for pep.

Or even beter can you fileshare the video. Ive been tryining to get a pep file of this undersuit to try out a new method of sizing, peping, and creating it. i got a list of materials that i want to try (most from this thread) but i need a decent pep.

I've taken some screenshots and just need to transfer them to the PC but I've tried to get at least half of the body lined up vertically to then copy to the left/right side.

I'll attempt to host them tonight and post the link up for you.

I've still yet to receive any word from Blue Realm Studios (emailed them back in December) but have got word back from McDavids.

Unfortunately the Hexpad doesn't come in sheets or rolls of fabric, so custom solutions is back on the board.

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 990

- Replies

- 1

- Views

- 55

Similar threads

- Replies

- 4

- Views

- 990