Hello, my lovely 405thers. I am desperately reaching out here after fiddling with a pattern for two weeks.

This is confusing, but bear with me.

Last October I made a thigh that fits to me perfectly, but I lost the templates and file. I spent a few days adjusting the size to find the circumference of the bottom of the thigh, and I eventually figured it out.

However, when I cut out a sample of the thigh and convert it to foam, I get a discrepancy of 2-3cm:

Not a big deal for some of you, but it adds up when you're my size.

Okay, no matter. I printed out some samples to put together, but once again, 6 mm and 8 mm foam curved "lengthens" the overall diameter of the foam when curved and enclosed. No matter what I did, even if I added bevels or separated the parts, there was still a huge discrepancy.

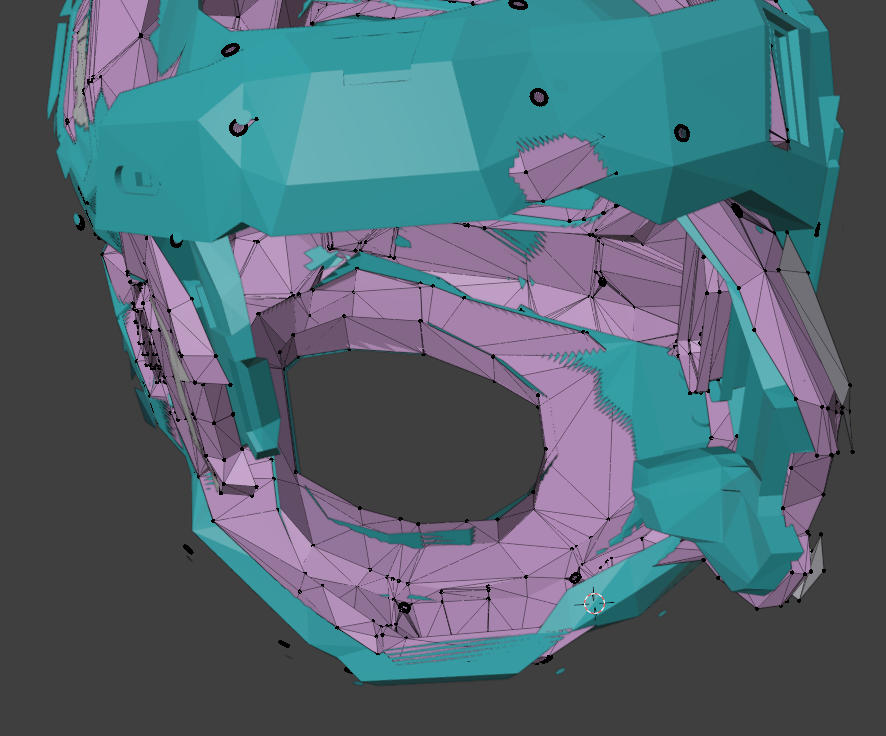

Armorsmith file with an accurate scan

_____________Test build that devours my leg

..............Discrepancy

The 13.5cm measurement on my test thigh measures 15cm across, and the 17.6cm measurement on my test thigh measures over 19cm. Once again, not a huge deal, but those are a simple length versus width measurement, not the entire inside area of the thigh.

The thighs height does not change because there is no extreme vertical curving.

This is where I come to you, desperate and tired, 405th.

What would you do in this situation? The thighs are the only part of the Reach Spartan that is fully curved (with the biceps being somewhat curved) so I will not have this issue with any other part due to its blocky geometry. I do not want to cut the inside of the gasket to fix the problem because then the thigh will be heavily lop-sided, and I don't want to cut the front or back as it will have an unhideable seam. I also don't want to pad them as they are going to look far bigger and ill-fitted than the rest of my armor due to the errors. I also can't make a custom pattern with my original thigh, because the extra length issue will persist (tested). At this time, I cannot wait to make my thighs last as my chest and other armor parts are scaled off of them. I am not trying to be nitpicky here, I just want things to be true-to-scale out of Armorsmith.

I have already tried printing out several copies of the thighs, gradually getting smaller to test if I can find the right size with the foam discrepancy, but it is very time-consuming and full of error. Does anyone know a ratio or formula I could follow to estimate how much smaller I need to make the pattern to account for the extra length when the foam is curved?

Thank you as always,

Kae