You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pipninja's Ultimate Gungnir Helmet!

- Thread starter pipninja

- Start date

- Member DIN

- S770

I didn't realize just how much there was in my helmet until I put it all down in a circuit diagram. I made the diagram so I could wrap my head around the layout of the back of the helmet with the control circuitryWOW man this has got to be the most electronics Ive seen in a helmet! Awesome stuff!

- Member DIN

- S770

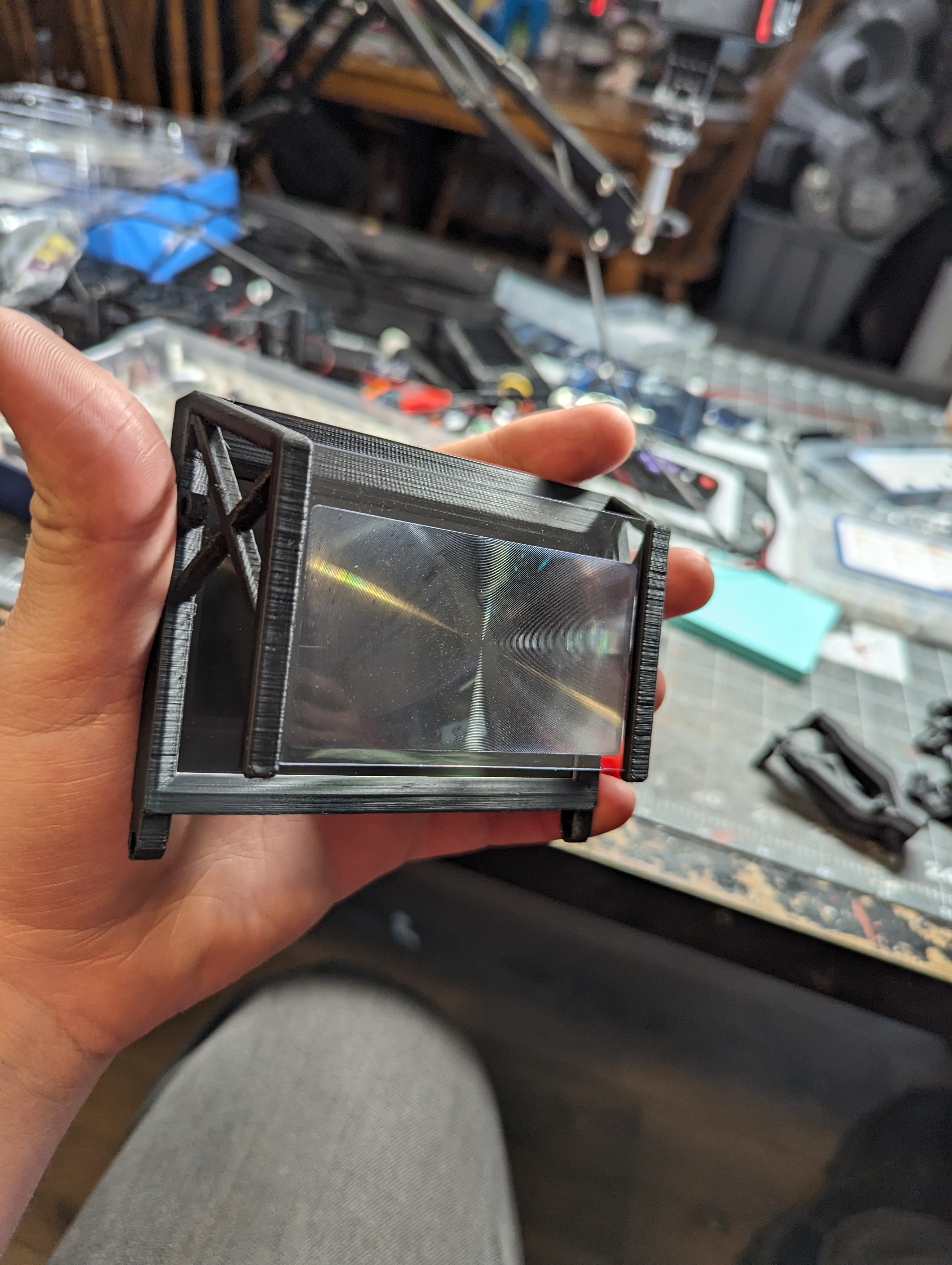

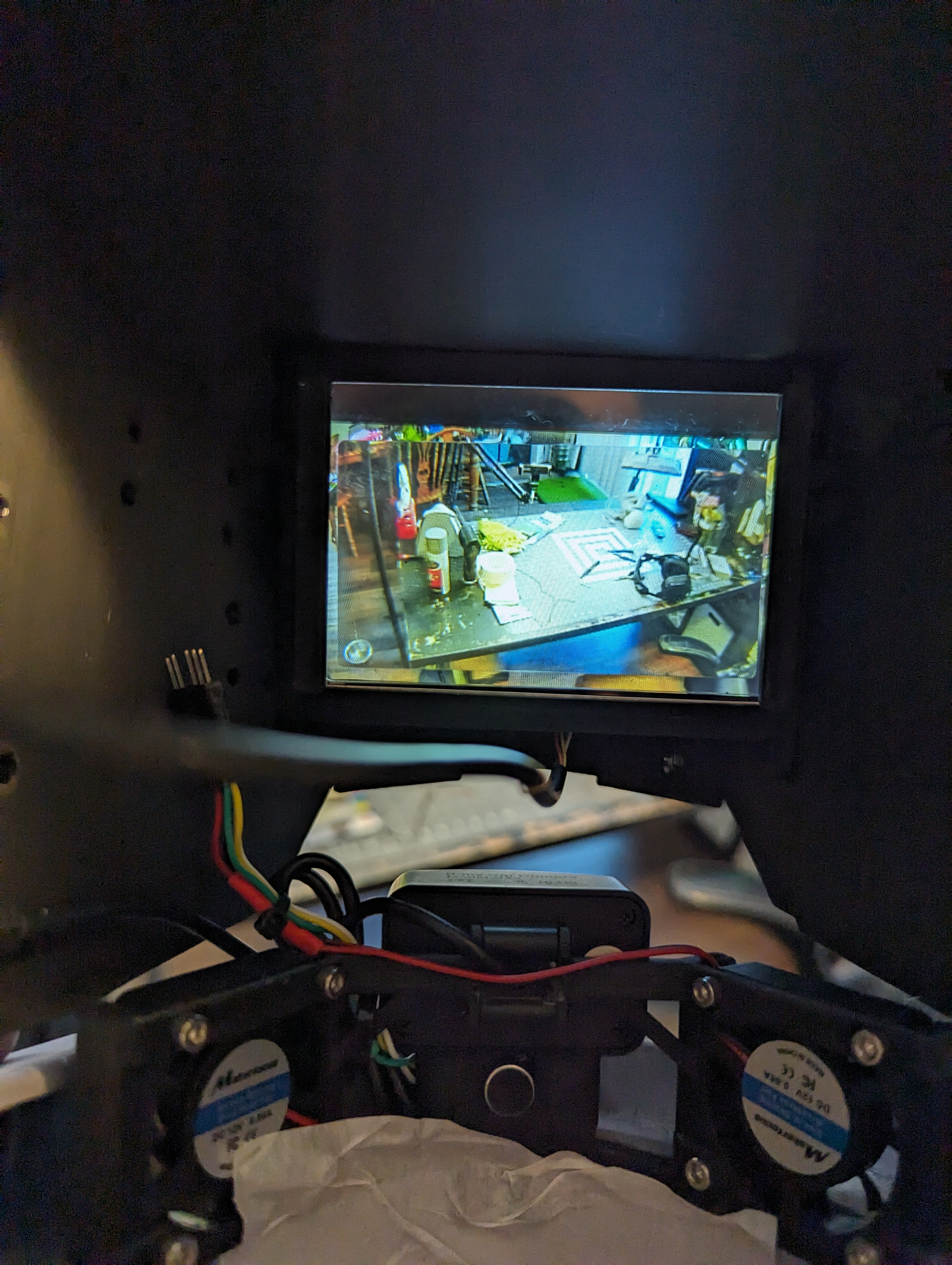

Today's update was a small one, I only had a little bit of time. First off, the V2 of the screen and lense holder finished, and it works beautifully! The screen resolution it also much better than the last one, so it is also much clearer.

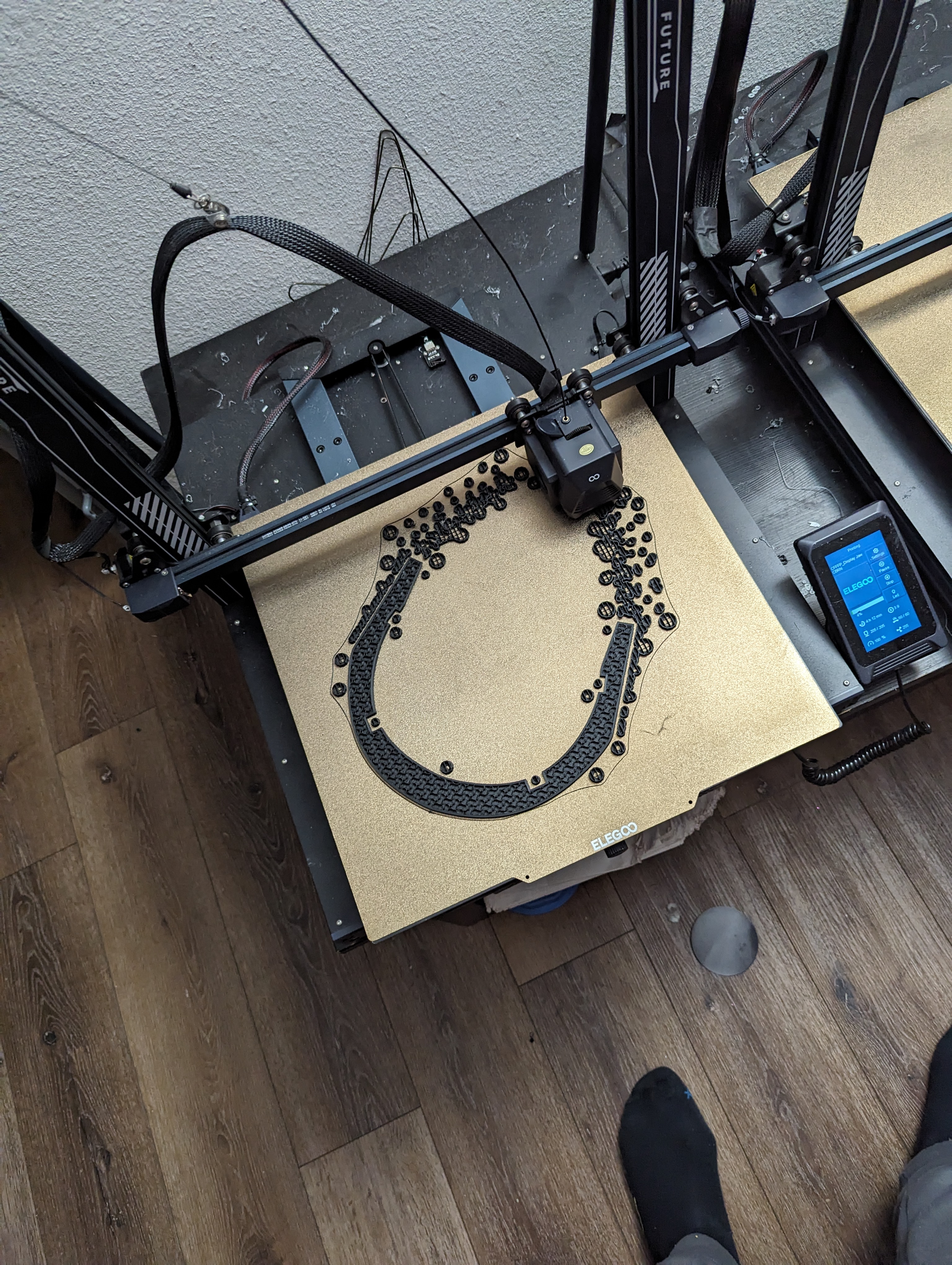

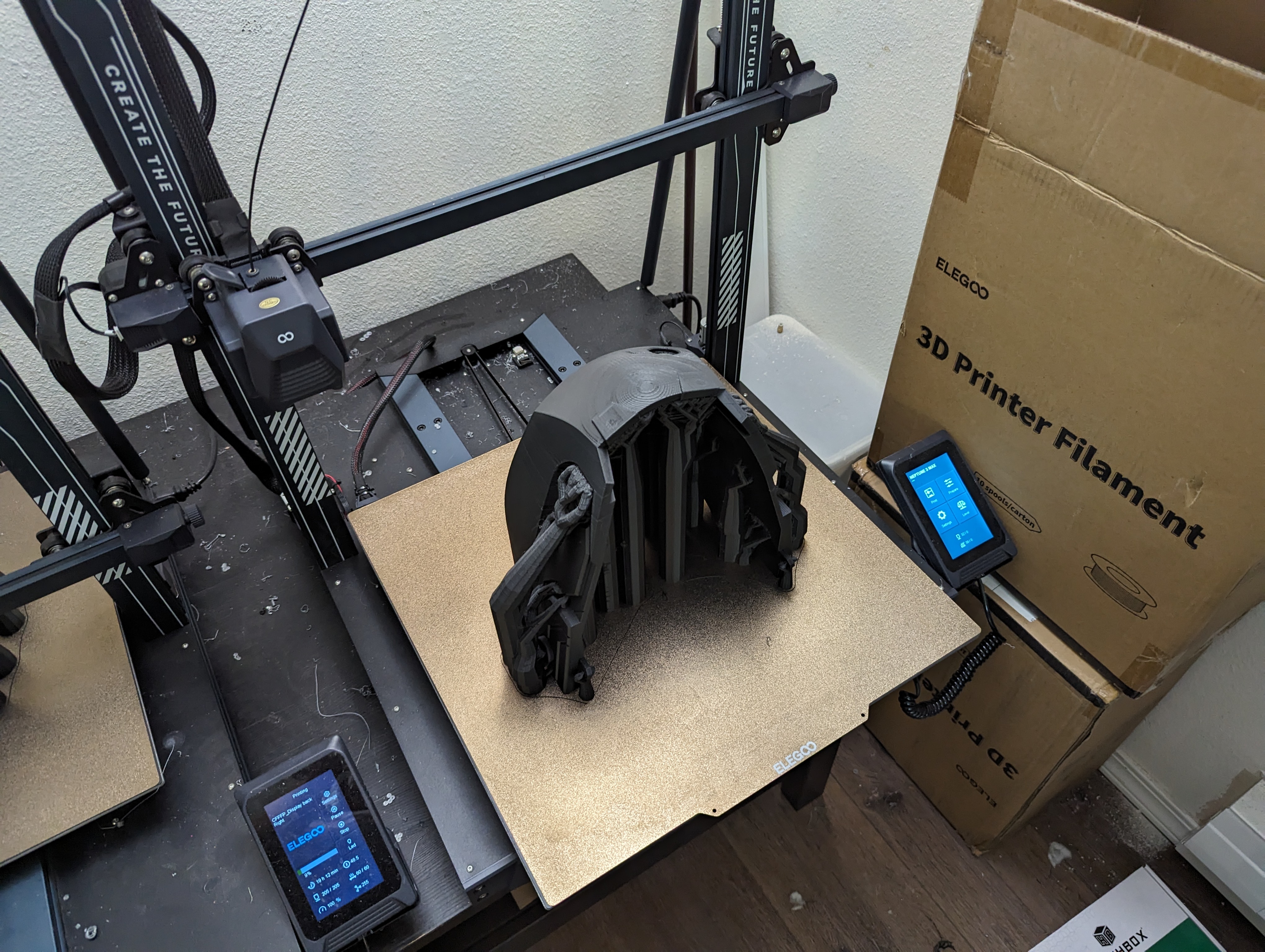

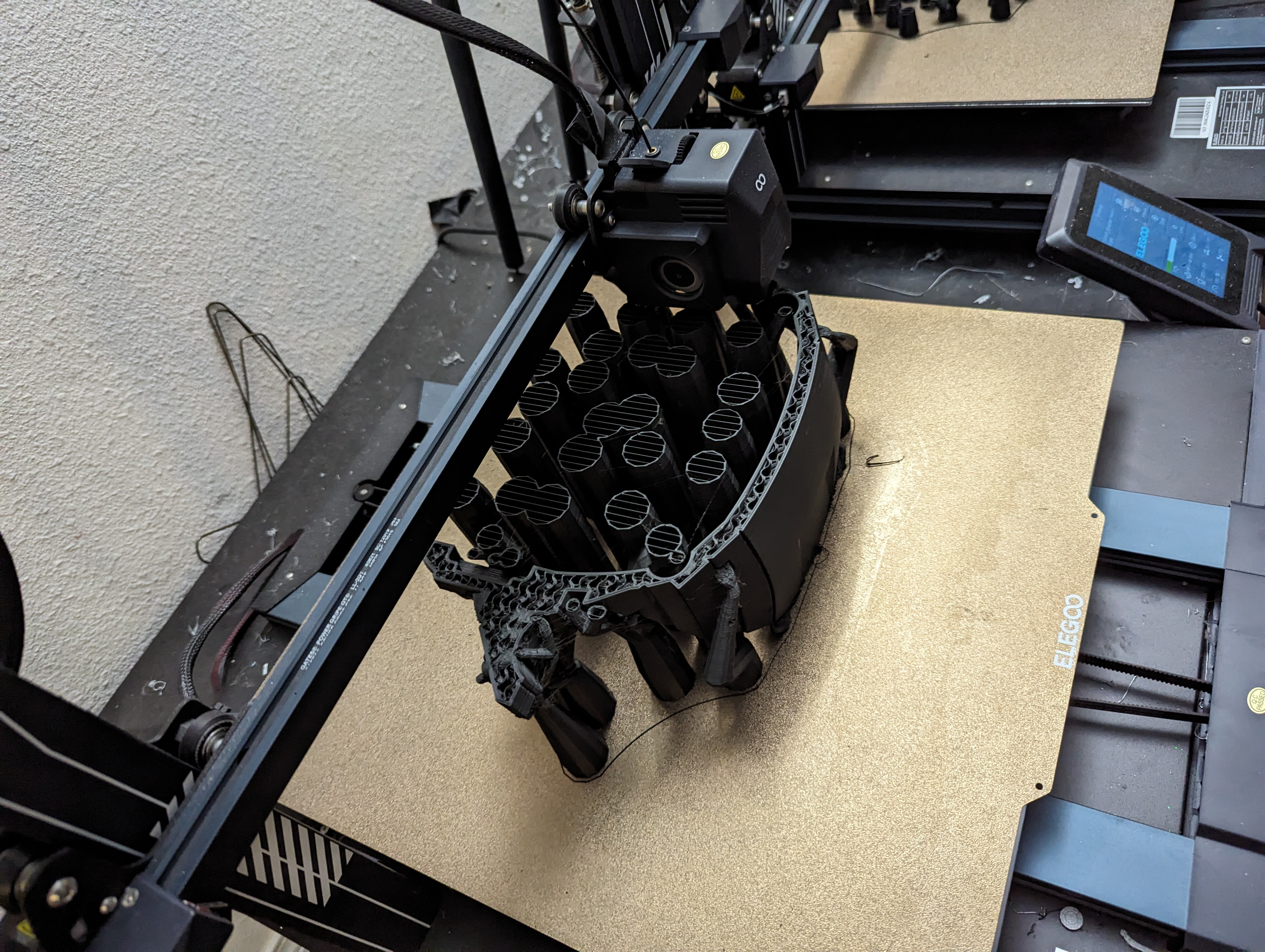

Next I also started printing the lower jaw, and a bunch of the smaller parts on the right printer. It was misbehaving, had a big failure today, so the small prints are to make sure that I fixed it well enough before printing the upper hood.

I also spent a little time today working on the back of the helmet, but not enough significant progress to have anything to show. More just the basic structure to build into.

Next I also started printing the lower jaw, and a bunch of the smaller parts on the right printer. It was misbehaving, had a big failure today, so the small prints are to make sure that I fixed it well enough before printing the upper hood.

I also spent a little time today working on the back of the helmet, but not enough significant progress to have anything to show. More just the basic structure to build into.

- Member DIN

- S770

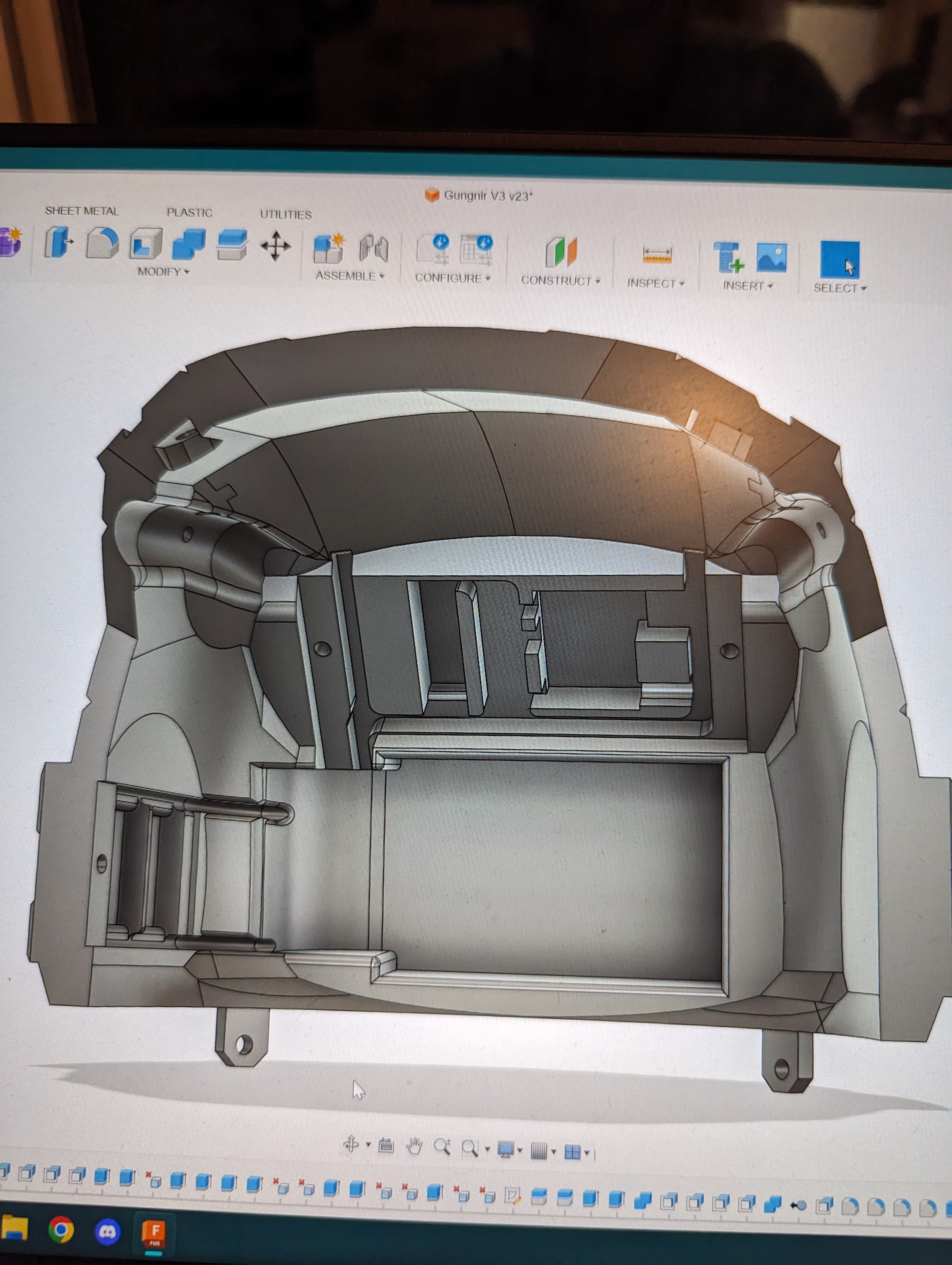

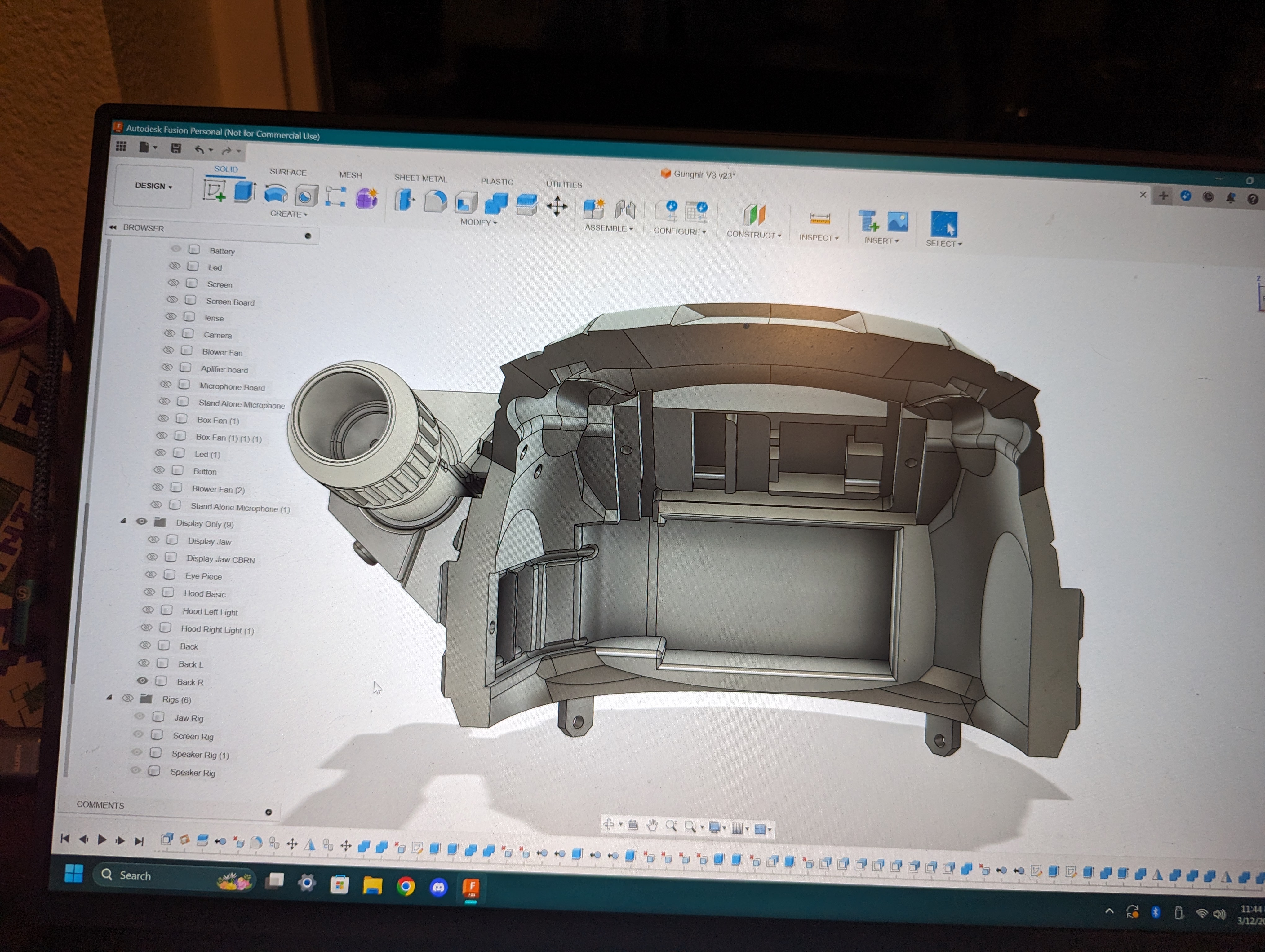

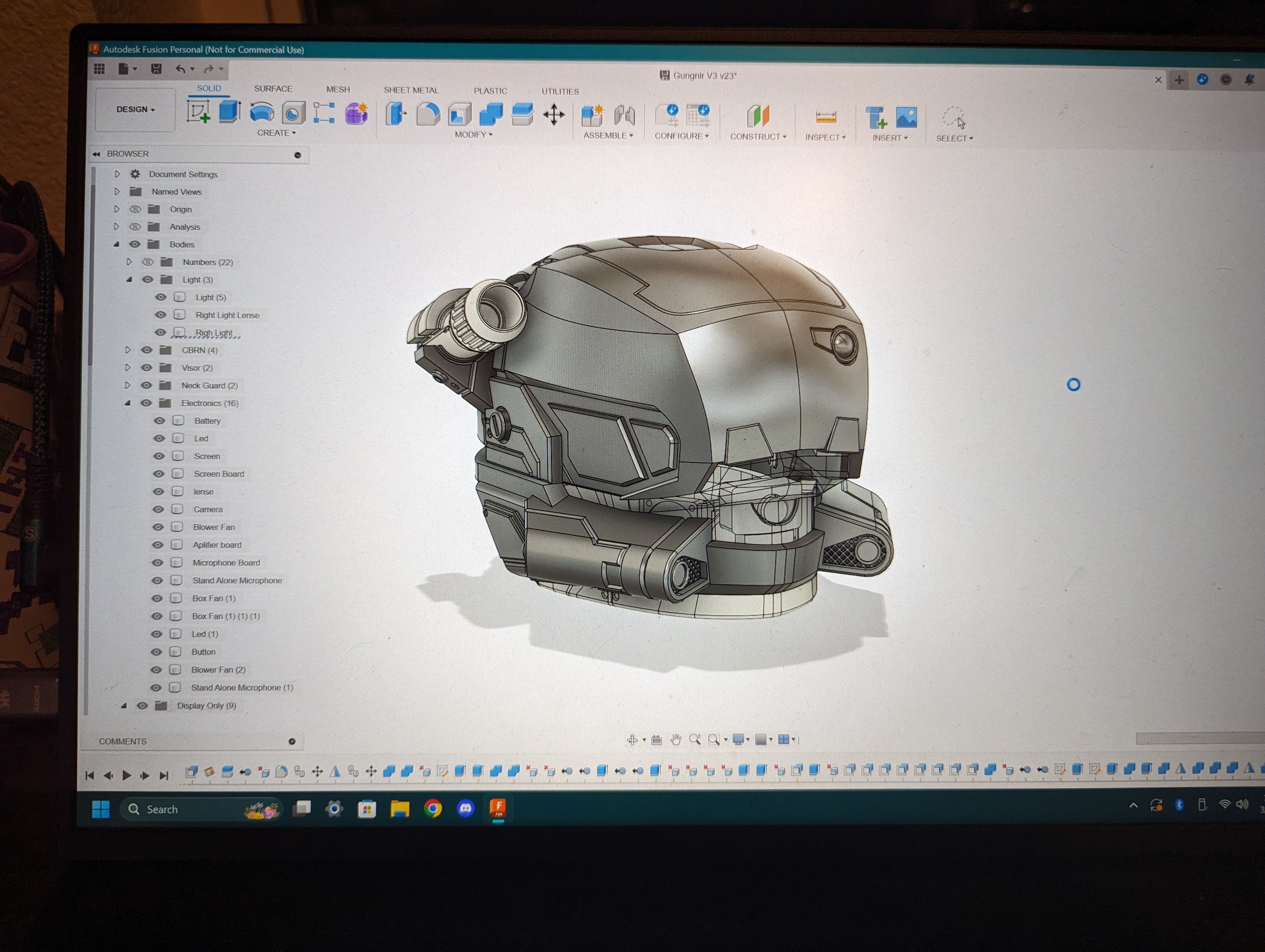

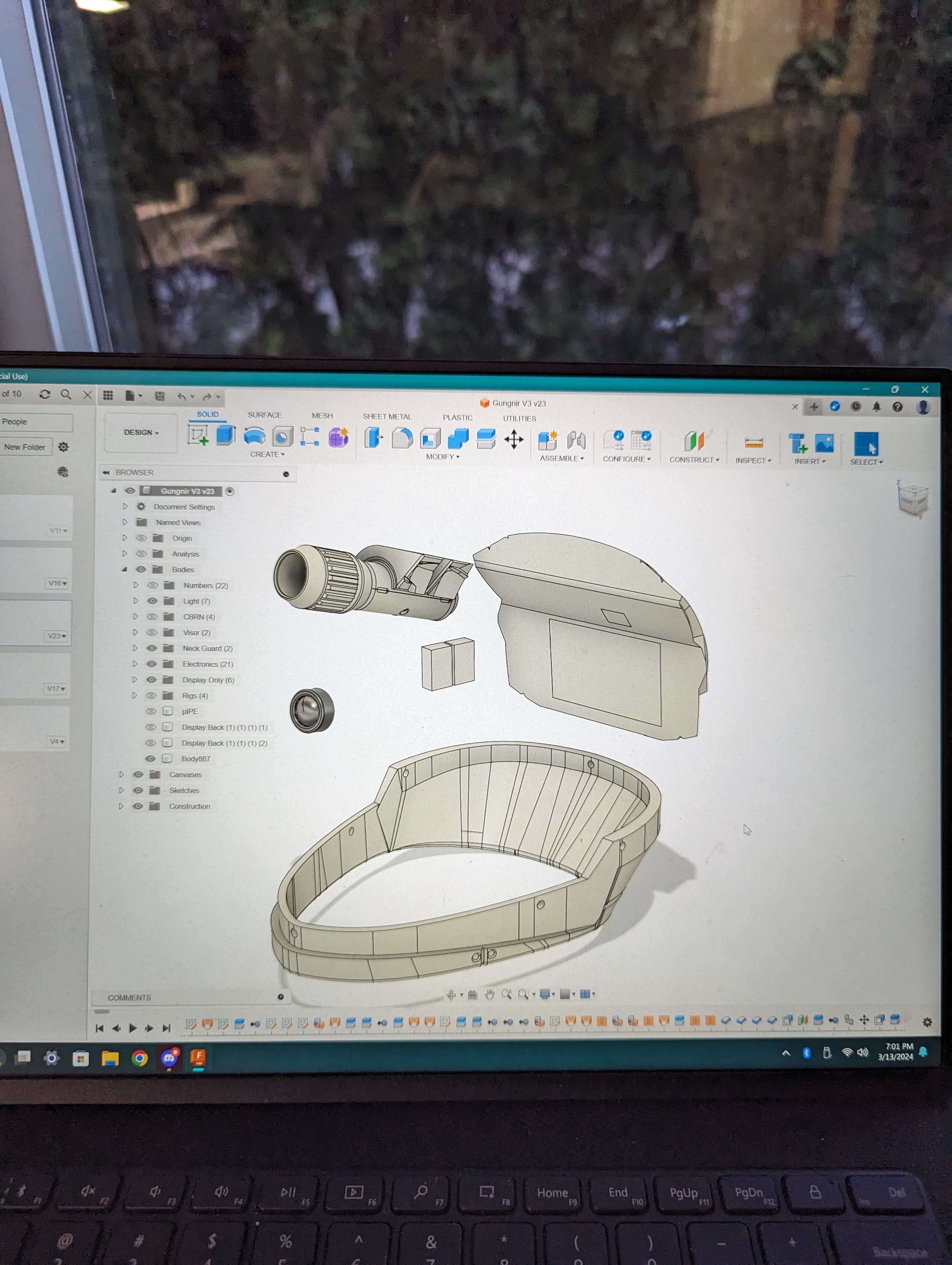

This is truly a special day!! I finished the 3d model!!!

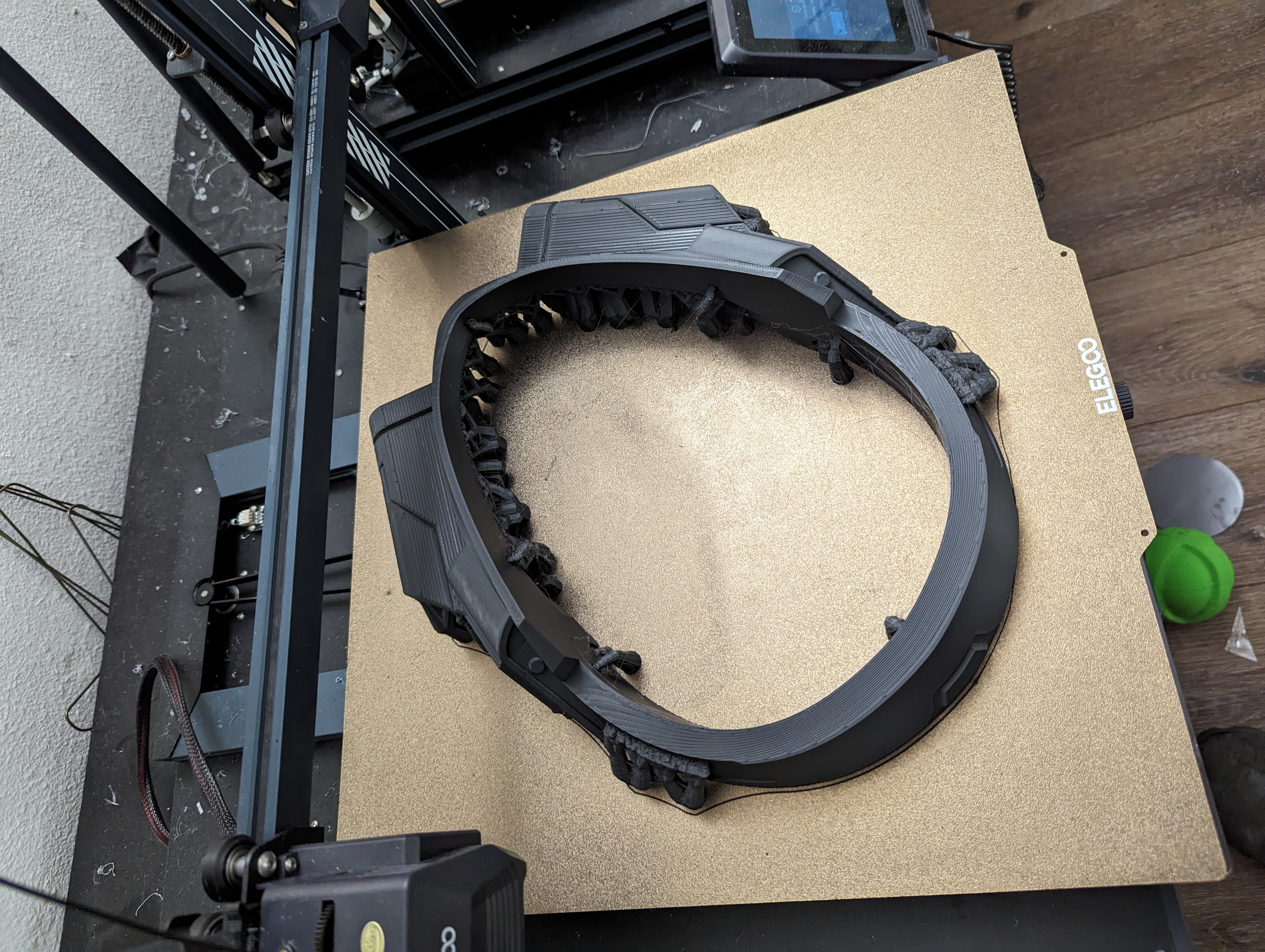

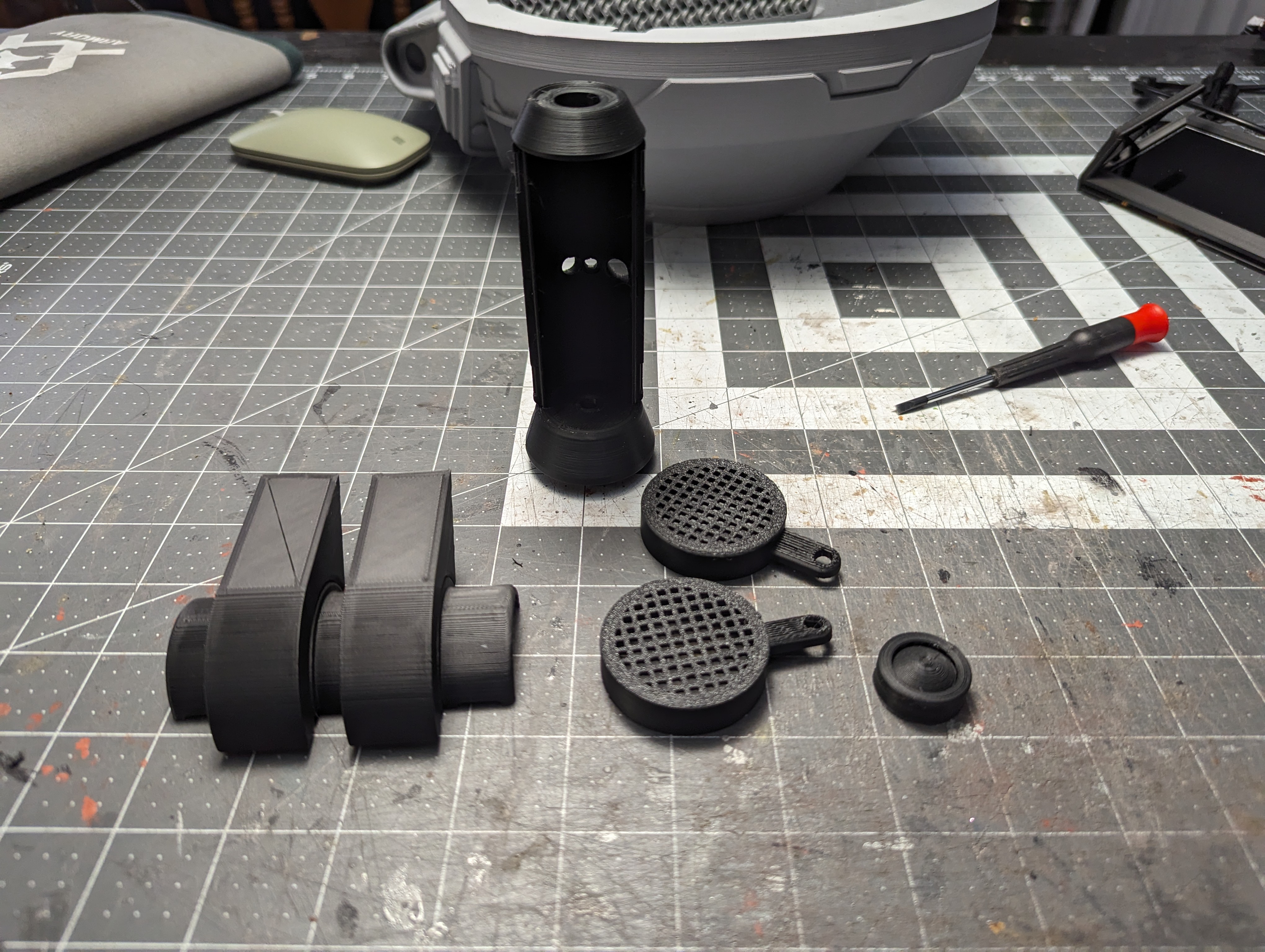

First things first, this group of small parts did finish printing, and they turned out great! The failed print on this printer was just a clogged nozzle that I fixed with the jo-clogger tool.

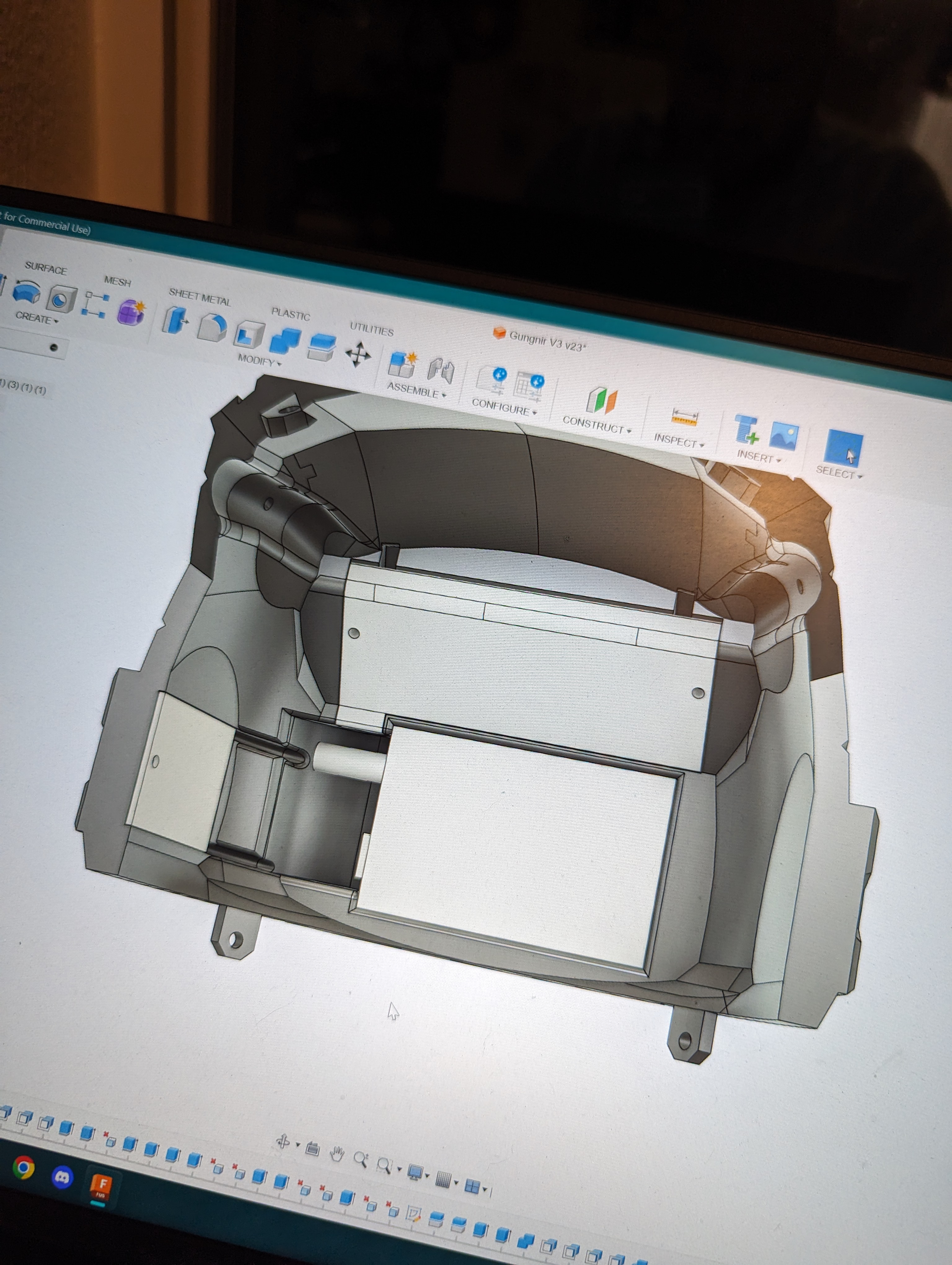

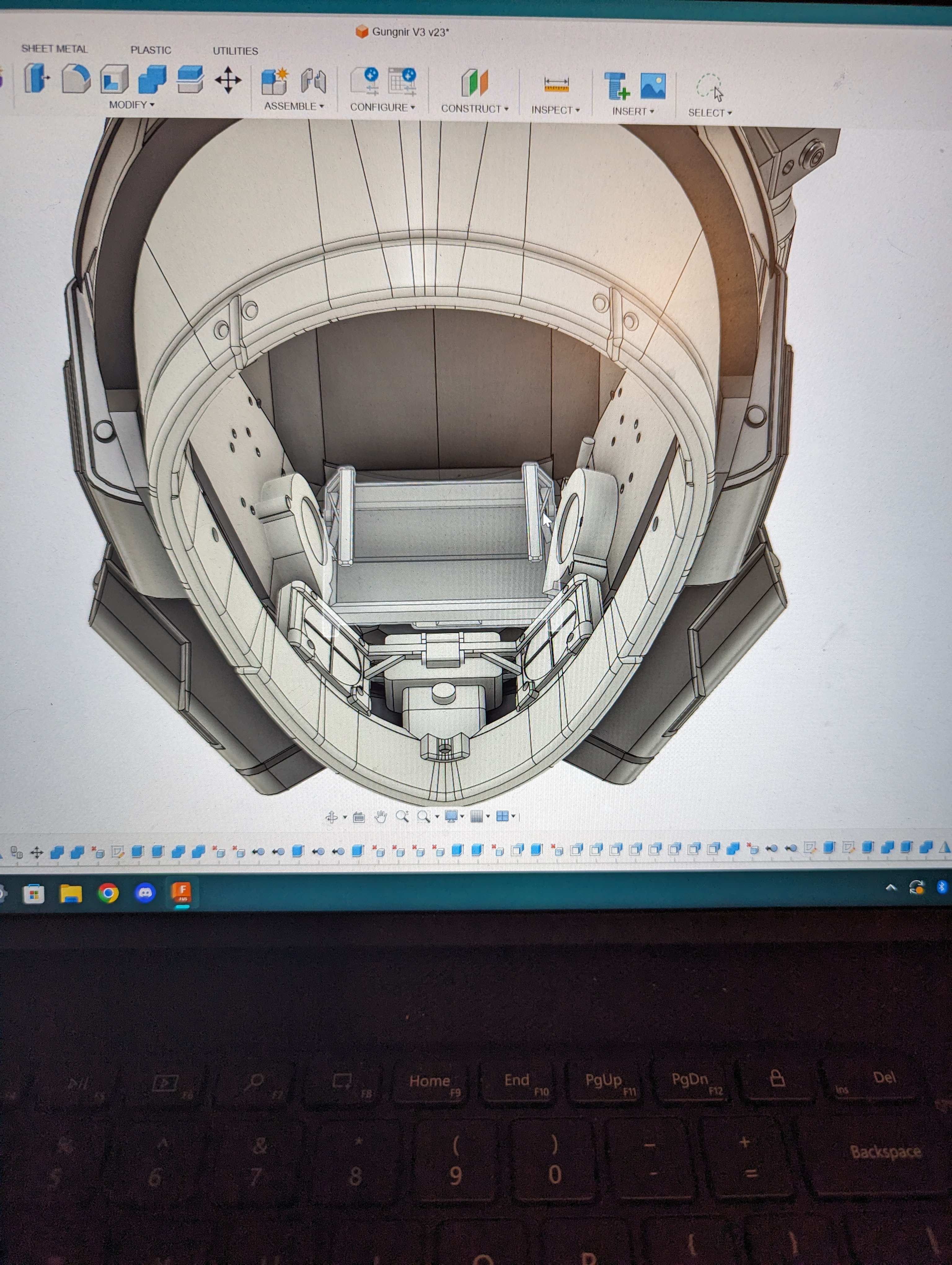

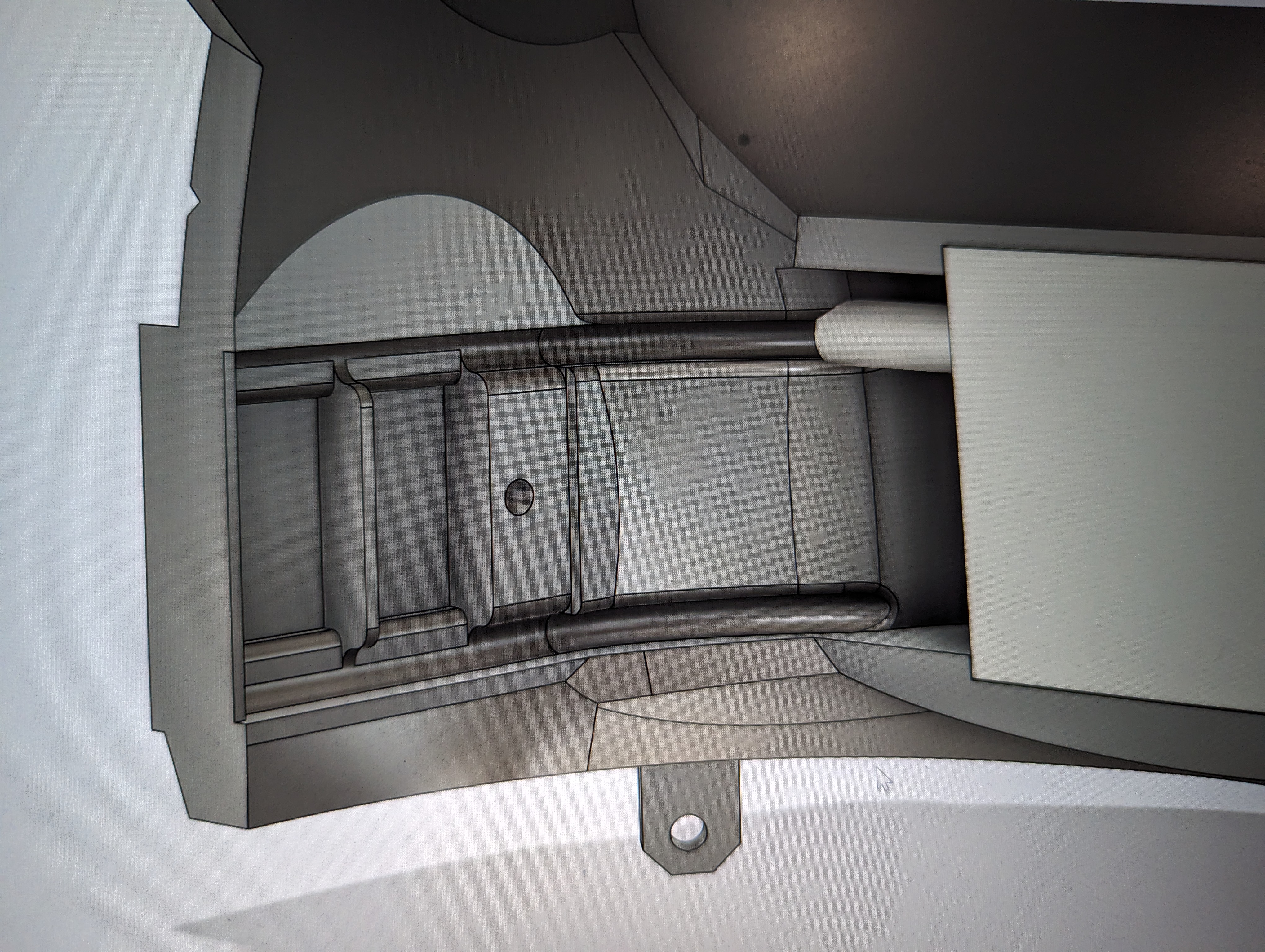

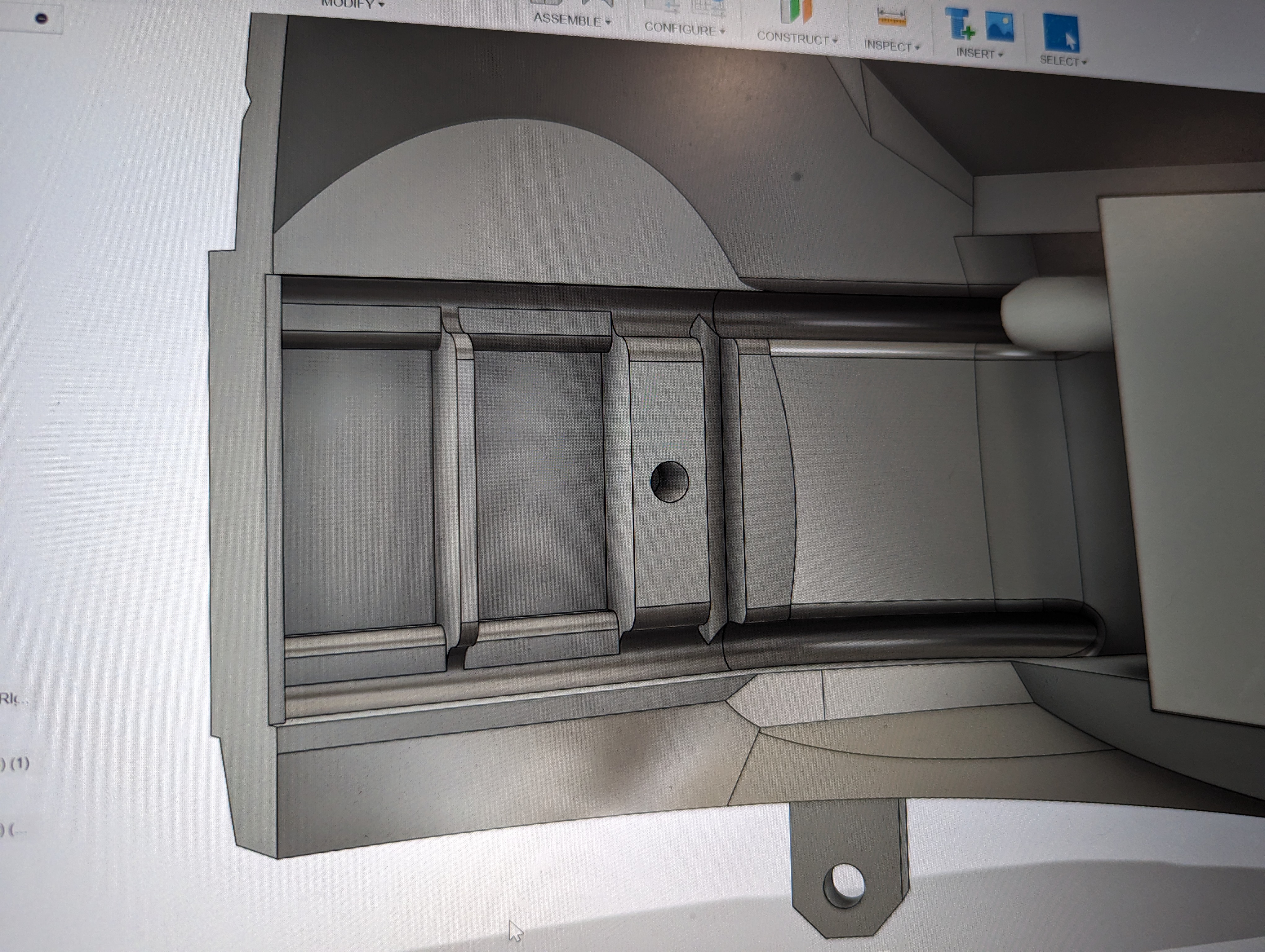

Ok to the modeling! I started with the back plate today, getting the spots for all the control boards and wire routing. This was a challenge to fit it in here.

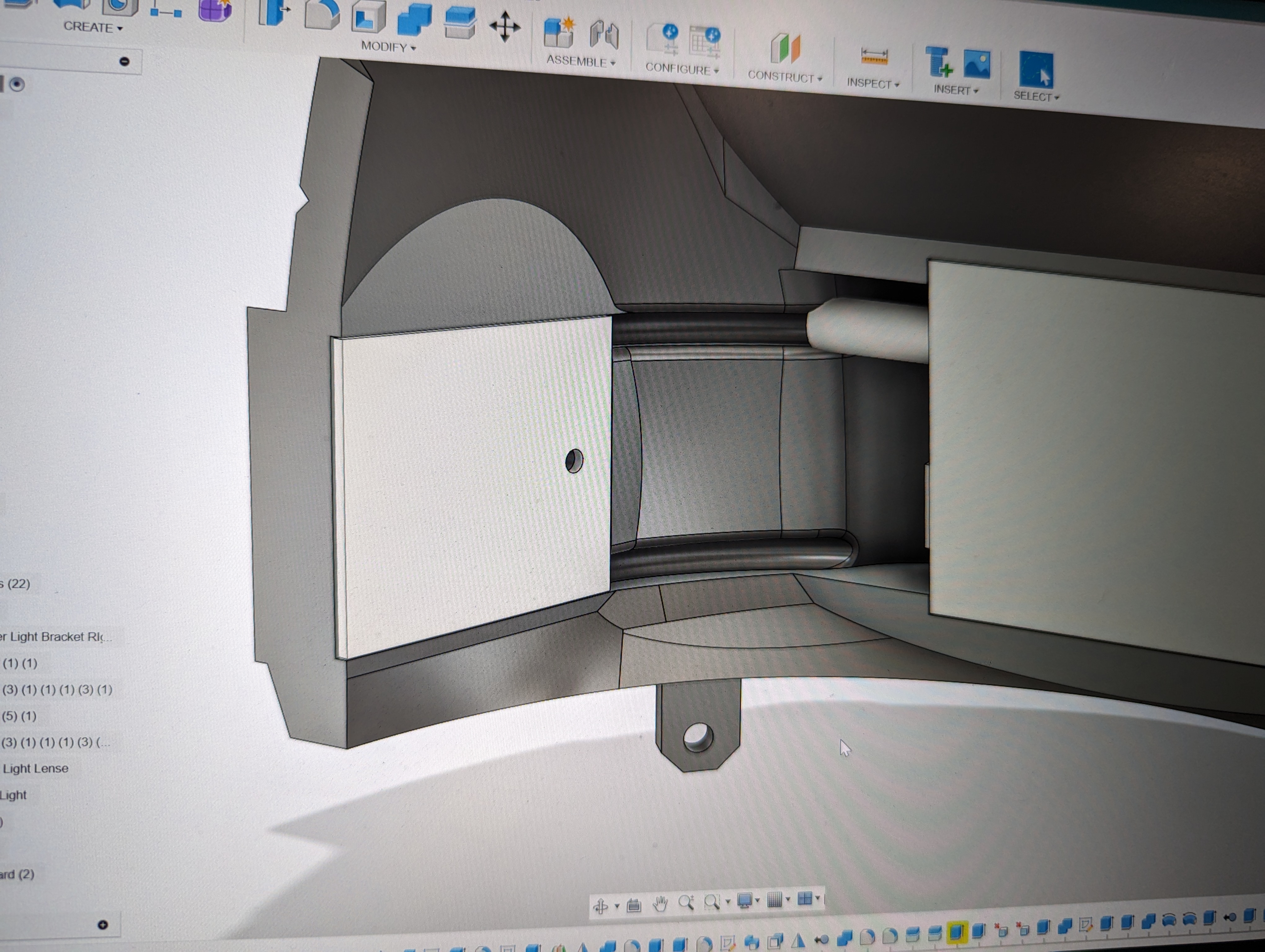

Then I made the covering plates for the circuit boards. Also the bottom box here is the battery pack that is going to be powering everything. It is going to be Velcroed in like before.

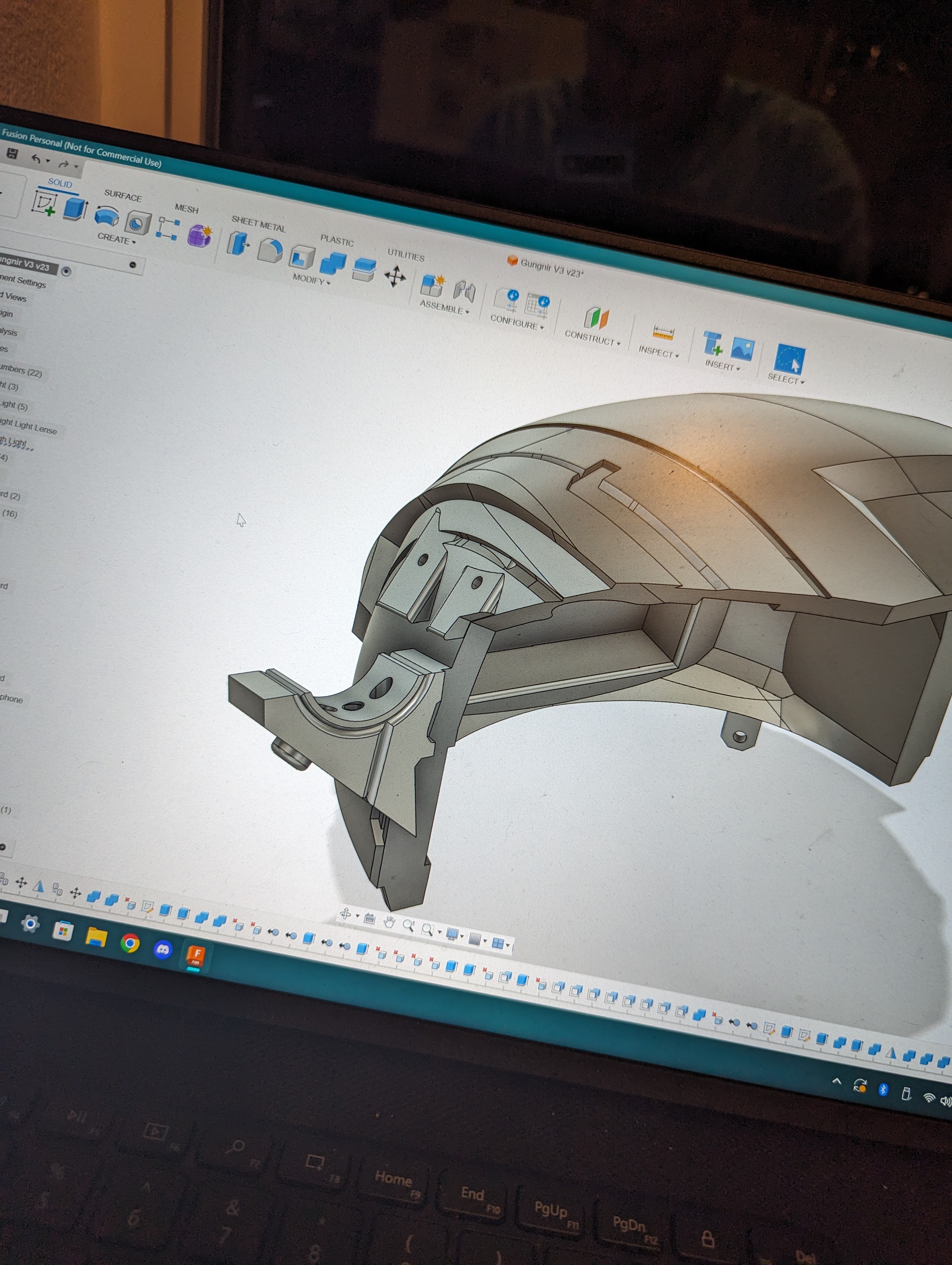

After that, it was just finishing the mounts for the version of the helmet with the side light!

Now for some full shots with all the components in it!

Now I just have 2 and a half weeks to finish printing it, and finish it! So much work to do!

First things first, this group of small parts did finish printing, and they turned out great! The failed print on this printer was just a clogged nozzle that I fixed with the jo-clogger tool.

Ok to the modeling! I started with the back plate today, getting the spots for all the control boards and wire routing. This was a challenge to fit it in here.

Then I made the covering plates for the circuit boards. Also the bottom box here is the battery pack that is going to be powering everything. It is going to be Velcroed in like before.

After that, it was just finishing the mounts for the version of the helmet with the side light!

Now for some full shots with all the components in it!

Now I just have 2 and a half weeks to finish printing it, and finish it! So much work to do!

- Member DIN

- S097

A tip from someone who has gone the integrated voice amp route before: make sure you isolate the microphone from the speakers as much as humanly possible. Especially with them being as close as they are to the mic location, feedback may occur with very little gain applied. It's awesome to see this project coming along though, best of luck!

- Member DIN

- S770

The good news is that the speaker position is already tried and true! It's in the same place as my last Gungnir helmet, up by the eye piece, and it's pointed upwards. There is feedback at all!A tip from someone who has gone the integrated voice amp route before: make sure you isolate the microphone from the speakers as much as humanly possible. Especially with them being as close as they are to the mic location, feedback may occur with very little gain applied. It's awesome to see this project coming along though, best of luck!

- Member DIN

- S770

I had that problem too on a different helmet. I really am lucky that I had such an isolated spot for my speaker in this buildI need to meet you at a convention and take a look! I still want to do this for my helmet, just never could quite get it as loud as I wanted without it feeding back.

- Member DIN

- S770

Okay, so a setback, but an update

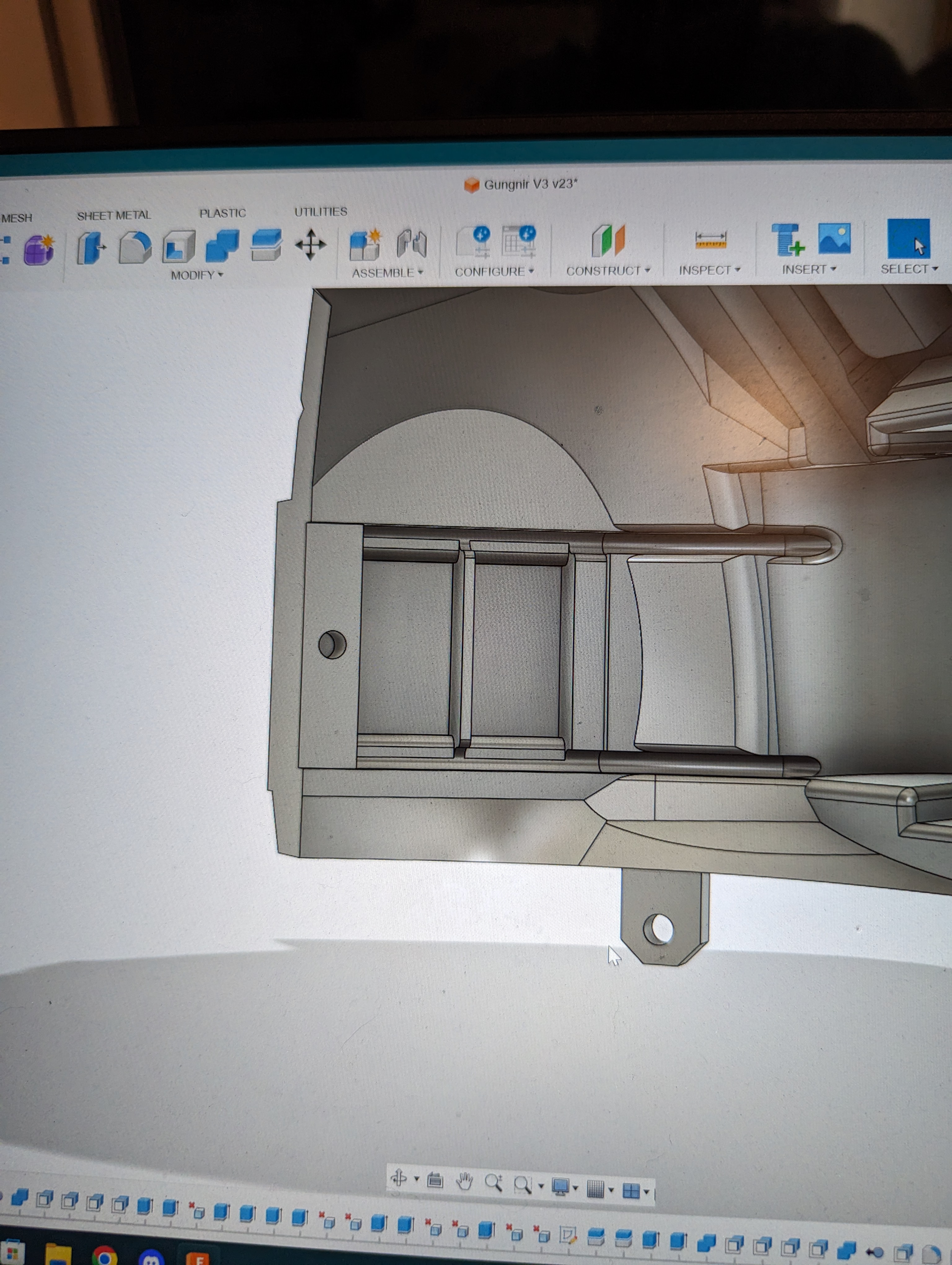

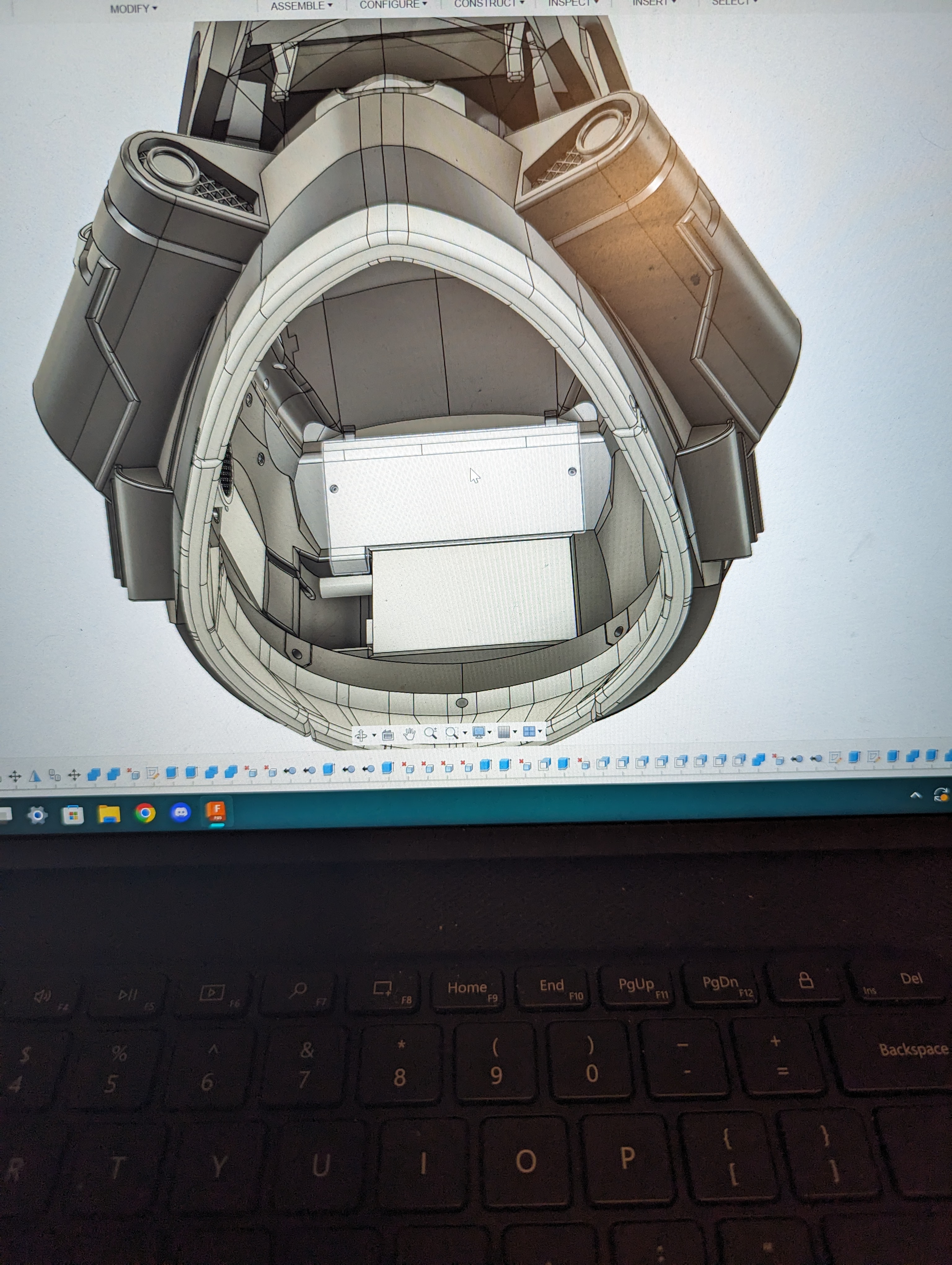

First the setback. My computer decided that while fusion was in the middle of saving, it would restart Automatically for an update, and wipe 6 hours of my finishing process... So that sucks. I was left at this stage with the back plate

All is not bad though, because I got back on the horse, and I'm actually much happier with the remodel of this section compared to the first one! I got this power conversion section done!

Also, I actually did this modeling while visiting my parents, so I took my desktop with me! One of the best things about my setup, is by design my monitor keyboard and mouse are all portable so I can move them around to desk as necessary, but that means that my desktop is also only one cord connection for power. The monitor gets its power from the PC USB port!

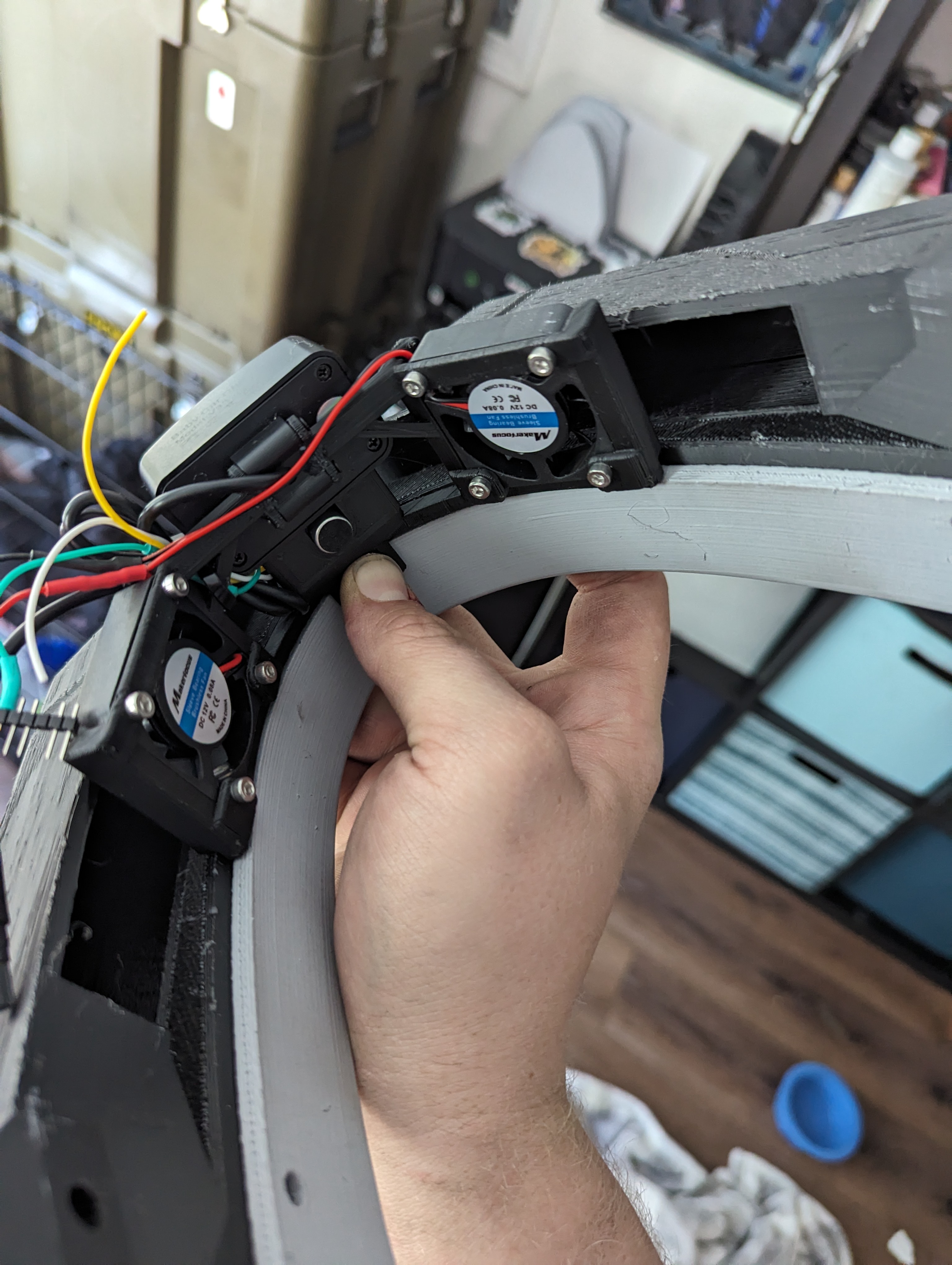

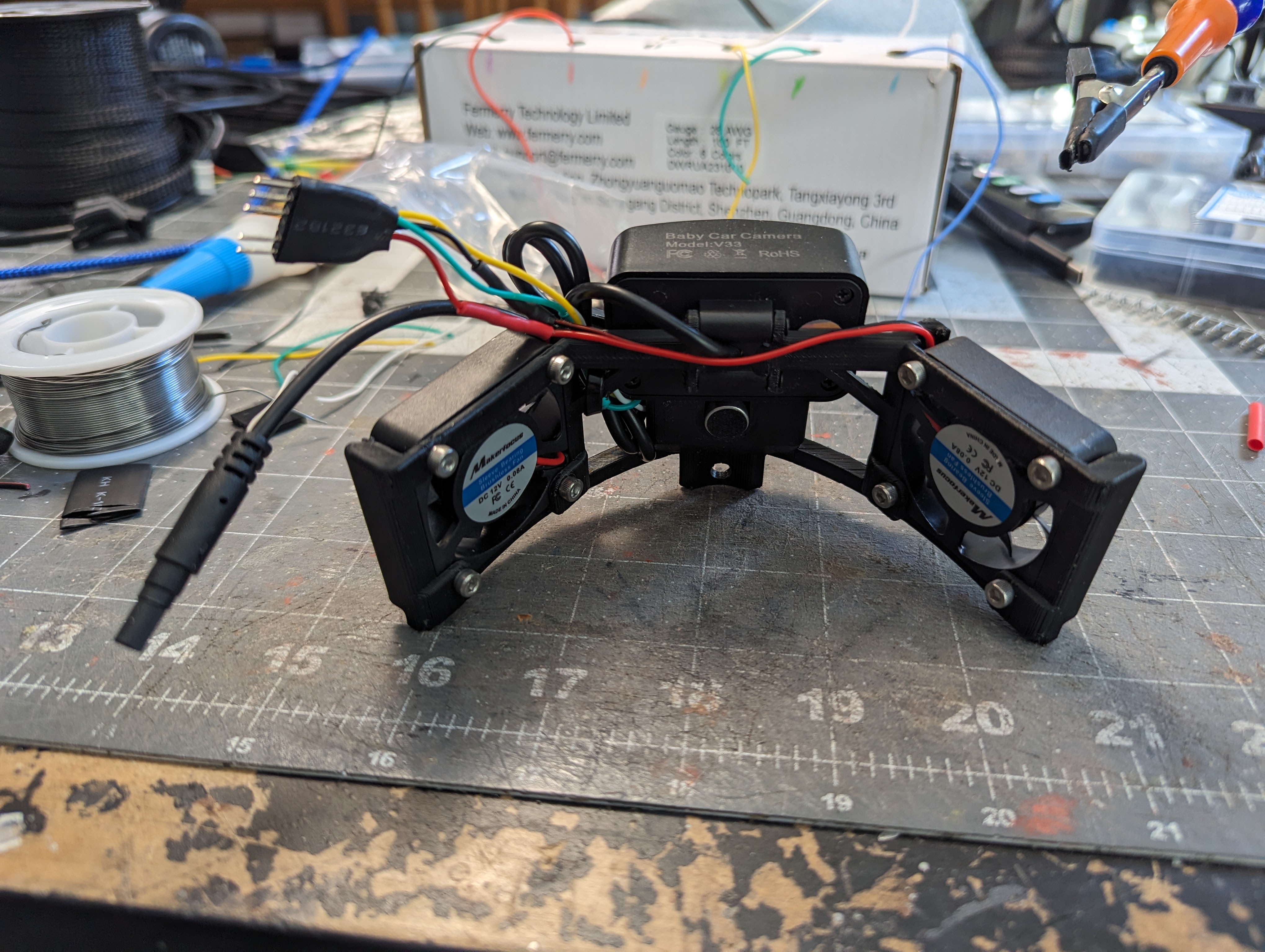

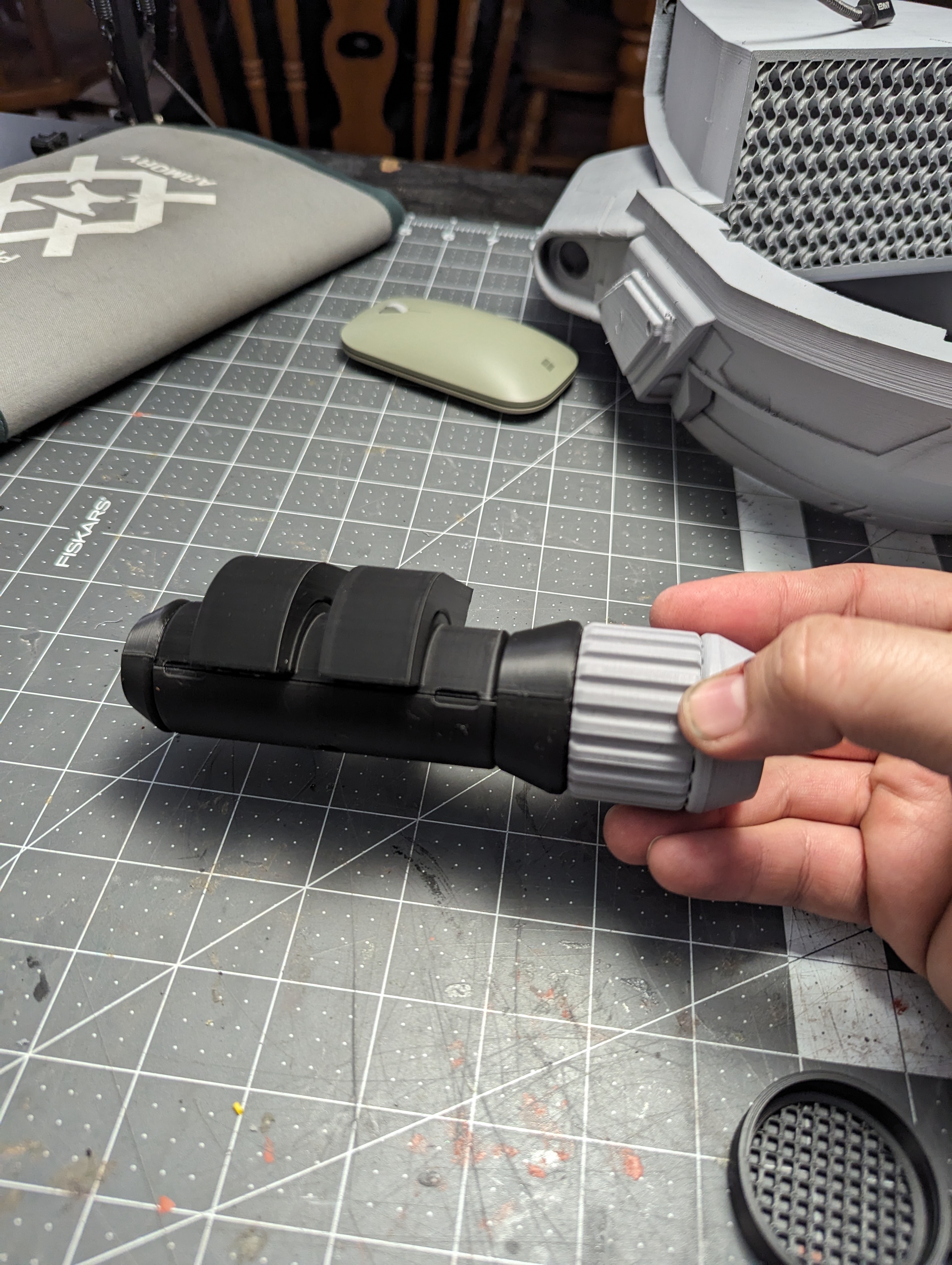

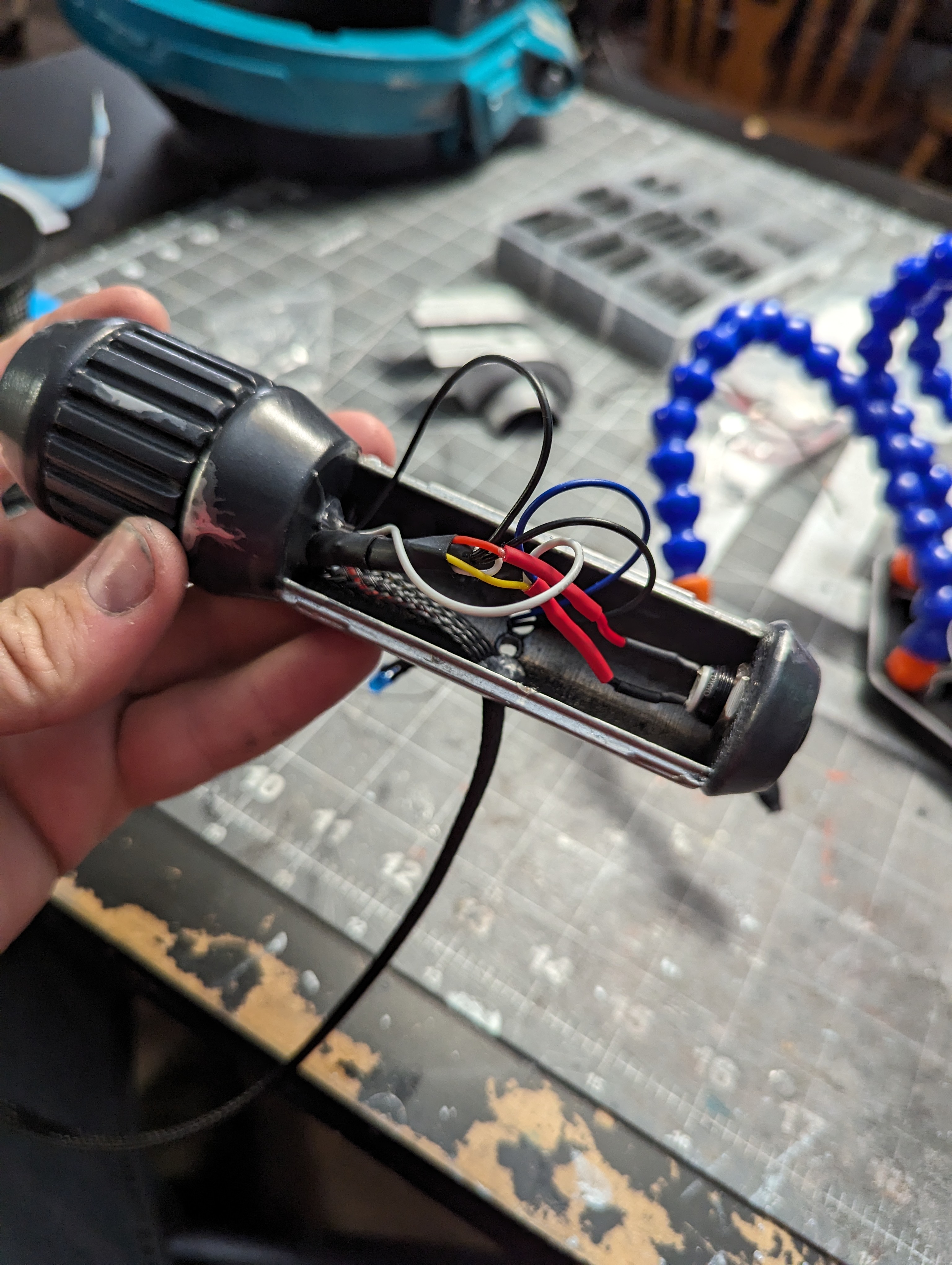

Back to the project, I did get some physical pieces going. The jaw piece finished printing, and I did a test fit with all the parts, and the visor buck and jaw electronics rig.

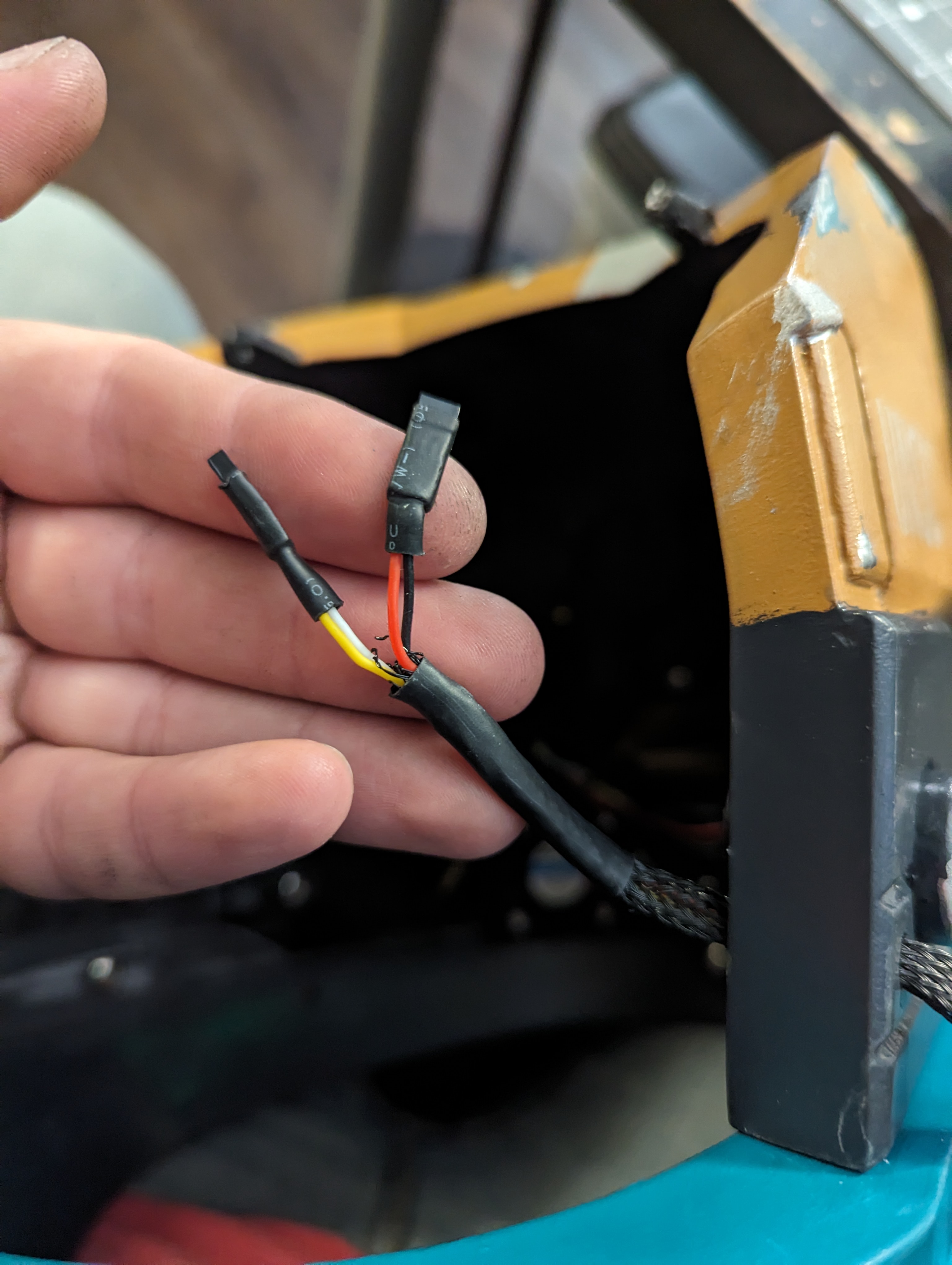

Speaking of the jaw electronics rig, I got that completely finished! For the plug, I skipped a post so I can't plug it in backwards on the male end of the plug. I'll fill the female hole in the other side of the plug.

The last update for the day is that I primed the jaw piece!

First the setback. My computer decided that while fusion was in the middle of saving, it would restart Automatically for an update, and wipe 6 hours of my finishing process... So that sucks. I was left at this stage with the back plate

All is not bad though, because I got back on the horse, and I'm actually much happier with the remodel of this section compared to the first one! I got this power conversion section done!

Also, I actually did this modeling while visiting my parents, so I took my desktop with me! One of the best things about my setup, is by design my monitor keyboard and mouse are all portable so I can move them around to desk as necessary, but that means that my desktop is also only one cord connection for power. The monitor gets its power from the PC USB port!

Back to the project, I did get some physical pieces going. The jaw piece finished printing, and I did a test fit with all the parts, and the visor buck and jaw electronics rig.

Speaking of the jaw electronics rig, I got that completely finished! For the plug, I skipped a post so I can't plug it in backwards on the male end of the plug. I'll fill the female hole in the other side of the plug.

The last update for the day is that I primed the jaw piece!

- Member DIN

- S770

Okay, I am here with the weekend update! I spent the whole weekend working on this project!

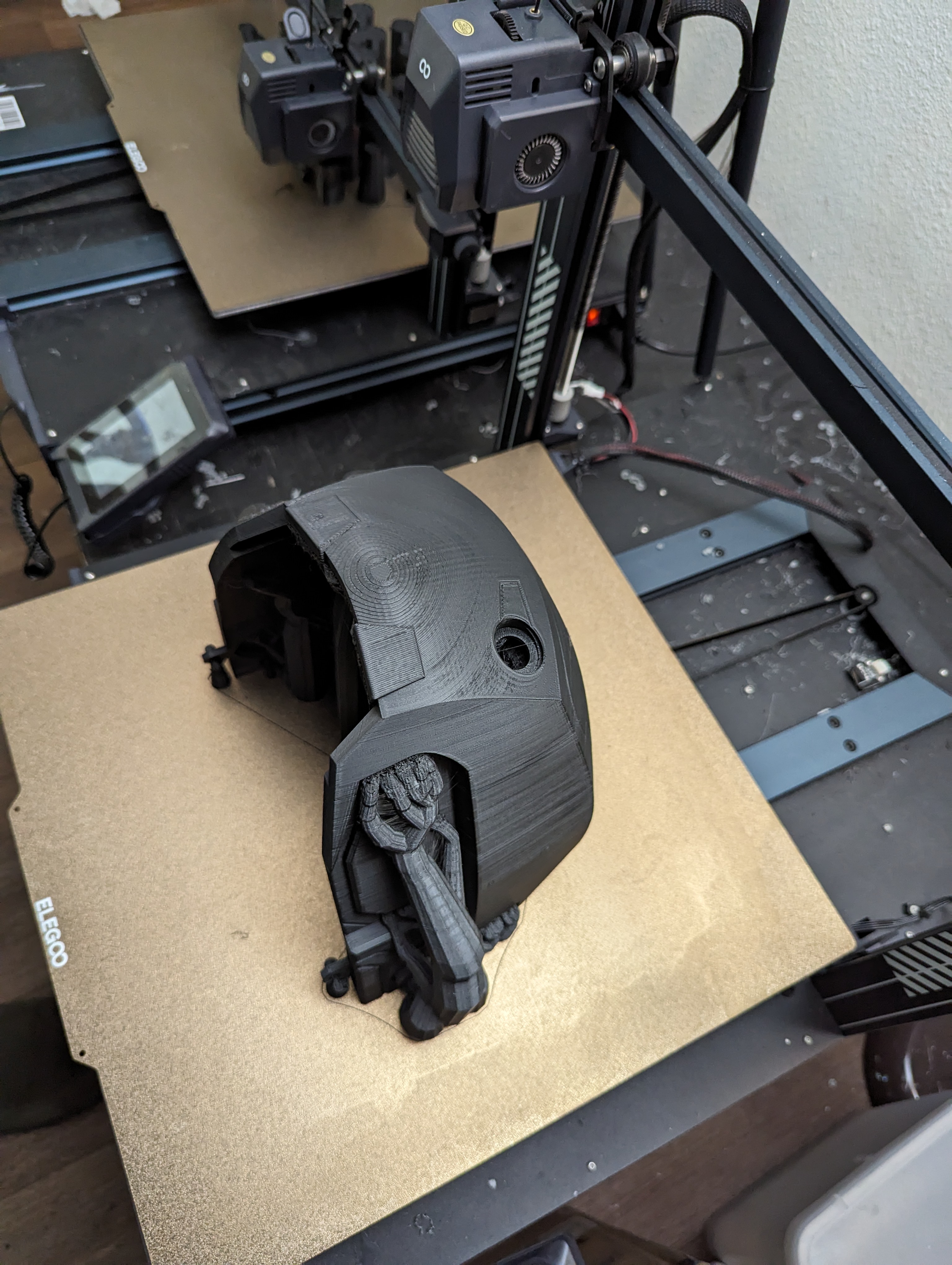

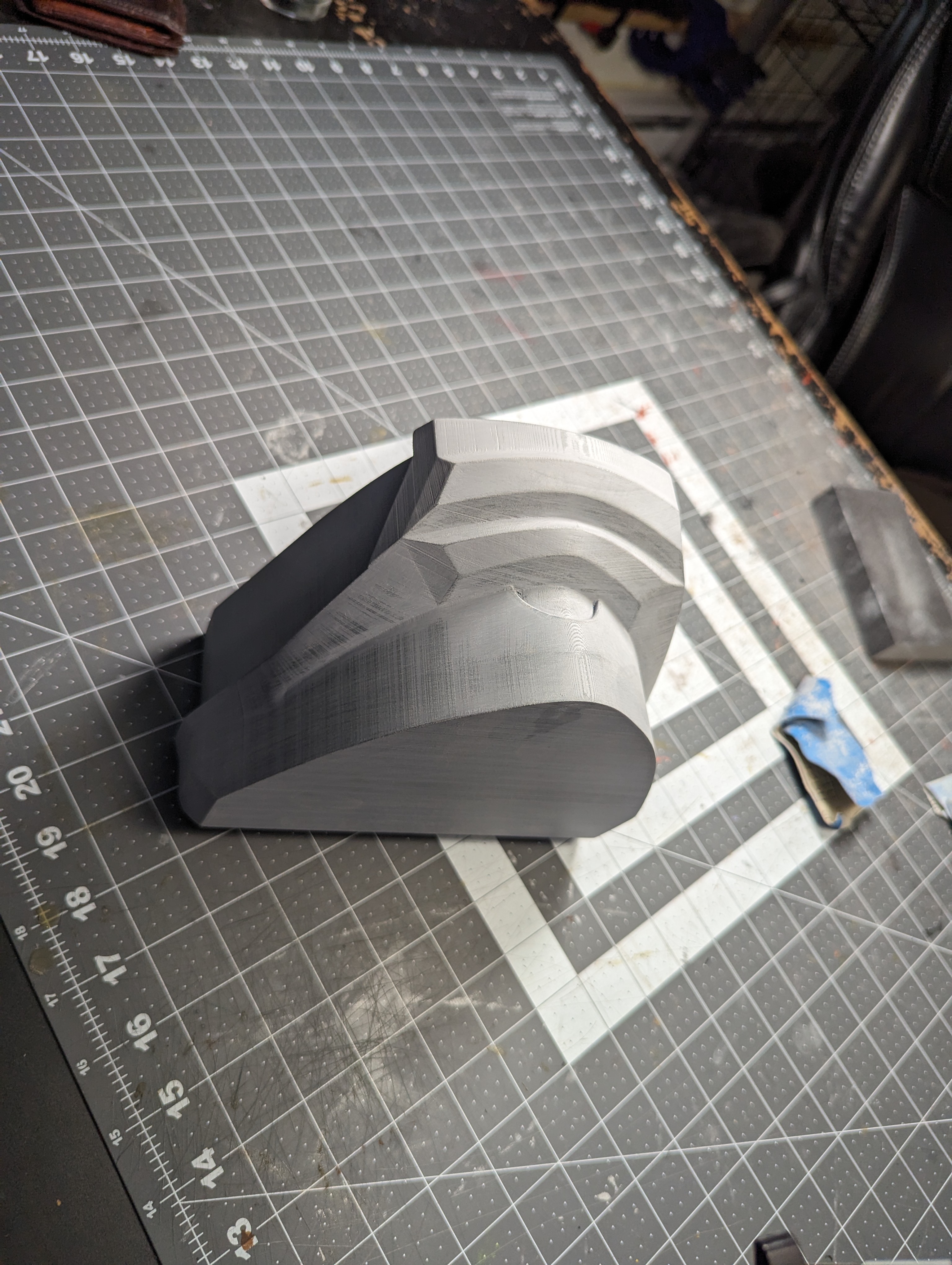

So first things first, I got a bunch of the parts printed! The upper hood came off the printer, and the fit is perfect!

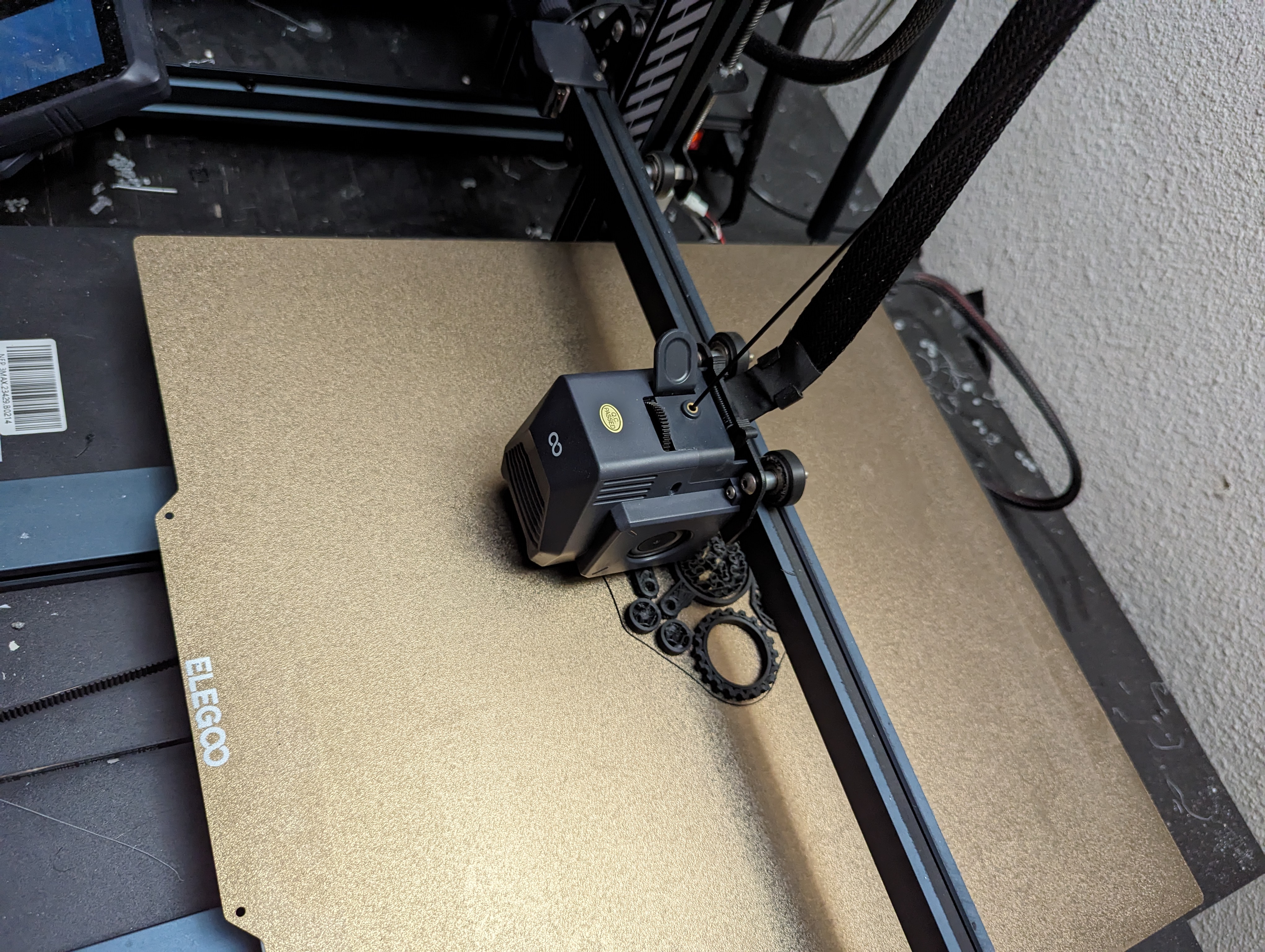

I also got to test the camera setup with the hood printed, and it is perfect!

Next, I got the upper light pieces completed!

With that, I also test fit the electronics!

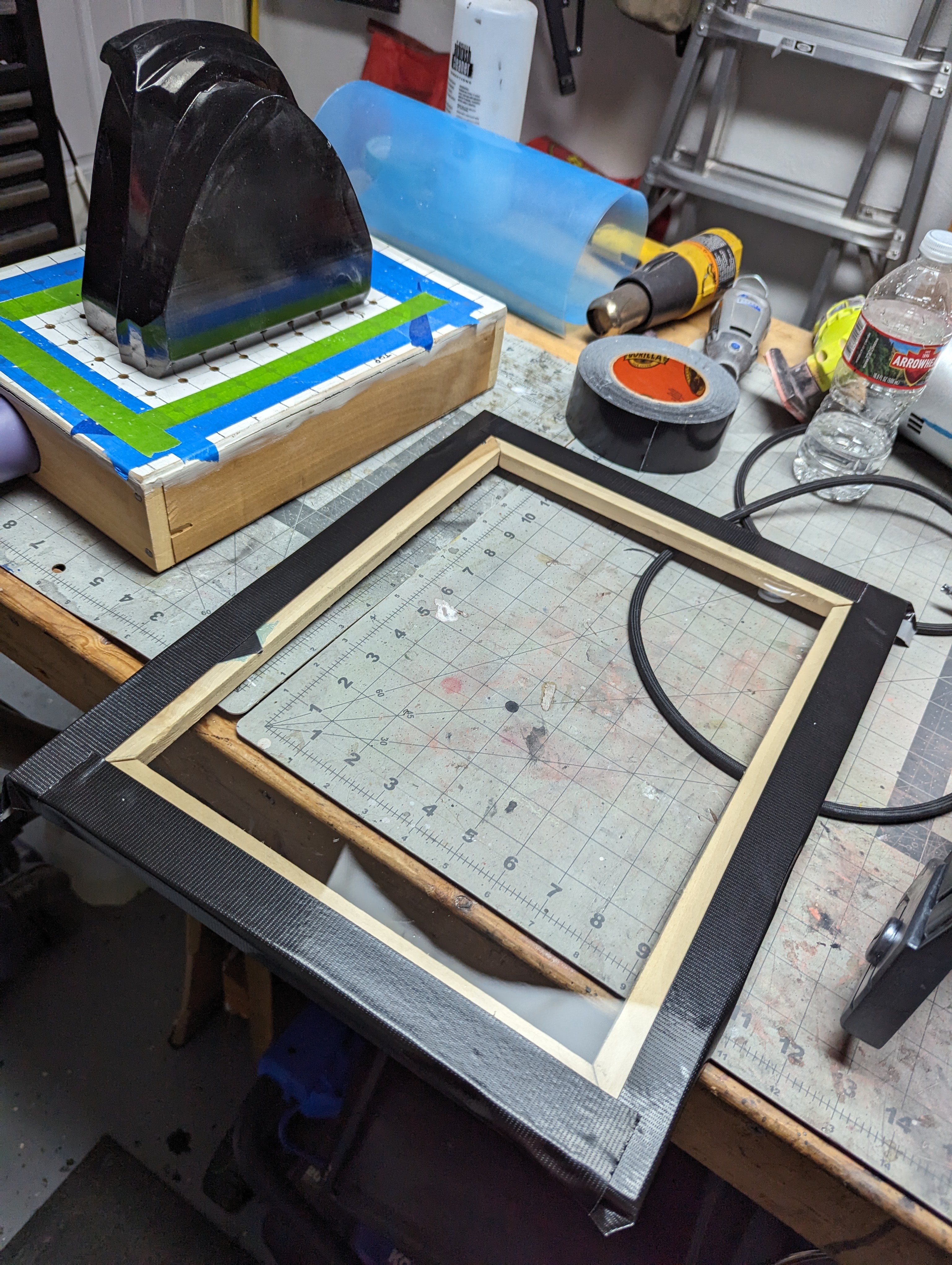

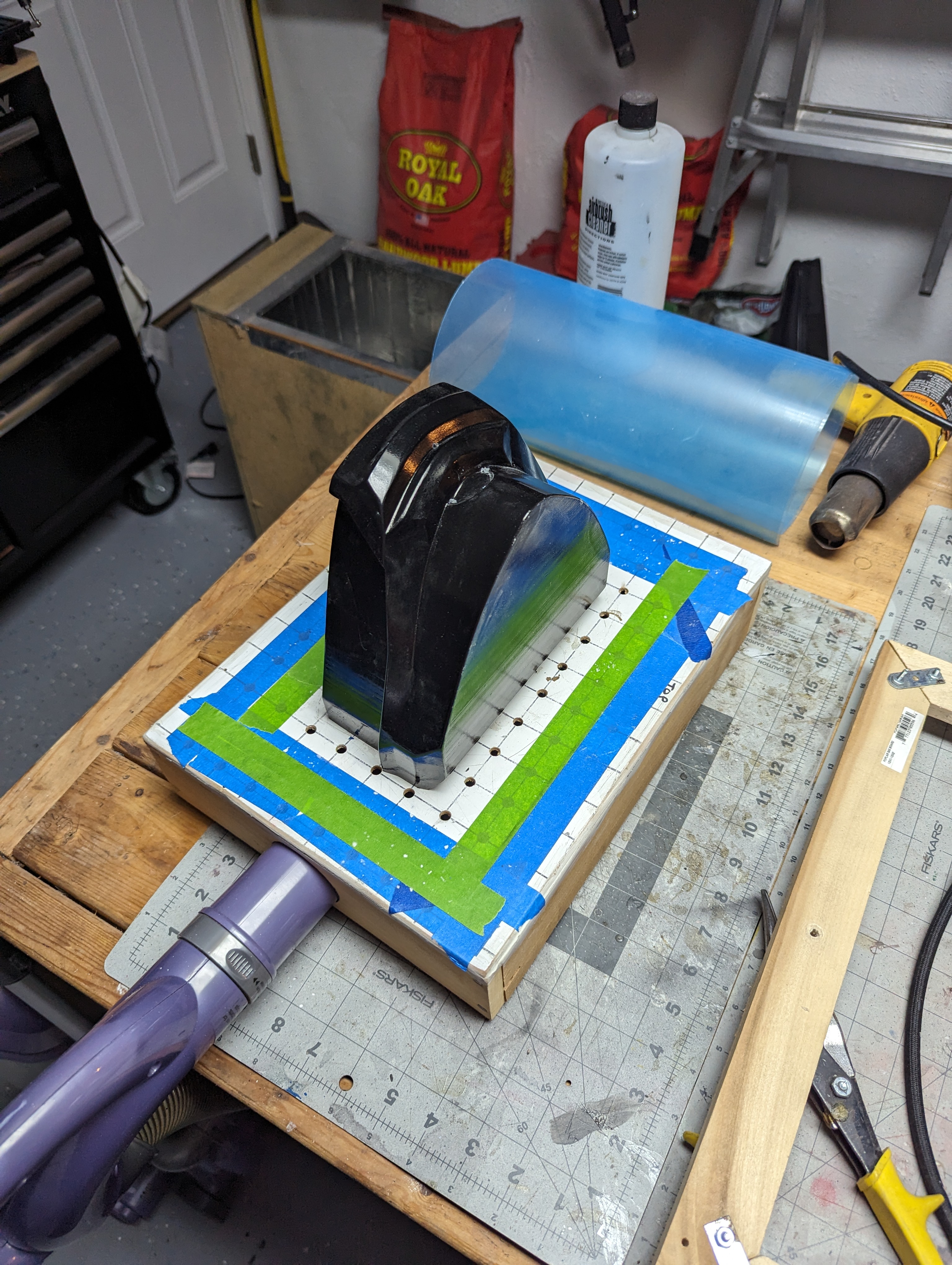

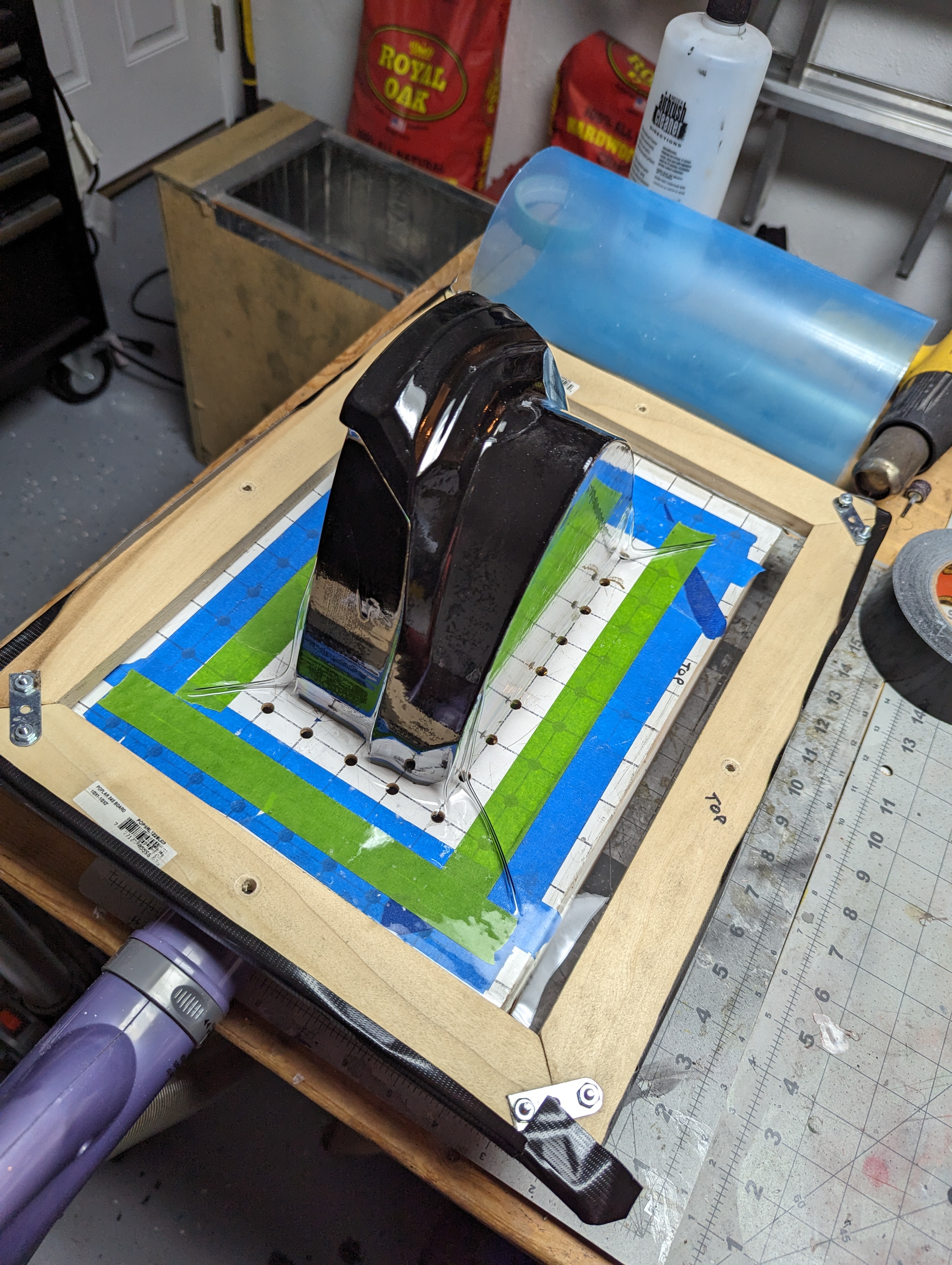

After that, I for the Vacuform buck finished!

And now for the biggest part of this weekend with minimal pictures, but I got a lot of parts sanded and ready for paint! All I have left to sand is the upper hood, and the back plate.

There is only one piece left on the other, and that's the back plate!

So first things first, I got a bunch of the parts printed! The upper hood came off the printer, and the fit is perfect!

I also got to test the camera setup with the hood printed, and it is perfect!

Next, I got the upper light pieces completed!

With that, I also test fit the electronics!

After that, I for the Vacuform buck finished!

And now for the biggest part of this weekend with minimal pictures, but I got a lot of parts sanded and ready for paint! All I have left to sand is the upper hood, and the back plate.

There is only one piece left on the other, and that's the back plate!

- Member DIN

- S770

So today is a big update!! First things first, I got the first zinc coating on all the printed parts, with exception of the back plate that is still printing.

I also did a test fitting with the eye piece because I wanted to see if all together!

Now for the biggest update, with the help, expertise, and tools from SubXzeroXhero , we got the visors Vacuformed and dyed!

We started with .040 petg, cut it to size, fit it into the frame, and cleaned off any lint. Sub found out that taping the plastic into the frame was much easier and simpler than clamping the plastic between two frames.

Next it was on to the heating box! We put the plastic until it drooped about half of the height of the buck. Once it was ready, we picked up the frame and pulled it over the form and hit the vacuum.

We did 3 pulls, all of them turned out well! Next it was up to dyeing the visors! We used Rit synthetic charcoal to dye it. We found that the optimal temperature to dye the visors was in between 140-150 °F for this plastic.

Aaaand we found out the temperature range the hard way. We lost one of the three visors to the dyeing process

At this point, after I tested the fit, I packed up, and went home to my own shop. Here is the visors installed after the whole process!

And here is the visibility from inside!

The only bad news today, was the back plate failed its print due to a layer shift! I restarted it, and I am really going to have to sprint once it's done to get this helmet done in time for Washington gaming expo!

I also did a test fitting with the eye piece because I wanted to see if all together!

Now for the biggest update, with the help, expertise, and tools from SubXzeroXhero , we got the visors Vacuformed and dyed!

We started with .040 petg, cut it to size, fit it into the frame, and cleaned off any lint. Sub found out that taping the plastic into the frame was much easier and simpler than clamping the plastic between two frames.

Next it was on to the heating box! We put the plastic until it drooped about half of the height of the buck. Once it was ready, we picked up the frame and pulled it over the form and hit the vacuum.

We did 3 pulls, all of them turned out well! Next it was up to dyeing the visors! We used Rit synthetic charcoal to dye it. We found that the optimal temperature to dye the visors was in between 140-150 °F for this plastic.

Aaaand we found out the temperature range the hard way. We lost one of the three visors to the dyeing process

At this point, after I tested the fit, I packed up, and went home to my own shop. Here is the visors installed after the whole process!

And here is the visibility from inside!

The only bad news today, was the back plate failed its print due to a layer shift! I restarted it, and I am really going to have to sprint once it's done to get this helmet done in time for Washington gaming expo!

- Member DIN

- S770

Also for anyone interested, here is the link for that PETG sheet

Superior Graphic Supplies PETG Clear Plexiglass Plastic Sheet (24”W x 48”L) 40mil(.040 /1.02MM) Thickness Plexiglass, DIY, Display 24” x 48inch Amazon.com

Superior Graphic Supplies PETG Clear Plexiglass Plastic Sheet (24”W x 48”L) 40mil(.040 /1.02MM) Thickness Plexiglass, DIY, Display 24” x 48inch Amazon.com

- Member DIN

- S410

Depending on shipping costs it may be cheaper to get PETG from mcmaster carr. It's $19 plus shipping for the same size instead of $35 with free shipping.

www.mcmaster.com

(for those who are in the market and comparing prices)

www.mcmaster.com

(for those who are in the market and comparing prices)

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

Titan007

New Member

Looks great!So I have started the journey to make the ultimate Gungnir helmet! I am going to be 3d printing the helmet, with a vacuformed lower visor, and camera system, as well as an assisted audio system, like my current helmet! I also plan to mold and cast the neck gasket in rubber.

I pulled some orthographic views of the in game model from blender, and am modeling in fusion 360. I have been learning a lot of the surface and form tools, and so far it's coming out! The first step I made was the hood.

View attachment 334687

This is where I have got in the past two days of work! I am so happy with how it is coming along, and this is going to be a truly epic build!

View attachment 334686View attachment 334685View attachment 334684View attachment 334683

- Member DIN

- S410

- Member DIN

- S770

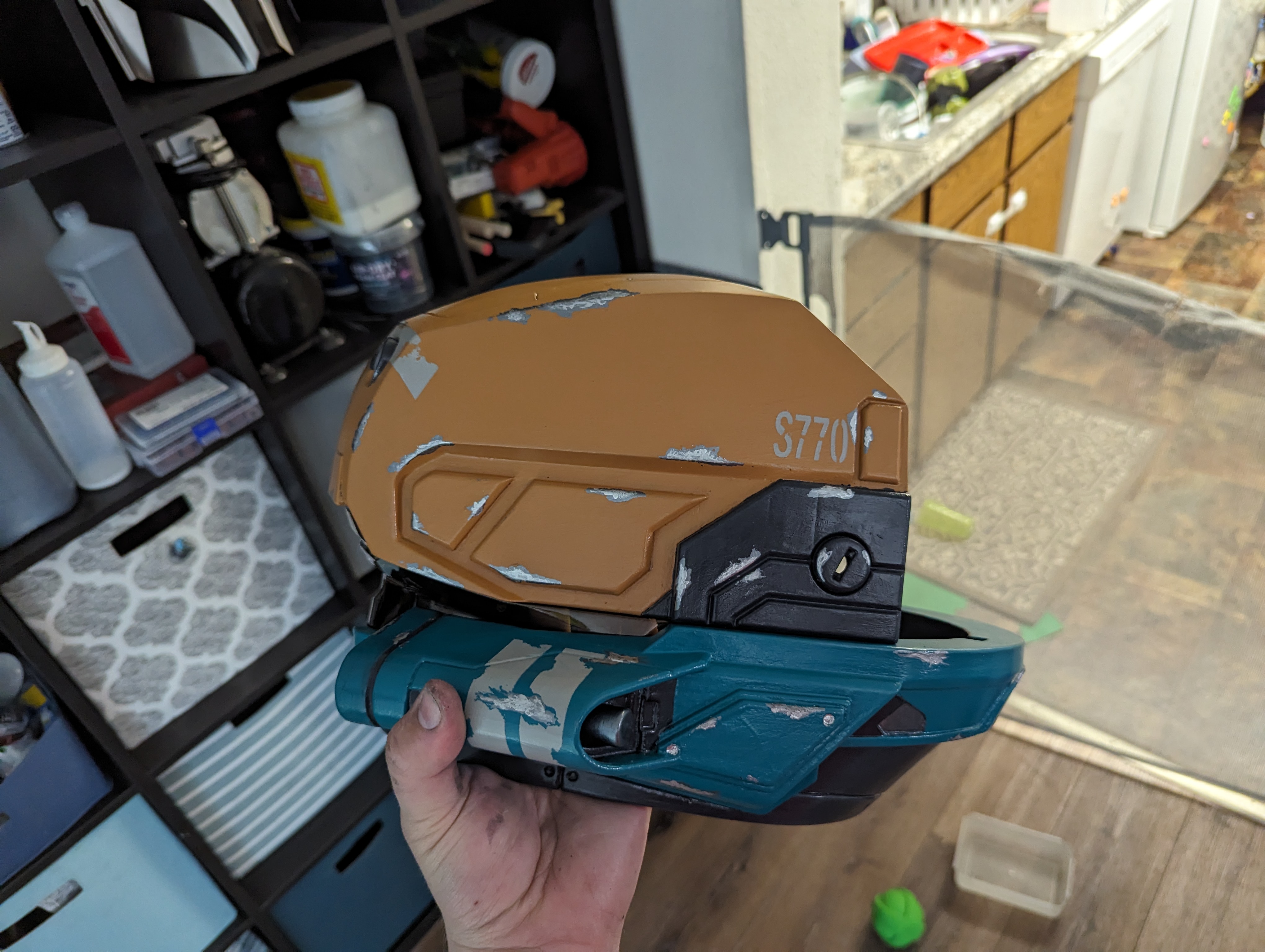

Another update! Today was mainly a paint day! I got all the parts painted, with exception of the back plate still printing!

I started with using liquid latex to create layered paint chips!

From there, it was base colors, I did 3 coats of the colors, and then the detail colors.

A big part of this being so clean, is I learned a new technique for masking! The essential parts are I mask, put down more masking fluid, and then I first paint the under color to seal the edges of the masking tape, and then I paint the color on tops of that!

Once that was dried, I took of the masking, and I'm so happy with how it turned out!

From there, it was the side light. I painted, and then installed and diffused the front lense.

I started with using liquid latex to create layered paint chips!

From there, it was base colors, I did 3 coats of the colors, and then the detail colors.

A big part of this being so clean, is I learned a new technique for masking! The essential parts are I mask, put down more masking fluid, and then I first paint the under color to seal the edges of the masking tape, and then I paint the color on tops of that!

Once that was dried, I took of the masking, and I'm so happy with how it turned out!

From there, it was the side light. I painted, and then installed and diffused the front lense.

- Member DIN

- S770

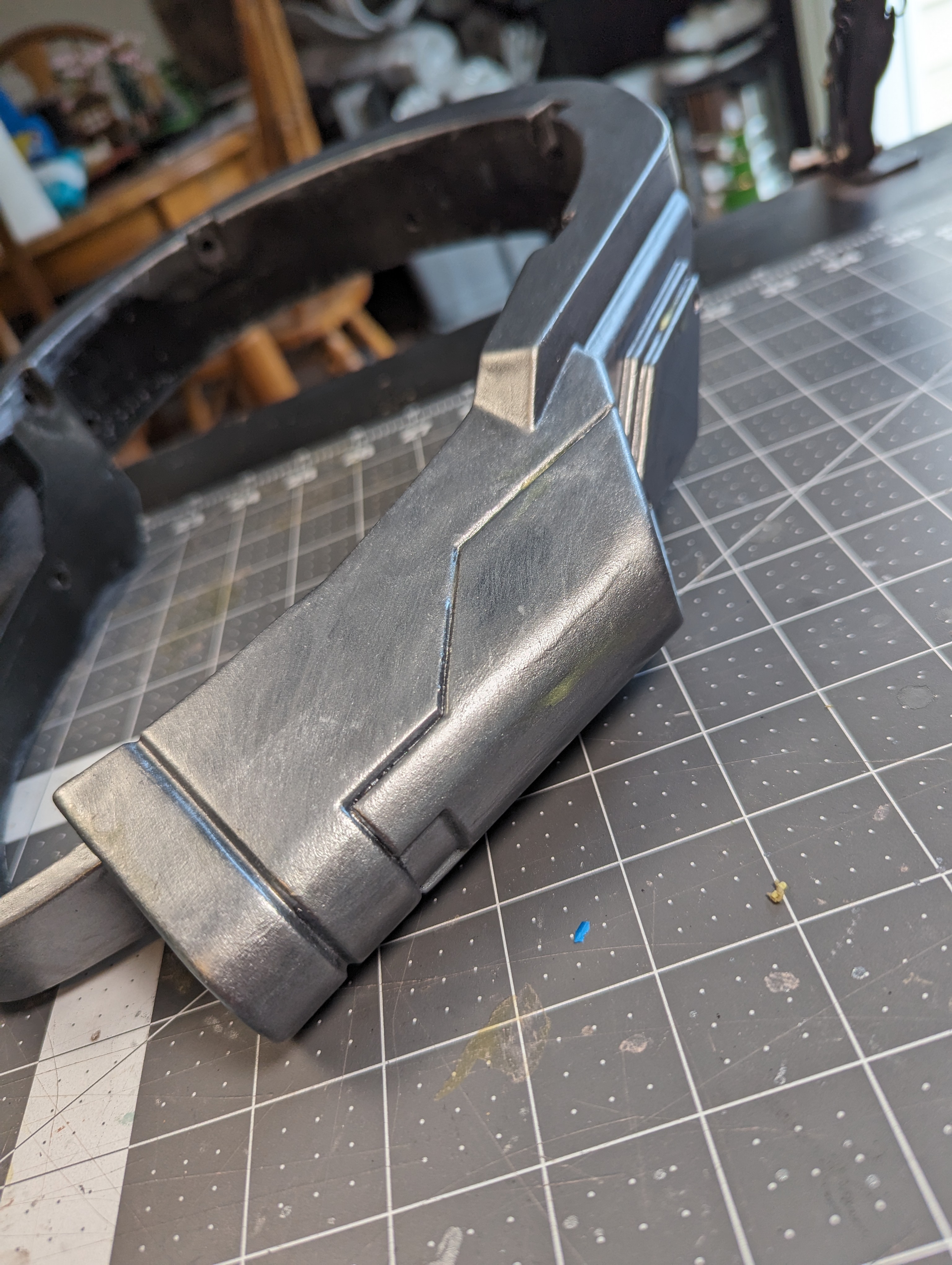

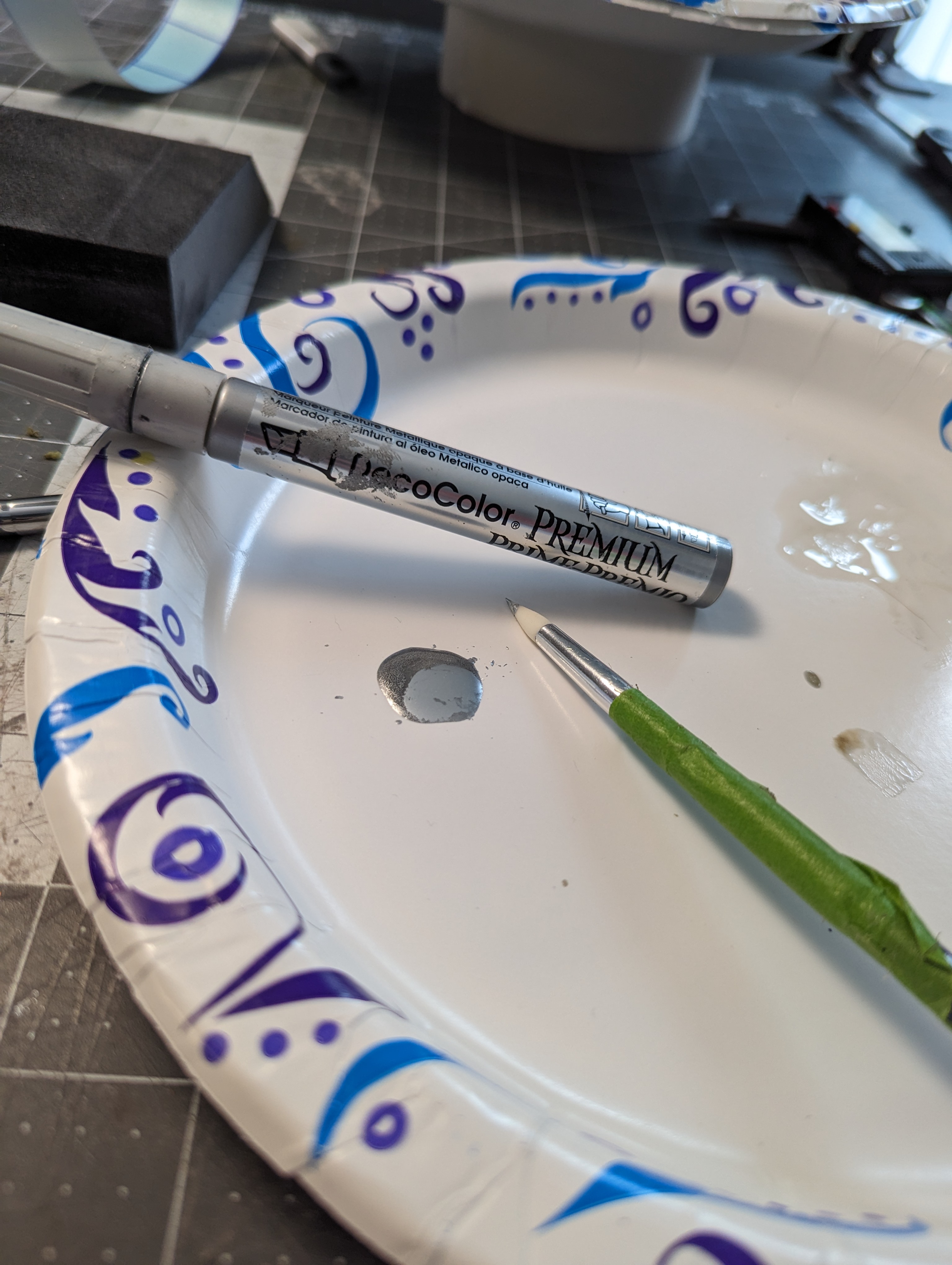

Time for another update! We have a bunch of assembly today! But before that, I got the chipped highlights done! I take this chrome paint pen, and a small silicone brush, and just add a really bright silver highlight in the middle of the zinc paint chip areas.

From there it was on to adding the heat press inserts!

I did learn a few lessons for heat press inserts:

1: add more tolerance in the holes that the bolts pass through

2: add registration for the threaded inserts for the smaller side. This is especially important for the ones I have to put in at an angle.

3: make sure there is no residual plastic or support inside the hole to press. It can jam the threads if you don't check the hole first!

From there assembly bagan!

The visor ended up needing these little foam standoffs to account for the longer bolt, and allow for more tolerance in the holes in the visor.

Something to note here, I did cut out a hole in the visor behind the fans that allowed them to pull air from the cbrn vents

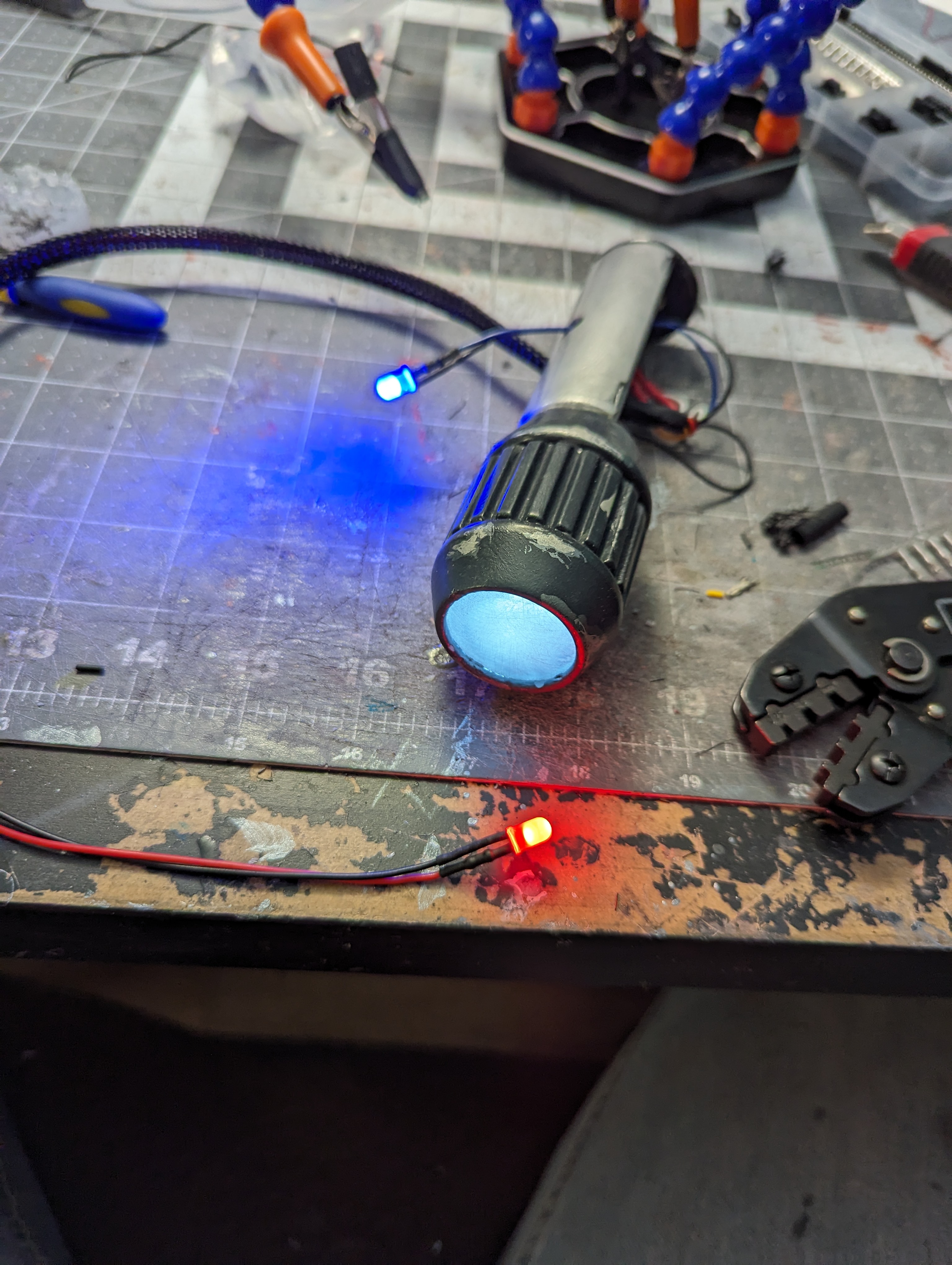

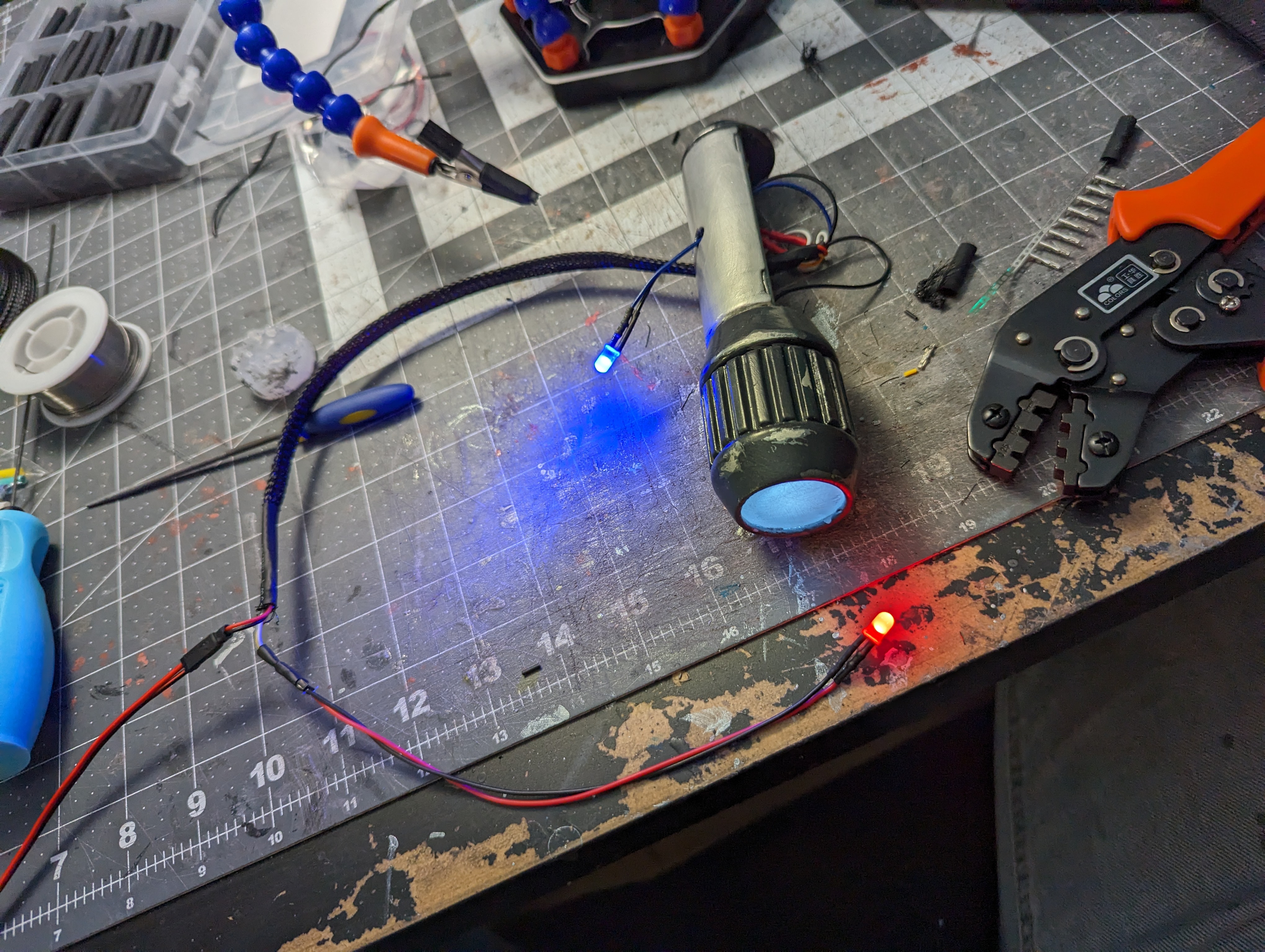

Now it's on to electrical! I got the electrical done on the upper light!

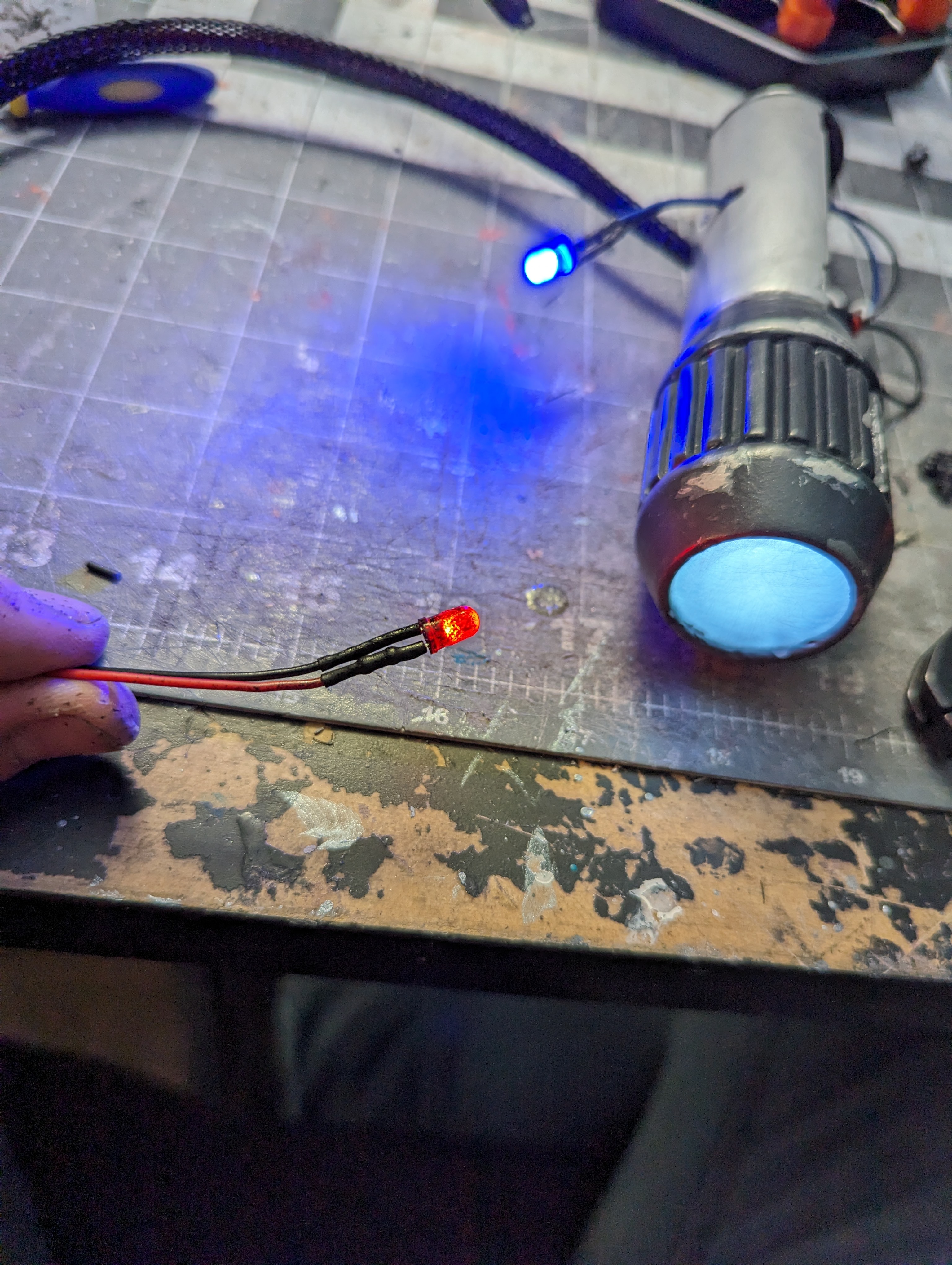

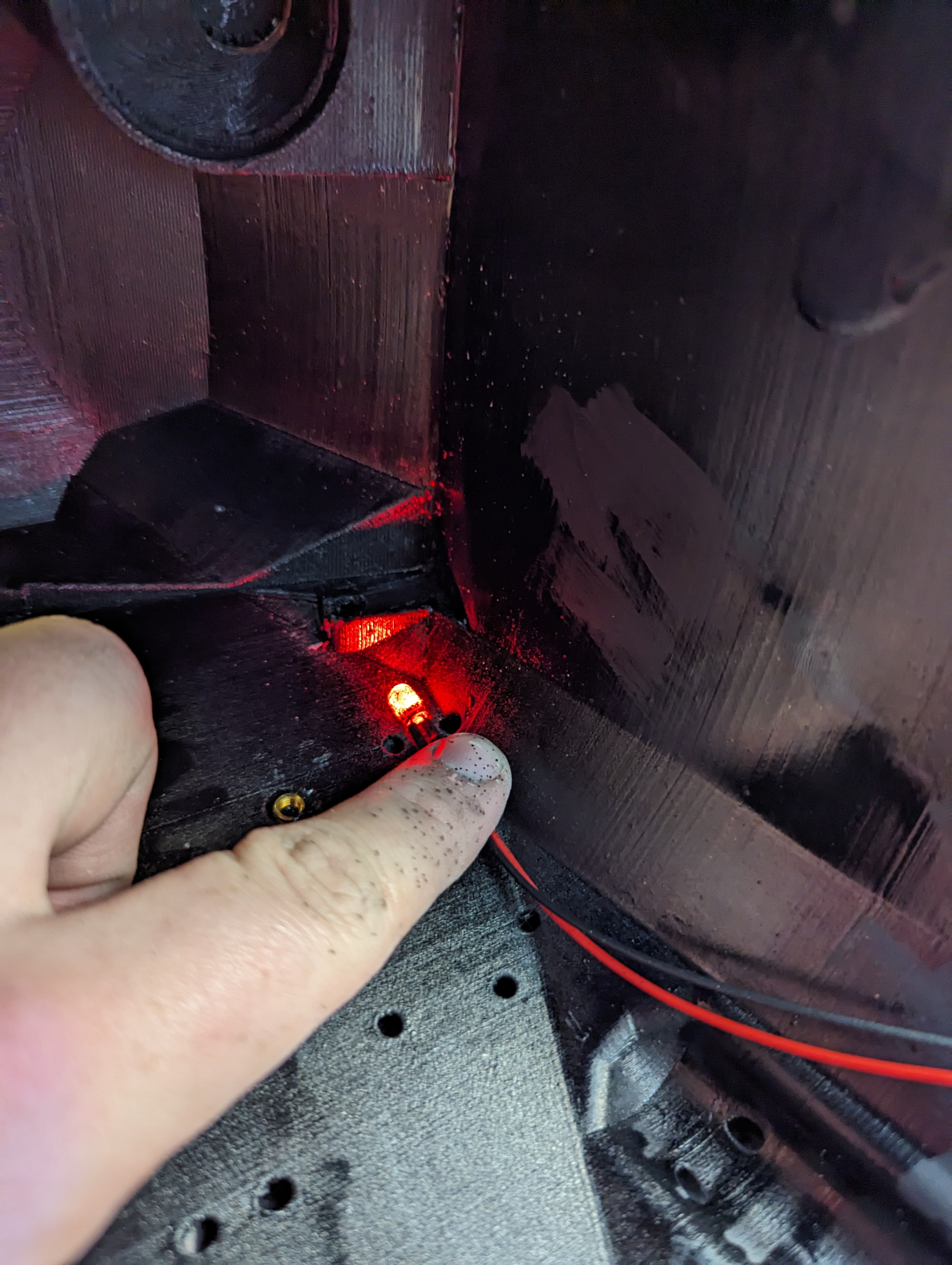

So the red light is my in helmet indicator, so I dulled the light down by dusting it with black spray paint. These are my tests with the red led

From there it was on to adding the heat press inserts!

I did learn a few lessons for heat press inserts:

1: add more tolerance in the holes that the bolts pass through

2: add registration for the threaded inserts for the smaller side. This is especially important for the ones I have to put in at an angle.

3: make sure there is no residual plastic or support inside the hole to press. It can jam the threads if you don't check the hole first!

From there assembly bagan!

The visor ended up needing these little foam standoffs to account for the longer bolt, and allow for more tolerance in the holes in the visor.

Something to note here, I did cut out a hole in the visor behind the fans that allowed them to pull air from the cbrn vents

Now it's on to electrical! I got the electrical done on the upper light!

So the red light is my in helmet indicator, so I dulled the light down by dusting it with black spray paint. These are my tests with the red led

Attachments

Holy cow, seeing your process and progression is AMAZING. Your helmet has to be easily the most technologically advanced in the 405th.

Similar threads

- Replies

- 0

- Views

- 153

- Replies

- 1

- Views

- 162