Update time!

So I've been working on this on\off all week but have not had time to post, so I'll catch up.

Last I left, I had just applied the second half of the mother mold and needed to wait 24hrs for it to cure. So I did that and came back the next day to de-mold, and see if everything came out OK. Arguably, this is the most nerve wracking part of the process for me, because when you demold you want to see that everything went right, you don't have any bubbles or surface imperfections and that you didn't waste a bunch of silicone.

So I took the helmet off the stand, and before I separate the halves, I drill in holes where I where bolts will be inserted so that the halves re-join exactly as they need to. I didn't use too many for this bucket, as it didn't seem like I'd need to. I can always add more later tho. Just make sure you do this BEFORE you demold.

With the hole drilled, I then carefully separated the mother mold shells. Because I used a release agent, the halves did not bond to each other and came off pretty easily with some minor use of a hammer and chisel. Just want to gently pry them apart.

After that, we move on to removing the rubber. This part can be a royal pain the first time, depending on the item you are molding and the configuration setup. For this helmet, my goal was to take advantage of the properties of ReBound 25 & DragonSkin and do a seamless mold. If you do it right, and keep the silicone just thin\thick enough, you should be able to roll it up gently as you go, and invert the mold.

The reason I went that route for this case, is that the Gungnir helmet doesn't really have any undercuts, or major protrusions that would risk tearing the mold. This results in a casting that needs WAY less cleanup, as there are no seam lines. (Another reason I went this route, is that if I find I can't demold it as a seamless mold, THEN I can make a cut in the rubber with a razor knife, if I need to. Worth a shot to give it a try)

The tradeoff though, is that you generally get less castings out of the mold, total. Why? Well you are asking

a lot of the silicone to invert itself repeatedly. So it can do it, but it shortens the life of the rubber. If I did a two part mold, I could probably pull double the amount of castings, but there would be slightly more clean up work.

So it depends! It depends on the piece, the mold, the results you want, and what your time is worth.

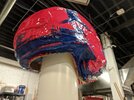

Here I am, carefully demolding the master. Thankfully it rolled up rather easily.

Ta-da! An inverted Gungnir!

Ringung, if you will.

Now. To inspect the fruits of my labor. What flaws await me, the amateur...

Only a couple, and thankfully they aren't deal breakers!

On one of the side details, it looks like a small air bubble got trapped. You can see it below. This means that every time I pour a cast, this will result in a blemish that will need sanded off. There are also a couple in what I would call the 'trenches' of some of the details where silicone just didn't fill in, or air got trapped. That's the game tho. It happens. Certainly not worth making a fuss over in this case.

So I'll call that successful! I'm a happy maker. Time to try some castings and see how they go.

So what are your guys' thoughts? How do you feel about 'quality' on something like this, where there is a high chance of error, or minor flaws? Does that deter you from wanting to keep going? How about when you think about offering something for sale? Do you get in your head about minor flaws?

I'm trying to get better about it, but would love to hear your opinions.

![IMG_20201010_141919[1].jpg IMG_20201010_141919[1].jpg](https://405th-f28a.kxcdn.com/forums/data/attachments/297/297762-ee0daf10c915245b491d2d97ad4dcd62.jpg)

![IMG_20201010_144809[1].jpg IMG_20201010_144809[1].jpg](https://405th-f28a.kxcdn.com/forums/data/attachments/297/297763-ae208e3f97162cb94bb1dfc79dab460e.jpg)

![IMG_20201010_154026[1].jpg IMG_20201010_154026[1].jpg](https://405th-f28a.kxcdn.com/forums/data/attachments/297/297764-05c0fb6ebdfae9285d37624ac5aab9b0.jpg)

![IMG_20201010_161609[1].jpg IMG_20201010_161609[1].jpg](https://405th-f28a.kxcdn.com/forums/data/attachments/297/297765-e6b5a4b428fb1f82c01d616615fd17ed.jpg)

![IMG_20201010_161847[1].jpg IMG_20201010_161847[1].jpg](https://405th-f28a.kxcdn.com/forums/data/attachments/297/297766-afab7ed27ec34003f5a8cdaaa605c4ef.jpg)