Alright, the weekend is here!

First, big update.... I finally saw a Doctor! I swallowed my pride and went to the free clinic. I for sure have diabetes and was put on oral medication. It has only been one week and my pain has already been reduced to less than half of what it was! I'm feeling very optimistic.

Now, before I show you my progress, I'd like to show you my techniques for increasing strength on straps and velcro when working with foam. For this I am using

Gorilla Glue High Temp Hot Glue (this stuff is great), Industrial strength Velcro, Nylon Webbing and EVA40 foam.

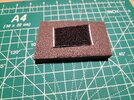

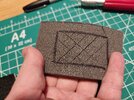

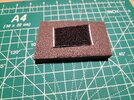

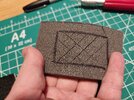

1. Extra grip on Velcro. My issue is that the glue holding the velcro to the piece usually gives way before the actual velcro does. To combat this I do a similar technique to anytime I'm gluing something... I rough up the surface to add texture for the glue to grab.

Craft knife slice a crisscross pattern shallow into foam. Using pliers, twist to create gaps. Fill in hot glue to the gaps.

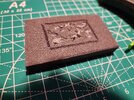

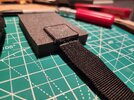

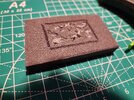

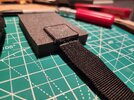

2. Extra strength to straps. You can for sure just glue nylon webbing to foam, but there is a high likelihood that it will snap off at the wrong time. Reduce this chance by burying the strap in the foam.

Cut out a recess into the foam the same size as the webbing squared and not too deep (less than half the thickness of the foam. Put a little hot glue down in the recess and attached the strap. Then put cover the strap in hot glue and press down the foam piece you cut out. You've got to keep even pressure down while it dries and also not burn yourself.

PS: I had ArcSol try to rip this strap out of this test piece and 30 some odd tries and we were both unable to. Gorilla glue is good, plus glue on both sides of the strap is fantastic.

Little bit of extra time in construction to avoid extra repairs in the feild.

On the bicep (shoulder mount) I added a strap so I can snap it to my BDU and also cut out a square, built up a foam block and added velcro so I can attached my shoulder pieces.

I did the strengthening strap technique to add a channel for the thigh straps to go through to help keep them from flopping around.

I also did up some of the decorative straps and added a couple loops of thread onto the 3d printed buckles to help keep them in place.

***Fingers cross for good weather to keep painting this weekend!