JayOneSeven

Jr Member

Oh yeah! That Arc Reactor is awesome! I love it when household items are used to make something as impressive as that! Also, (just because I have to say it!) your duct tape dummy seems to have a bit o' gansta lean goin' on! I probably shouldn't say anything though, I have yet to make mine, and it will probably look like a duck-billed platypus when I am done!

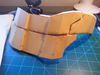

Lmao yeah I didn't quite get the stand completed before bed so I just set it up like that! Hopefully it'll have a nice solid stand here soon so I can sand it up straight and start setting some pieces onto it!

I changed the reactor a little too, I'll post some more pics later :]

Thanks for the encouraging words!! Good luck with your dummy!