It's been a minute since my suit has made its appearance at TORG, and I should've updated since then... Ope, well, here we are. Anyways, finished the paint. And strapped everything up. The shins aren't great, but I'm hoping to fix that this week...before C2E2.

Also, I'm gonna upgrade my ¾" straps to 1" straps to hopefully give it better support, and use higher quality hardware. And I think I'm gonna remake the visor, but that's of a lower priority, as my current visor works.

Without further ado, the pictures:

Here's an example of what I used for my base coat:

The other spray paints I used:

Now it's all weathered. I used just a simple black acrylic to weather it.

Sadly, the weathering made it incredibly difficult to see my name and the UNSC tag.

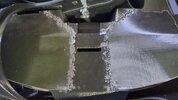

Now onto the visor! My delve into this hobby was to encourage me to gain new skills and try new things. With that in mind, I decided to make my own vacuum former, and I think it turned out alright. I used a toaster oven to heat the PETG, and found out that I wasn't paying enough attention to what I purchased, as it wasn't pure PETG, so it's melting point was much lower. That lead to some issues when dyeing the visor.

While vacuuforming, I used some tape on the bottom of the buck to to hold it in place.

(Yes, those are 2x4s used to keep the PETG sheet up. And no, it hasn't caught fire.)

Can't see it too well, but got a few good pulls out of it.

And this is what happens when it's not pure PETG and you try to dye it...

I was able to salvage one of them well enough to make it work. I haven't sprayed it with the alclad, or whatever it is called. I forget, by now. But it's not super see through if the light isn't on the visor, and that's good enough.

So that's everything I had together by the first day of TORG. I may have stayed up until like 7am the day of to finish the strapping, but hey, that's cosplay for ya. Thanks to those who helped before they had to bed. I don't remember who all was there... I recall it was in

Skidmorpheus's room, and I remember

HoundsOfMeath being there. So thanks to those two, and everyone else who helped!