The nice thing about hot glue is if needed you can pull it off the material.I may have to use hot glue ... *shiver* hate using that stuff...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Foam ODST: Version 1 was okay. Now for Version 2

- Thread starter PaiganBoi

- Start date

- Status

- Not open for further replies.

- Member DIN

- S240

Some thin materials may melt as well..... need to keep that in mind.The nice thing about hot glue is if needed you can pull it off the material.

That was on my mind as well.Some thin materials may melt as well..... need to keep that in mind.

If the super glue weld doesn't pan out I can stick with the painters tape on the inside. It doesnt obstruct my vision.

How would modeling glue/plastic cement work?

- Member DIN

- S068

How would modeling glue/plastic cement work?

Depends on the chemical composition of the visor and the tinting material. It could end up working well, it could do nothing other than pour everywhere and make a mess or the worst option is that it works really damn well and has an exothermic reaction as some glues do and fogs up the pretty visor. A clear epoxy might be the safest route but as long as you have samples to test with everything is awesome.

Okay... Using super glue to stick the edges together failed miserably. Glue won't set fast enough and it starts to mess up the tinting on the dark side.

Hmmmmm... What can I do now to solve this? Maybe clear packing tape?

Or maybe I should drop this idea. The plastic is very flexible so it does deform easily. Maybe I should learn how to make a buck and heat form a visor with some PETG.

I'll also need to learn how to dye and chrome it as well... Sigh.

Finally gotten around to start doing some painting.

Used FlexiPaint to seal the foam, then a light grey along the edges. Used some liquid mask to simulate paint chipping.

After two coats of black I peeled up the mask. Next will be some dry brush and do a brown wash to dirty it up.

I had about half a can of Rustolium FlexiDip left and managed to seal/prime my helmet as well.

As for overall paint scheme I am gonna try camo patterns on the helmet, gauntlets and thighs.

Just a bit of finger painting on my phone to get a general idea of what I am considering.

Used FlexiPaint to seal the foam, then a light grey along the edges. Used some liquid mask to simulate paint chipping.

After two coats of black I peeled up the mask. Next will be some dry brush and do a brown wash to dirty it up.

I had about half a can of Rustolium FlexiDip left and managed to seal/prime my helmet as well.

As for overall paint scheme I am gonna try camo patterns on the helmet, gauntlets and thighs.

Just a bit of finger painting on my phone to get a general idea of what I am considering.

- Member DIN

- S240

Looking pretty sweet!! Flexipaint in a spray can? I’ve tried plastidip in spray form and I think it is subpar. It splatters out, it doesn’t spray. Then the large globs it ends up making the surface all pitted. So I stick with brushing it on.... but I haven’t tried flexipaint.looks like it came out nice. Anyway, there my plastidip rant lol. Builds coming out great. Can’t wait to see it all come together

Last edited:

- Member DIN

- S068

Looking pretty sweet!! Flexipaint in a spray can? I’ve tried plastidip in spray form and I think it is subpar. It splatters out, it doesn’t spray. Then the large globs it ends up making the surface all pitted. So I stick with brushing it on.... but I haven’t tried flexipaint.looks like it came out nice. Anyway, there my plastidip rant lol. Builds coming out great. Can’t wait to see it all come together

If you're having issues with PlastiDip you can go one of two routes that have worked for me in the past.

- float the spray can in a bucket of warm water before spraying for a couple of minutes and then shake prep the can for a minute as per usual to get a finer mist and reduce the orange-peel texture.

- use Rustoleum FlexiDip black which has a finer spray than PlastiDip naturally. I usually just spray 3 coats of it and everything is awesome. Black is better than white for some reason, white has a similar consistency to PlastiDip.

FlexiPaint is brush on. It is a bit on the thick side so it is recommended to mix in water at 5:1.Looking pretty sweet!! Flexipaint in a spray can? I’ve tried plastidip in spray form and I think it is subpar. It splatters out, it doesn’t spray. Then the large globs it ends up making the surface all pitted. So I stick with brushing it on.... but I haven’t tried flexipaint.looks like it came out nice. Anyway, there my plastidip rant lol. Builds coming out great. Can’t wait to see it all come together

I've had the same issues with PlastiDip as well, even after warming up the can in water. The Rustolium stuff is pretty much the same product and at half the cost. I found that it flows out much better but, at a much finer mist.

Dagnabbit.... beat me to the punch. I type to slow....If you're having issues with PlastiDip you can go one of two routes that have worked for me in the past.

- float the spray can in a bucket of warm water before spraying for a couple of minutes and then shake prep the can for a minute as per usual to get a finer mist and reduce the orange-peel texture.

- use Rustoleum FlexiDip black which has a finer spray than PlastiDip naturally. I usually just spray 3 coats of it and everything is awesome. Black is better than white for some reason, white has a similar consistency to PlastiDip.

Word of caution on painting, one of the hardest things about foam armor is making it not look like plastic. My motto is, "Avoid gloss at all costs".

A method I've had fantastic results with is to apply a coat of paint darker than what you want, waiting for it to go sticky, then apply your actual color on top.

As soon as the top layer is near dry, scrape across it with a cloth to achieve some extra realistic weathering.

To achieve edge wear, I often opt to paint my edges a matte silver. Let it dry then wipe the edge when my top coat is going on.

If you don't like the way it looks, its easy enough to repaint

A method I've had fantastic results with is to apply a coat of paint darker than what you want, waiting for it to go sticky, then apply your actual color on top.

As soon as the top layer is near dry, scrape across it with a cloth to achieve some extra realistic weathering.

To achieve edge wear, I often opt to paint my edges a matte silver. Let it dry then wipe the edge when my top coat is going on.

If you don't like the way it looks, its easy enough to repaint

Word of caution on painting, one of the hardest things about foam armor is making it not look like plastic. My motto is, "Avoid gloss at all costs".

A method I've had fantastic results with is to apply a coat of paint darker than what you want, waiting for it to go sticky, then apply your actual color on top.

As soon as the top layer is near dry, scrape across it with a cloth to achieve some extra realistic weathering.

To achieve edge wear, I often opt to paint my edges a matte silver. Let it dry then wipe the edge when my top coat is going on.

If you don't like the way it looks, its easy enough to repaint

The unfortunately the Liquatex acrylics that I use has a natural satin finish. The good thing though is when I weather the parts and apply a black/brown wash, it dulls the shine. I also apply a matte clear coat to seal the paint and that dulls out the shine even more.

Small update. Over the weekend I did wee bit of painting. Did the helmet and the pauldrons. I did a camo pattern of the helmet... Im not too happy with it.

The different shades of grey that I used were too close to each other and just muddled the whole thing up. Will have paint over it and start again.

Also, I am not happy with the visor. The material is just too flimsy. Need to make a new one or have some one do it for me. Sigh.

Anyone in 405th land willing to help a brother out? If I mail my cheeky little template out would it be enough to make a buck and vacuum form a visor?

The different shades of grey that I used were too close to each other and just muddled the whole thing up. Will have paint over it and start again.

Also, I am not happy with the visor. The material is just too flimsy. Need to make a new one or have some one do it for me. Sigh.

Anyone in 405th land willing to help a brother out? If I mail my cheeky little template out would it be enough to make a buck and vacuum form a visor?

- Member DIN

- S530

I love the things I'm seeing here.

There is a visor tutorial around here somewhere....

Dual Layer Visor Mini-Tutorial

There it is! An ODST visor would be much simpler to construct than the Mjolnir visors, but this method does require some self control and concentration. All you would need to do is double layer the front lower portion of the visor and cut the top portion. A little trim work on the bottom portion so the overlap isn't huge, tack them together at the corners below the helmet line, and install into the helmet! Bam.

Just my two cents worth.

I've been reading this for a while and am super excited to see how this turns out. Please stop being lazy, the suspense is *KILLING* us! Haha You've done a great job, keep it up!

There is a visor tutorial around here somewhere....

Dual Layer Visor Mini-Tutorial

There it is! An ODST visor would be much simpler to construct than the Mjolnir visors, but this method does require some self control and concentration. All you would need to do is double layer the front lower portion of the visor and cut the top portion. A little trim work on the bottom portion so the overlap isn't huge, tack them together at the corners below the helmet line, and install into the helmet! Bam.

Just my two cents worth.

I've been reading this for a while and am super excited to see how this turns out. Please stop being lazy, the suspense is *KILLING* us! Haha You've done a great job, keep it up!

- Member DIN

- S068

I'm currently finishing off a visor sized vacuum former for my CQB helmet, what're the dimensions of your visor? I might be able to make a buck that works for you good sir.Small update. Over the weekend I did wee bit of painting. Did the helmet and the pauldrons. I did a camo pattern of the helmet... Im not too happy with it.

The different shades of grey that I used were too close to each other and just muddled the whole thing up. Will have paint over it and start again.

View attachment 255646 View attachment 255647 View attachment 255648 View attachment 255649

Also, I am not happy with the visor. The material is just too flimsy. Need to make a new one or have some one do it for me. Sigh.

Anyone in 405th land willing to help a brother out? If I mail my cheeky little template out would it be enough to make a buck and vacuum form a visor?

Sweet! Thanks man.I'm currently finishing off a visor sized vacuum former for my CQB helmet, what're the dimensions of your visor? I might be able to make a buck that works for you good sir.

Once I get home from work, I will get some numbers together.

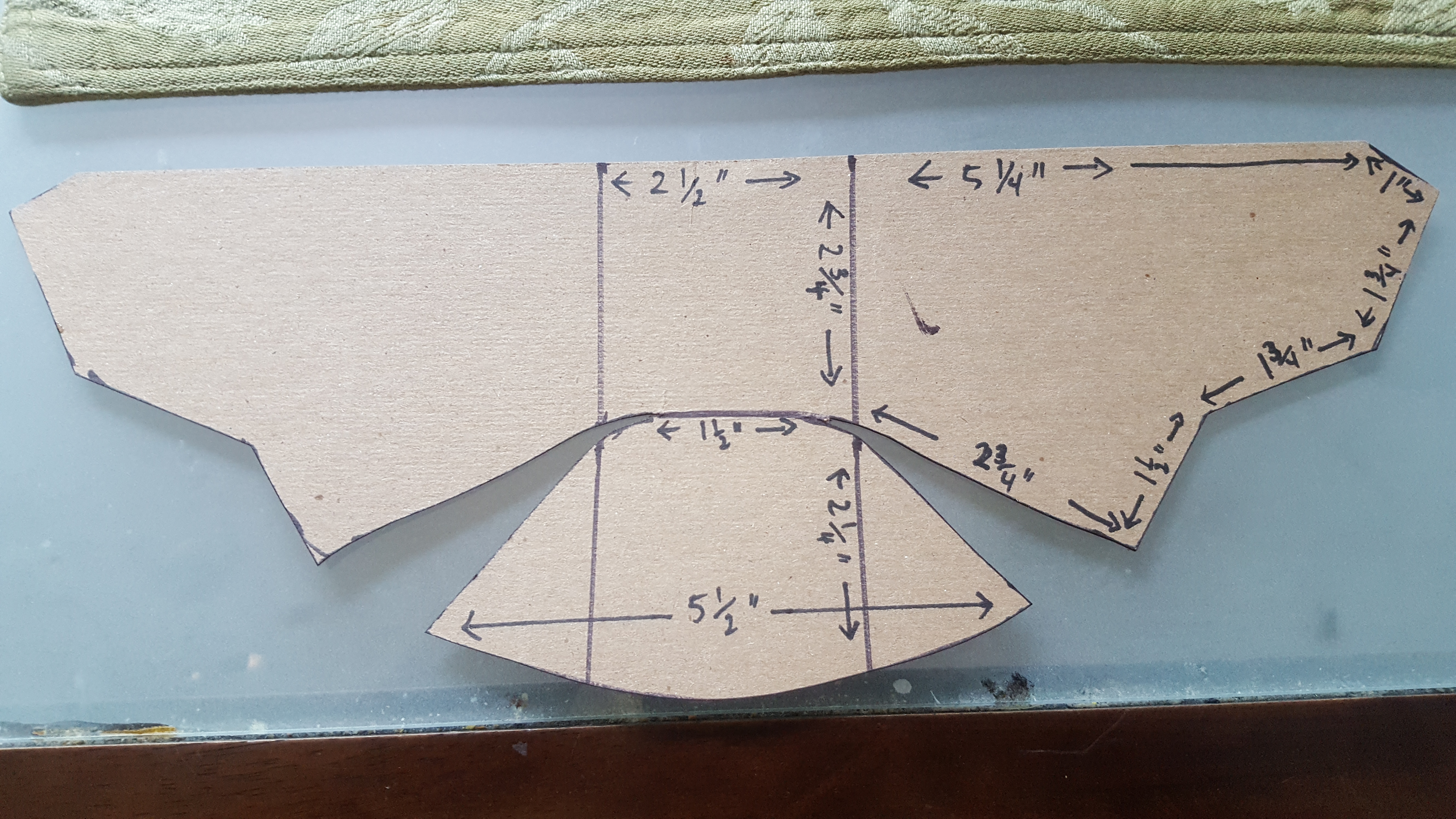

Alrighty TurboCharizard, here is the template that I have. It is larger than it needs to be so I can attach it to the inside of helmet hope these numbers help.

If you want I can mail it to you as well.

If you want I can mail it to you as well.

- Status

- Not open for further replies.

Similar threads

- Replies

- 19

- Views

- 1,815

- Replies

- 2

- Views

- 846