You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Robot Chicken's PILLAR OF AUTUMN Build - 3D Printed

- Thread starter RobotChicken

- Start date

- Status

- Not open for further replies.

No, upon further inspection I see it has only a single extruder. I want my next printer to be dual so I can print dissolvable support structures from a second spool. Now looking at Max Micron – The First Affordable Dual Head 3D Printer With Auto Leveling and Laser Engraving Function - 3D Printing

Too many printers to choose from....

Too many printers to choose from....

Max Micron has many bad reviews. Still looking for a printer.

Blerk. can't sleep. Came back today after minor surgery wednessday. Everything still hurting when I lay down. Hurts even more when I sit. So I'm typing this standing upright.

About the Dremel : the way it escalates pretty much points to either very bad filament (.... Dremel has known to have their fair batch of shitty filament too, just like nearly all other brands had at some point in time) or th nozzle just got so clogged it didn't want to play along anymore. So it's probably time for this

... and a new nozzle.

Tevo's BW doesn't have dual extruder. Of all Tevo's, I think only the Tarantulla has a dual nozzle option. But if there's one Tevo machine I would stay away from, it's the Tarantulla.

If you're looking for a sturdy design and a dual extruder at prices that won't kill your piggy bank, there's a couple of interesting routes to investigate.

I'm going to take the price point of your current Dremel Idea builder as reference, which still retails around 1000€ on this side of the ocean.

For example, there's "Jennyprinter", which is essentially a near-perfect Ultimaker2+ knockoff with enlarged build space (bigger than the Ulti). Can be bought as a kit or ready made. The problem I have with this kit : it replicates the Ultimaker down to the somewhat iffy hotend design which can be a real pain in the ... bottom regions, something I'm currently an expert at. But other than that, it's probably one of the most matured big dual extruder machines you can buy for a price that would not exceed that of the price most people bought their Dremel Idea Builders for. For that money, you get a pretty huge build space, a very stable design and probably one of the best supported machines out there.

Nieuwste JennyPrinter3 Z360 Dual Extruder Nozzle 3D Printer DIY KIT Voor Ultimaker 2 UM2 Extended Met Top Cover en Deur in Newest Assembled JennyPrinter3 Z360 Dual Extruder Nozzle Extended For Ultimaker 2 UM2 High Precision Auto Leveling 3D Pr van 3d printers op AliExpress.com | Alibaba Groep

On the lower scale of the market, Zonestar builds a P802QR2, a machine more or less comparable to the Max Micron, but it has been around for longer at a comparable price point. I've actually build that one for a friend once. It's a nifty machine and probably one of the easiest kits I've ever assembled, as large parts of the machine come totally pre-assembled out of the box.

There's also a series of BFG printers (Doom reference) sporting Dual Extruder+laser Engraver setups for around the 1200€ mark, like the Mutli MT series. These huge machines are essentially gMax1.5 clones, and come nearly fully pre-assembled. I've not found much about them in terms of reviews but if I was in the market for a dual extruder, laser engraver enabled machine and I would like to have as much bang for the buck as possible, I'd give this one a close look too.

Grote Maat 410*400*400mm multoo Dual Extruder Hoge Precisie FDM 3D PRINTER in de Meest Professionele Merk van Grote Maat 3D Printer Top Adavantages: 1. De echte print maat:410*400*400mm, en kan de van 3d printers op AliExpress.com | Alibaba Groep

There's also a XY-core like design out there called an XCR335, has a dual extruder option. Info on that one is pretty sketchy though. But in itself, I like the design and idea.

As for reviews .... well yeah if 100 people say a design stinks, you have reasons to worry. But I see quite a lot of positive feedback on the Max Micron. It all depends on expectations. If you're buying a kit, prepare to spend quite some time into tinkering with it before you get good results. It's part of the package. I wonder how many people start with the idea a kit printer is a fool-proof-it-works-perfectly-once-assembled thingy. It's not.

On the other hand, I helped a little friendly German Spartan Lady some time ago with a dirt cheap Anet Prusa, she assembled it with no help from me at all in terms of the build of the machine, and the results she got from a 150€-or-so-kit are good enough to fool anybody thinking they come from a 1000€ machine.

I've seen Tom Salanderer totally f___-up a Tevo Black Widow build live on YT, while most people report this machine was very easy to build and produces usable results directly after the build.

So ..... there's no substitude for own experience, clearly.

About the Dremel : the way it escalates pretty much points to either very bad filament (.... Dremel has known to have their fair batch of shitty filament too, just like nearly all other brands had at some point in time) or th nozzle just got so clogged it didn't want to play along anymore. So it's probably time for this

Tevo's BW doesn't have dual extruder. Of all Tevo's, I think only the Tarantulla has a dual nozzle option. But if there's one Tevo machine I would stay away from, it's the Tarantulla.

If you're looking for a sturdy design and a dual extruder at prices that won't kill your piggy bank, there's a couple of interesting routes to investigate.

I'm going to take the price point of your current Dremel Idea builder as reference, which still retails around 1000€ on this side of the ocean.

For example, there's "Jennyprinter", which is essentially a near-perfect Ultimaker2+ knockoff with enlarged build space (bigger than the Ulti). Can be bought as a kit or ready made. The problem I have with this kit : it replicates the Ultimaker down to the somewhat iffy hotend design which can be a real pain in the ... bottom regions, something I'm currently an expert at. But other than that, it's probably one of the most matured big dual extruder machines you can buy for a price that would not exceed that of the price most people bought their Dremel Idea Builders for. For that money, you get a pretty huge build space, a very stable design and probably one of the best supported machines out there.

Nieuwste JennyPrinter3 Z360 Dual Extruder Nozzle 3D Printer DIY KIT Voor Ultimaker 2 UM2 Extended Met Top Cover en Deur in Newest Assembled JennyPrinter3 Z360 Dual Extruder Nozzle Extended For Ultimaker 2 UM2 High Precision Auto Leveling 3D Pr van 3d printers op AliExpress.com | Alibaba Groep

On the lower scale of the market, Zonestar builds a P802QR2, a machine more or less comparable to the Max Micron, but it has been around for longer at a comparable price point. I've actually build that one for a friend once. It's a nifty machine and probably one of the easiest kits I've ever assembled, as large parts of the machine come totally pre-assembled out of the box.

There's also a series of BFG printers (Doom reference) sporting Dual Extruder+laser Engraver setups for around the 1200€ mark, like the Mutli MT series. These huge machines are essentially gMax1.5 clones, and come nearly fully pre-assembled. I've not found much about them in terms of reviews but if I was in the market for a dual extruder, laser engraver enabled machine and I would like to have as much bang for the buck as possible, I'd give this one a close look too.

Grote Maat 410*400*400mm multoo Dual Extruder Hoge Precisie FDM 3D PRINTER in de Meest Professionele Merk van Grote Maat 3D Printer Top Adavantages: 1. De echte print maat:410*400*400mm, en kan de van 3d printers op AliExpress.com | Alibaba Groep

There's also a XY-core like design out there called an XCR335, has a dual extruder option. Info on that one is pretty sketchy though. But in itself, I like the design and idea.

As for reviews .... well yeah if 100 people say a design stinks, you have reasons to worry. But I see quite a lot of positive feedback on the Max Micron. It all depends on expectations. If you're buying a kit, prepare to spend quite some time into tinkering with it before you get good results. It's part of the package. I wonder how many people start with the idea a kit printer is a fool-proof-it-works-perfectly-once-assembled thingy. It's not.

On the other hand, I helped a little friendly German Spartan Lady some time ago with a dirt cheap Anet Prusa, she assembled it with no help from me at all in terms of the build of the machine, and the results she got from a 150€-or-so-kit are good enough to fool anybody thinking they come from a 1000€ machine.

I've seen Tom Salanderer totally f___-up a Tevo Black Widow build live on YT, while most people report this machine was very easy to build and produces usable results directly after the build.

So ..... there's no substitude for own experience, clearly.

Last edited:

Ugh, another video where they say "um" or "uh" every 5 seconds. People need to learn how to talk. Anyways, thanks for the links. I think first I'll try cleaning/replacing the nozzle. Will cost less and might get the project moving again sooner.

Yes, I did just get done viewing a comparison of the Tarantula and the Black Widow and concluded the Tarantula is a no go. Too flimsy, and I'd rather stay away from cheap Chinese poor-quality "me too" clones. The laser engraving is not a deal breaker, but if I was to get a new printer then dual extruder and heated bed are must haves. Automatic leveling would be nice too, as I've got better things to do with my time than sit at a printer tweaking this and tuning that in order to get good prints. I'm the sort who like to switch it on, load up a model, and have it start printing (correctly). If only it were that simple.

(That video is good up to about 4 minutes in, then it switches to no-sound time-lapse for me. Dang. I'll have to look on YouTube or Google for the rest of the steps.)

Yes, I did just get done viewing a comparison of the Tarantula and the Black Widow and concluded the Tarantula is a no go. Too flimsy, and I'd rather stay away from cheap Chinese poor-quality "me too" clones. The laser engraving is not a deal breaker, but if I was to get a new printer then dual extruder and heated bed are must haves. Automatic leveling would be nice too, as I've got better things to do with my time than sit at a printer tweaking this and tuning that in order to get good prints. I'm the sort who like to switch it on, load up a model, and have it start printing (correctly). If only it were that simple.

(That video is good up to about 4 minutes in, then it switches to no-sound time-lapse for me. Dang. I'll have to look on YouTube or Google for the rest of the steps.)

Last edited:

Apparently he just time-lapses through the important stuff, like disassembling the extruder. So I got mine apart and sure enough the nozzle is clogged. kaween, you need to move here and be my neighbor.  I've got a plated replacement nozzle ordered and it will take a few days to get here. I guess in the meantime I could get re-acquainted with my family. Nah...I still need to finish cleaning up the model. (hehe)

I've got a plated replacement nozzle ordered and it will take a few days to get here. I guess in the meantime I could get re-acquainted with my family. Nah...I still need to finish cleaning up the model. (hehe)

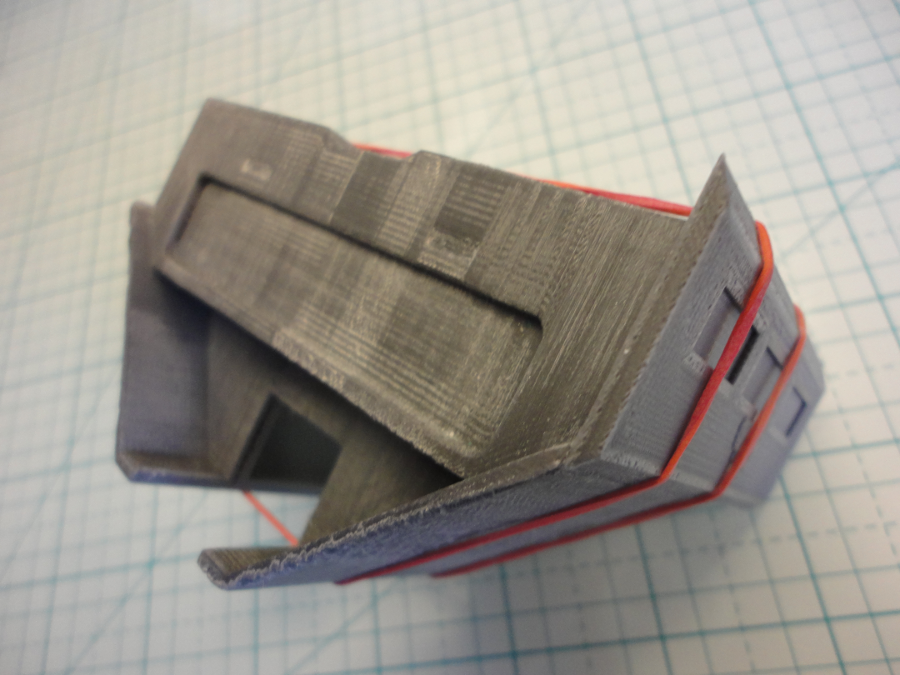

I did manage to get some work done this morning before the Dremel decided to wreck the rest of my day. The parts are being glued together with Loctite gel super glue and all the seams will be strengthened on the inside later with epoxy.

Here's the infamous rubber band shot holding parts together:

Applied spot putty to the next part (using a razor blade as a spatula) and will set the kid up tomorrow with sanding it smooth, and show him how to apply putty to the assembled forward parts.

Obviously there won't be any build photos for a few days (at best).

I did manage to get some work done this morning before the Dremel decided to wreck the rest of my day. The parts are being glued together with Loctite gel super glue and all the seams will be strengthened on the inside later with epoxy.

Here's the infamous rubber band shot holding parts together:

Applied spot putty to the next part (using a razor blade as a spatula) and will set the kid up tomorrow with sanding it smooth, and show him how to apply putty to the assembled forward parts.

Obviously there won't be any build photos for a few days (at best).

For example, there's "Jennyprinter", which is essentially a near-perfect Ultimaker2+ knockoff with enlarged build space (bigger than the Ulti). Can be bought as a kit or ready made.

I took a glance over at that Jennyprinter and it looks pretty cool. I can't read most of the page's content, but from what could see it's definitely worth looking up some reviews when the Dremel gets the boot in favor of a dual extruder system. Torn on whether to do kit (save some money but probably longer setup/calibration) or pre-built (more money but hopefully simpler/faster setup).

That second one I don't like as much - those frame-only (no enclosure) setups always look too rickety to me and I see too many complaints about vibration, alignment, etc messing up a print. My personal preference is an enclosed system like that Jennyprinter - just seems sturdier to me.

I was considering a Black Widow for awhile today, but there were too many reports of broken parts and poor customer service. For now at least I'll just wait for the new nozzle to arrive and see if that resuscitates the Dremel for a little while longer. I appreciate your input, as well as that of mblackwell1002

Rubber bands, zipties, WD40 and duct tape. Solves 90% of worlds' mechanical issues. 101% if you're DIY'ing.

Lol, yeah, and Trev on the other side too I'd expect. (moving). Hahaha. _ouch_. It hurts when I laugh.

I love to see the way Pillar takes form in your competent hands. I once saw a print of it which was so euh .... less detailed I really had to guess what I was looking at. Considering the tell-tale shape of the design even for a non-fan, you might imagine how that one looked.

Ah, languages. Keep forgetting about that sorry : Newest JennyPrinter3 Z360 Dual Extruder Nozzle 3D Printer DIY KIT For Ultimaker 2 UM2 Extended With Top Cover and Door-in 3D Printers from Computer & Office on Aliexpress.com | Alibaba Group

English.

I've build one of these Jenny's last year. I'm not really sure what to say about it. The kit came with a damaged side panel, but the good thing was that after reporting, a new sidepanel was send and I got that one within 4 working days from China, with a little extra stuff in the form of some extra spare nozzles and a "we're sorry" note included. They're using the original Ulti assembly manual (I kid you not !) which does prove to be correct for let's say 95% of the build. But as the original Ulti didn't have a dual extruder, that's not in the manual. Now if you have build machines yourself before this one, it's pretty obvious what has to be done. If not, there's undoubtably that feeling of "eeeeuhm ?".

But it's true, even with designs like these, if you've assembled them yourself you'll spend quite some time debugging, callibrating, experimenting .... before you're really satisfied. If you're not into that, might as well buy the assembled one. I like they have that new version with a door in front. I also can vouch for the companies' seriousness. In my experience, they react very fast (within hours) in case of questions both technical and otherwise, and they're generally pretty easy-going and -and this is important too- their command of the English language puts my own to shame. Admittinly having a supersized full featured near perfect Ultimaker clone on your desk that costs less than half of the original ? It does have some appeal. The only thing I would dare to recommend as a modification (when using this baby like the no-nonsense-24/7 production machine the Ulti's are known for) is to swap the original hotend design for a E3D Chimera conversion : these kits exist as no-brainer "drop in replacements" for the original Ulti2 ... which of course works perfectly on the Jenny3 too). While Jenny ships their machines with the Olsson conversion block as standard, I still prefer the E3D approach in terms of hotend design : as long as you cool it enough, an E3D -or a good clone of an E3D- won't let you down.

As for the Mutloo being rickety ... I understand that fear but trust me : I wouldn't worry about that. As said, they're basically gMax/Formbot T-Rex clone machines : clocking 20kg on the scale, I can tell you from my own experience a Formbot T-Rex2 (essentially the same machine, but with BLTouch Autolevel, dual heat zone heated bed and a dual independant extruder setup which is spooky to see it work) is one of the most stable giant printers out there. And a total monster on your desk.

BUT, and that's true : if you'd want to use these monsters for ABS printing, you'll need to build a pretty darn monsterous enclosure to keep it in, where something like a Jenny "comes with the enclosure as part of the design".

The only place I could find something about how the MT1 prints was here

Its more expensive brother (the T-Rex2) is pretty well documented on YT by several owners now. Tom Hansen is totally in love with his and he's been posting some spectacular YT videos/ of his older T-Rex 1. Formbot too I can vouch for from personal experience as being a company that will nearly stalk you when you report a problem with your machine.

I'm convinced your Dremel will come back to life pretty fast. Be sure to test your filament prior to use. If the problem started after swapping a spool for a new one, even an originally branded spool can get you into trouble if it was on the shelf too long or wasn't stored in ideal conditions.

As for the plated nozzles .... well I'm not sure.

100% personal view : If youre not going to print some pretty abbrasive filament types (say, magnetic filament with metal particles, wood or brick), I kinda prefer to just buy a couple of brass ones for the price of a single plated one. "In case of doubt, just toss it" is my advise, which isn't an issue with good, cheap Vulcano brass nozzles which I buy 60cent a pop.

As for Tevo .... I can't say I can confirm the "bad support" rumours. I've found them to be pretty responsive, and I know that when you report issues with a new kit within the first 7 days in terms of broken or missing parts -which is virutally impossible-, they'll send you replacement parts free of any charge. When I say "virtually impossible", I saying this because in all my life I've never seen a 3D kit this professionally packaged. The moment you open the box you just feel how they're trying to make a difference. Black cut-out foam everywhere, Compare that to the "nuts and bolts" setup you get when buying something like a Folger Tech FT5 ? No matter how much I like the idea behind the FT5, the execution is laughable : you get a horrible, riddled with errors manual and parts packaged like you'd just visited the local hardware store and just threw a couple of plastic bags of material in your basket.

Folger Tech FT5 with the current manual and packaging of Tevo ? That would be a sight to see.

It is true : Tevo got - and deserved - a lot of flak in terms of poor manuals, but the current batch of BW machines come with a great manual and some excellent build videos to boot.

But yeah, no dual extruder and I can see how that would be a deal breaker, I kinda predict we'll be seeing a dual extruder version in the near future : the used MKS control board is ready for dual extruder setups for sure.

Enough of this. Sorry for the offtopic blabbering on a build thread like yours. This place desperatly needs a "all 3D printer stuff" kind of meeting ground thread to avoid dirtying up threads like this where generic tips, infos and titbits can be exchanged.

Anyhow, looking forward to see Pillar shine soon.

Lol, yeah, and Trev on the other side too I'd expect. (moving). Hahaha. _ouch_. It hurts when I laugh.

I love to see the way Pillar takes form in your competent hands. I once saw a print of it which was so euh .... less detailed I really had to guess what I was looking at. Considering the tell-tale shape of the design even for a non-fan, you might imagine how that one looked.

Ah, languages. Keep forgetting about that sorry : Newest JennyPrinter3 Z360 Dual Extruder Nozzle 3D Printer DIY KIT For Ultimaker 2 UM2 Extended With Top Cover and Door-in 3D Printers from Computer & Office on Aliexpress.com | Alibaba Group

English.

I've build one of these Jenny's last year. I'm not really sure what to say about it. The kit came with a damaged side panel, but the good thing was that after reporting, a new sidepanel was send and I got that one within 4 working days from China, with a little extra stuff in the form of some extra spare nozzles and a "we're sorry" note included. They're using the original Ulti assembly manual (I kid you not !) which does prove to be correct for let's say 95% of the build. But as the original Ulti didn't have a dual extruder, that's not in the manual. Now if you have build machines yourself before this one, it's pretty obvious what has to be done. If not, there's undoubtably that feeling of "eeeeuhm ?".

But it's true, even with designs like these, if you've assembled them yourself you'll spend quite some time debugging, callibrating, experimenting .... before you're really satisfied. If you're not into that, might as well buy the assembled one. I like they have that new version with a door in front. I also can vouch for the companies' seriousness. In my experience, they react very fast (within hours) in case of questions both technical and otherwise, and they're generally pretty easy-going and -and this is important too- their command of the English language puts my own to shame. Admittinly having a supersized full featured near perfect Ultimaker clone on your desk that costs less than half of the original ? It does have some appeal. The only thing I would dare to recommend as a modification (when using this baby like the no-nonsense-24/7 production machine the Ulti's are known for) is to swap the original hotend design for a E3D Chimera conversion : these kits exist as no-brainer "drop in replacements" for the original Ulti2 ... which of course works perfectly on the Jenny3 too). While Jenny ships their machines with the Olsson conversion block as standard, I still prefer the E3D approach in terms of hotend design : as long as you cool it enough, an E3D -or a good clone of an E3D- won't let you down.

As for the Mutloo being rickety ... I understand that fear but trust me : I wouldn't worry about that. As said, they're basically gMax/Formbot T-Rex clone machines : clocking 20kg on the scale, I can tell you from my own experience a Formbot T-Rex2 (essentially the same machine, but with BLTouch Autolevel, dual heat zone heated bed and a dual independant extruder setup which is spooky to see it work) is one of the most stable giant printers out there. And a total monster on your desk.

BUT, and that's true : if you'd want to use these monsters for ABS printing, you'll need to build a pretty darn monsterous enclosure to keep it in, where something like a Jenny "comes with the enclosure as part of the design".

The only place I could find something about how the MT1 prints was here

Its more expensive brother (the T-Rex2) is pretty well documented on YT by several owners now. Tom Hansen is totally in love with his and he's been posting some spectacular YT videos/ of his older T-Rex 1. Formbot too I can vouch for from personal experience as being a company that will nearly stalk you when you report a problem with your machine.

I'm convinced your Dremel will come back to life pretty fast. Be sure to test your filament prior to use. If the problem started after swapping a spool for a new one, even an originally branded spool can get you into trouble if it was on the shelf too long or wasn't stored in ideal conditions.

As for the plated nozzles .... well I'm not sure.

100% personal view : If youre not going to print some pretty abbrasive filament types (say, magnetic filament with metal particles, wood or brick), I kinda prefer to just buy a couple of brass ones for the price of a single plated one. "In case of doubt, just toss it" is my advise, which isn't an issue with good, cheap Vulcano brass nozzles which I buy 60cent a pop.

As for Tevo .... I can't say I can confirm the "bad support" rumours. I've found them to be pretty responsive, and I know that when you report issues with a new kit within the first 7 days in terms of broken or missing parts -which is virutally impossible-, they'll send you replacement parts free of any charge. When I say "virtually impossible", I saying this because in all my life I've never seen a 3D kit this professionally packaged. The moment you open the box you just feel how they're trying to make a difference. Black cut-out foam everywhere, Compare that to the "nuts and bolts" setup you get when buying something like a Folger Tech FT5 ? No matter how much I like the idea behind the FT5, the execution is laughable : you get a horrible, riddled with errors manual and parts packaged like you'd just visited the local hardware store and just threw a couple of plastic bags of material in your basket.

Folger Tech FT5 with the current manual and packaging of Tevo ? That would be a sight to see.

It is true : Tevo got - and deserved - a lot of flak in terms of poor manuals, but the current batch of BW machines come with a great manual and some excellent build videos to boot.

But yeah, no dual extruder and I can see how that would be a deal breaker, I kinda predict we'll be seeing a dual extruder version in the near future : the used MKS control board is ready for dual extruder setups for sure.

Enough of this. Sorry for the offtopic blabbering on a build thread like yours. This place desperatly needs a "all 3D printer stuff" kind of meeting ground thread to avoid dirtying up threads like this where generic tips, infos and titbits can be exchanged.

Anyhow, looking forward to see Pillar shine soon.

Last edited:

Whew, that was a read. Honestly, you lose me with all the acronyms and 3D printing lingo. "Ulti"? "E3D"...?? I guess I probably need to get something already built. Nearly every discussion I've viewed about kit printers mentions assembly instructions with errors and although being a technical person, having never assembled a 3D printer from a box of parts is more than a little unnerving knowing the instructions could be incorrect and my machine might not work (through no fault of my own - simply followed the instructions, sir).

Sorry, but that link is also mostly German, or Russian, or something. Yeah, there's some English on the page (I got to that same page yesterday from clicking their English translation link) but much of the content is still not translated. The Formbot T-Rex 2 (non-clone) was suggested to me but just can't justify the $1800 right now. We had to replace our home's failed HVAC system last month and we had all the ductwork redone to support separate thermostats for downstairs/upstairs. Dual-extruder indeed is a deal breaker when shopping for a different printer because I've already got a single-extruder printer, if it works again after I re-assemble it. (I know, if I can't disassemble an extruder and replace a nozzle then how am I expected to build a whole printer!) If I get a different printer I want it to be able to print dissolvable supports from a second spool, and a heated table would be nice for ABS printing, and automatic leveling would help with one less thing to go wrong when printing, and I don't want just any squirrel - I want a trained squirrel and I want it now!

I got a plated nozzle for the Dremel because that's what I found first with Google, and that seemed to be what other people are using. Besides, my philosophy is if a part fails don't replace it with the same part - it's gonna fail too. Replace it with something better. I really don't think filament was the culprit here. Four Master Chief hand plates and 5 Pillar parts were printed off this spool without issue (if you don't count filament not sticking to the table an issue). I probably store filament better than most people do. I see a lot of opened filament just placed on a shelf or rack, but I store mine in zip-lock bags with moisture absorption packets inside. Apparently a clogged nozzle is common and inevitable with these printers, especially if used a lot and especially if a low-end OEM part is used (*cough* Dremel *cough*). I was printing 24/7 for a week with the Pillar Of Autumn parts, and perhaps switching to the silver filament played a part too (it must contain some metallic particles in order for it to look....metallic). But it's Dremel filament so I naively assumed it wouldn't be an issue on a Dremel machine. I paid $15 for one nozzle plus crazy shipping to get it here less than a week. Too bad I didn't know about nozzle lifespans or I could have had replacements on-hand and the printer back to spitting out parts (in slo-mo at several hours per part) instead of sitting idle for a few days. Lesson learned.

The Pillar build is looking less and less like it's going to meet the 4-week deadline (which now is only 3 weeks away) with an idle printer. I told him it's time to drum up Plan B, but we'll still complete the Pillar anyway. When I look at how long it's taking for each part to print and how many parts are on the model, there's little chance of it getting all printed before the due date, and that's not accounting for finishing and painting. All that means it now probably won't be such a "rush job" build, but as far as "accuracy" well I'm still building this from a model that isn't 100% accurate to begin with. It would take considerable effort to correct some areas so.....it is what it is. I am fixing the obvious issues, but areas needing more intense surgery will just have to remain as they are. (We wouldn't want a ship with a painful behind, now would we?!) Without the nuisance of an unrealistic due date for this type of project, I'm prepared to build this with functional lighting designed-in rather than as a retro-fit later on. That will look cool (and I do have experience with LED lighting circuits). Gonna have to order more blue-flicker LEDs for the engines because my existing supply is for a future Battlestar Galactica build and not being reallocated.

I've almost got the next model section completed and hope to get a pic up soon of the progress. One of the problems I'm having with model detailing is nearly all the Google images are dark as a caped Gotham vigilante so I'm thinking of going into "Reach" today and have a look around the questionable parts of the ship. I'm still not striving for screen-accurate but I've already put in a number of improvements on the model so why stop now. At the moment I'm redesigning the turrets so they can be assembled to swivel and tilt, and now that I've likely got more time for the build I think I'll go back and revise for lighting.

Sorry, but that link is also mostly German, or Russian, or something. Yeah, there's some English on the page (I got to that same page yesterday from clicking their English translation link) but much of the content is still not translated. The Formbot T-Rex 2 (non-clone) was suggested to me but just can't justify the $1800 right now. We had to replace our home's failed HVAC system last month and we had all the ductwork redone to support separate thermostats for downstairs/upstairs. Dual-extruder indeed is a deal breaker when shopping for a different printer because I've already got a single-extruder printer, if it works again after I re-assemble it. (I know, if I can't disassemble an extruder and replace a nozzle then how am I expected to build a whole printer!) If I get a different printer I want it to be able to print dissolvable supports from a second spool, and a heated table would be nice for ABS printing, and automatic leveling would help with one less thing to go wrong when printing, and I don't want just any squirrel - I want a trained squirrel and I want it now!

I got a plated nozzle for the Dremel because that's what I found first with Google, and that seemed to be what other people are using. Besides, my philosophy is if a part fails don't replace it with the same part - it's gonna fail too. Replace it with something better. I really don't think filament was the culprit here. Four Master Chief hand plates and 5 Pillar parts were printed off this spool without issue (if you don't count filament not sticking to the table an issue). I probably store filament better than most people do. I see a lot of opened filament just placed on a shelf or rack, but I store mine in zip-lock bags with moisture absorption packets inside. Apparently a clogged nozzle is common and inevitable with these printers, especially if used a lot and especially if a low-end OEM part is used (*cough* Dremel *cough*). I was printing 24/7 for a week with the Pillar Of Autumn parts, and perhaps switching to the silver filament played a part too (it must contain some metallic particles in order for it to look....metallic). But it's Dremel filament so I naively assumed it wouldn't be an issue on a Dremel machine. I paid $15 for one nozzle plus crazy shipping to get it here less than a week. Too bad I didn't know about nozzle lifespans or I could have had replacements on-hand and the printer back to spitting out parts (in slo-mo at several hours per part) instead of sitting idle for a few days. Lesson learned.

The Pillar build is looking less and less like it's going to meet the 4-week deadline (which now is only 3 weeks away) with an idle printer. I told him it's time to drum up Plan B, but we'll still complete the Pillar anyway. When I look at how long it's taking for each part to print and how many parts are on the model, there's little chance of it getting all printed before the due date, and that's not accounting for finishing and painting. All that means it now probably won't be such a "rush job" build, but as far as "accuracy" well I'm still building this from a model that isn't 100% accurate to begin with. It would take considerable effort to correct some areas so.....it is what it is. I am fixing the obvious issues, but areas needing more intense surgery will just have to remain as they are. (We wouldn't want a ship with a painful behind, now would we?!) Without the nuisance of an unrealistic due date for this type of project, I'm prepared to build this with functional lighting designed-in rather than as a retro-fit later on. That will look cool (and I do have experience with LED lighting circuits). Gonna have to order more blue-flicker LEDs for the engines because my existing supply is for a future Battlestar Galactica build and not being reallocated.

I've almost got the next model section completed and hope to get a pic up soon of the progress. One of the problems I'm having with model detailing is nearly all the Google images are dark as a caped Gotham vigilante so I'm thinking of going into "Reach" today and have a look around the questionable parts of the ship. I'm still not striving for screen-accurate but I've already put in a number of improvements on the model so why stop now. At the moment I'm redesigning the turrets so they can be assembled to swivel and tilt, and now that I've likely got more time for the build I think I'll go back and revise for lighting.

Last edited:

After 2 hours of looking around online I've settled on 1206-package warm white 3v SMD chip LEDs for the lighting. I also ordered a set of the slightly larger 2835-package and 5730-package because it looks like the Pillar's "window" lights aren't all the same size. Had to go with chip LEDs because of some of the light locations (thin-walled sections like in the front). Lights in the main hull area will be simple enough to install from the backside, I just need to modify the CAD model with openings for the LEDs and provide a mounting area on the inside. Still contemplating how I'll put lights within 2.1mm thick parts. The lights and wiring will fit easily (the 1206's are 1.1mm tall), it's trying to get them glued in. Might have to go with a styrene "skin" in those areas. Today I'll look through my LED stockpile for the green lights on the ship's top. (Green? ...or blue? Can't quite tell from the images - will look into that when in the game later today.) I also want to include some blinking lights somewhere, like aircraft running lights or strobes, to help this look more "alive" when it's finished. I'll either find existing ones on the game model today or I'll "make up" some in logical locations. I'm also hoping to fish some of my fiber optic stock through small metal tubes for the various antennas. I have fibers small enough, the issue will be finding small enough metal tubes so the antennas are in scale. Anybody have other suggestions or comments about lighting this baby up?

Last edited:

Ulti : "Ultimaker". You know. Them printers everyone will imagine when you're saying "3D printer".

E3D : makers of a series of hotends. Generally regarded as one of the better brands. Gets copied by Chinese mfg'ers like there's no tomorrow. Tip : some of these chinese clones are indeed capable of producing output quality that's indistinguishable from the original versions at 1/6th of the price.

Odd, that link is pure English when I open it here btw.

As for hotends .... yeah I understand the idea about failing parts, but do remember the hotend nozzle of a 3D printer is indeed a _consumable_, just like filament is. These things aren't designed to last.

Plated nozzles may _seem_ to be the best idea, but there's quite some things were low cost brass nozzles are superior. Temperature conductivity of a brass nozzle is superior to a plated one for starters. Certainly if you're looking into printing ABS, if your heat element is already struggling hitting your specific ABS temp sweet spot, that high grade muchos dineros plated nozzle can become a real issue instead of a solution. Certain versions of hardened/plated nozzles may acutally be more vulnerable to corrosion than brass ones (learned that the hard way).

And there's of course this : if you really "F_ck up" a nozzle in a crash or whatever, tossing a 0.50USD one or a 15USD one .... you choose.

That's why, imho, unless your're doing special filament types that eats through you brass nozzles like carbon filament ect... use the brass one for normal stuff and the expensive one for when you really need to.

Hah, leds in Pillar. I have two pieces of advise, do with them as you like :

1) do whatever feels cool. It will be okay.

2) give CommanderPalmer Mara a shout. If I get into this kind of questions, she's my go-to girl. She has a "pokedex like" knowledge of the Halo universe (Halodex ?), and she's got an artists' eye. Whatever she tells me is law.

E3D : makers of a series of hotends. Generally regarded as one of the better brands. Gets copied by Chinese mfg'ers like there's no tomorrow. Tip : some of these chinese clones are indeed capable of producing output quality that's indistinguishable from the original versions at 1/6th of the price.

Odd, that link is pure English when I open it here btw.

As for hotends .... yeah I understand the idea about failing parts, but do remember the hotend nozzle of a 3D printer is indeed a _consumable_, just like filament is. These things aren't designed to last.

Plated nozzles may _seem_ to be the best idea, but there's quite some things were low cost brass nozzles are superior. Temperature conductivity of a brass nozzle is superior to a plated one for starters. Certainly if you're looking into printing ABS, if your heat element is already struggling hitting your specific ABS temp sweet spot, that high grade muchos dineros plated nozzle can become a real issue instead of a solution. Certain versions of hardened/plated nozzles may acutally be more vulnerable to corrosion than brass ones (learned that the hard way).

And there's of course this : if you really "F_ck up" a nozzle in a crash or whatever, tossing a 0.50USD one or a 15USD one .... you choose.

That's why, imho, unless your're doing special filament types that eats through you brass nozzles like carbon filament ect... use the brass one for normal stuff and the expensive one for when you really need to.

Hah, leds in Pillar. I have two pieces of advise, do with them as you like :

1) do whatever feels cool. It will be okay.

2) give CommanderPalmer Mara a shout. If I get into this kind of questions, she's my go-to girl. She has a "pokedex like" knowledge of the Halo universe (Halodex ?), and she's got an artists' eye. Whatever she tells me is law.

Okay, you convinced me - but where are you finding these $0.50 nozzles? All I'm finding on Google and eBay are wear-resistant plated nozzles. Not too late for me to cancel my order on the $15 one, but the wife thinks I should just leave it ordered so it's here and ready if some day I need one for "special" filament.

I'm no noob when it comes to model details and I've designed enough digital sequencing circuits (USS Enterprise warp engine domes, KITT front scanner light, etc) to easily handle the small amount of lighting on the POA. This has now turned from being a stressful gotta-getter-done-in-4-weeks project to a leisurely fun side project. (Yes, SirPalesAlot, I'll get back to that cod model...!)

Apparently we cannot edit our own thread titles anymore? Used to be able to do that when editing the first post of a thread, but not seeing that option anymore.

I'm no noob when it comes to model details and I've designed enough digital sequencing circuits (USS Enterprise warp engine domes, KITT front scanner light, etc) to easily handle the small amount of lighting on the POA. This has now turned from being a stressful gotta-getter-done-in-4-weeks project to a leisurely fun side project. (Yes, SirPalesAlot, I'll get back to that cod model...!)

Apparently we cannot edit our own thread titles anymore? Used to be able to do that when editing the first post of a thread, but not seeing that option anymore.

Last edited:

Aw jeez... i leave for a day or two and the printer craps out! well, if you're still looking for printer recommendations, i'll throw mine out. i've been using the Robo 3D R1+. i've basically put it through a trial by fire, what with sticking it in my grimy work area in the garage, running it almost 24/7 with prints sometimes going 80 hours long, getting it covered in bondo dust, wood dust, and paint dust from sanding (sometimes while its running) and the thing just keeps chugging along! its got a HUGE build plate and is a reprap based platform, which means you can mod it out the butt into some freakish Frankenstein's monster (the whole extruder assembly comes apart SO easily!) also, their support office is super cool, and most of the guys are amateur prop builders themselves, so they were able to answer all my weird technical questions when i was still learning how to print large prop and helmet pieces.

Great, I'll look it up to see if it's got the features I want. Just looked up the non-clone Ultimakers - holy crap out of my price range. The more I read about nozzles and 3D printing, the more I'm convinced replacing the nozzle will get the Dremel working again. I found a 5-pack of 0.4mm MK10-thread plain-jane brass nozzles at Amazon for $10 and that's the best I could find with reasonable shipping time (2 business days). I could have gotten a 6-pack for $8 but would have to wait until April for them to arrive and that's just insane. I'm now modding your model further, adding openings for LEDs and wiring conduits through the thin parts. Also going to revise the interior "wall" thicknesses to better accommodate the SMD LEDs. Researching reference images, it looks like the original designer of this model might be Aaron Fung? The proportions are way off on a lot of areas but correcting it will just be too much work so the basic shape I'm (mostly) keeping as is.

Great, I'll look it up to see if it's got the features I want. Just looked up the non-clone Ultimakers - holy crap out of my price range. The more I read about nozzles and 3D printing, the more I'm convinced replacing the nozzle will get the Dremel working again. I found a 5-pack of 0.4mm MK10-thread plain-jane brass nozzles at Amazon for $10 and that's the best I could find with reasonable shipping time (2 business days). I could have gotten a 6-pack for $8 but would have to wait until April for them to arrive and that's just insane. I'm now modding your model further, adding openings for LEDs and wiring conduits through the thin parts. Also going to revise the interior "wall" thicknesses to better accommodate the SMD LEDs. Researching reference images, it looks like the original designer of this model might be Aaron Fung? The proportions are way off on a lot of areas but correcting it will just be too much work so the basic shape I'm (mostly) keeping as is.

i forgot to mention the R1+ is also a sub-$1000 printer! (which was most of what made me buy it in the first place). and you're really teasing me with all these improvements and LED light attachments! its definitely something i wanted to do (especially with the covenant ships) but i knew that my 3D modeling skills just weren't there yet. maybe in the future! As for the model itself, lil bit of a confession: i got almost all of the models off of those kinda shady "3D model aggregate" sites that pull from tons of different other sites. i scrubbed them for any viruses, obviously, but maybe i should take "game-ripped model! 100% game accurate!!" with a grain of salt... either way, i doubt the kids in your son's class will be pulling out calipers to check proportions and accuracy for every panel and hangar bay.

Yep, it still "looks" like the Pillar Of Autumn even with its distorted proportions. (Overlay a screen shot with the model and you'll see what I'm talking about.) Some of the stuff I'm fixing because it's a simple matter of stretching a face or adding/subtracting faces. Funny you should mention hangar bays. Got a surprise coming up on this build since acquiring a Pelican model (and we're not talking about birds...)

I get my nozzles from Ali express. Regular nozzles : 10pcs/lot 3d printer nozzle V6 V5 j head brass nozzle 0.2 0.3 0.4 0.5 0.8mm For 1.75 or 3.0mm supplies extruder-in 3D Printer Parts & Accessories from Computer & Office on Aliexpress.com | Alibaba Group

You'll have to search whatever type you need, but those are even cheaper than 0.50 at 1,17USD for 10 of them.

STainless steel ? 2016 5pcs/lot High Quality 3D Printer Nozzles 0.25/0.4/0.8mm V6 Stainless Steel Nozzle optional size for 1.75/3.0mm-in 3D Printer Parts & Accessories from Computer & Office on Aliexpress.com | Alibaba Group I know this seller, he's legit.

I get nearly all my small 3D consumables from Aliexpress. Takes weeks to arrive for sure, but I buy 10 of them, and by the time I'm down to 3 I'll just order a new pack.

Hehehe. Yeah, Ultimaker is very, very expensive. One could argue if they're worth it. Fact is Utlis can do 300+ hour prints without too much of an issue and you'll find them mainly in University Builder labs and such, not that many other machines can take the abuse an Ulti can. And the closed box system is nice when doing ABS. But honestly owning an Ulti is a bit of a prestige thing. Like "look at my Beamer".

In terms of output quality, there's enough out there doing certainly not less good and costing just a fraction, and the Robo is certainly one of them.(well, the + at least, the previous one was reported giving a lot of issues on longer prints). As Mendez says, buying a Robo means you're buing a "ready made, but modifyable platform" and that's pretty unique.

As for being the Robo being huge ? Hahaha. Sorry. No. Compared to a Dremel ? Sure.

It's about as small as my smallest machine (slightly smaller actually wich is a self build Kossel Pro) and it's a midget compared to my self build Big Delta, my Alpha Hatchbox, my Formbot and my LM. . And with the exception of the very expensive Formbot, they all are available at a sub-1000USD level if you shop around.

. And with the exception of the very expensive Formbot, they all are available at a sub-1000USD level if you shop around.

But I would ride that Dremel as long as it works. 3D machines are getting cheaper all the time. A year ago, it would be totally impossible to find a sub1000USD Delta like an Tevo LM with a build space of 340x500. Or even the (expensive) Formbot at that size ? Impossible below 5000USD. So my advise is to postpone buying a new one as long as possible.

And whenever you're ready for an upgrade, ask again when the time comes. The market moves way too fast to pin yourself on models and types now. One piece of advise : look at a model and look how much printed or plastic parts are being used. Want a machine that lasts ? Go for a full metal design. Havng a model that allows printed upgrades and such is cool, but in my experience those are the machines that tend to break just when you need them. Fully metal made machines are meant to last ..... for a very long time.

You'll have to search whatever type you need, but those are even cheaper than 0.50 at 1,17USD for 10 of them.

STainless steel ? 2016 5pcs/lot High Quality 3D Printer Nozzles 0.25/0.4/0.8mm V6 Stainless Steel Nozzle optional size for 1.75/3.0mm-in 3D Printer Parts & Accessories from Computer & Office on Aliexpress.com | Alibaba Group I know this seller, he's legit.

I get nearly all my small 3D consumables from Aliexpress. Takes weeks to arrive for sure, but I buy 10 of them, and by the time I'm down to 3 I'll just order a new pack.

Hehehe. Yeah, Ultimaker is very, very expensive. One could argue if they're worth it. Fact is Utlis can do 300+ hour prints without too much of an issue and you'll find them mainly in University Builder labs and such, not that many other machines can take the abuse an Ulti can. And the closed box system is nice when doing ABS. But honestly owning an Ulti is a bit of a prestige thing. Like "look at my Beamer".

In terms of output quality, there's enough out there doing certainly not less good and costing just a fraction, and the Robo is certainly one of them.(well, the + at least, the previous one was reported giving a lot of issues on longer prints). As Mendez says, buying a Robo means you're buing a "ready made, but modifyable platform" and that's pretty unique.

As for being the Robo being huge ? Hahaha. Sorry. No. Compared to a Dremel ? Sure.

It's about as small as my smallest machine (slightly smaller actually wich is a self build Kossel Pro) and it's a midget compared to my self build Big Delta, my Alpha Hatchbox, my Formbot and my LM.

But I would ride that Dremel as long as it works. 3D machines are getting cheaper all the time. A year ago, it would be totally impossible to find a sub1000USD Delta like an Tevo LM with a build space of 340x500. Or even the (expensive) Formbot at that size ? Impossible below 5000USD. So my advise is to postpone buying a new one as long as possible.

And whenever you're ready for an upgrade, ask again when the time comes. The market moves way too fast to pin yourself on models and types now. One piece of advise : look at a model and look how much printed or plastic parts are being used. Want a machine that lasts ? Go for a full metal design. Havng a model that allows printed upgrades and such is cool, but in my experience those are the machines that tend to break just when you need them. Fully metal made machines are meant to last ..... for a very long time.

Last edited:

Thanks. I see what you're doing, motivating me to learn Dutch, huh? I'm not much a fan of ODST. I went with a supplier who could get me the nozzles delivered in days rather than weeks. They should be here Tuesday (or Wednesday considering the holiday). When it's time to restock I'll have the luxury of shopping around for a better price without trying to get it quickly. Time now to go start up Reach and get some better reference images.

Well darn. After snapping a lot of screen shots I want to change some of the details that were already "done". Little things like chamfering corners and stuff. Also going to print some custom decals towards the end of this project for decorating the escape pod hatches and various other bits that we noticed. We've also decided to do a few Combat Evolved levels to try getting some better pictures, knowing full well that the ship is slightly different in that game - but it's still "Pillar Of Autumn" so technically not "wrong" to incorporate any CE details that we like (making the model our own).

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 249

- Replies

- 2

- Views

- 461

Similar threads

- Replies

- 2

- Views

- 461