I think I've got sizing worked out for the 3D printed model. I didn't use windows for a reference (and that's not because I'm a Mac user!) as they should be easy enough to scale with available SMD LED packages. Instead I went with the smallest light feature on the build, the tiny little red marker lights all over the hull. They're kind've the limiting factor because realistically you can only get so small and keep that rectangular shape. Even though a new 0201 package size is now available (0.35mm x 0.65mm), that's honestly going to be too tiny to work with and I do want the final size of this build to convey the massiveness of this ship. So I went with SMD 0402 chip LEDs for those marker lights (0.5mm x 0.8mm), which ends up yielding a build size of around 1076mm long (just over 1 meter). That was my rough ballpark target anyway. Next up I need to place an order for 112 of them (that's how many are distributed around the ship) and now also compute the LED sizes for the blue and white marker lights, antenna markers, and windows. Also, now that I've got a size worked out I can start on the modeling this weekend. I will likely need to re-order the hypodermic tubing for antennas and turrets, since the first ones were computed based off a different sizing. (No matter, I'm sure I'll use them on some other project.) 0.5mm fiber optic will be used for the antenna lighting. I won't have pictures for awhile since the work being done right now is collecting up sizing information for the various metal tubes and lighting, and getting parts ordered now that I've settled on a final scale.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Robot Chicken's PILLAR OF AUTUMN Build - 3D Printed

- Thread starter RobotChicken

- Start date

- Status

- Not open for further replies.

51 blue beacon/marker lights will be SMD 0603 LEDs, ordered from Digi-Key along with the 112 red SMD 0402 LEDs. It's still weird to me that none of the marker lights blink on this ship. Regular aircraft, passenger and military, have flashing marker lights, and even Starfleet has blinking marker lights on their starships. Odd that UNSC ships have all the markers always-on, and no green starboard or red port markers. I did some power tests on LEDs today and holy crap they are BRIGHT. Will be toning them down through resistors to look more like in the game.

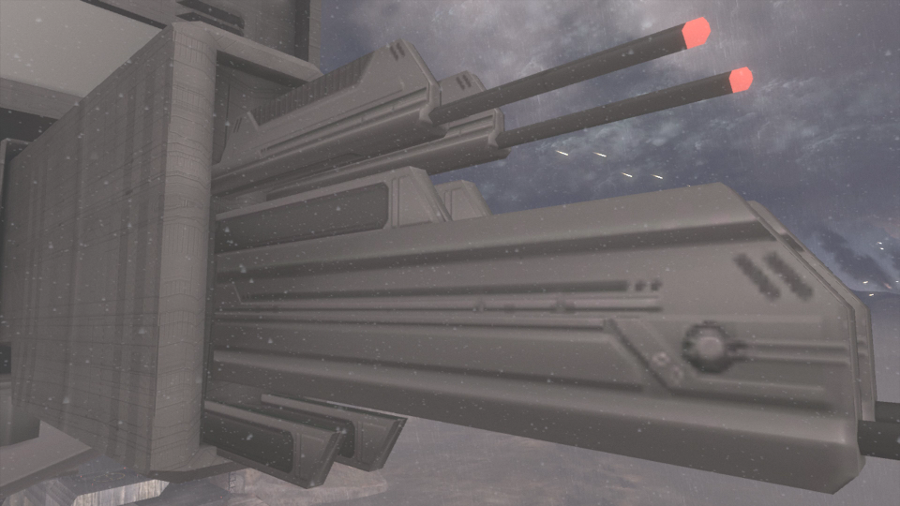

I finally was successful in getting up close and personal with the ship in-game and snapped several reference photos of the forward antenna array, the first area of the model I'm going to dress up with details:

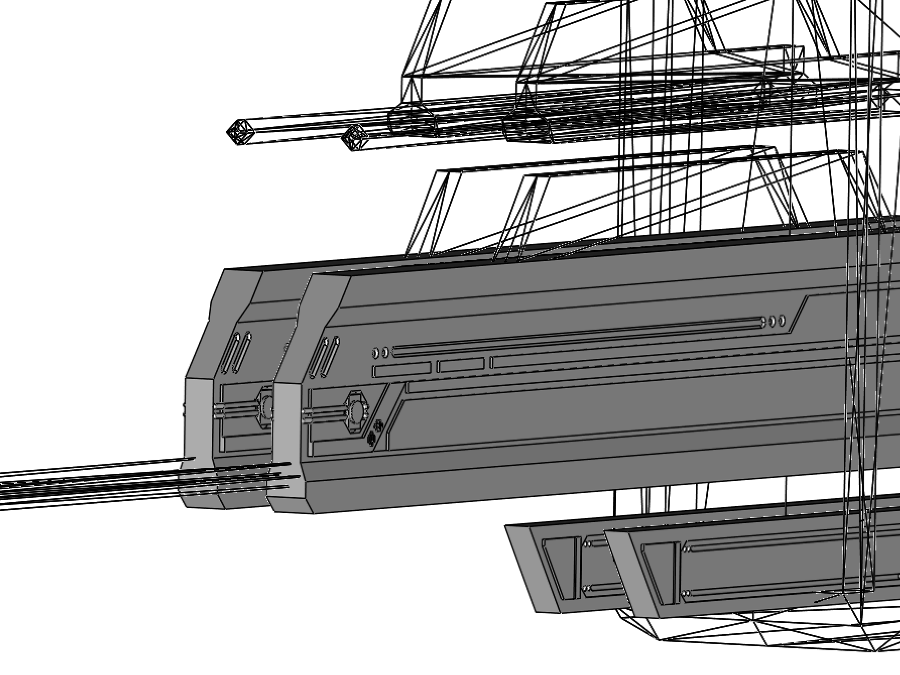

After getting extreme close-up shots on some of the other details, I'm now convinced it will be better to photo-etch them then try printing them. For example, the many red marker lights are 0.5mm x 0.8mm SMD chip LEDs and even if this detail around them would print, based off what I've printed so far I don't think it would turn out as crisp as photo-etched brass:

My kid pointed out that the red lights on the various antennas have a slight flicker to them. This would be doable by using a red flickering LED behind the fiber optic. What do you think we should use - steady light or flickering?

After closer comparison between Reach and Combat Evolved, it turns out there are a number of differences between the models so I'll be going strictly with the Reach version. Next begins the very time-consuming task of modeling details into the model.

After getting extreme close-up shots on some of the other details, I'm now convinced it will be better to photo-etch them then try printing them. For example, the many red marker lights are 0.5mm x 0.8mm SMD chip LEDs and even if this detail around them would print, based off what I've printed so far I don't think it would turn out as crisp as photo-etched brass:

My kid pointed out that the red lights on the various antennas have a slight flicker to them. This would be doable by using a red flickering LED behind the fiber optic. What do you think we should use - steady light or flickering?

After closer comparison between Reach and Combat Evolved, it turns out there are a number of differences between the models so I'll be going strictly with the Reach version. Next begins the very time-consuming task of modeling details into the model.

Last edited:

Here's a peek at what I've been doing this week. Compare against the first photo of this thread and you get an idea of how the model's going to look...

It took a few days to get the "octagon" area looking acceptable, but I think now it will pass considering its size on the printed model. I'm hoping to make a test print on the weekend to see how well (or not!) this prints. The antenna "rods" will be made from stainless steel hypodermic tubing I got from Amazon and 0.5mm fiber optic fits through it for lighting the tips.

The scale has to be increased a little more due to all the little antennas. The smallest metal tube I've been able to find that will sheath a 0.5mm fiber with minimal wall thickness is 0.7112mm diameter, which yields a model size of about 1,330mm long. I want to use metal tube for the antennas so they don't break, and hollow so I can light their tips. Yeah, I know the various antennas are square tubes rather than round (well, technically, rectangular rather than square, since 343 didn't model them quite perfectly) but square tubing isn't available that small, fiber optic is round anyway, so I'm making them round. (In the "real world" they would probably be round anyway.)

So the ship is going to be a bit larger than I was targeting.

It took a few days to get the "octagon" area looking acceptable, but I think now it will pass considering its size on the printed model. I'm hoping to make a test print on the weekend to see how well (or not!) this prints. The antenna "rods" will be made from stainless steel hypodermic tubing I got from Amazon and 0.5mm fiber optic fits through it for lighting the tips.

The scale has to be increased a little more due to all the little antennas. The smallest metal tube I've been able to find that will sheath a 0.5mm fiber with minimal wall thickness is 0.7112mm diameter, which yields a model size of about 1,330mm long. I want to use metal tube for the antennas so they don't break, and hollow so I can light their tips. Yeah, I know the various antennas are square tubes rather than round (well, technically, rectangular rather than square, since 343 didn't model them quite perfectly) but square tubing isn't available that small, fiber optic is round anyway, so I'm making them round. (In the "real world" they would probably be round anyway.)

So the ship is going to be a bit larger than I was targeting.

Last edited:

Well, after scaling and slicing, it turns out much of the detail is beyond the print capabilities of the Idea Builder. I'm not prepared to get another printer just yet and I've been wanting to try out custom photo-etching, so I guess I'll be modifying copies of these parts (I want to keep a version that has everything modeled in) to remove the raised details and piping. I think the recessed areas will print okay based off the slicing preview (I'll know for sure after a test print on the weekend) but the raised areas are looking like they'll need to be photo-etched and I'll use small wire for the piping.

Hey kaween, a few questions for you regarding print output. Call it a sanity-check, if you will (but you seem to have a lot of 3D printing experience).

- The Idea Builder is documented at having a minimum layer height of 0.1mm, but Simplify3D allows me to set a layer height of 0.001mm for the printer. Do you think setting a layer height of 0.001mm in the slicer will result in printed parts having 0.1mm or 0.001mm layer height? Do I just print two parts at each setting and compare them (under magnification)? I've been using 0.05mm layer height so far, and this does seem to produce smoother prints than using a 0.1mm setting.

- Assuming a layer height of 0.1mm, I'm suspecting any raised top-side detail with less than 0.1mm tall will not print (simply omitted from slicing)? Likewise, any recessed top-side detail less than 0.1mm deep will not print? (This appears to be the observed slicing behavior.) Recessed side details (indentations on the vertical sides of a part) do not seem to be affected by this, leading to question 3 regarding extrusion width.

- The Idea Builder's default extrusion width in Simplify3D is 0.48mm, which is quite large in the slicing preview (each layer drawn similar to using a fat preschool crayon). In Simplify3D, extrusion width is allowed to go down to 0.0mm (really, what's the point then), but what are the practical limitations in choosing a value for this setting? Nozzle diameter? How does a printer yield different extrusion widths using the same nozzle? The replacement nozzles I got are Amazon.com: Witobt MK10 M7 0.4mm Extruder Upgrade Brass Wear Resistant Nozzle for Makerbot RepRap 3D Printer (Pack of 5pcs): Industrial & Scientific (0.4mm) - does this limit me to 0.4mm extrusion width and I need to get smaller nozzles for printing finer details? I believe I would benefit from a brief (in plain English...) discussion about extrusion width settings.

- Member DIN

- S240

When you do get to printing this it's going to be crazy.... your worried about .1mm details on a 4ft+ model?

your worried about .1mm details on a 4ft+ model?

It's a disease.

With regards to printing, I've tried 5 times already this morning and so far nothing is sticking to the build platform. I've replace the build tape with fresh tape that I bought special for this (it's highly rated and supposed to be really good), leveled the platform (sucks that has to be done manually), and still nothing is sticking. I'm going to try a low-res print with default settings to see how that goes. Somebody needs to just slap Dremel for not having a heated platform.

- Member DIN

- S240

Have you tried scuffing the tape a little with some sand paper may possibly help I don't know? I have a cube 3 and it has some weird bed material and a glue that is used with it. Works well but I have to scuff the bed after a handful of prints to keep it sticking real well.

I tried printing one of the demo models after scuffing the tape, and still filament just collects up on the nozzle instead of sticking to the tape. This printer blows so now I'm back to shopping for a different printer - one with a heated platform, dual extruder, self-leveling, and hopefully higher resolution than the Idea Builder. I cannot recommend the Dremel printer at all.

- Member DIN

- S240

That's sucks  ya I know the feeling. 3D printing has its moments one day just plug in and print no problems... others seems like nothing will go right.

ya I know the feeling. 3D printing has its moments one day just plug in and print no problems... others seems like nothing will go right.

You nailed it - one day and no problems, all the other days nothing goes right. Anyway, now shopping for a different printer and hopefully one exists out there somewhere that has the features I want, the print-resolution I want, and at a price I'm willing to pay (or rather, that the wife is willing to let me pay....)

Haha, try a FF creator pro, when you say "every other day something goes wrong", my printer does really well. I don't have to deal with issues very often, I've had this thing for about a year and a half, and I've had maybe 10 bad-print-days. It's a very reliable printer. The only thing I've really had to do is dust it and maintenance every so often.

will the wife let you go to $900?

why not just be even more "responsible" and put $200 or so in a jar or something every time you get a paycheck?

I mean the family will probably prefer that method rather than spending all at once. just my two cents.

will the wife let you go to $900?

why not just be even more "responsible" and put $200 or so in a jar or something every time you get a paycheck?

I mean the family will probably prefer that method rather than spending all at once. just my two cents.

$900 is affordable, but I just went over to FF and reviewed the specs - it's essentially a Dremel with dual extruder and heated metal platform. But, it still has manual leveling (same as the Dremel) and only 0.1mm maximum resolution. I'll keep it in mind, but still shopping for something better. (When I said "affordable", I meant less < $5000.)

When I've narrowed down the candidates I'll put a list here for you printer guys to comment on before I make a final selection. So far it seems I'm in a ~$3,000 price bracket for the quality/reliability/features I'm looking for. So far, the "no" list is way longer than the "maybe" list.

When I've narrowed down the candidates I'll put a list here for you printer guys to comment on before I make a final selection. So far it seems I'm in a ~$3,000 price bracket for the quality/reliability/features I'm looking for. So far, the "no" list is way longer than the "maybe" list.

Last edited:

- Member DIN

- S240

Ok mblackwell1002. I should have worded my post there a little different lol. Printing with "certain" printers has its moments. Knock on wood I've been having success with mine lately while working on my newest project. Good luck RobotChicken finding your new printer.

Okay, I've narrowed it down to just 2 printers, unless you guys know of something I haven't discovered yet. I'm curious to hear your thoughts about them before I buy.

MAKEiT PRO-M MatterHackers - 3D Printing Supplies

BCN3D Sigma MatterHackers - 3D Printing Supplies

I'm not yet leaning more to one than the other because they each have their pros and cons. What do you guys think?

MAKEiT PRO-M MatterHackers - 3D Printing Supplies

BCN3D Sigma MatterHackers - 3D Printing Supplies

I'm not yet leaning more to one than the other because they each have their pros and cons. What do you guys think?

Hmmm...I'd go with the Sigma. The bigger build plate is nice, plus they have an add-on for a 12x12. that IDEX feature is reaaaaly handy with dissolvable supports. it would decrease print time as well, because one extruder could be printing dissolvable filament while the other prints the actual finished material, aside from the hotends bumping into each other.

check out reviews first, though.

check out reviews first, though.

I've been reading/viewing reviews all day and I'm really leaning towards the Sigma now. I don't think the 12x12 add-on is for larger build volume (according to one of the reviews I watched) - they said it's build tape that actually needs to be trimmed down for the Sigma. I wasn't able to find out much (yet) about the Pro-M, which isn't a good indicator for me. Plenty on a Pro-L, but not the Pro-M. I really do like the printer interface on the Sigma and its automated calibration. I haven't seen at all where both extruders are moving at the same time. Three hours of looking at reviews and each one shows one extruder parked while the other is printing. But, it's got full-metal heat ends, heated build table, automatic nozzle wiping, large build volume, independent dual extruders, metal enclosure - I'm really liking that printer thus far. The one (and only) downside is it takes strictly 3mm filament. I've got 6 spools of 1.75mm Dremel filament (most unopened or barely used) that I wouldn't be able to use with the Sigma, so I'd have to buy all new filament if I went with the Sigma. But when I compare that against the Pro-M interface I think it's not a deal-breaker. What keeps me undecided is the Sigma's maximum resolution is 50-microns, and the Pro-M is 10-microns. That's a big difference in print resolution, but the Pro-M seems rickety to me (no support of the extruder frame, 3D printed parts construction) and I really don't care for their LCD interface compared to the Sigma. The Sigma looks to be a much sturdier construction. There are some really cool non-Dremel filaments out there that I'd be able to use with either of these printers. I think I'll wait for kaween to toss in his 2 cents and a response from MatterHackers to some questions I sent them before committing to a purchase, but based on features/design/calibration-ease/IDEX/etc the Sigma seems more appealing. I also just learned of the Ultimaker 3 (and the more-desirable Ultimaker 3 Extended) but now we're getting a little too pricey.

Those of you 3D printing people who are following this build, would you recommend PLA or ABS when I get to actually printing this thing, and why? Since I'll be needing to buy new filament anyway if going with the Sigma and since I'm such a noob at printing, I'd like to hear material suggestions and why. I really like the ability either of these printers will provide for dissolvable filament, either PVA (PLA) or HIPS (ABS), and I'm also intrigued by "conductive filament" for 3D printing internal wiring either on this build or future projects. I hear some people prefer ABS because of its characteristics but I also hear it can be fussy to print (lifting corners, warping, etc). I honestly don't know if PLA is good or bad - it's just all I was able to use with Dremel so just had to live with that. I've also thought about printing the various windows and lights in translucent filament using the second extruder and backlighting them, but I want their edges to be crisp without any potential "color bleed" so I still think it might be better to print those as holes, clean them up as needed, and fit chip LEDs flush with the outside surface after painting.

Those of you 3D printing people who are following this build, would you recommend PLA or ABS when I get to actually printing this thing, and why? Since I'll be needing to buy new filament anyway if going with the Sigma and since I'm such a noob at printing, I'd like to hear material suggestions and why. I really like the ability either of these printers will provide for dissolvable filament, either PVA (PLA) or HIPS (ABS), and I'm also intrigued by "conductive filament" for 3D printing internal wiring either on this build or future projects. I hear some people prefer ABS because of its characteristics but I also hear it can be fussy to print (lifting corners, warping, etc). I honestly don't know if PLA is good or bad - it's just all I was able to use with Dremel so just had to live with that. I've also thought about printing the various windows and lights in translucent filament using the second extruder and backlighting them, but I want their edges to be crisp without any potential "color bleed" so I still think it might be better to print those as holes, clean them up as needed, and fit chip LEDs flush with the outside surface after painting.

Last edited:

I use ABS+ It's super easy to sand and doesn't curl like regular ABS does. PLA is really hard to sand in comparison. Plus, you can 'weld' ABS or ABS+ parts together with acetone. The stuff kaween and I buy is called Esun ABS+ silver. Silver behaves better than the other colors. ABS filaments do curl, but if you have a heated enclosure, it behaves like a well-trained dog.

PLA is good and all, it's just hard to glue and sand, thus my reasons for ABS+. kaween has been testing out some filament called "Devil Design" He says it's a really nicely printing filament, but you'd have to hear it from him...He's a pretty serious printing master, in fact, his nickname is [I]MasterPrinterTheWise[/I]

PLA is good and all, it's just hard to glue and sand, thus my reasons for ABS+. kaween has been testing out some filament called "Devil Design" He says it's a really nicely printing filament, but you'd have to hear it from him...He's a pretty serious printing master, in fact, his nickname is [I]MasterPrinterTheWise[/I]

Actually, I learned yesterday researching PLA welding that you can weld PLA like you can ABS. Acrylic glue, like Plastruct Bondene-2, or chloroform or MEK will fuse PLA stronger than the PLA material itself (supposedly). With 0.05mm layer height I don't know how important sandability will be. I anticipate (and hope for) a lengthy post from kaween answering the various questions I've posted today. So that's one vote for ABS+.

Update: Apparently the MAKEiT PRO-L is newer than the PRO-M (I would have thought the reverse, alphabetically) and supposedly can print a layer height less than 0.05mm. I still have issue with an unsupported frame design, 3D printed parts construction, non-enclosed print area, non-independent extruders, and the LCD interface, but the print resolution is very appealing, the MAKEiT printers take 1.75 filament (so I would be able to use my existing PLA with this printer, if not on the Pillar Of Autumn then on some other project), and the Pro-L (L for "large") has a build volume of 12" x 10" x 13" (i.e. BIG). Both the Pro-M and Pro-L have the ultra high-resolution, only difference is build volume (and a big difference in price). So darn it, now I'm undecided again. Anxious to hear kaween's thoughts on sub-100 micron printers. Maybe he'll know of one that's a DIY kit version at a significantly less price point.

Update: Apparently the MAKEiT PRO-L is newer than the PRO-M (I would have thought the reverse, alphabetically) and supposedly can print a layer height less than 0.05mm. I still have issue with an unsupported frame design, 3D printed parts construction, non-enclosed print area, non-independent extruders, and the LCD interface, but the print resolution is very appealing, the MAKEiT printers take 1.75 filament (so I would be able to use my existing PLA with this printer, if not on the Pillar Of Autumn then on some other project), and the Pro-L (L for "large") has a build volume of 12" x 10" x 13" (i.e. BIG). Both the Pro-M and Pro-L have the ultra high-resolution, only difference is build volume (and a big difference in price). So darn it, now I'm undecided again. Anxious to hear kaween's thoughts on sub-100 micron printers. Maybe he'll know of one that's a DIY kit version at a significantly less price point.

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 248

- Replies

- 2

- Views

- 458

Similar threads

- Replies

- 2

- Views

- 458