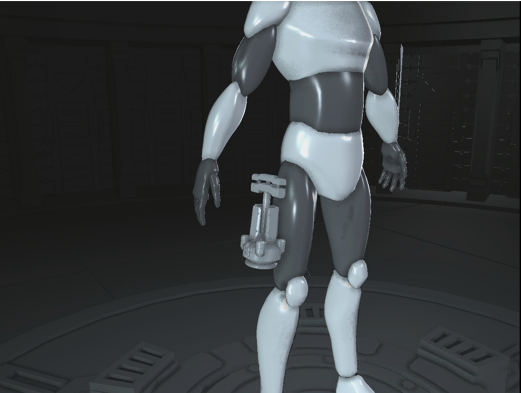

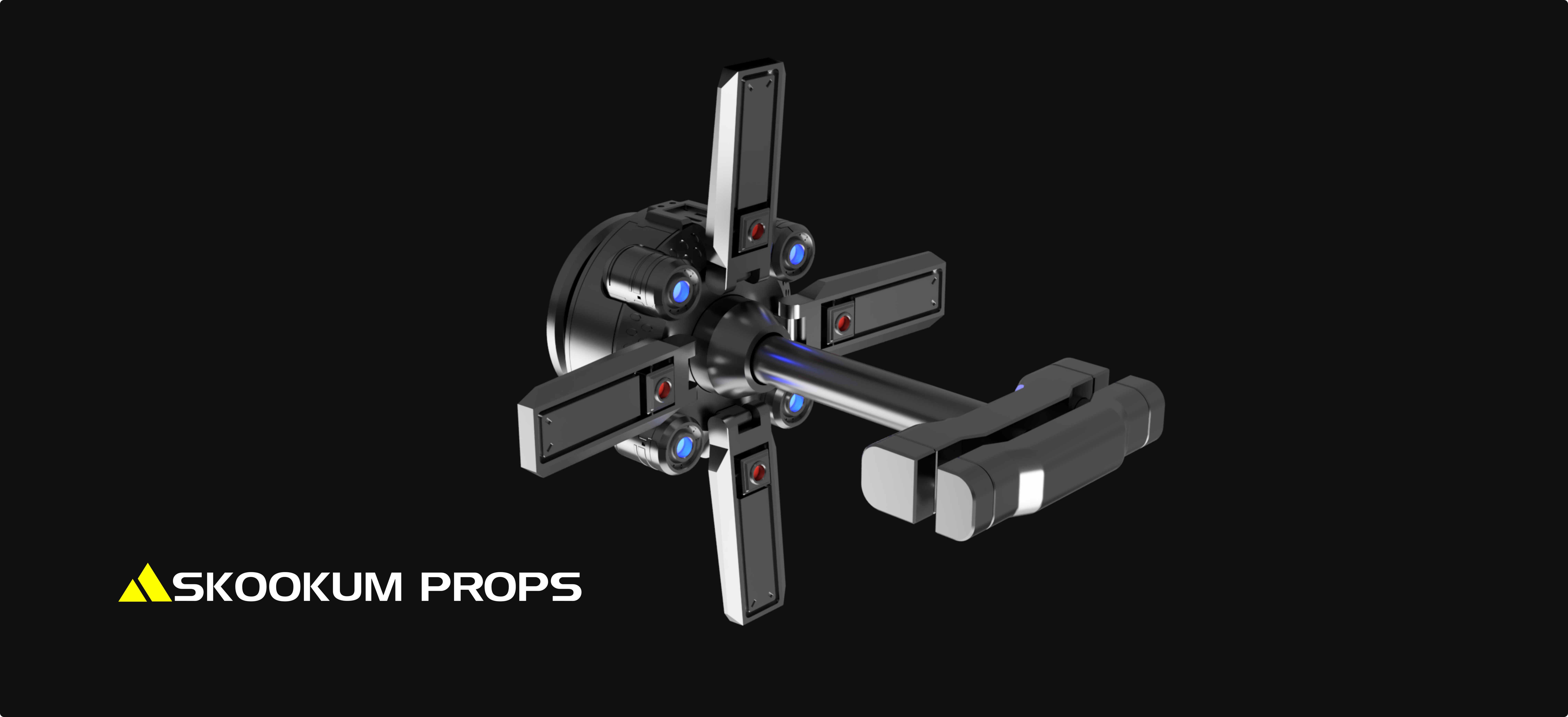

Updating for Model 52 Navy Knife from Halo Infinite.

This one was done on the 405th Day 2022 Crafting Stream and was really fun overall to rework an existing design of the Reach Combat Knife into a new game and use lessons learned from an old design into an easier build for this one.

Order of operations of assembly matters on this build for full functionality. As well as a 3D printing filament of choice you'll also need

1 - 60mm x 10mm x 3mm magnet or a series of magnets that can fit within the same volume

2 - 2.5mm Ø x 60mm brass rods for alignment

1 - 1mm thick sheet steel or other ferrous material

1 - 2mm foam sheet for gasket material

McMaster Carr item 91292A021 can be used for the four M3 fasteners if they are trimmed slightly and the holes are drilled through. A printable version of the caps is included in the file pack.

The magnet is embedded within the core of the blade and is trapped forever. Yes this might make metal detectors at events a bit of a pain but showing that it's for the magnetic connection is easy to explain.

The two brass rods extend between the grip, guard and assembled blade. Brass is not necessary but this diameter is usually easier to find and is cheaper than steel or other materials.

Before assembling the two halves of the sheath, insert the sheet steel segment cut to size. I recommend a strong epoxy here so that the magnet does not pull out the steel over time. Sand the surface flush and remove any burrs that may marr the painted surface of your knife.

Add the foam gasket in the lower recess. This is a bit of extra insurance against bumps and jolts in that will dislodge the knife from the magnet. The magnets I listed will be unlikely to let it go but having a press fit material there helps a lot for sanity.

Overall a super easy build if you have a printer and it was fun to make on Stream.

As always these are provided for free under the Creative Commons BY-NC-ND for personal use. I've had a bunch of headaches recently of people selling Commando kits without asking and all that extra paperwork takes away from time being a Fusion monkey. If you ever see anyone selling this file kit and not doing the makers trade of materials plus a six pack, something is funny.

Good luck and happy printing!

Model 52 Navy Knife