You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another Space Marine

- Thread starter Judge

- Start date

- Status

- Not open for further replies.

Because I printed this out to A3 I didn't check smaller options. I've just adjusted it & also done a very basic unfold for letter for you guys. This is already scaled to 520mm for Venom, who inadvertantly picked up the problem.

Heres the Unfold Sm Chest Letter

I'll check the others at some time too.

Heres the Unfold Sm Chest Letter

I'll check the others at some time too.

Nightmare451

Member

Venom_Di_Lemon said:Also i have this lurking around that was made by Trintlord awhile ago it looks amazing but its a real pain to pep ^^ got several attempts. i figured you didn't need to make the tubes on the side just use shower hose or drainage pipe seems to work fine.

Regards

Matt

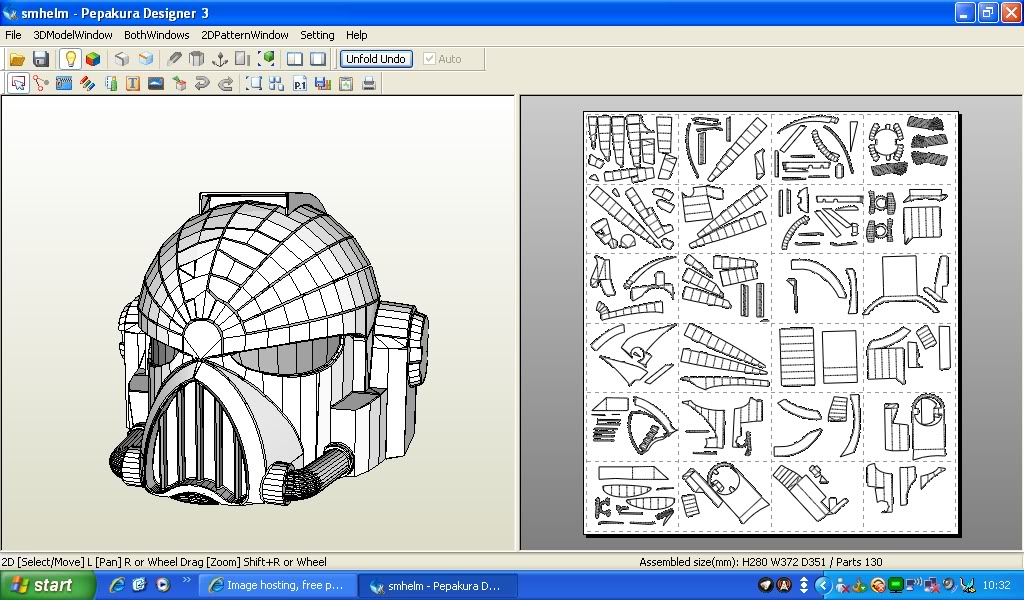

I hate to point this out but TrintLord's helmet file is just a modified version of Nintendude's unfold of the Space Wolf files XxCALIBERxX put up. The hole where the diamond was in XxCALIBERxX and Nin's helmet is very poorly covered up by TrintLord

And pic for proof

Last edited by a moderator:

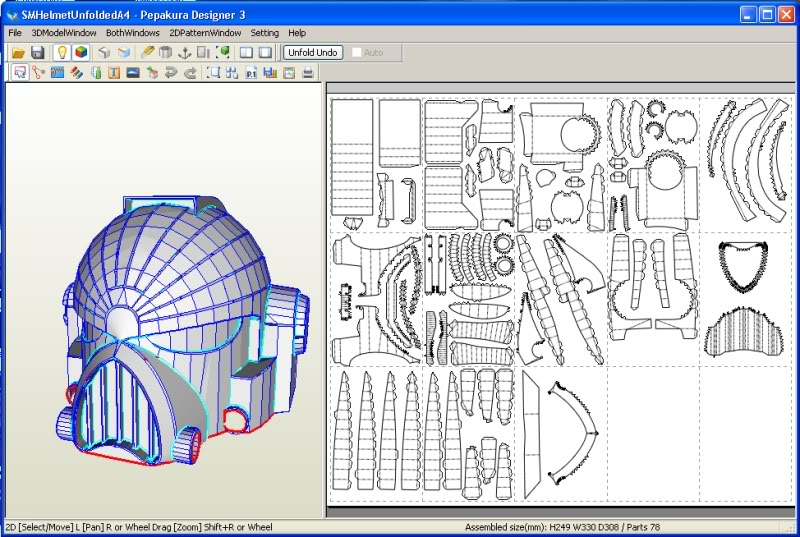

great work chwbcc I've been following this for a while In lurk mode just finished building my helmet off nintendue's files helmet came out way larger then I expect to be right I can wear my PASGT helmet Inside my SM lid comfortably to give an idea of how the scale seems to be off for my next build I plan on trying your scaling assistant keep up the great work

amancue said:great work chwbcc I've been following this for a while In lurk mode just finished building my helmet off nintendue's files helmet came out way larger then I expect to be right I can wear my PASGT helmet Inside my SM lid comfortably to give an idea of how the scale seems to be off for my next build I plan on trying your scaling assistant keep up the great work

Cool I've been using the assistant for all my peps and so far so good. They look huge at first but in comparison they are all perfectly proportioned. (Helm, Shoulder and Arms and I'm working on Samuray's Chest and it's looking good so far.)

Last edited by a moderator:

Venom Di Lemon

New Member

Well i got the chest piece all sorted thank you judge i'm just configuring it to fit A4  not a problem i can do that part but thank you for simplifying it

not a problem i can do that part but thank you for simplifying it

packs the same though i'm afraid doesn't seem to like the change haha ^^

@Tango : Ah i didn't know that thanks for letting me know.

Also i know people don't like to fibreglass and i'm probably the person picking the hardest way to do this. But i know how we would all like to be able to not fibreglass and the armour be as tough as nails wouldn't we? Well i know some people who would like to be able to make pep pieces then clay over them so they can slush cast but can't as the weight of putting clay on the model warps it. Well i think i found a way.

I'm going to try a test run first on a Space Marine shoulder file.

Theres a product called jesmondite which i use. It is a powder, resin and thixotrope i think it's called and you can coat on the inside and outside of pep pieces with a paintbrush i use, i would recommend doing it slowly and in thin layers so only a small amount needs to be mixed. As you don't want the pep piece to warp. You can then apply it outside the pep piece if you choose to depends. Then you can affix your clay in a small layer and sculpt it following the shape of the pep. Then you can mould and slush cast i was thinking. Or you could jesmondite the outside and inside for more strength then you would have to sand bondo and fill and sand and curse and eventually get it all smooth. Then you have a completed piece. So far i know it's avaiable in the uk but i think it can be shipped internationally. Also it's non toxic

Strength Test

[media]http://www.youtube.com/watch?v=OvUgH0SumaI[/media]

Regards

Matt

packs the same though i'm afraid doesn't seem to like the change haha ^^

@Tango : Ah i didn't know that thanks for letting me know.

Also i know people don't like to fibreglass and i'm probably the person picking the hardest way to do this. But i know how we would all like to be able to not fibreglass and the armour be as tough as nails wouldn't we? Well i know some people who would like to be able to make pep pieces then clay over them so they can slush cast but can't as the weight of putting clay on the model warps it. Well i think i found a way.

I'm going to try a test run first on a Space Marine shoulder file.

Theres a product called jesmondite which i use. It is a powder, resin and thixotrope i think it's called and you can coat on the inside and outside of pep pieces with a paintbrush i use, i would recommend doing it slowly and in thin layers so only a small amount needs to be mixed. As you don't want the pep piece to warp. You can then apply it outside the pep piece if you choose to depends. Then you can affix your clay in a small layer and sculpt it following the shape of the pep. Then you can mould and slush cast i was thinking. Or you could jesmondite the outside and inside for more strength then you would have to sand bondo and fill and sand and curse and eventually get it all smooth. Then you have a completed piece. So far i know it's avaiable in the uk but i think it can be shipped internationally. Also it's non toxic

Strength Test

[media]http://www.youtube.com/watch?v=OvUgH0SumaI[/media]

Regards

Matt

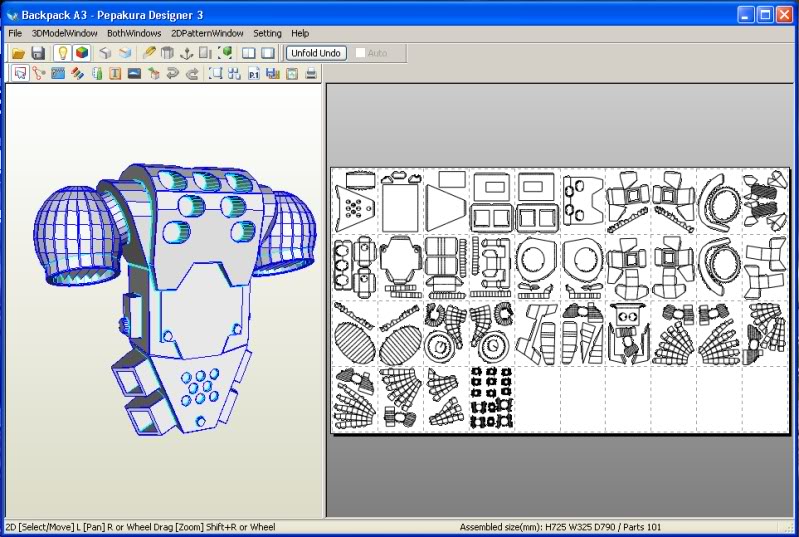

The backpack is going to take some time to change. I'll try & get it started. If you can get A3 printed fairly cheap heres an A3 unfold sized to fit the letter chest. It is 34 pages though. You may be able to adjust it, but some pieces will stay huge I think.

File Backpack to suit letter size

It may or may not help, see how you go.

I have a A4 helmet unfold also, from when I cleaned up the original model and yes, it's just the same as everybody elses.

A4 Helmet.

It is huge, so scale it as per ExtremeTactics101 tuts.

File Backpack to suit letter size

It may or may not help, see how you go.

I have a A4 helmet unfold also, from when I cleaned up the original model and yes, it's just the same as everybody elses.

A4 Helmet.

It is huge, so scale it as per ExtremeTactics101 tuts.

Venom_Di_Lemon said:Well i got the chest piece all sorted thank you judge i'm just configuring it to fit A4not a problem i can do that part but thank you for simplifying it

packs the same though i'm afraid doesn't seem to like the change haha ^^

@Tango : Ah i didn't know that thanks for letting me know.

Also i know people don't like to fibreglass and i'm probably the person picking the hardest way to do this. But i know how we would all like to be able to not fibreglass and the armour be as tough as nails wouldn't we? Well i know some people who would like to be able to make pep pieces then clay over them so they can slush cast but can't as the weight of putting clay on the model warps it. Well i think i found a way.

I'm going to try a test run first on a Space Marine shoulder file.

Theres a product called jesmondite which i use. It is a powder, resin and thixotrope i think it's called and you can coat on the inside and outside of pep pieces with a paintbrush i use, i would recommend doing it slowly and in thin layers so only a small amount needs to be mixed. As you don't want the pep piece to warp. You can then apply it outside the pep piece if you choose to depends. Then you can affix your clay in a small layer and sculpt it following the shape of the pep. Then you can mould and slush cast i was thinking. Or you could jesmondite the outside and inside for more strength then you would have to sand bondo and fill and sand and curse and eventually get it all smooth. Then you have a completed piece. So far i know it's avaiable in the uk but i think it can be shipped internationally. Also it's non toxic

Strength Test

Regards

Matt

Hahaha That looked like fun!!! Could you post a tutorial on how you apply this stuff?

Sorry Judge we keep Hi-jacking your thread!

Last edited by a moderator:

The scale is exact same as the letter sized chest file. The chest was scale 9.689775 520mm DEPTH (because it's actually width), I made the backpack the same. The dimensions you can see at the bottom of the backpack screenshot. Just remember that Width & Depth are swapped. Still don't know how to change it.

Hope it helps.

Hope it helps.

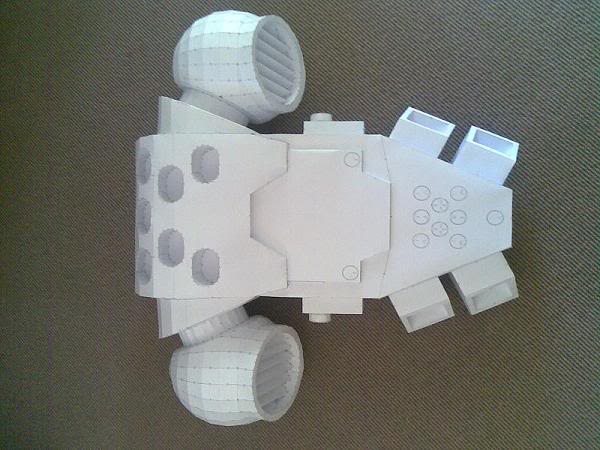

Apologies for another double post but it's been a week & I've been a little busy. Backpack is fully pepped, now I just have to work out how to go about the resin stage.

I'll be removing a couple of panels & also after glassing replacing some vents with mesh.

This thing is huge. 725mm high, 325mm deep & 790mm wide.

The various buttons or knobs that are in the front will be made seperate from PU foam & resinned on later.

I'll be removing a couple of panels & also after glassing replacing some vents with mesh.

This thing is huge. 725mm high, 325mm deep & 790mm wide.

The various buttons or knobs that are in the front will be made seperate from PU foam & resinned on later.

XxCALIBERxX

Member

Looking sexy Judge, can't wait to see it done,

Cheers, Dave.

Cheers, Dave.

the Idea me and my apothecary have been tossing around is,.. to resin up the outsides of the backpack then carefully and measuredly fill the inside w/ Great Stuff to Solidify it,.. then Paint on some Shellshock and work as normal should make it pretty invincible.

I did the same method w/ my Anti-Material Rifle,.. minus the Shellshock, I resinated the paper,.. then carefully injected greatstuff till evenly filled,.. then after it was all set,.. glassed the outside (yes its a pain,. but being a gun didnt have many other ideas @ the time)

should work better w/ this

I did the same method w/ my Anti-Material Rifle,.. minus the Shellshock, I resinated the paper,.. then carefully injected greatstuff till evenly filled,.. then after it was all set,.. glassed the outside (yes its a pain,. but being a gun didnt have many other ideas @ the time)

should work better w/ this

Nintendude

Well-Known Member

Super pep work Judge finally someone got the guts to pep that monster sized backpack, now the glassing part is where it's really going to gain weight but as a suggestion you may want to figure out a way to put some supports inside because I bet it might warp when the resin process is done. Key word there is : Might. But other than that Judge your Marine is coming along nicely and I hope to see you at a convention soon. I apologize on my out of scale Marine files and it is perfectly OK to re-unfold or re-scale any of them, kinda hard to get the scaling of a Space Marine for a person right, LOL.

- Status

- Not open for further replies.

Similar threads

- Replies

- 33

- Views

- 3,802