This build thread will chronicle the construction and unique custom designed features of "Master Groves'" Halo 4 Master Chief suit I will be making. He stands at 6'11", so getting as close to the real MC will be the primary goal. I will be making all of this from scratch, creating on-the-fly templates that are tailored to his duct tape dummy he sent me. Since he is tall and thin, I am charged with bulking him up, by way of the Exo-suit. The Exo-suit will be primarily constructed with EVA foam and woven elastic as the base, and skinned with a custom latex hex pattern currently under development. It will also feature "hard armor mounting points", to alleviate any possibility of armor pieces shifting or moving out of place during normal wear and movement. The due date is Nov. 11th, and I will be building the whole suit, minus the helmet.

I will keep this post up-to-date with the build as it progresses, and will thoroughly document any new or special techniques I utilize during this time. When this is completed, ALL of the physical templates will be handed over to Master Groves, and he will be the sole owner of them, with the agreement the they are not to be released. I apologize for this fact, but this is one of the very few times I have decided to do so.

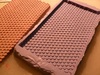

I know it is traditional to post photos in the beginning, so I will start off with the three renditions of the custom hex pattern I have relentlessly tried to achieve.

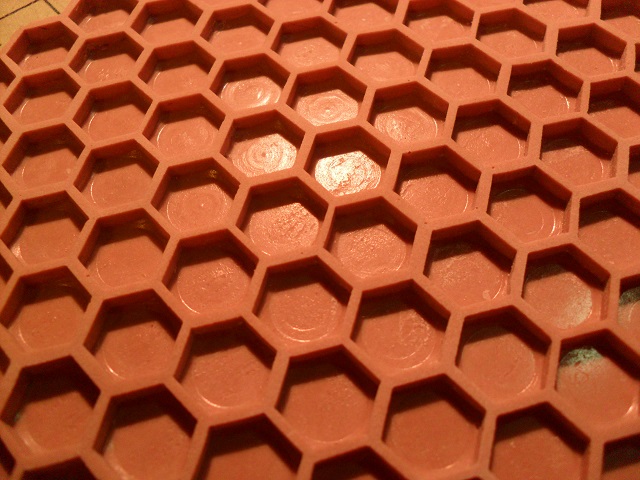

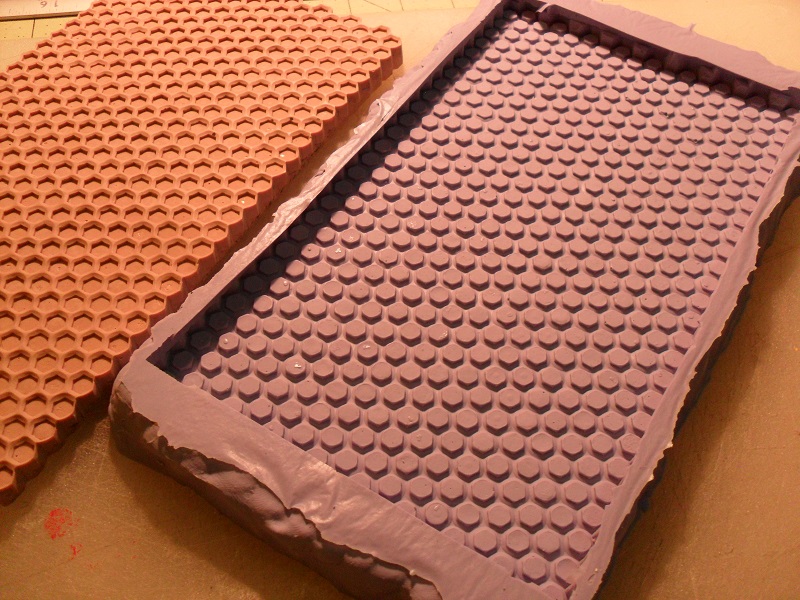

Version 1: 3/8" hex heads, with 1/16" padding. Problem: The full head size was too large, the depth was too deep, and the padding created inaccurate walls

Version 2: 1/4" hex heads with 1/16" padding. Problem: Even after the padding was drilled down, it still presented a distinct wall between the hex heads. The hex heads were too pronounced, and had walls of their own.

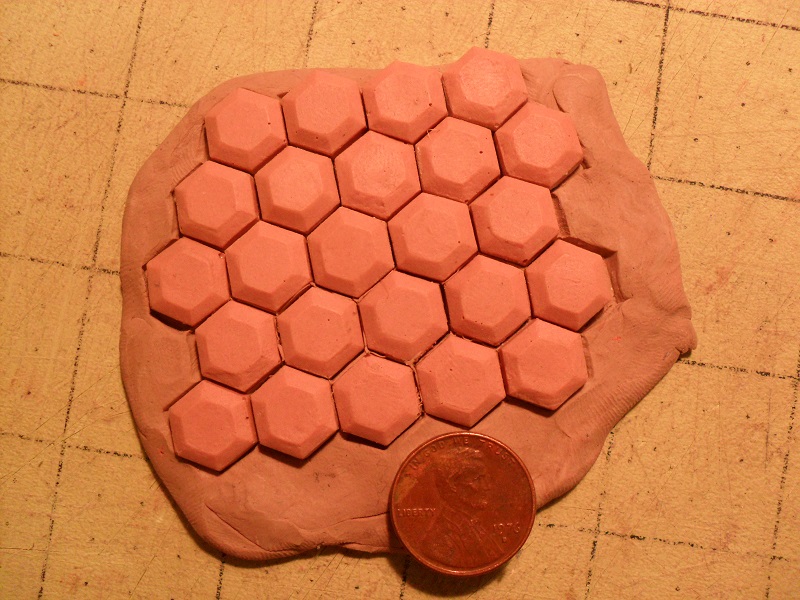

Version 3: This is the current version, with 3/8" hex heads, filed down in angles on each of the 6 sides to create a 1/4" hex pattern inside. Problem: So far, no problems, but possible hurdles as each hex piece is individually created by casting an impression of the original steel hex head from craft clay. This is a small representation of what the pattern will look like when completed.

I will keep this post up-to-date with the build as it progresses, and will thoroughly document any new or special techniques I utilize during this time. When this is completed, ALL of the physical templates will be handed over to Master Groves, and he will be the sole owner of them, with the agreement the they are not to be released. I apologize for this fact, but this is one of the very few times I have decided to do so.

I know it is traditional to post photos in the beginning, so I will start off with the three renditions of the custom hex pattern I have relentlessly tried to achieve.

Version 1: 3/8" hex heads, with 1/16" padding. Problem: The full head size was too large, the depth was too deep, and the padding created inaccurate walls

Version 2: 1/4" hex heads with 1/16" padding. Problem: Even after the padding was drilled down, it still presented a distinct wall between the hex heads. The hex heads were too pronounced, and had walls of their own.

Version 3: This is the current version, with 3/8" hex heads, filed down in angles on each of the 6 sides to create a 1/4" hex pattern inside. Problem: So far, no problems, but possible hurdles as each hex piece is individually created by casting an impression of the original steel hex head from craft clay. This is a small representation of what the pattern will look like when completed.