- Member DIN

- S128

I never knew this was even possible! Create professional looking decals at home with your own color printer!

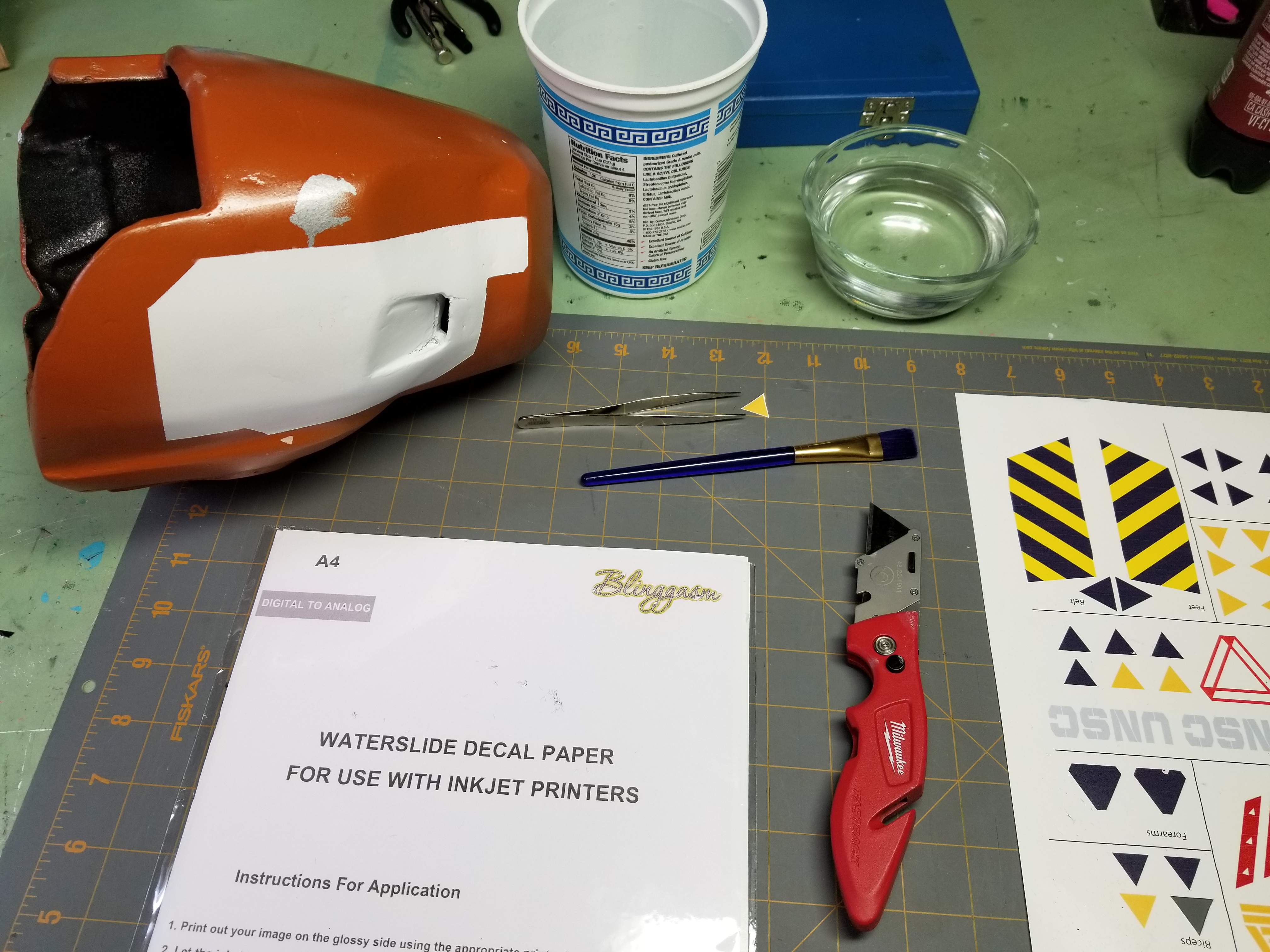

It takes some time to set up, but the application is super simple. So let’s get you started!

Materials you need:

An electronic image of what you want, pre sized and in a printable document (pdf, jpeg etc)

Waterslide Decal Paper (there are four options, explained later)

Krylon Crystal Clear Spray Paint Matte or Glossy (or other clear acrylic spray)

Decal Setting Solution (optional)

Decal Blending Solution (optional)

½” paint brush

Tweezers

Xacto knife

Self Healing Cutting Board

Black sharpie

Bowl with warm water

Tissues/paper towels

Blow Dryer or Heat gun with low setting

Acetone (for weathering)

*Disclaimer* This only works on a painted surface. Best to do this after you have painted your suit or prop, but before you’ve weathered and sealed.

First we need to talk about the paper you will need to buy. There are two types of printers that this will work for, Ink jet or Laser and you will need to buy paper specific to which printer you have. Then you will have the options of clear or white. Printers cannot print white, so if your decal has white in the image you will need to rely on the white paper to create that white space. Use clear if you don't want any white in your decal. *but only if the decal has dark colors. Light colors become transparent with the clear paper and are hard to see on a painted surface.*

Examples (Letter size):

Ink Jet –Clear Paper

Ink Jet – White Paper

Laser – Clear Paper

Laser – White Paper

For an easy way to start, try just typing your Spartan # in Word and printing it out. Here's how mine turned out. Definitely needs weathering to blend in.

1. Printing: Once you have your image, print it out on to the decal paper. I like to print test pages with plain paper first so that I know it will feed properly and print on the correct side. Follow the directions for printing provided with the decal paper.

2. Sealing: Using a clear acrylic spray paint, coat the printed side of your papers. Make nice even passes in one direction. For example, up and down along the long edge of the paper. Let dry a few minutes. Make another even coat the other direction, left to right along the shorter edge of the paper. Let dry a few minutes. Make a final coat up and down again along the long edge. Set in a well ventilated area to dry for a few hours. This stuff smells bad!

3. Cutting/Planning: Get out your solutions, paint brush, knife, cutting board, tweezers, tissues and bowl of warm water. Carefully cut out the decal you plan to use. If possible, allow a millimeter border around the colored portion of the decal. If your decal is an irregular shape consider an interesting border around it instead of just a rectangle or square. Take the dry decal and place it on the painted piece where you want it so you have a plan.

3.5 if you're decal is dark and printed on white paper, I have started using a sharpie to color the sides. Say you've cut out black lettering, well before you place it in the water, take a sharpie and color all the sides of the decal. Turning the white paper black. It will look better once placed on the armor.

4. Setting Step 1: Place the decal on the surface of warm water, printed side up. In 30-60 seconds the water will loosen the paper backing which will fall to the bottom. Cold water takes longer to remove the backing.

While you are waiting take your brush and apply a small amount of the setting solution/water/vinegar to the surface you wish to set it too. The store bought solution is not needed, but will help create a superior bond between the decal and the surface. Some people report watered down distilled vinegar does the trick as well.

5. Setting Step 2: Now that the backing has fallen off, take your tweezers and carefully grab a corner trying not to let the decal collapse on itself as you carry it over to your piece.

Simply lay the decal down where you want it. The water will allow you to slide the decal around until you are happy with the location.

Hold the edge down on one side with the tweezers so it doesn’t move. On the other side firmly press a tissue into the decal to wick up the water. The tissue will pull the water out from under the decal setting it firmly in place. Now firmly dab the other side of the decal to make sure that all water has been removed from the piece. Avoid any back and forth motions, dabbing only. For best results now use a blow drier or heat gun on low to fully evaporate the water.

6. Blending: *disclaimer* I have not done this yet as my solutions did not arrive in time. But, this is a product that will help blend the edges of your decal into the paint so it doesn’t look just like a sticker. I did it without and thought they looked just fine.

7. Finish/Weather: Use a heat gun or blow dryer to really complete the bond. Now you are free to weather paint and clear coat your entire piece. If the decal needs to look damaged you can use acetone. It doesn’t take much and can also ruin your paint job, so try in a concealed spot first. The acetone reaction is similar to melting a plastic sticker.

Congratulations! Pro status achieved.

Thank you Asgardianhammer for the help!

It takes some time to set up, but the application is super simple. So let’s get you started!

Materials you need:

An electronic image of what you want, pre sized and in a printable document (pdf, jpeg etc)

Waterslide Decal Paper (there are four options, explained later)

Krylon Crystal Clear Spray Paint Matte or Glossy (or other clear acrylic spray)

Decal Setting Solution (optional)

Decal Blending Solution (optional)

½” paint brush

Tweezers

Xacto knife

Self Healing Cutting Board

Black sharpie

Bowl with warm water

Tissues/paper towels

Blow Dryer or Heat gun with low setting

Acetone (for weathering)

*Disclaimer* This only works on a painted surface. Best to do this after you have painted your suit or prop, but before you’ve weathered and sealed.

First we need to talk about the paper you will need to buy. There are two types of printers that this will work for, Ink jet or Laser and you will need to buy paper specific to which printer you have. Then you will have the options of clear or white. Printers cannot print white, so if your decal has white in the image you will need to rely on the white paper to create that white space. Use clear if you don't want any white in your decal. *but only if the decal has dark colors. Light colors become transparent with the clear paper and are hard to see on a painted surface.*

Examples (Letter size):

Ink Jet –Clear Paper

Ink Jet – White Paper

Laser – Clear Paper

Laser – White Paper

For an easy way to start, try just typing your Spartan # in Word and printing it out. Here's how mine turned out. Definitely needs weathering to blend in.

1. Printing: Once you have your image, print it out on to the decal paper. I like to print test pages with plain paper first so that I know it will feed properly and print on the correct side. Follow the directions for printing provided with the decal paper.

2. Sealing: Using a clear acrylic spray paint, coat the printed side of your papers. Make nice even passes in one direction. For example, up and down along the long edge of the paper. Let dry a few minutes. Make another even coat the other direction, left to right along the shorter edge of the paper. Let dry a few minutes. Make a final coat up and down again along the long edge. Set in a well ventilated area to dry for a few hours. This stuff smells bad!

3. Cutting/Planning: Get out your solutions, paint brush, knife, cutting board, tweezers, tissues and bowl of warm water. Carefully cut out the decal you plan to use. If possible, allow a millimeter border around the colored portion of the decal. If your decal is an irregular shape consider an interesting border around it instead of just a rectangle or square. Take the dry decal and place it on the painted piece where you want it so you have a plan.

3.5 if you're decal is dark and printed on white paper, I have started using a sharpie to color the sides. Say you've cut out black lettering, well before you place it in the water, take a sharpie and color all the sides of the decal. Turning the white paper black. It will look better once placed on the armor.

4. Setting Step 1: Place the decal on the surface of warm water, printed side up. In 30-60 seconds the water will loosen the paper backing which will fall to the bottom. Cold water takes longer to remove the backing.

While you are waiting take your brush and apply a small amount of the setting solution/water/vinegar to the surface you wish to set it too. The store bought solution is not needed, but will help create a superior bond between the decal and the surface. Some people report watered down distilled vinegar does the trick as well.

5. Setting Step 2: Now that the backing has fallen off, take your tweezers and carefully grab a corner trying not to let the decal collapse on itself as you carry it over to your piece.

Simply lay the decal down where you want it. The water will allow you to slide the decal around until you are happy with the location.

Hold the edge down on one side with the tweezers so it doesn’t move. On the other side firmly press a tissue into the decal to wick up the water. The tissue will pull the water out from under the decal setting it firmly in place. Now firmly dab the other side of the decal to make sure that all water has been removed from the piece. Avoid any back and forth motions, dabbing only. For best results now use a blow drier or heat gun on low to fully evaporate the water.

6. Blending: *disclaimer* I have not done this yet as my solutions did not arrive in time. But, this is a product that will help blend the edges of your decal into the paint so it doesn’t look just like a sticker. I did it without and thought they looked just fine.

7. Finish/Weather: Use a heat gun or blow dryer to really complete the bond. Now you are free to weather paint and clear coat your entire piece. If the decal needs to look damaged you can use acetone. It doesn’t take much and can also ruin your paint job, so try in a concealed spot first. The acetone reaction is similar to melting a plastic sticker.

Congratulations! Pro status achieved.

Thank you Asgardianhammer for the help!

Last edited: