Zat German

Member

Wow, it looks nice. I like the clear plate rather than the holes in mine. It would be a lot easier to see what you are doing. It is not listed as fitting my Dremel model though.I was referring to this one

it's really nice

Wow, it looks nice. I like the clear plate rather than the holes in mine. It would be a lot easier to see what you are doing. It is not listed as fitting my Dremel model though.I was referring to this one

it's really nice

I have the cordless 10.8v Lithium Ion Dremel 8000. I was looking at comments on Amazon after I posted and someone said that it does fit the 800/8000. Dremel is really annoying about supporting the cordless 10.8v tools, some stuff works, some does not. No attachments list the 8000 as fitting. I used sugru to fill in the giant gap that happens if you try to use the cordless with the Detailers Grip. Works great now.which do you have? it fits just about every dremel, it screws in by the housing cap

I think i'm gonna work on a foam build soon but i need some numbers from people that have completed the entire armor with foam and plasti dip:

How many mats of eva foam was used for the entire suit:

how many cans of how many oz of plasti dip was used?

if you have not completed the entire armor:

then list the pieces completed and how many cans of plasti dip used so far.

this data will help me as well as others the cost of a foam build.

I don't know if it is just the foam I found or if this is how it is for all of it, but I find the top layer is much squishier and then there is a dense layer on the bottom at the textured part. Is this normal? does anyone else find that it makes it very difficult to adjust cuts after the fact?

Personally I think a straight edge is more effective for cutting the foam. Scissors mess with my thumbs and exacto knives dull easily and can't really put enough force behind them. You can score it and cut it with a straight edge/box cutter and it comes out mostly clean. Just like all other methods use sand paper to clean up the strings left from carving into it.

For rounded parts I shape them first with the heatgun, that way when you glue it together there is less stress on the seam, making it easier to hold together for greater accuracy. I have a tutorial video for the heatgun and other techniques here: www.squidoo.com/how-to-make-halo-armorI have to ask, do you just glue the pieces together straight out or do you use a heat gun or something similar to shape the pieces first?

Advanced foam crafting tip:

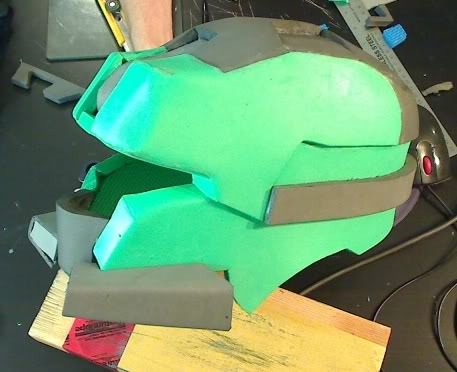

Another way to help eliminate seams is to attach the pep file edges together and make your foam templates larger. You can also cut the templates along definition, or paint change lines and re-tape them where you don't want a seam. This works great on rounded areas too. You can still cut mountains and valleys directly into the back of the foam where needed to give the front definition. It takes practice to get it right but once you can do this many of the seams will vanish and combined with the heatgun you can make a nice helmet too:

#1 I hide seams by joining the pep parts together before I cut the foam and then cutting mountains and valleys out of the backside of the part. I also try to put the seams on a raised ridge, a burned definition line or a paintchange line.Okay so i am going to re-do my chest piece out of foam and I am wondering How do you seal it (Remove the seams)